6 minute read

Glass conditioning: Horn

Probes for extractive measurement

Eurox, a product line from Horn Glass Industries, has almost 30 years of experience with zirconia-based oxygen probes. Christian Reichl* discusses the line’s latest applications for the glass industry.

For eight years, Eurox Sauerstoff MessSysteme has been part of Horn Glass Industries and is now an integral part of its facilities. The measuring systems have many applications in the glass industry, which have been further developed in recent years.

With the extractive measurements of Eurox, several measuring points can be measured with just one sensor. Together with a valve unit up to 12 measuring points can be analysed. The evaluation unit of the measuring system controls the valve unit, evaluates all measurement data and provides the results to the customer. Not only can the signals from the oxygen sensors be processed, but also information from the control system can be read in and thus enrich the evaluation of the measuring signals.

With this system each measuring point of interest is measured one after the other, thus a quasi-continuous check of the system can be achieved.

Depending on the application and the values of interest, different evaluation modes can be defined for the respective application. By default, visualisation takes place on the measuring unit itself, but it can also take place on the control system or on other output devices. The measuring systems are basically modularly expandable.

There are measuring systems for glass conditioning, for tin baths and a mobile measuring unit for both applications.

Glass conditioning

The atmosphere in forehearths as well as in working ends has a great influence on the glass quality. Therefore, the combustion condition is an important influencing factor in glass conditioning systems.

In reality, various parameters influence the combustion condition. So, the theoretical oxygen content in dry air is 20.9%. However, the exact O2 content depends, among other things, on the air humidity, which is often neglected in theoretical calculations. Therefore, a variation of 0.5% in the O2 content can thus lead to a change in the minimum air demand of 2%.

The composition of the fuel gas is not stable, which has an influence on the heating value but also on the minimum air demand. This problem will certainly increase in the future.

But there are also technical aspects that influence the stability of the combustion conditions. The non-linearity of the control valves, but also the hysteresis of the control system for setting the mixing ratio should be mentioned here. All these influencing variables are not large in themselves, but their influence can add up. Especially under near stoichiometric conditions, it is possible to change unnoticed from an oxidising to a reducing ratio and vice versa, which can lead to problems in glass production.

The extractive measuring system of Eurox measures the real Lambda value of the premixed gas. For this purpose, it is catalytically decomposed in a reaction chamber and then analysed by a zirconium oxide sensor. Each measuring system is precisely calibrated to ensure a reliable Lambda measurement. Thus, the real combustion condition can be determined. Together with a control system, stable combustion can be achieved in all connected zones.

Tin baths

To avoid glass defects and problems due to tin oxidation, it is necessary to monitor the atmosphere of tin baths in float glass plants. To protect the liquid tin from oxygen, a protective gas mixture of nitrogen and oxygen is continuously injected into the tin bath. To obtain a statement about the oxygen content, the dew point was measured from a sample of the tin bath atmosphere. Since water, hydrogen and oxygen are always in equilibrium, this is a reliable way to describe the state of the atmosphere. Measuring the dew point to determine

Continued>>

Fig De point temperatures along tin bath meas re ith ro meas re-

ment system.

the state of the tin bath is still state of the art today.

The extractive measuring system from Eurox can reliably determine the oxygen partial pressure even under extremely reducing conditions because, as already mentioned, there is always a certain residual partial pressure of oxygen due to the chemical equilibrium between water, hydrogen and oxygen. The measured oxygen partial pressure is given as a characteristic value. This value is formed by relating the measured oxygen partial pressure to the equilibrium of tin/tin oxide, which depends on temperature.

Fig 1 shows both real measured O2 partial pressures (blue dots) and the Sn+O2/SnO2 equilibrium curve (black dots). A pO2 saturation curve is also shown (yellow dots), which is important for the formation of SnO (tin-2-oxide). The required measuring point temperatures are obtained from the temperature measurement in the tin bath.

The characteristic value describing the oxidation state of the tin bath surface (connection between liquid tin and tin bath atmosphere) is equal to one by definition when the measured oxygen partial pressure is on the black line. When the measured O2 partial pressure is lower than the equilibrium value, the equation Sn + O2 -> SnO2 is more on the educt side. The characteristic value is lower than one. When the partial pressure is higher, then the equation is more on the product side and the characteristic value is higher than one.

As already described, there is an equilibrium in the equation 2 H2 + O2 -> 2 H2O. Also, the pO2 saturation curve has an influence on the calculation of the characteristic value. Thus, the value considers the formation of both 2- and 4-valent tin oxide.

In reality, the measured O2 partial pressures along the tin bath are below the black curve at the glass inlet, and above the black curve when the glass belt leaves the tin bath under normal conditions, which indicates oxidation of the liquid tin, especially towards the end of the tin bath because of the lower temperature in this area. To obtain a statement about the gaseous 2-valent SnO, Eurox developed another characteristic value - the hydro state: SnO + H2 -> Sn + H2O.

Here the H2O fraction calculated from the H2 O2 / H2O equilibrium is related to the H2 fraction in the atmosphere and compared with the maximum solubility of water in the atmosphere, which depends on temperature.

By definition, the characteristic value on the saturation line is equal to one. When the measured specific H2O content is lower than the maximum solubility, the specific value is lower than one, when it is higher than the maximum solubility, it is above one.

Fig 2 shows the calculated specific H2O content compared to the maximum specific H2O content in the atmosphere.

The third output value by an extractive

Fig ortable p o nit ith accessories measurement in the tin bath is the dew point and thus also the H2O content in the atmosphere.

The Eurox measuring system is calibrated in such a way that it also measures the dew point temperature correctly under normal operating conditions. Thus, it is also possible to notice a corresponding increase in the dew point temperature in the event of cooling water leakage, as the equation then shifts to the educt side due to the high H2O content.

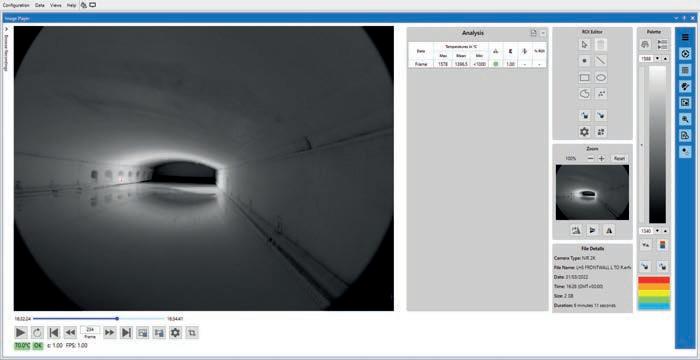

Fig 3 shows measured dew point temperatures with the Eurox measuring system. The temperatures on measuring point one and two are quite high, an air ingress was detected in this area. This means that there is not only a statement about the oxygen content in the atmosphere, but also about the water content and an estimate whether there is the right amount of H2 in the inert gas.

A portable solution

In addition to a stationary measuring unit for extractive measurements, Eurox has also developed a mobile measuring unit (Fig 4). The portable system can be used for measurements on glass conditioning systems and for tin bath atmosphere analysis. The measurement results can be visualised on a mobile device via WiFi. Together with the storage function, the measuring results can be archived over a longer period of time, analysed at a later date and compared with other measurements. �

*Furnace Technology, Horn Glass Industries, Plössberg, Germany https://www.hornglass.com/