Savitribai Phule Pune University

Certified that “Textile Revival: Malegaon Capacity Center”, this is an Architectural Design Project submitted to MVPS’s S .P. College of Architecture, Nashik Affiliated to the Savitribai Phule Pune University in partial fulfillment of requirement for the degree of Bachelor of Architecture.

Textile Revival: Malegaon Capacity Center Design

Name of candidate: Purnada J. Bachhav

Signature of Candidate

Name- Miss. Purnada J. Bachhav

Signature of Principal

Dr. Prajakta Baste

Signature of Guide

Name- Ar. Ashish Patil

ACKOWLEDGEMENT

I extend my sincere gratitude to MVP’s College of Architecture for providing me with the opportunity to engage in playful learning. This institution has not only been a place of academic growth but also a second home to me, where I’ve imbibed discipline and encountered invaluable life lessons throughout my architecture journey

Foremost, I express my heartfelt appreciation to my thesis guide, Ar. Ashish Patil, for his unwavering belief in my research and for imparting practical insights into innovative design possibilities. I am immensely grateful to all the faculty members for their consistent guidance and support, with special thanks to Ar. Abhishek Nashikar for his invaluable assistance in addressing design challenges. I also extend my gratitude to Ar. Umesh Hirve for his support throughout.

My family deserves my deepest thanks for their constant support and encouragement throughout this journey. I am grateful for the friendships I have forged during my time at college.

I extend my thanks to all the industry experts whose guidance was instrumental in shaping the outcome of my thesis, ensuring its successful completion. Lastly, I extend my sincere thanks to the esteemed members of the old CANS family for their mentorship and for contributing to my personal growth and development.

This journey has been enriched by the collective support and encouragement of all those mentioned above. Thank you for being integral parts of my undergraduate thesis experience.

2.1 Introduction

2.2 Need of the project

2.3 Indian Textile industry

2.4 History

2.5 Textile industry of Malegaon

2.6 Problem Obsevations

2.7 Recommendations & Solutions

2.8 Literature study: Powerloom Service center

2.9 Literature study: Ichalkaranji College of Textile Engineering

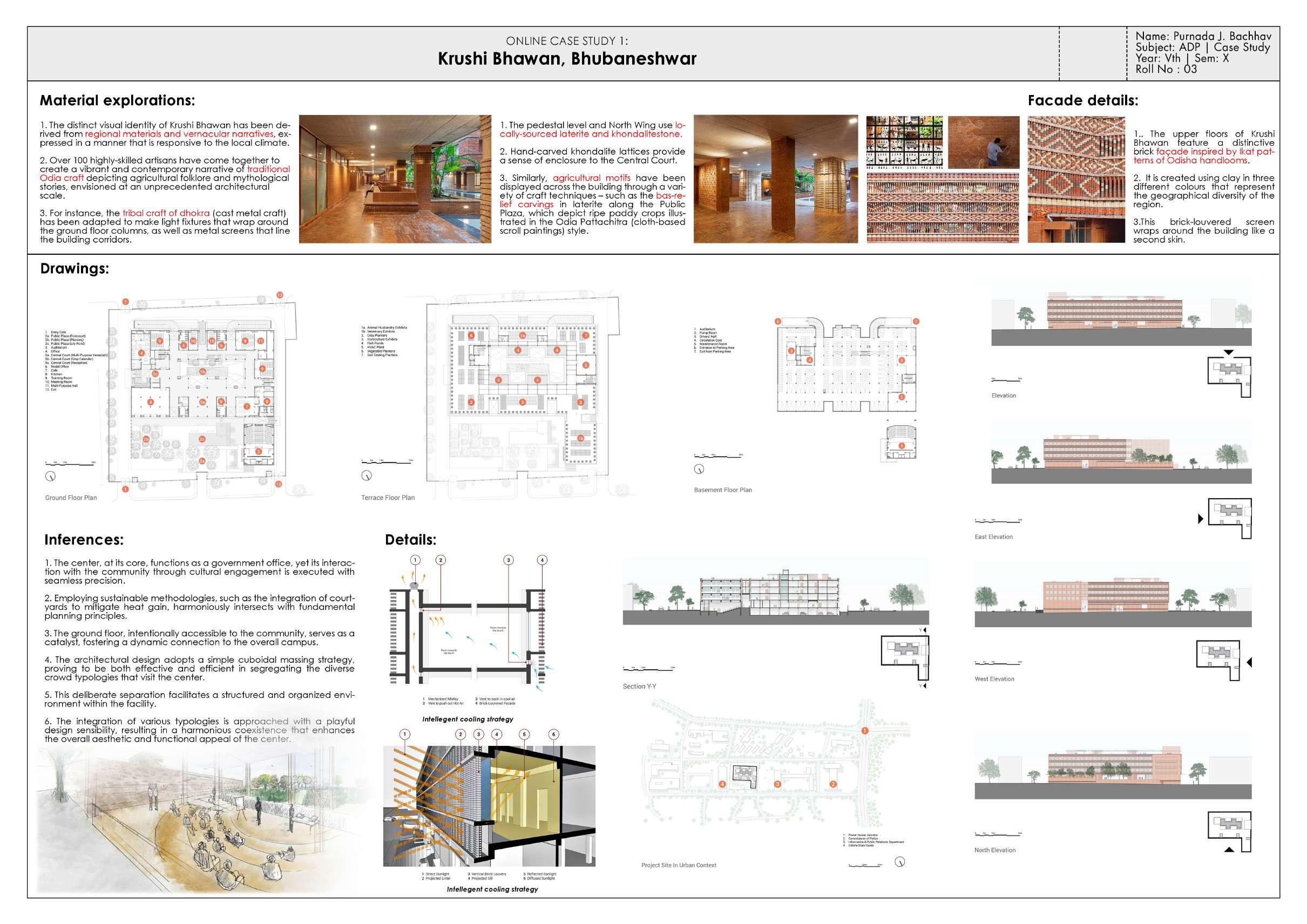

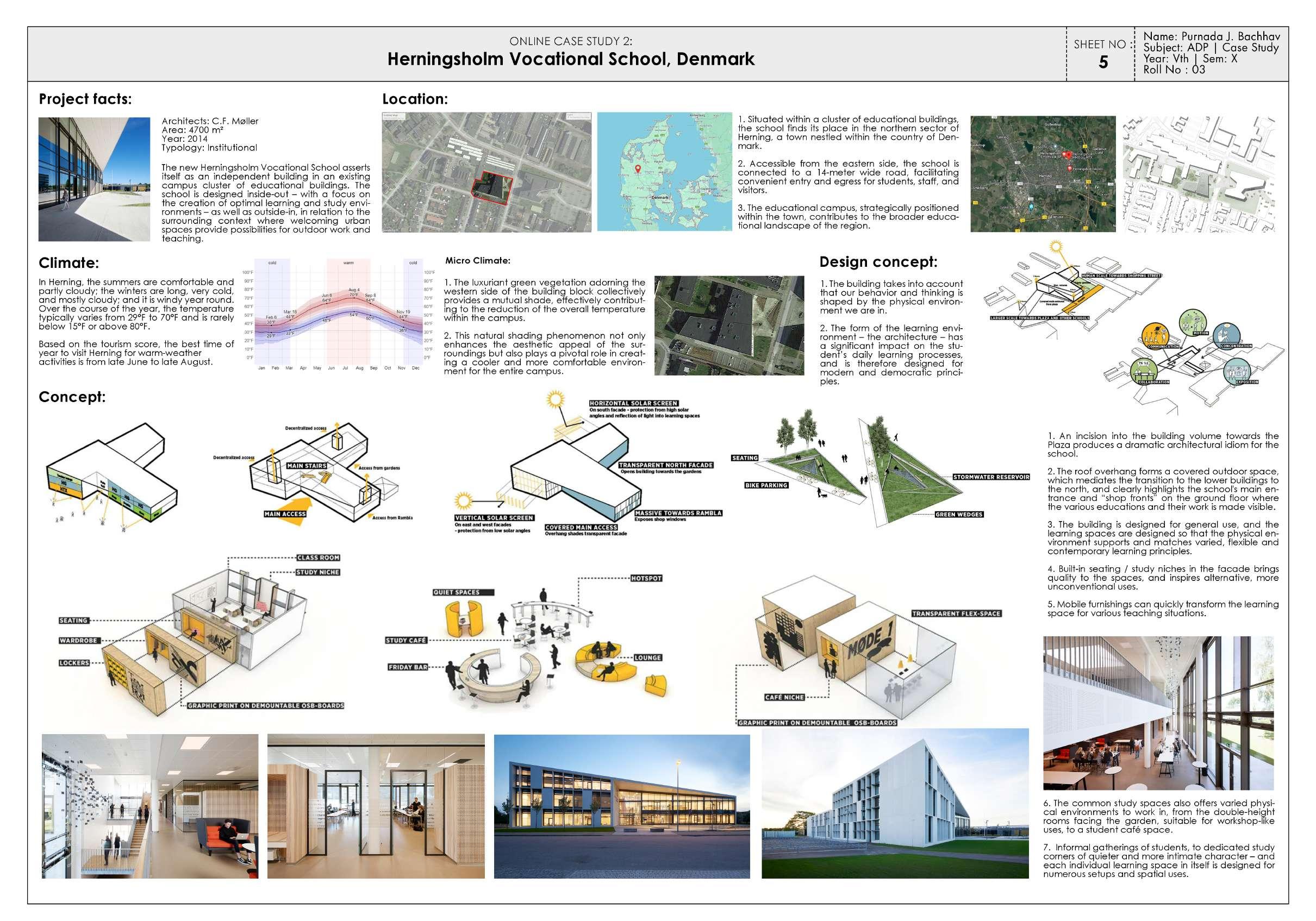

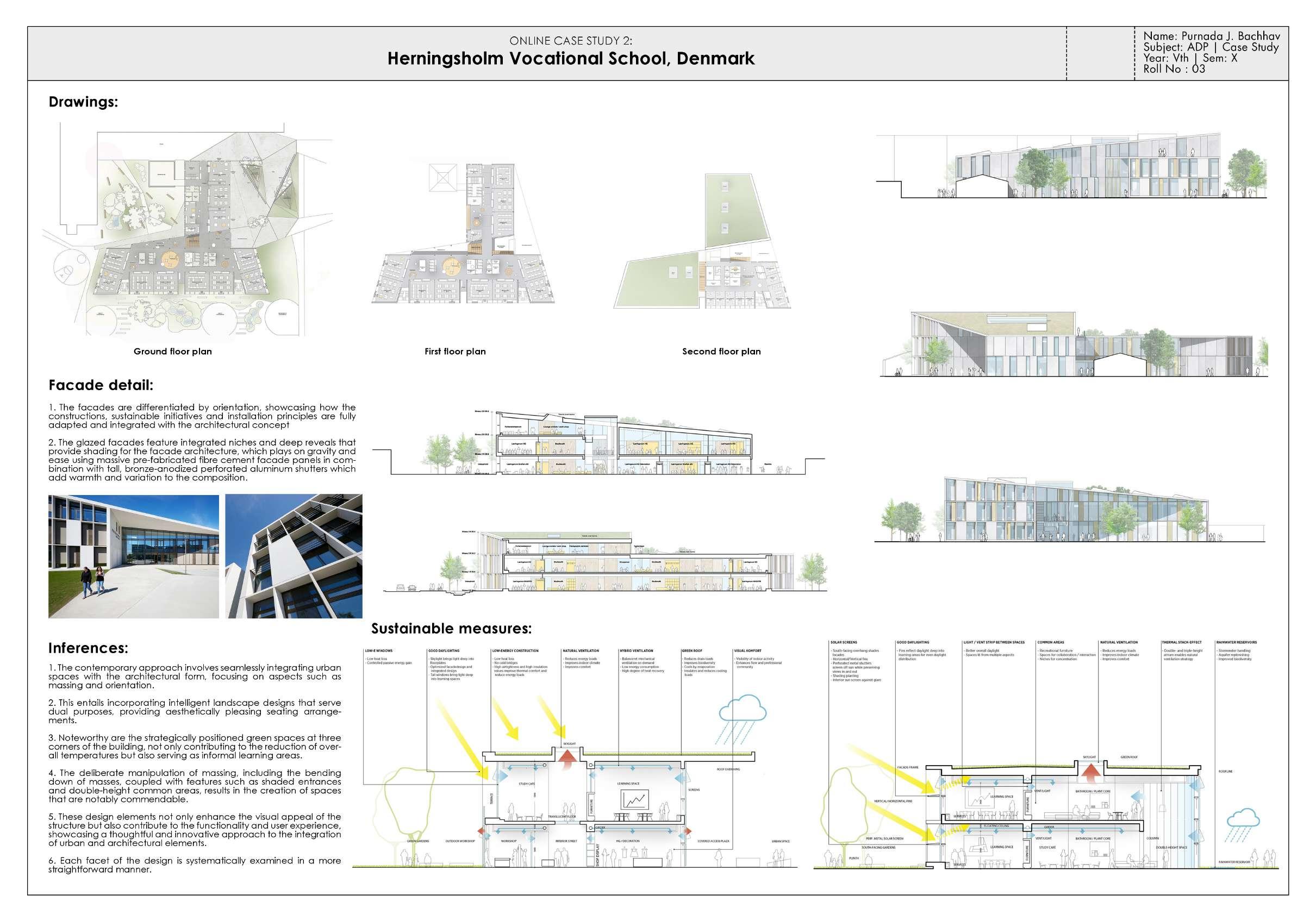

3 Case Studies

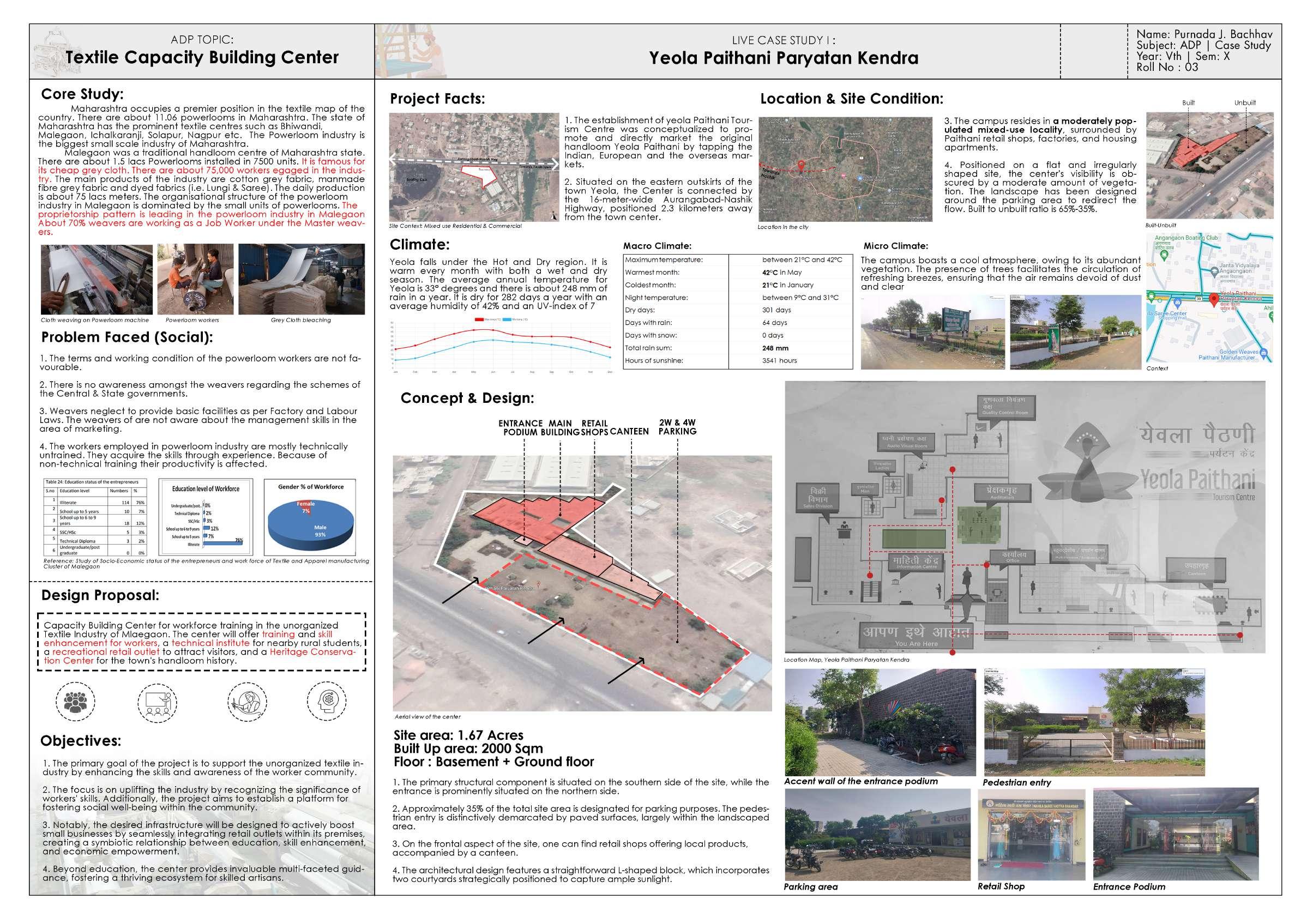

1. Yeola Paithani Paryatan Kendra, Yeola

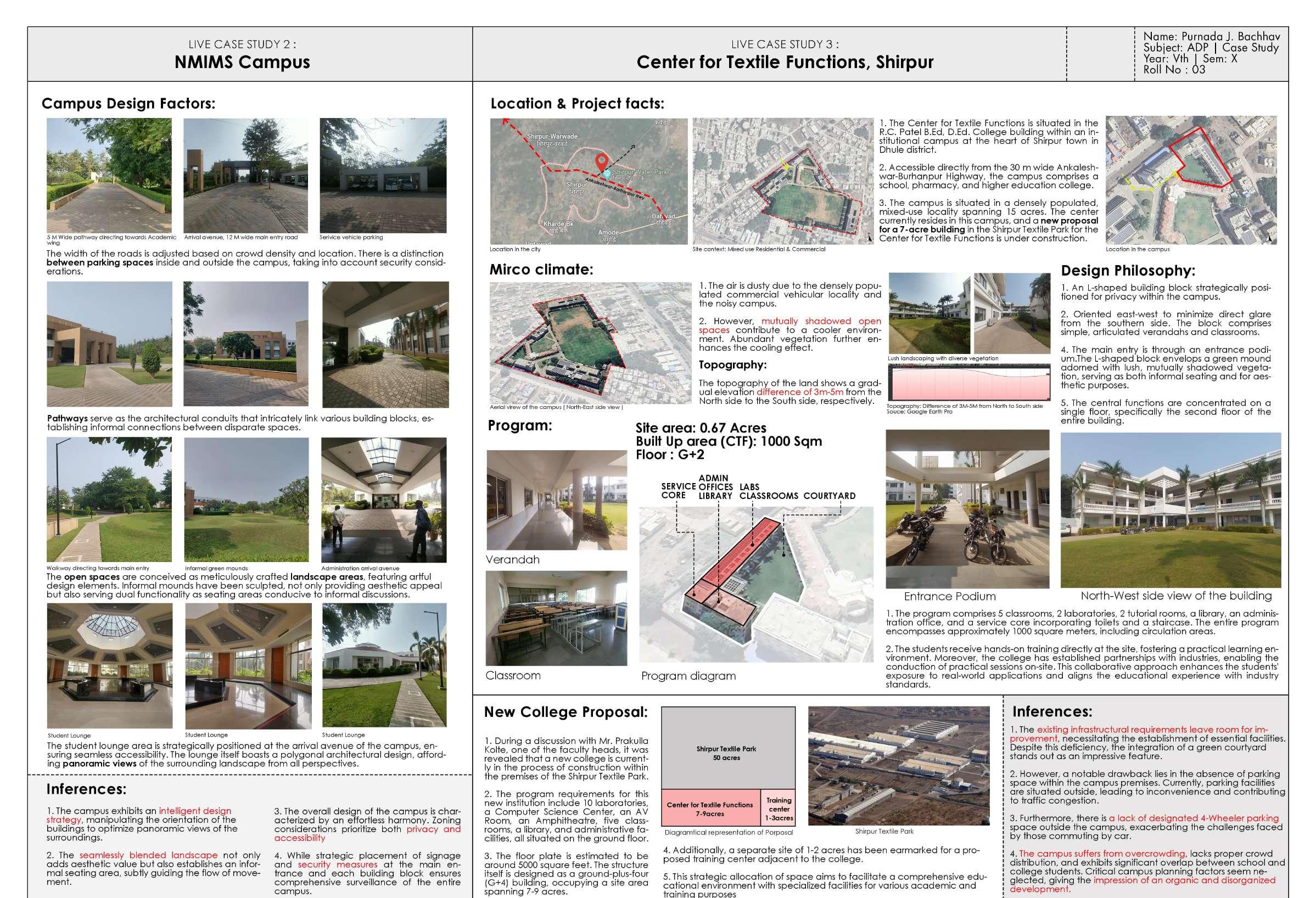

2. Center for Textile Functions, Shirpur

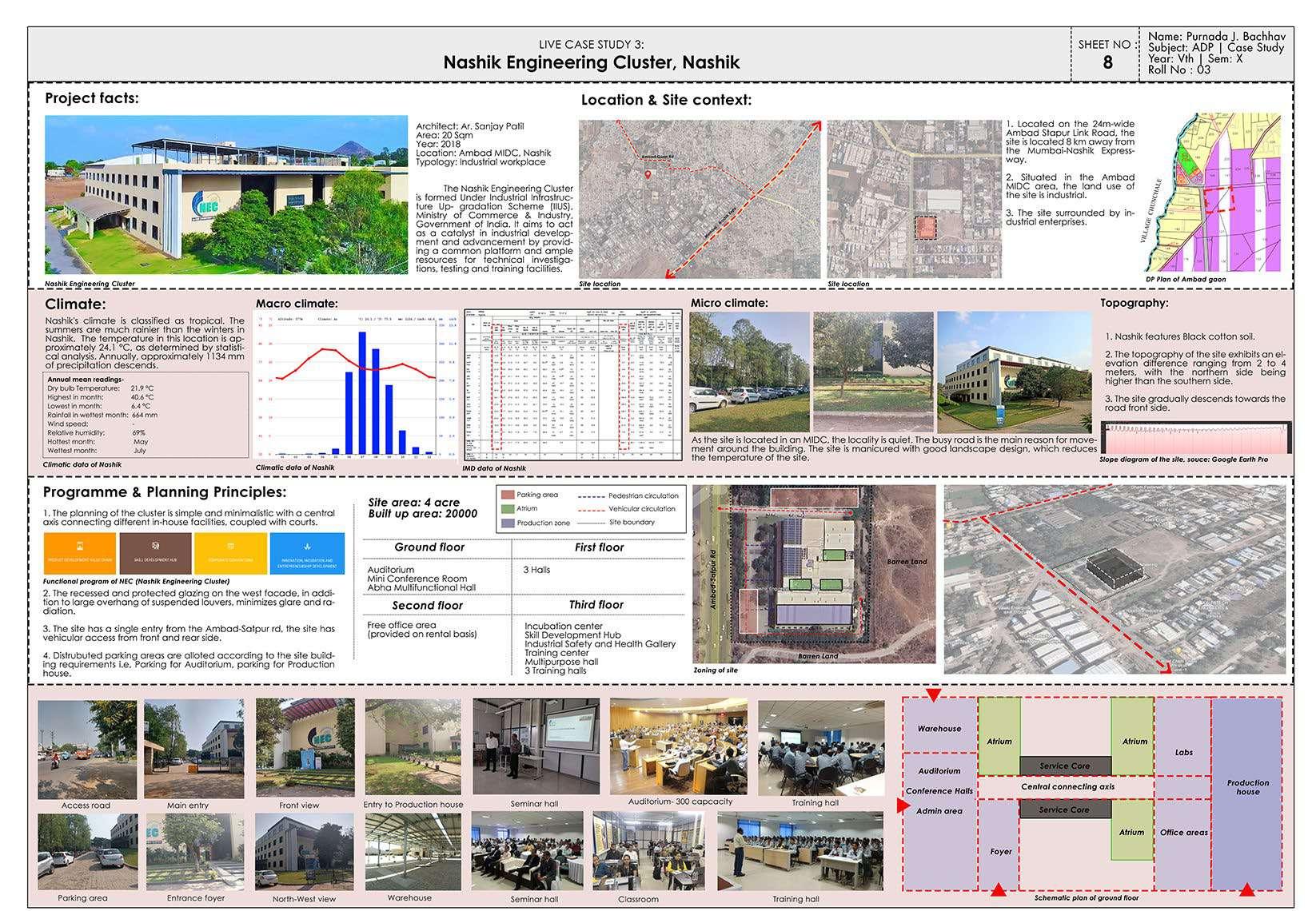

3. Nashik Engineering cluster

4. Hersholm Vocational School, Denmark

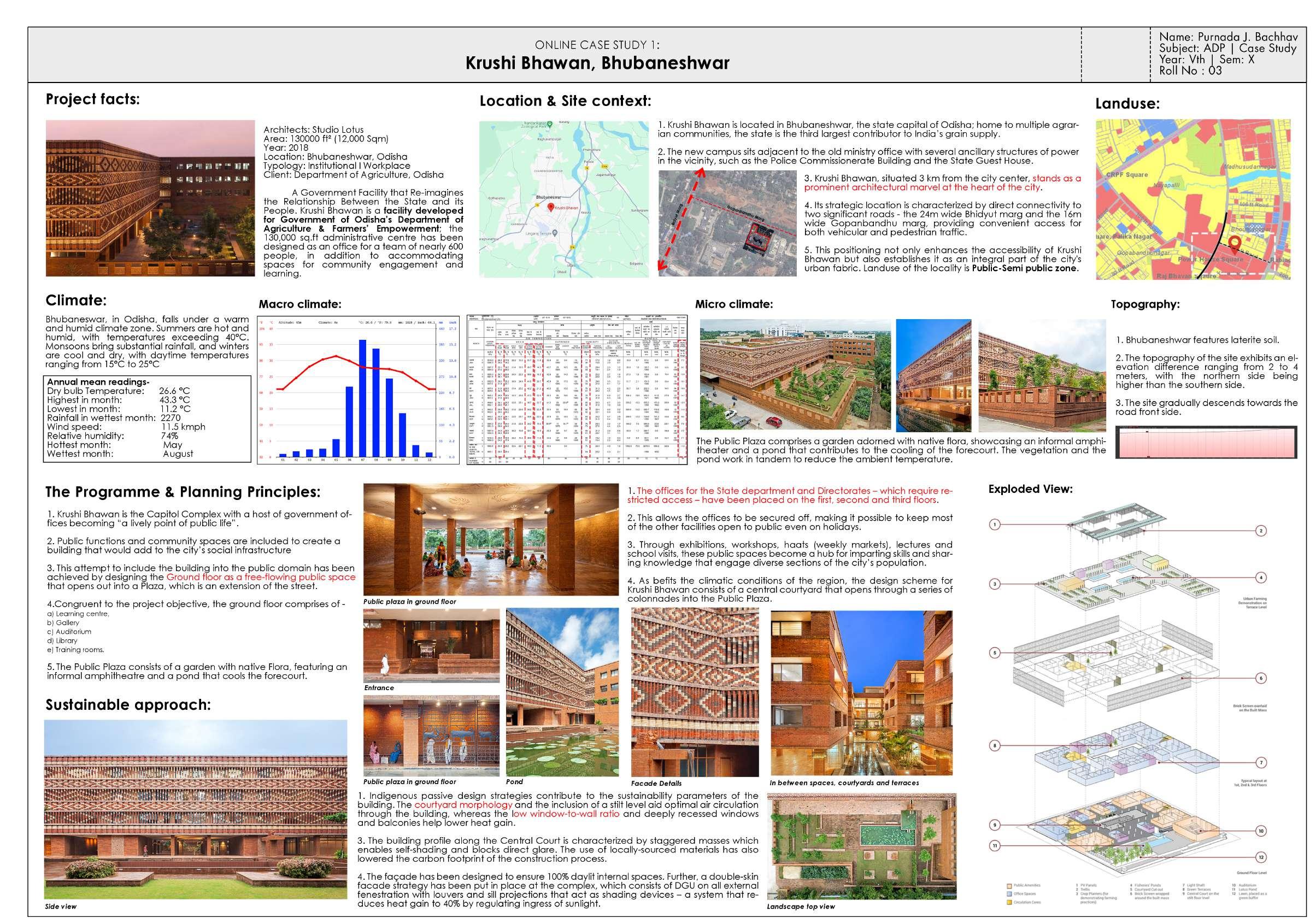

5. Krushi Bhawan, Bhubaneshwar

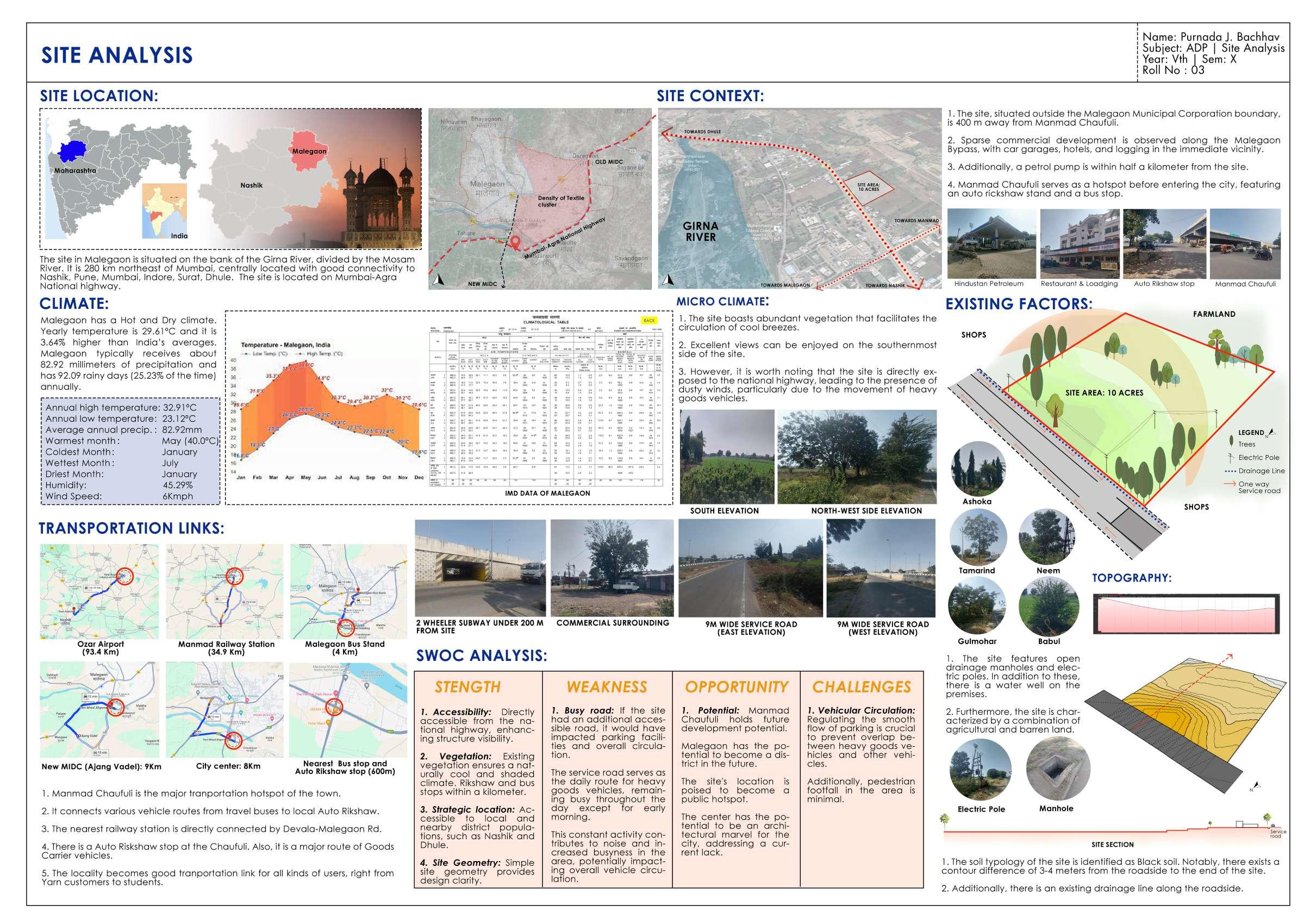

4 Design Brief, Site selection & Site Analysis

5 Area statement

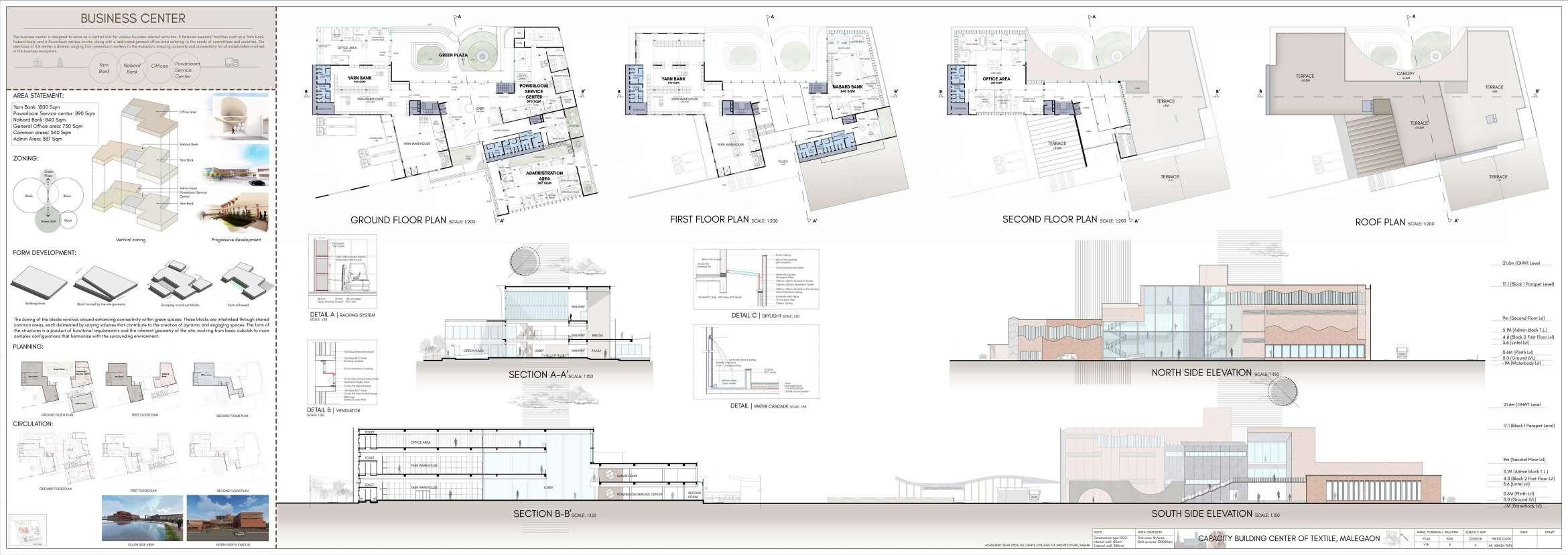

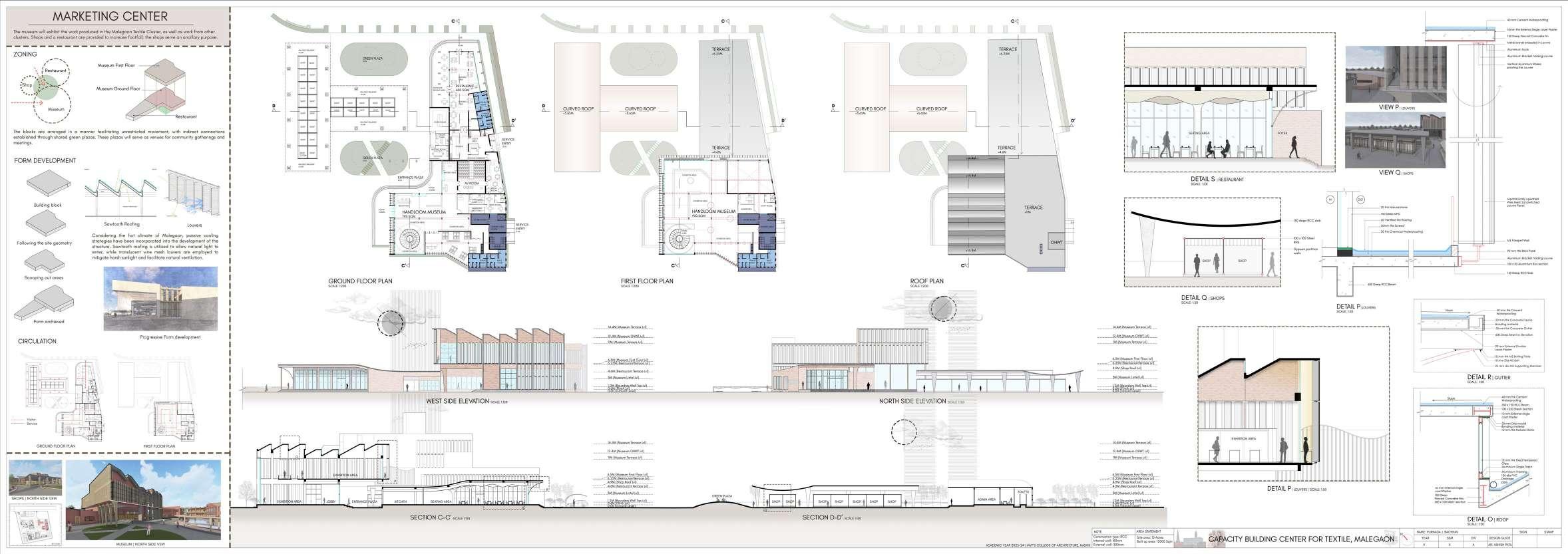

6 Drawings –

• Program introduction

• Concept

• Master plan and site sections

• Detail Floor plans, Sections, Elevations, Construction & Architecture Details (Block wise)

1. Business Center

2. Marketing Center

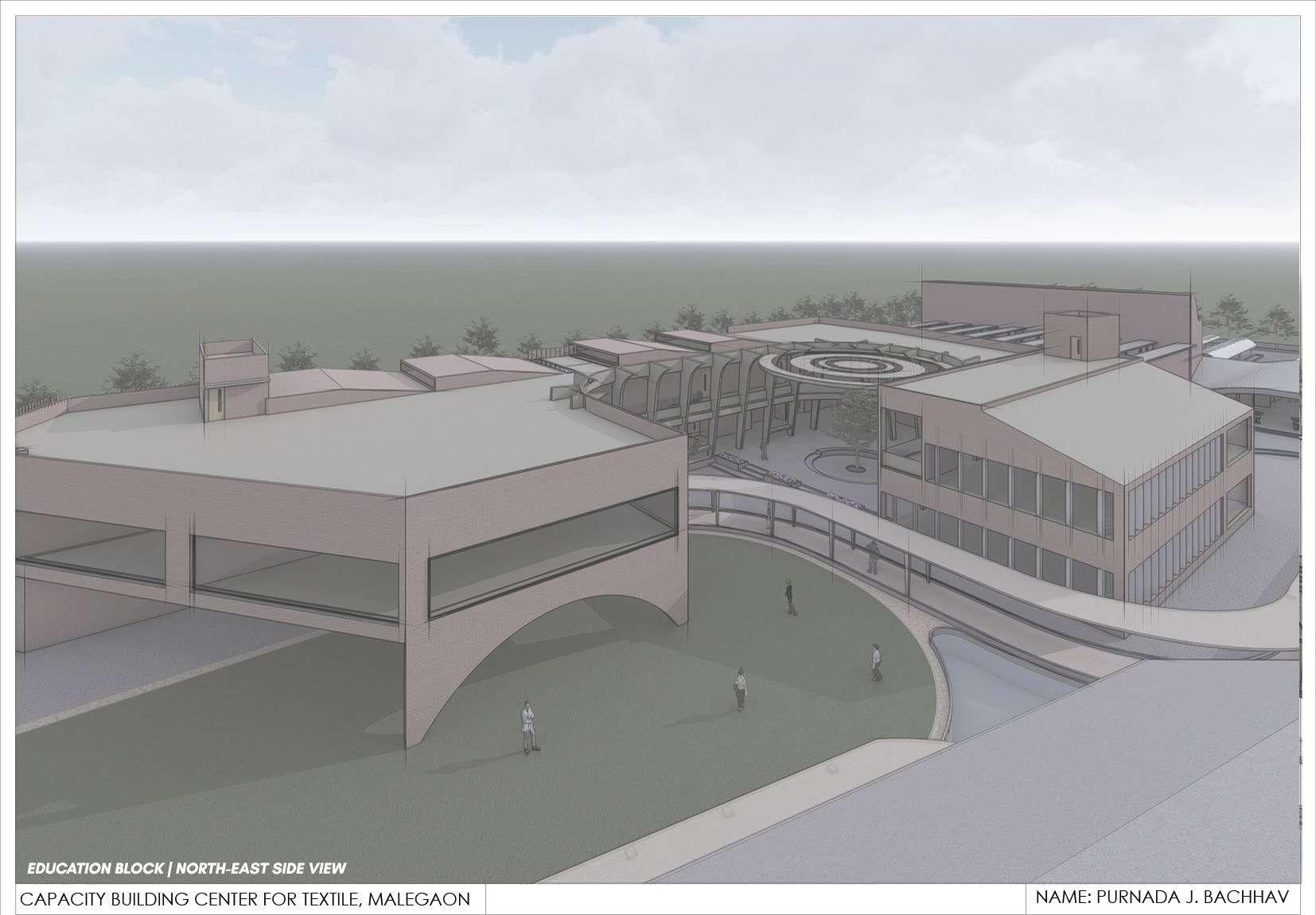

3. Education center

• Roof plan & Horticulture plan and Landscape details

• Service Layouts and Details

1. Drainage and Water supply Layout

2. Fire Layout

3. HVAC Layout ( Block wise)

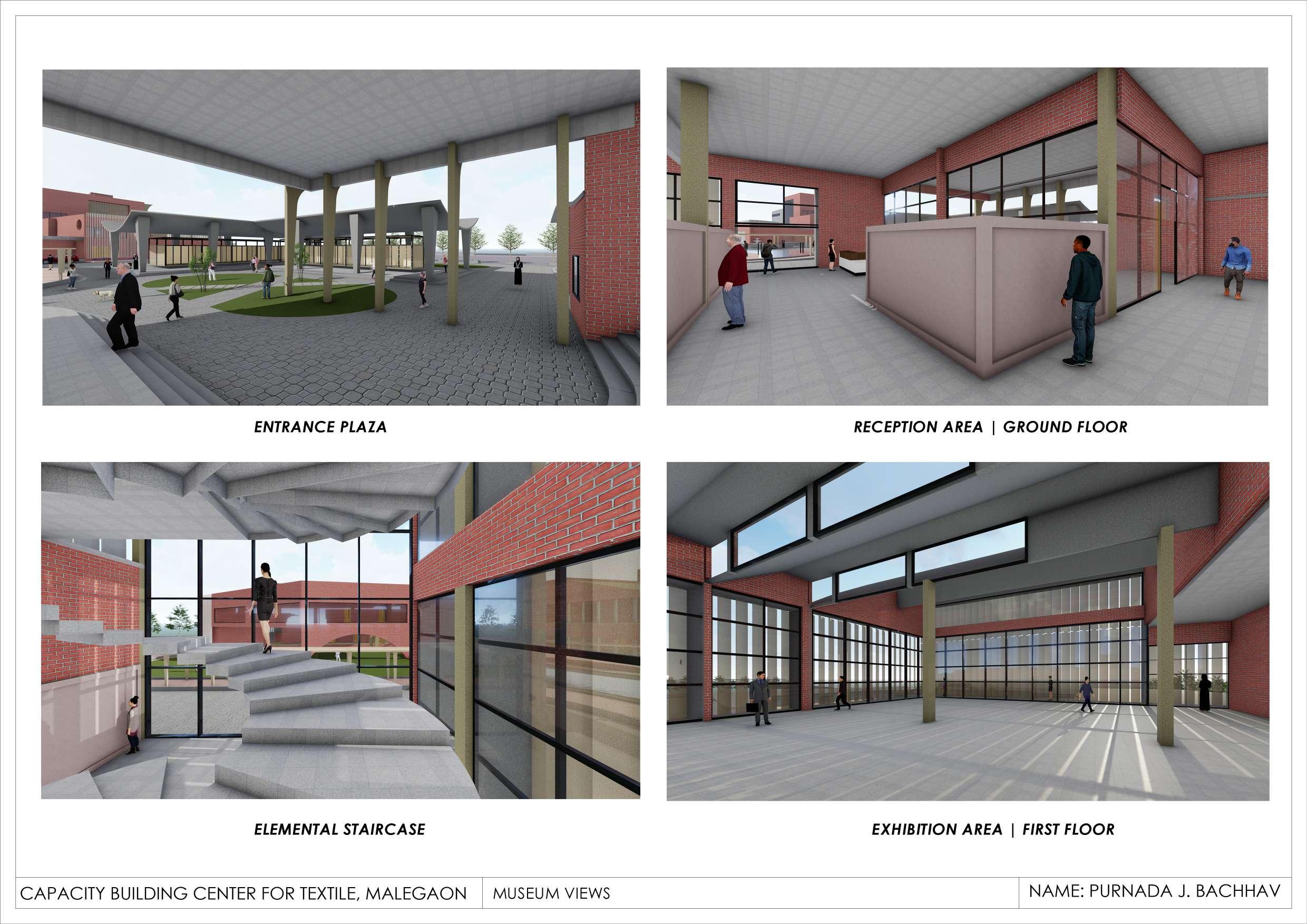

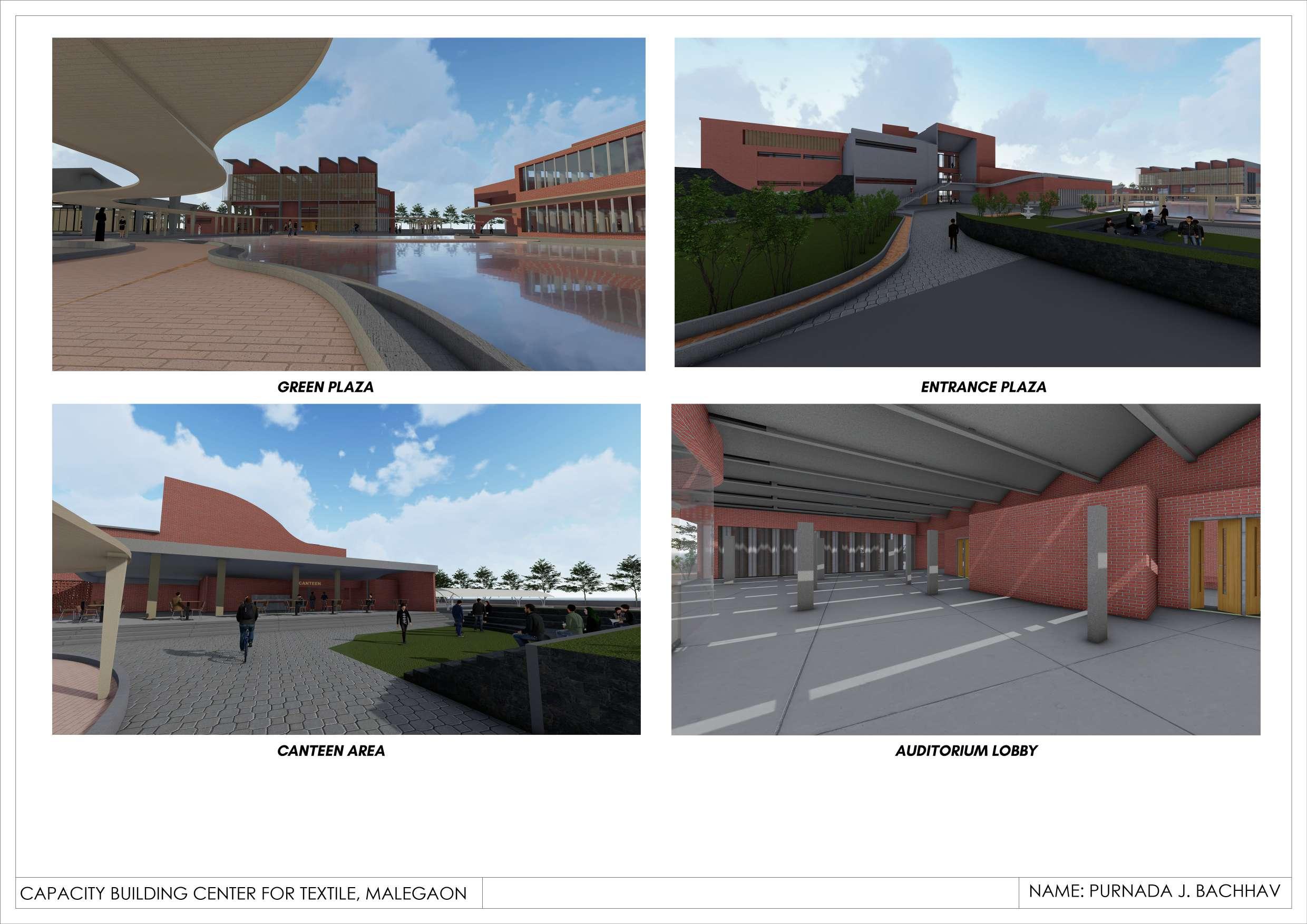

• Views

Abstract:

The architecture thesis investigates the integral role of the Indian textile industry within the national economy, focusing on the power loom sector in Maharashtra, particularly Malegaon. Through an analysis of socio-economic factors, the study identifies challenges faced by the industry and their impact on weavers, traders, and consumers. By revealing deficiencies and proposing architectural interventions, the thesis aims to enhance the industry’s efficiency and address social issues. Recommendations for the holistic development of Malegaon’s Textile industry are provided, aiming to bolster its socio-economic contribution and ensure a sustainable future for all stakeholders.

TEXTILE REVIVAL: CAPACITY BUILDING CENTER, MALEGAON

Introduction:

The Capacity Building Center in Malegaon aims to uplift the unorganized Textile Industry. It will provide essential training and skill enhancement for workers, establish a technical institute for rural students, offer a recreational retail outlet to draw visitors, and house a Heritage Conservation Center preserving the town’s handloom legacy. This multifaceted initiative not only enriches the workforce but also promotes education, tourism, and cultural heritage.

Aim:

The project aims to boost the unorganized textile industry by improving worker skills, addressing workforce issues, and raising industry standards.

Objectives:

1. The primary goal of the project is to support the unorganized textile industry by enhancing the skills and awareness of the worker community.

2. The focus is on uplifting the industry by recognizing the significance of workers’ skills. Additionally, the project aims to establish a platform for fostering social well-being within the community

3. Notably, the desired infrastructure will be designed to actively boost small businesses by seamlessly integrating retail outlets within its premises, creating a symbiotic relationship between education, skill enhancement, and economic empowerment.

4. Beyond education, the center provides invaluable multi-faceted guidance, fostering a thriving ecosystem for skilled artisans.

Scope:

The research focuses on Malegaon’s Textile Industry, particularly the powerloom workforce and involving all industry stakeholders.

Limitations:

The research excludes infrastructural and urban issues within the industry from its scope.

Methodology:

1. The methods employed for the research include live case studies of the Powerloom Service Center

2. Reading published research papers on industry and workforce issues.

3. Studying a case example of Ichalkaranji Textile Engineering College.

4. Multiple Live case studies regarding function and form explorations.

Conclusion:

This thesis envisions the future of Malegaon over the next 20 years, addressing urban and social issues within the community. Beyond architectural solutions, it emphasizes the importance of community involvement, awareness, and forward-thinking approaches to enact meaningful change.

2.1 Introduction:

Indian textile industry has an awesome existence in the Indian economy. It is second largest employer after Agriculture in India. It is one of the largest in the world with a massive raw material and textiles manufacturing base. Currently, it contributes about 14 percent to industrial production, 4 percent to the GDP, and 17 percent to the country’s export earnings. Around 35 million people are directly employed in the textile manufacturing activities. Indirect employment including the manpower engaged in agricultural based raw-material production like cotton and related trade and handling could be stated to be around another 60 million. The India Textile Industry has three main segments-

1. Mill sector

2. Handloom sector and

3. Decentralised powerloom sector

1.2 Need of the Project:

The project revolves around a specific textile industry community that requires attention from individuals for industry growth. It’s a decentralized industry that is lagging behind and requires revitalization and modernization.

1.3 Indian Textile Industry:

The analytical study of the statistical data about decentralised powerloom sector shows that the industry’s growth is remarkable. The production trend of powerloom industry continues in the right direction. It produces around thirty thousand millions square meters annually and employing about 55 lakh workers. The Indian powerloom industry is not only self-sufficient in the raw materials but also it is one of the suppliers of the raw material in the global textile market. More than 40% of the cloth that goes into exports originates from this sector. Since 200203, 30657 Semi-Automatic, 10303 Automatic and 26972 Shuttleless looms were installed under modernisation scheme. The sector today not only fulfils the need of the domestic market but it exports to major countries across the world.

1.4 History:

The growth of the powerloom industry started with the loosing of the ground by the textiles mills. The powerlooms were first introduced in India in the starting of the 20th century. During the great depression period (1929 to 1933) the mill sector started to discard the powerlooms. The labours of the textile mills refurbish the discarded powerlooms and started the small units as a small and cottage industry. It was the existence of the decentralised sector of powerloom industry.

In 1954, for the economic development of the handloom weavers, the scheme of conversion of handloom to powerlooms was introduced by the government. In 1930 there are about 3000 powerlooms in the country while at the end of 2008-2009 it raised to about 22.05 lakh powerlooms in the country. The powerloom industry is spread in all over India. The major states are Maharashtra, Tamil Nadu, Gujarat, Andhra Pradesh, Uttar Pradesh, Madhya Pradesh, Punjab, Rajasthan, Karnataka, and Hariana. Maharashtra occupies a premier position in the textile map of the country.

1.5 Textile Industry of Malegaon:

The powerloom industry in Malegaon has seen many ups and downs in its development and it is one of the important industries of Maharashtra. The powerloom industry in Malegaon has glorious past and bright future. There are many socio economic problems in the powerloom industry of Malegaon like scarcity of the finance, marketing problems, labour problems. There are about 11.06 powerlooms in Maharashtra. The state of Maharashtra has the prominent textile centres such as Bhiwandi, Malegaon, Ichalkaranji, Solapur, Nagpur etc. Powerloom industry in Maharashtra is more rapidly growing industry than in other states in India. The Powerloom industry is the biggest small scale industry of Maharashtra.

In Malegaon there are about 68 shuttleless powerlooms out of 1.5 lakh powerlooms. With the advent of globalised free-trade regime the Indian market is open for the other countries. The Indian powerloom industry has to face the competition from low cost and high quality textile products. So the pace of modernisation needs more speed. It is clear that the powerloom industry need more upgradation and modernisation in the present scenario.

Lungies 1% Rs.36 to

Table: Fabric Production in Malegaon

Discussion with the people reveals that in Malegaon there are approximately 1, 25,000 plain and

Outdated powerlooms installed in 6500 units, a unit generally consists of 1 to 24 powerlooms. However as per the Tax Department, Malegaon Municipal Corporation, there are only about 56194 powerlooms in the town. The lesser number of powerlooms by the Municipal Corporation is mainly due to the fact that those located in residential houses are not counted, or revealed by the owners.

b. Decentralized Industry:

The units are mainly located in residential areas in such a way that it has become highly difficult to distinguish between the industrial and the residential areas. There are many advantages of the location of powerlooms in the residential houses as they can be operated by women and men who can simultaneously can carry on their other household chores. It is the powerloom sector which unites as well as divides the Hindus and Muslims and other religious groups in the town. The Muslim community is mainly owner of the powerlooms as well as workers, while Marwari community monopolises the supply of yarn and purchase of grey cloth/other products. However, there are also many disadvantages of this. From the sound pollution the hearing capacity of people gets affected, exposure to fibres causes asthma/TB, industrial garbage are dumped in residential areas, electricity supply scheduling and load shedding becomes difficult, etc. The load shedding for residential areas also impacts industries.

c. Industry production:

Presently the town processes about 85 lakh metres of cloth per day. People claim that the production was better in the past, about one crore metre per day. It has come down in recent years mainly due to power cut for 6-8 hours daily at irregular intervals.

Direct clothing purposes

d. Supply of the raw materials and additional processing:

For production of about 80 lakh metre for fabric, the town uses yarns mainly manufactured in Ahmedabad, Surat, Baroda, and Dhule. The yarn is supplied mainly by Marwari community intermediaries. The town does not have its own production of yarn, which in many ways undermines the industrial profitability and production reliability. One of the major reasons behind this is that the powerloom industry is highly decentralised and exists as household/small industry and owners are also mostly illiterate. As such, they are unable to take the advantage of the banks and the financial institutions. This is the main reason why the weavers cannot directly purchase from the mills and an earlier attempt to open local depots failed as well. Hence they have to totally depend on intermediaries, the yarn merchants.

The grey fabric manufactured in the town is a semi-finished products, and are sold to various processing centres located mainly in Pali, Jodhpur, Barmer and Balotra in Rajasthan, Kolkata in West Bengal, Surat and Ahmedabad in Gujarat and Mumbai, mainly through the agents in Malegaon.

As per one estimate, there are about 150000 persons directly or indirectly employed in the sector. Besides the labourers from the town, the migrants from other districts of Maharashtra, and Uttar Pradesh and Bihar (mainly from Ansari community) work in the industry. The workers are mainly in 15-30 years of age-group. They are generally uneducated or have left their studies at primary level. Many otherwise unskilled workers find easier to learn operating powerlooms. A worker can learn how to operate a loom in 1-2 week. That is why most of the uneducated youth flock to this sector. During learning period, the worker get Rs. 200-250 per week from the owner of the looms.

Table: Ward wise number of Powerlooms, 2010 Malegaon

2.6. Problem Observations:

a. Lack of facilities provided:

It is clear that the owners of power loom units failed to provide basic amenities to the workers. The majority of the workers are not satisfied with the working conditions of the factory

• Working with dust and fumes, no proper lighting and ventilation, ignorance of cleanliness.

• No care on hygienic conditions and no safety measures to avoid accidents.

• Jobs are unsecured.

• Workers are not satisfied with their jobs in terms of welfare facilities and wages.

b. Unfair trade practices:

1. By Yarn Merchants: It is reported that local yarn merchants have made it standard practice to fluctuate the yarn prices every hour, while mills fixes up the rate for 15 days. This leads to the exploitation of the poor weavers who can do nothing but buy the yarn and manage within whatsoever margin they get.

2. By Grey Cloth Merchants: The buyers of grey cloth and other products generally delay the payment to the weavers/powerloom owners. The payment is generally made by cheque. Many a times the merchant disappear without paying for the cloths they buy from powerloom owners. That leads to the enormous losses to the weavers and keeps them indebted to the yarn suppliers.

c. Marketing practices:

There is no proper marketing mechanism in the Powerloom Industry in Malegaon. It was observed that, the price of the yarn and fabric always fluctuates. As the majority of the weavers are job work weavers, they cannot afford buying yarn and marketing of the cloth. Middlemen takes the main profit & they also exploit the weavers who are unorganised.

d. Awareness:

There is no awareness amongst the weavers regarding the schemes of the Central & State governments.

The state government has so far assisted the powerloom sector only for the powerloom co-operative societies. The state government’s role is ignorant regarding decentralised powerloom sector. So far activities done by the government are not sufficient and development done only for the co-operative sector of powerloom industry is limited.

e. Powerloom service center:

In Malegaon, Ministry of Textiles, Govt. of India established Powerloom Service Centre in 1976, which provides training facilities on pre – weaving and weaving technology. The centre also provides the testing facilities to check the quality parameter of the yarn. But most of the weavers are unaware about the Centre.

f. Scope for Modernisation:

The majority of the powerloom units are mostly small units. They run their business with small investment. Because of small scale they are not in a position to upgrade & modernise their units. In Malegaon, majority of the powerlooms are conventional plain powerlooms. Near about 500 powerlooms having semi-automatic technology and about less automatic shuttleless powerlooms are in Malegaon.

2.7 Recommendations & Suggestions:

Industrial Estate & Textile Park:

In order to pull the pace of the growth of the powerloom industry, the government should elevate it to the moderate industrial level. The government should develop and create the industrial estates or textile parks in the major clusters of the state.

Technical Institute:

In Malegaon, Powerloom Service Centre is only institution which provides technical training to the powerloom workers, which is not sufficient for the powerloom industry. The government should initiate to promote textile education in the city by starting technical institutions with specialisation in textile.

Financial Institution:

Adequate, timely and cheap financial facilities should be provided by the financial institutions. On the lines of NABARD special financial institution for textile sector should be formed for the financial help of the sector

Entrepreneurial Training:

In order to improve the level of managerial and administrative skills of the weavers. There is a need to expand the services of powerloom service centres. They should also provide training to proprietors/ weavers regarding entrepreneurship. Steps should be taken to provide basic entrepreneurial training to weavers.

Product Diversification:

The majority of the weavers are producing grey fabrics. They should divert their production from grey cloth to dyed fabrics and home textiles.

Technical Training:

The workers employed in powerloom industry are mostly technically untrained. They acquire the skills through experience. Because of non-technical training their productivity is affected. Labour productivity can be further enhanced by providing systematic training to the powerloom workers. The Powerloom Service Centre, technical institutes and textile department should conduct special technical training programmes for the workers.

Awareness about Powerloom Service Centre:

Most of the weavers are unaware about the powerloom service centre. The centre should organise awareness campaigns about the services provided by them. The government should strengthen the powerloom service centre in terms of capacity and infrastructural facilities.

1. Establishing Market Resource Center to educate the entrepreneurs on markets and providing marketing linkages.

4. Suggestion for establishing a B2B office and a yarn bank.

2.8 Powerloom Service Center, Malegaon:

Location: Malegaon, Nashik

Year of establishment: 1977

Built up area: 250 Sqm

Building typology: Government building ( On lease)

The Center, established in 1977 by the Ministry of Textiles, serves as a dedicated entity addressing the challenges and concerns faced by both workers and market traders within its purview. Housed in a rented infrastructural building situated within the bustling commercial precinct of Malegaon, the center has become a focal point for fostering growth and addressing pertinent issues.

1. Function: Specializing in the training of designers and mechanicians, the center actively engages in exhibitions, showcasing its products at diverse locations tailored to specific events. A dedicated team of 20 individuals is mobilized to ensure the success of each exhibition, wherein a curated selection of 5-6 products is presented with meticulous attention to detail.

2. Suggestions: The head of the office Mr. Mishra, recognizing the need for progress, had suggested a comprehensive upgrade for the center, that a maximum area requirement of 1 acre be allocated for its expansion. This visionary proposal aims to enhance the facility’s capabilities and cater to the evolving needs of its stakeholders

3. Change of location: Despite its current location in a rented building within a cooperative society, the possibility of relocating the center to a new, more suitable venue is being considered. This prospective move underscores the dynamic nature of the center’s operations, demonstrating its commitment to adaptability and growth in the ever-evolving landscape of the textile industry

gallery:

2. Counseling to workers on the work ethics and co-operation for the win-win position of workforce and entrepreneurs.

3. Creating awareness on the Government Schemes to the entrepreneurs for better utilization.