GRAPE CHECK

Early inland indicators

Pouring into the future -

will Australia’s

wine rebound hold?: ANZ

Australia’s wine industry is showing signs of recovery after one of its most challenging decades – but the rebound remains fragile and uneven.

According to ANZ’s latest Agri InFocus report, wine exports rose 13 percent in value to $2.48 billion in the year to June 2025, driven largely by renewed trade with mainland China following the reopening of that market.

Export volumes also increased 3 percent to 639 million litres, though growth was heavily concentrated in China, with mixed results across other destinations.

ANZ executive director of agribusiness insights, Michael Whitehead, said: “China has re-emerged as a vital outlet for Australian wine, but the market itself is far smaller than it once was, meaning the sector cannot rely on China alone to secure its future.”

Exports to China reached 85 million litres worth $893 million, more than doubling year-on-year. However, the June 2025 quarter was 35 percent smaller in value than the same quarter in 2024,

when restocking demand was at its peak, suggesting more modest trade ahead.

At the same time, China’s overall wine consumption has collapsed from 1.5 billion litres in 2019 to just 550 million litres in 2024 — a structural reset that makes the market more competitive despite Australia’s renewed access.

Beyond China, performance varied across key markets:

• United States - exports fell to a two-decade low, down 12 percent to $314 million, as shifting health perceptions, declining youth demand, and rising competition from spirits eroded market share.

• United Kingdom - held steady at $350 million.

• Canada - rose 7 percent in value.

• Southeast Asia - continued its steady growth trajectory.

Domestically, the 2025 winegrape crush lifted 11 percent on the previous year to 1.57 million tonnes, though this remained around 8 percent below the 10-year average of 1.71 million tonnes.

Despite the lift, oversupply in red varietals such as Shiraz and Cabernet Sauvignon continues to weigh on returns, reflecting a mismatch with global consumer demand, which is increasingly shifting toward whites, sparkling and premium alternatives.

Global conditions are also challenging. World wine consumption fell to a 63-year low of 21.4 billion litres in 2024, as younger generations turn to beer, spirits and non-alcoholic options.

“The future lies in diversification, premiumisation and adapting to new drinking habits,” Whitehead said. “This includes a stronger focus on whites, sparkling and premium wines, alongside emerging markets.”

With a weaker Australian dollar and improving freight conditions, the outlook for 2025–26 is one of cautious optimism. Australia’s wine industry is regaining ground, but long-term sustainability will depend on better alignment between supply and demand, and repositioning products to meet evolving consumer tastes.

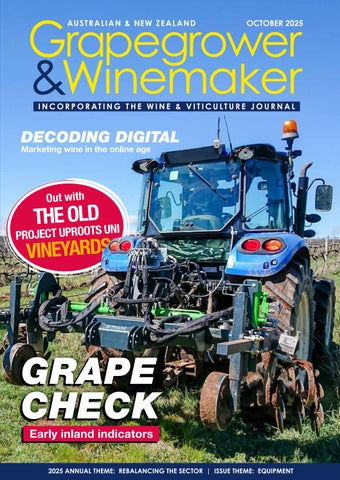

Sign of the vines University vineyard adapts to changing climate and evolving industry

By Meg Riley

Vines at the University of Adelaide’s Waite Campus vineyard will be pulled out to make way for different clones and varieties, in a redevelopment that will help the university adapt to the changing climate and prepare its students for the evolving industry.

The original vines were planted in the early ’90s, and now at roughly 37 yearsold, some are showing signs of Eutypa dieback and a decline in productivity, especially in the face of Adelaide’s warm weather.

Redeveloping the vineyard will give the educators a chance not only to select more climate-suited varieties, but to ensure they are grouped together intuitively, with similar ripening patterns and spray requirements, making the viticulturist’s job somewhat easier.

For Benjamin Pike, vineyard manager at the University of Adelaide, the

redevelopment is an exciting opportunity to redesign a vineyard with the knowledge of its weak points and a vision for the future.

Virus-affected or underperforming vines will be removed and replaced with different clones of the same variety, or with new varieties all together. The development is planned to take place in installations over the next five years, with the full extent of new plantings still to be finalised.

“One of the things that we will be doing when we’re shortlisting our varieties is making sure we understand the morphological idiosyncrasies of the vines, and when all of those developmental dates will coincide,” explained Pike, “so that we’re actually planting varieties in rows of three or four that all go into budburst at similar dates, hit flowering at similar times and [are ready for] harvest.

“The reason why we’re particularly concentrating on that is that in its previous configuration, we have real fruit salad blocks. We might have Cabernet next to Merlot, next to Riesling, next to Sauvy, next to Chardonnay. And so that makes targeting fungicide applications in particular really problematic. If we just want to spray the early-bursting varieties while everything else is still a week or two behind, then we can just spray those rows and do them all at once in one patch.”

There are two sites at the Waite Campus: the Alverstoke vineyard, which was the original orchard area for the campus, and the Coombe vineyard, which was planted in the ’90s when the Roseworthy Agricultural College merged with the University of Adelaide.

The Coombe vineyard was extended with additional rows of Shiraz, Mataro and Grenache added approximately seven

Ben Pike stands in front of what used to be rows of Semillon at the University of Adelaide’s Waite Campus

Winery Equipment

By Ian Jeffery

Building sustainable wineries

Maintaining tradition while embracing innovation

In this article I will discuss the design and building of four environmentally sustainable wineries: Château de Beaucastel in the Rhône Valley of France; Mezzacorona in Trento, Italy; Silver Oak Cellars in California’s Napa Valley; and UC Davis’ Teaching and Research Winery.

There is a huge embrace of innovations across all of these four wineries. It is matched by an equally strong embrace of tradition in two these.

The two US wineries have been awarded LEED Platinum certificates. Silver Oak was the first ‘operational winery’ to receive platinum certification, in 2016. University of California, Davis’ ‘teaching’ facility became the first winery to achieve LEED Platinum in 2010.

LEED (Leadership in Energy and Environmental Design) Platinumcertified is the highest level of certification from the US Green Building Council.

According to the UC Davis’ own ‘Sustianbility’ website, ‘Many of the University of California’s policy goals for sustainable buildings are based on standards developed by the US Green Building Council whose Leadership in Energy and Environmental Design (LEED) ratings are an internationally recognised standard for “green” buildings’.

The architects, engineers and winemakers involved in the design of these four wineries have set out to construct wineries that achieve both the minimal use of energy and minimal greenhouse gas emissions, as well as those that will enable wine to be produced using minimal energy, water and chemicals.

Château de Beaucastel

The Rhône Valley wine producer commenced their €12 million new winery and cellar project in 2018. Completed

earlier this year, the innovative facility features temperature and humidity controlled by a combination of natural ventilation and natural cooling. Four large, excavated reservoirs (approx.. 10 metres deep) under the winery are filled with captured rainwater. Cool ‘mistral’ breezes enter through openings and are ‘channelled’ over the underground water reservoirs. The resultant ‘air conditioning’ requires no energy or expenditure.

It was reported that the aim of Château de Beaucastel was to bring down their cellar temperature from 14°C to 12°C, and that this would be achieved through their ‘ecological project that harnesses the cooling effect of the mistral’, a powerful north-westerly wind that blows from southern France, as well as utilising a rainwater basin to further cool the air. The project therefore reduces reliance

Silver Oak's Alexander Valley Winery. Image courtesy Silver Oak

Ben Hirsch on bottling business in the Yarra Valley

Upbeat, business-brained and full of energy, Ben Hirsch has set out to shake up the Yarra Valley wine industry, injecting freshness and forethought into Hirsch Hill Wines and Hirsch Hill Wine Group with a mindset for growth and his sights set on fully servicing the local wine sector. Now CEO of Hirsch Wine Group, Ben spoke to journalist Meg Riley about building the business to new heights.

Entering the wine industry as a young person at this point in time is complex—there are some areas of the industry which are flourishing more than ever, and other areas which are experiencing some of most trying times the industry has seen. Readjustment is everywhere. Whilst this is something of a tumultuous environment in which to begin a career, it also means gaps in the industry are beginning to appear, and with them, opportunity.

From studying commerce law in Melbourne to being contracted to play soccer in Madrid, Ben’s entry into the wine industry was not linear. A selfprofessed “nut for business”, he was

always determined to pursue business in some way, but he never expected things to eventuate the way they did.

The Hirsch family has had the Hirsch Hill brand since its inception in 1998— Ben’s uncle and sister were both involved in planting the vineyards. After Ben’s uncle passed away in 2013, Hirsch Hill was just getting by.

Returning home from overseas in 2018, Ben threw himself into the business, focussing on wine sales and increasing the online presence and sales of the brand.

“I really just wanted to get stuck into something that I felt was my own, and

Hirsch Hill was a perfect balance for me, and a perfect mix,” he said.

Get stuck in he did, with a generous mix of duties now his to juggle. “We grew our own fruit, but then we would contract wine make, we’d contract bottle, we’d contract store, we’d contract logistics...,” said Ben. The only operation the business wasn’t engaging contractors for was grapegrowing.

“I was doing the grunt work of selling on the road and doing things online and working with all the subcontractors,” said Ben. “And I learned pretty quickly that it wasn’t a sustainable way to grow

Ben Hirsch, CEO of Hirsch Wine Group in the Yarra Valley, with the company’s in-house bottling line.

Winery Equipment

Fast and reliable temporary cooling and heating solutions: winery edition

Advanced temperature control for every stage of winemaking

The hallmark of exceptional wine is a blend of expert craftsmanship and precision control, and nowhere is this more evident than in the management of temperature throughout the winemaking process. From pre-fermentation and fermentation to stabilisation and final storage, precise climate control is essential to preserving quality and enhancing flavour profiles. Any deviation can risk spoilage, compromise aromas, and alter taste. Given the inherently seasonal nature of these requirements, temporary cooling and heating solutions offer winemakers both flexibility and cost-effectiveness.

Trane Rental Services delivers the industry’s most advanced and reliable temporary climate control solutions, ensuring your production standards are always at their highest and protecting every nuance of your wines.

Tailored solutions featuring Trane and MTA industryleading equipment

Our specialists work side-by-side with your operations team to conduct detailed assessments and configure solutions

aligned perfectly to your winery’s needs. Trane’s Cold Storage containers feature ultimate flexibility, maintaining precise temperatures from -40°C to +45°C with rapid cooling, even during ambient conditions up to +50°C. Available in both 20ft and 40ft high cube sizes, these units guarantee secure, temperaturecontrolled storage for your most valuable vintages through every season, whether for barrel aging or finished product inventory.

For process cooling, Trane’s RTAF chillers set the gold standard for reliability and precision. With models ranging from 350 to 1250 kW, they deliver ultra-quiet performance and efficient operation, even outdoors in temperatures down to -20°C. Their advanced controls and compact design provide consistent, cost-effective management all year round, accommodating both large-scale production and boutique artisanal batches.

MTA chillers and heat pumps, trusted by wineries globally since 1982, offer robust, plug-and-play options for temporary installations with minimal onsite disruption. The AST range, engineered for industrial performance, boasts fieldproven reliability with cooling capacities from 232 to 1334 kW and technology

designed for optimal efficiency and seamless integration.

For smaller process demands or specialty applications, the MTA TAEevo range (2–260 kW) features an evaporator-intank design for maximum reliability, offering responsive, precise temperature control from -10°C to 30°C. TAEevo units adapt swiftly to changes, ensuring every stage of vinification is perfectly managed, even in the most challenging conditions.

Flexible

integration, reliable support

No two wineries are identical, and neither are their climate control needs. Trane engineers ensure our rental solutions seamlessly align with your workflows, whether for a single season or long-term management. Installation is planned to integrate smoothly with your annual production schedule, minimising downtime and maximising productivity. Full logistical support guarantees a hassle-free experience, from delivery and setup to ongoing operation and rapid response in emergencies.

Our rental fleet is among the youngest and most technologically advanced in the industry, fitted with special accessories for fast connection to water and power. Supported by our extensive network of factory-authorised technicians, we provide expert service throughout installation, operation, and breakdown support. With Trane, technical expertise is always just a call away, ensuring continuous, uninterrupted operation.

Experience the Trane and MTA difference

Discover how Trane and MTA’s stateof-the-art solutions can safeguard the integrity and quality of your wine from vine to bottle. With fast, reliable, and flexible temperature-controlled solutions, your winemaking process will reach new heights of consistency and excellence year after year.

Visit www.trane.com.au to explore how our products and experts can support your winery’s unique requirements and help you produce the finest wines.