The New South Wales State Government’s Great Koala National Park (GKNP) will obliterate the North Coast timber industry, directly impacting up to 5500 regional jobs, and creating severe shortages across NSW, according to the Nationals.

The NSW Nationals say the full 176,000 hectare footprint will further exacerbate the housing crisis, wiping out 40 per cent of the state’s future hardwood supply and forcing the price of construction materials through the roof.

Response has been swift with industry leaders and the unions condemning the decision.

Australian Forest Contractors Association Tim Lester said that for the forest contracting crews the decision means they are being sacked on Father’s Day and with no notice.

He said the government has settled on the one option with the weakest evidence and the most problems.

Forestry Australia president Dr Michelle Freeman said the Great Koala National Park made a headline, not a science-led plan.

“Recent research highlights that koala populations in NSW state forests remain high and stable, thanks to thoughtful regulated management,” she said.

And the Australian Workers’ Union and the Timber, Furnishing & Textiles Union said the decision would devastate regional communities, cost hundreds of jobs and risk thousands more across the state’s $3 billion hardwood timber industry.

Timber NSW CEO Maree McCaskill told members that a Ministerial Direction had been given to Forestry Corporation NSW that as of Tuesday no timber supply will be provided on Type D contracts to four mills.

Continued page 5...

| OCT 2025 Issue 5 – Volume 36

Established 1991

News 3-8

My View 4

ForestryNOW 9-28

Silviculture 30 Awards 32-33

Transport 34-35

Mill profile 41

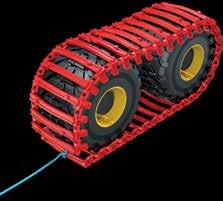

Front Cover: The founder of Tasmanian based Elphinstone Engineering, Graeme Elphinstone, has been inducted into the Shell Rimula National Road Transport Wall of Fame. Over the years Graeme has led the way with a series of engineering breakthroughs in trailer design, suspension technology, and vehicle configurations.

Story Page 34-35

Publisher and Chief Executive: Hartley Higgins

General Manager: Robyn Haworth

Editor: Bruce Mitchell

b.mitchell@ryanmediapl.com.au

Adelaide Office: (08) 8369 9521

Advertising:

Jamie Richardson

j.richardson@winetitles.com.au

Adelaide Office: (08) 8369 9514

Creative Services: Robyn Haworth

Trader classifieds:

Jamie Richardson

Adelaide Office: (08) 8369 9514

Subscriptions: subs@forestsandtimber.com.au

Adelaide Office: (08) 8369 9500

Subcription rates

One-year (6 editions) $44.65

Two-years (12 editions) $77.65

Accounts: ar@winetitles.com.au

Adelaide Office: (08) 8369 9500

Postal Address: 630 Regency Road, Broadview South Australia 5083

Phone: (08) 8369 9500

Melbourne Office: Suite 2262, 442 Auburn Rd, Hawthorn VIC 3122

Phone: (03) 9810 3262

Website www.timberbiz.com.au

Printed by Lane Print, Adelaide, SA

Conditions

The opinions expressed in Australian Forests & Timber News are not necessarily the opinions of or endorsed by the editor or publisher unless otherwise stated. All articles submitted for publication become the property of

or by

means (graphic,

or

including information and retrieval systems) without written permission of the publisher. While every effort has been made to ensure the accuracy of information, the published will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

It’s time to put the “net” back into Net Zero Emissions and the Government won’t achieve its carbon reduction ambitions without doing so.

The land sector can play a much larger role if given the chance, it can also add to our biodiversity stock.

Smarter farming and healthier soils help to build resilience and food security by sequestering more carbon and holding more drought proofing moisture. Yet the regulatory regime remains unfriendly to those hoping to secure carbon credits for improving carbon sequestration in our soils.

Australia has a pretty good carbon trading framework and yes, we need to protect the integrity of that framework, and we want sequestration to be both meaningful and permanent. But we need to provide more certainty for those prepared to further invest in carbon farming and other food production innovations.

The forestry sector is also part of the solution. To the federal government’s credit, some big strides have recently been made. For example, the so-called “water rule” has been removed.

Land prices are holding tree planting back. The current government – to its credit – is now issuing plantation grants to lower the investment hurdle. But the private sector could do more if we worked to make this asset class better understood.

The less productive areas of farm holdings can be used to plant trees for our housing and other needs. More trees not only means more sequestration, it means better soil health, better animal welfare and improved on-farm ecosystems. These opportunities should be central to our aspirations to improve our natural environment.

Trees are our great carbon sink. A native tree slowly ceases to absorb carbon with age. If it dies or is burned in situ it releases

the carbon back into the atmosphere. A harvested tree used to build the furniture, window frames and staircases stores the carbon in that product forever.

Another is seeded in its place, starting the photosynthesis process all over again. Yet two of our states have banned selective and sustainable native forestry harvesting.

Banning sustainable native harvesting has increased bushfire risk, made it difficult for fauna to navigate the forest floor, and made us more dependent on imports from countries that do not enforce our high environmental standards. It has also undermined our sovereign capability.

State governments now have responsibility to acknowledge the greater role forestry can play in our efforts to address our climate change challenges.

Another great opportunity that rarely rates a mention is the quest to reduce the methane emitted by our cattle herd. Asparagopsis is one largely ignored innovation but for me, our nascent capacity to rapidly accelerate breeding changes is even more exciting.

We now have the technology to accelerate this

change at scale. To both reduce methane and to lift productivity in both our beef and dairy sectors. This technology would be a gift to the global south too.

One Queensland-based company is close to commercialising a platform which would provide every cattle producer and dairy farmer with the tools necessary to achieve affordable accelerated genetic improvement through the in vitro production of embryos.

But you don’t read about it or hear policy makers talking about it. Nor are financiers rushing to the door to back the technology. It disappoints me that so much public money goes to subsidising mature abatement technologies while so little is invested in the promotion of new innovation on the sequestration side of the equation.

A greater role for the land sector in our climate change response should be pushed to the top of the public policy agenda. And our ambitions for it should extend well beyond our shores.

Joel Fitzgibbon is deputy chair of The Crawford Fund and a former Labor agriculture minister.

The proposal to establish the Great Koala National Park (GKNP) on the New South Wales Mid North Coast presents serious concerns for the forestry industry.

While protecting koalas and conserving biodiversity are important goals, the current park proposal — covering over 300,000 hectares of public land — poses a direct and immediate threat to sustainable timber production, local em-

&

ployment, and the broader regional economy.

At the heart of the issue is the potential loss of access to productive state forests. This leads directly to the most pressing concern: job losses across the forestry supply chain. Logging crews, truck drivers, sawmill workers, machin-

ery operators, and maintenance businesses all depend on a stable, ongoing timber supply. Towns like Wauchope, Kempsey, Dorrigo, and Nambucca Heads have economies deeply tied to forestry.

Another serious concern for the industry is the undermining of long-term sustainable forest management.

And then there’s concern about the precedent this park might set. If large-

scale land reclassification becomes the norm, other industries reliant on state forest access — such as apiculture, off-road tourism, and cultural practices of Indigenous communities — could also face disruption. The forestry sector is not opposed to conservation. What it opposes is poor planning, lack of transparency, and a disregard for the communities that rely on forest-based industries.

From page 3

They have been contacted and there will be a business continuity package for 10 weeks. Negotiations will occur on those contracts.

Further, advice was that no FCNSW timber will be delivered to Pentarch mills on the North coast commencing Tuesday. Again a 10-week business continuity package will be provided.

“We are aware that some forest contractors have been stood down commencing Monday that are operating in native forest in the assessment area and that contractors operating in the plantations located in the assessment area will also be stood down pending receipt of maps from NPWS of the boundaries of the Park so that they can determine how to harvest safely without attracting EPA scrutiny and any further legal action,” Ms McCaskill told members.

“Those mills and contractors should have been contacted and provided with a 10-week support package.”

The ABC reported that Pentarch Forestry, which stood down 38 workers at its Koolkhan sawmill in March, citing a shortfall in logs from the state’s Forestry Corporation, was likely to be among those affected.

Director Steve Dadd told the ABC it was too early to speculate on what the future held.

“The government has announced the park and a moratorium on supply but no guidance yet on how critical supply to the housing industry will be served or what support for workers to be retrenched will be offered,” Mr Dadd said.

“Our priority will be on trying to comfort very concerned workers, customers and suppliers.”

NSW Nationals Leader Dugald Saunders said it shows the government’s intention has always been to shut down the industry, whether the park was delivered or not.

“What the Premier and Environment Minister an-

The so-called ‘Great Koala National Park’ is nothing more than a fluffy announcement focused on winning votes, than it is a practical balanced solution that protects the beloved koala and regional communities.

Nationals Senator for NSW, and Shadow Minister for Fisheries and Forestry, Ross Cadell, recently toured Adam’s Sawmill at Bonville.

He heard first-hand from locals who have been left with little idea on what their future holds after nearby logging sites were included within the Great Koala National Park.

Senator Cadell said while The Nationals support the need for action to protect one of Australia’s most recognised native animals, a balanced approach was required to ensure it didn’t come at an unacceptable cost to regional communities who rely on the timber industry.

nounced this week is nothing more than a phantom project that is destroying the lives of up to 5,500 workers and their families,”

Mr Saunders said.

“Through the lack of answers we received in Parliament this week, it’s abundantly clear this government has no plan to pay for the park and hasn’t even thought about the severe ramifications it will have on multiple regional communities and sectors.

“In a coward move, Labor wouldn’t even vote to follow through on its own commitment, regardless of the outcome of the carbon credit scheme, which proves this is far from a done deal.”

Shadow Minister for the North Coast Gurmesh Singh said Labor has completely turned its back on the people who will be hit the hardest.

“The timber industry tried to work with the Minns Government on the Great Koala National Park in good faith, even putting forward a more manageable 37,000

“Under the canopy, this decision has cost hundreds of jobs and will decimate regional communities.

“Locals, industry, and politicians alike are in agreement over the need to protect the Koala, but it must not be an all-or-nothing approach.

“With appropriate consultation and consideration of alternate proposals on the size of the proposed park boundary, a win-win scenario can still be achieved.

Alongside the visit to Adam’s Sawmill, Cadell toured a logging site at Orara East State Forest and Herons Creek Timber Mills.

“The koala is an iconic animal of Australia and a species worth protecting,” Senator Cadell said.

“In the media, the Minns Labor Government has made this out to be a win for the koala.

hectare option, but the twoyear consultation process clearly didn’t mean anything,” Mr Singh said.

“This decision will hurt our communities in the middle of a cost-of-living crisis, ripping out valuable jobs that allow people to put food on the table.”

Nationals Member for Clarence Richie Williamson said his region will be gutted.

“While Chris Minns and Penny Sharpe have looked after their jobs, they have allowed thousands of jobs in my region to go.”

“The failure to meet wood supply agreements will also impact so many things we rely on every day because no timber means no paper, no power poles, no transport pallets, no wooden frames and nothing to build the homes we so desperately need,” Mr Williamson said.

“You can’t just lock up a vital resource when there is enormous demand for it, particularly at a time where we need more houses than

ever before.”

“For decades, these businesses have provided the trusses and frames that have built our nation,” Senator Cadell said.

“Right now, they need our support, not to be left out to rot by capital city centric decision makers.”

Nationals Member for Myall Lakes Tanya Thompson said timber mills will dry up, pushing skilled workers out of the region.

“The timber industry is the backbone of the North Coast but that didn’t seem to have any bearing on the Premier or the Environment Minister when they were making this cruel announcement,” Mrs Thompson said.

“These are real people who have already gone through months of angst and uncertainty, only to be told they’re out of a job, and there’s also a massive mental health toll that comes with that.”

The plan also ignores the Government’s own data, after assessments by the National Parks and Wildlife Service (NPWS) showed abundant koala populations thriving in state forests that have been selectively harvested for decades.

Nationals Member for Oxley Michael Kemp said it was a choice based on poli-

tics not science.

“This decision completely ignores the fact the NSW timber industry is among the most sustainable and tightly regulated in the world. Unlike the myths by activists, it is the gold standard – renewable, recyclable, and essential in so many ways,” Mr Kemp said.

“Yet what we’re seeing here is Labor bending over backwards to pander to people’s emotions and ignore the science, it’s not based on any kind of evidence or logic and it’s silencing the voices of our regional communities.”

Timber NSW president Andrew Hurford told the ABC the industry was “shocked and disappointed” with the announcement.

“We’re certainly having to deal with workers and contractors who are extremely distressed and disappointed and really just trying to come to grips with this unnecessary decision,” Mr Hurford said.

Australian Forest and Wood Innovations, Australia’s national institute for timber fibre, will host a panel session at this year’s Forestry Australia Conference, inviting leading voices to explore how the forest and wood products sector might evolve by 2035, and what it will take to support that change.

The session, Path to 2035: How might we enable transformation in the Australian forest sector?, will be moderated by AFWI Executive Director Dr Joseph Lawrence. It will feature a diverse panel of experts from across Australia and internationally, offering global and local perspectives on the challenges and opportunities facing the sector.

Dr Lawrence said the discussion would be grounded in the realities the sector is already facing.

“Our industry is operating in a fast-changing environment. Emerging technologies, shifting markets, climate impacts and the increasing importance of social licence all play a role in shaping what’s next,” he said.

“Transformation doesn’t come easily. It takes long-term thinking, collaboration across sectors and supply chains, and a willingness to explore new approaches,” Dr Lawrence said.

The session will feature a panel of speakers exploring the socio-economics and technological dimensions of transformation:

• Professor John Warner (Warner-Babcock Institute, USA), a global leader in green chemistry, will discuss innovation in forest-derived bioproducts.

• Andrew Morgan (SFM) on new approaches to forest management, carbon and investment.

• Nicola Pero (Iberdrola Australia) will reflect on social licence to enable innovation, drawing on lessons from energy and agrifood industries.

• Tim Woods (IndustryEdge) will share insights into global market trends and resource availability for future housing demand in Australia.

Dr Lawrence said the session would be an opportunity to consider the future of the sector in a broader context.

“We want to encourage discussion about what the industry might look like in 2035, and what is needed to get there,” he said.

The 2025 Forestry Australia Conference will focus on Restoring forests and landscapes and securing Australia’s future. We are halfway through the UN Decade of Ecosystem Restoration, and the conference aims to bring together experts, researchers, forestry professionals, farmers, rangers and tree growing practitioners to explore how forest management and forest and landscape restoration can make a positive contribution to Australia’s future.

The conference aims to provide forest scientists, forestry professionals, tree growers and restoration practitioners with tools and best practice ideas to address critical challenges such as reducing carbon emissions, adapting to climate change and increased bushfire risk, engaging with changing social attitudes and values, empowering and involving Indigenous Australians, supporting regional development and local processing to meet national housing and forest product needs.

Forest & Wood Products Australia (FWPA) will also highlight the vital role of its Forest Growers Research Program at this year’s conference.

The Forest Growers Research Program is designed to deliver targeted, industry-led research and development that increases productivity, and value across the forest growing sector.

By investing in projects that mat-

ter most to growers, the program is delivering practical benefits – from enhanced silviculture practices and improved plantation health, through to tools that support smarter decision-making and long-

term resource security

AFWI’s Path to 2035 session will take place as part of the 2025 Forestry Australia Conference from Monday 20 to Thursday 23 October 2025 in Adelaide.

Mount Gambier’s Forestry Centre of Excellence (FCoE) has expanded its specialist team appointing Krishmina Thapa as a Senior Technical Officer in Forest Health – a role focused on monitoring and managing pest and disease to protect the resource and achieve industry sustainability goals.

With global experience in forestry, agriculture, and plant science, Krishmina has expertise spanning plant genomics, plant pathology and forest health surveillance. She holds a Bachelor of Science in Forestry completed in Nepal and a Master of Science in Agriculture from the University of New England.

Prior to joining the FCoE, Krishmina worked with Agriculture Victoria in Hamilton and Horsham, supporting plant genomics and pathology research across a range of crop and forage species. Her work included advanced molecular analysis, disease surveillance, and field trials aimed at improving plant health and resilience.

At the FCoE, Krishmina will play a key role in forest health monitoring and pest management projects, working closely with research teams, industry partners, and the local forestry sector to support the long-term resilience and productivity of forests in the Green Triangle region.

Krishmina said her journey from Nepal to Mount Gambier was shaped by a deep interest in sustainable land management and plant health.

“I was drawn to the Forestry Centre of Excellence because of its reputation for high-quality, applied research and its strong focus on forest health. The opportunity to work on real-world forest surveillance and pest management projects, alongside experienced professionals, really appealed to me,” she said.

“I was also excited by the chance to be part of a team contributing directly to the long-term productivity and resilience of Australia’s forest industry. Being based in Mount Gambier — at the heart of one of the country’s major forestry regions—makes the work even more meaningful.”

Krishmina’s role will combine fieldwork, lab work and research support, including conducting forest health surveys checking for signs of pest and disease. She will also play a key role collaborating with other industry partners on forest resilience and pest management projects.

“Pest and disease management is vital. If not addressed early, pests and pathogens can cause serious damage — affecting tree growth, reducing productivity, and in some cases leading to widespread forest decline.

This impacts not just the environment, but also the economic wellbeing of the forestry sector and local communities.

“By monitoring forest health and managing these risks proactively, we can catch problems early, respond effectively, and maintain the overall health and resilience of forests. It’s all about protecting forests so they can continue to provide economic, environmental, and social benefits for generations to come,” Krishmina said.

FCoE Director Professor Jeff Morell said Krishmina delivered a valuable skillset to the centre.

“Krishmina brings a unique blend of international and local experience, along with strong technical skills in forest health. Her work will be critical in strengthening pest and disease management research programs, which are essential for ensuring the sustainability and competitiveness of not only the Green Triangle but Australia’s forest industry,” Professor Morrell said.

The FCoE has been established in Mount Gambier by the South Australian Government, University of South Australia, Green Triangle Forest Industry Hub and the South Australian Forest Products Association.

‘Friends’ group returns

The Parliamentary Friends of Forestry, Timber and Paper Products has been officially re-established in the 48th Federal Parliament as a non-partisan friendship group to support the full supply chain of Australia’s forestry and forest products sector.

Victorian Labor Senator Raff Ciccone and NSW Nationals Senator Ross Cadell have been appointed as CoChairs for the group.

Biomass MoU

OneFortyOne and HAMR Energy have entered into a Memorandum of Understanding to collaborate on the supply of sustainable biomass for renewable methanol production in Australia and New Zealand.

The MoU marks a significant step forward in the development of HAMR Energy’s flagship Portland Renewable Fuels Project (PRF Project) in Victoria. The project will produce up to 300,000 tonnes per annum of renewable methanol, derived from forestry residue biomass and green hydrogen, which can be used to fuel planes and ships, helping decarbonise hard-toabate transport.

Slash for energy

A wasted opportunity is passing New Zealand by to make the most of damaging forest slash by failing to treat it as an energy solution, instead regarding it as a headache, says Bioenergy Association executive officer Brian Cox.

“While slash lays rotting in forests it costs communities in terms of flood damage, but as fuel it could slice household electricity bills,” he said.

New guidance to simplify safety for forestry businesses and workers has been published by WorkSafe New Zealand.

Forestry had the highest fatality rate of any sector in 2024, with 16.58 deaths per 100,000 workers. The fatality rate is 20 times higher than the average for all industries.

The Approved Code of Practice (ACOP) for forestry and harvesting operations was spearheaded by WorkSafe, in collaboration with the forestry industry. The ACOP has now been launched by the Minister for Workplace Relations and Safety, Brooke van Velden.

South Australia’s timber industry faces an uncertain economic future, according to South Australian Forest Products Association Chief Executive Officer Nathan Paine.

“South Australia is proud to be the birthplace of Australia’s plantation forestry industry. For 150 years, generations of South Australians have grown and processed the timber that builds our homes, supports our manufacturers and retailers, underpins our farms, and sustains our economy and way of life. Yet today, our timber processors are under unprecedented pressure from both soft domestic demand and the growing threat of surging imports,” Mr Paine said.

The United States has now lifted tariffs on Canadian timber to 35.19%, escalating a broader global trade shift with Canada explicitly identifying Australia as a key new market for its diverted supply.

“The scale of potential trade diversion is alarming, especially as Canada exported an estimated 28 million m³ of lumber to the US in 2024 – equivalent to almost 2 million homes. And, even if 5% of Canada’s displaced supply were redirected to Australia, it would mean an additional 1 million m³ flooding into our market – a volume large enough to destabilise local processors and trigger mill closures,” Mr Paine said.

“This is not just a trade is-

sue – it’s a sovereign capability issue, and to protect Australia’s timber future, SAFPA has released its Our Timber. Our Jobs. Our Future. policy paper, calling for urgent government action.

Key recommendations include:

• Maximise South Australian grown and processed fibre content in all State Government property projects and advocate for the Federal Government to adopt the same approach.

• Establish a State-level Supporting Domestic Manufacturing Strike Force to safeguard local capability.

• Promote retailer-led procurement of South Australian and Australian processed wood products.

• Support country-of-origin labelling for imported fibre in government projects.

• Invest in sovereign fibre and manufacturing capability while securing future plantation expansion and fibre supply.

“South Australia knows too well the cost of stepping in when an industry is on the brink of collapse

– Whyalla is a stark reminder. While our industry remains solid, we cannot afford to ‘wait and see’ with Mount Gambier, the heart

of Australia’s softwood industry,” Mr Paine said.

“SAFPA is working with industry to protect our sovereign capability, secure regional jobs, and ensure that the next 150 years of Australian forestry are defined by resilience, innovation, and sustainability – not disinvestment and decline,” Mr Paine said.

“Industry acknowledges the Government’s ongoing engagement and looks forward to working together to protect – and grow – our timber industries into the future. SAFPA will be seeking urgent discussions with the Government to secure support for these recommendations.”

The latest round of grants under the Support Plantation Establishment Program (SPEP) have opened for applications.

The Federal Minister for Agriculture, Fisheries and Forestry, Julie Collins, announced the latest round of grants at the National Farmers’ Federation (NFF) AgXchange Conference.

The Australian Forest Products Association welcomed the Albanese Government’s progress on initiatives that are providing support and opportunities to help our national forestry sector.

“The SPEP is a government-industry partnership that AFPA advocated strongly for. It’s now helping more get more, much

needed production trees planted, in the right place at the right scale, across Australia,” AFPA CEO Diana Hallam said.

Ms Collins also announced the Government will consult on and develop a National Bioenergy Feedstock Strategy.

“A huge volume of timber and wood-fibre residues are created during

harvesting in the forest, processing in mills and in manufacturing.

“Many businesses are already using the residues efficiently within their operations or to create commercial by products,” Ms Hallam said.

Applications will be open from 24 September 2025 to 5 November 2025.

The Australian forestry sector is a vital part of the nation’s economy and environment, contributing to regional employment, sustainable resource management, and carbon sequestration. Recent years have seen growing pressures, including climate change impacts like bushfires, biodiversity concerns, and evolving regulatory

frameworks. Native forest logging has faced increasing restrictions.

At the same time, demand for sustainably sourced timber and wood products remains strong, driven by construction and global markets. Investment in plantation expansion, innovation, and value-added processing is growing, supported by government

policies promoting sustainability.

The sector is undergoing significant transformation to balance economic, environmental, and social responsibilities in a changing climate and global market.

But it has been said that everyone in the industry needs to do well in order for anyone to do well.

From house frames to farm gates, the furniture in our homes and offices, to the paper and cardboard products we use every day, Australia’s proud forestry sector is at the heart of everything we do.

And when you look at the figures, the critical contribution Australia’s forest and forestry industries make to our nation’s economy and regional communities is clear.

A key part of Australia’s economy, these industries generate around $28 billion in sales and, support more than 52,000 jobs nationally, while providing a lifeline to rural and regional communities.

That is why the Albanese Labor Government is delivering $300 million to support the forestry sector and the critical contribution it makes across the country.

This funding is helping to grow plantations, modernise our manufacturing infrastructure, invest in forestry research and data, combat trade in illegally logged products and upskill our workforce.

The investment is the most significant in Australia’s history and is now delivering real green shots across the country for our forestry sector.

These green shoots were quite literally on display when I recently visited the Forico nursery in my home state to announce the latest round of grant recipients for the Support Plantation

Establishment program.

We know Australia needs to grow more trees and this key initiative is investing over $73 million in new long-rotation softwood and hardwood plantation forests across Australia.

Importantly, this program isn’t just increasing the future plantation forest resource available for domestic processing, it is also contributing to Australia’s commitment for a Net Zero economy by 2050.

To date, the government has supported 60 projects to establish over 25,000 hectares of plantation forest across all states and the Northern Territory.

Over $27 million is still on the table, and I look forward to making future announcements in support of growing our plantation estate.

Our Government is also maximising the use of our forest resources and we are starting to see strong productivity outcomes from our co-investment with pri-

vately-owned wood processors under the Accelerate Adoption of Wood Processing Innovation program.

For example, several complete projects have installed new scanning and sawmilling equipment, delivering as much as a 13% improvement to manufacturing capacity.

The program is providing almost $90 million to 30 projects across the country and leveraging more than $160 million of private capital to adopt new and upgraded technology and will increase our domestic production capacity, value add to existing and new product lines and reduce carbon emissions.

Our Government has also provided $100 million for

Australian Forest and Wood Innovations to support research, development, and innovation in partnership with industry.

Hosted by the University of Tasmania and supported by three Regional Research Centres across Australia, this once-in-a-generation investment in research and development help make the most of our wood resources.

The institute’s first national call for research projects resulted in eight research projects being supported. These projects, which are underway, share $5 million worth of funding.

The institute is now considering a second national open call, which received 34 expressions of interest, seeking over $30 million in funding.

While it is pleasing to see the progress of the investments we have already made, our Government is looking forward to ensure the continued growth of

our forestry sector.

That’s why it was a pleasure to recently release the Timber Fibre Strategy which was led by our Government’s Strategic Forest and Renewable Materials Partnership and guided by close consultation.

The strategy sets out 128 ambitious actions for industry and governments to help build a sustainable, world leading sector with products that are in demand domestically and internationally.

The Strategy will help the forestry sector to embrace future opportunities and contribute to solutions for the challenges facing Australia. This includes playing a key role in tackling our nation’s housing challenges and our transition to a Net Zero economy.

The Albanese Labor Government is ambitious for our forestry sector, and we will continue investing in its future - charting a path forward for the future success of this proud industry.

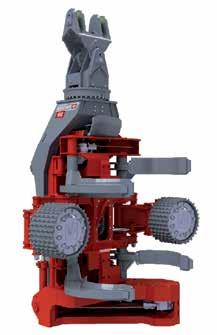

High-performance engine, powerful booms and enhanced hydraulic power delivers unmatched productivity and fuel efficiency.

Active Frame Lock provides stability and a larger working area.

The 220-degree cabin rotation offers flexibility and visibility.

A range of high performance attachments maximises your productivity.

Stilllookingformore?

Advanced analytics and global data sharing is delivers real-time metrics to support site planning and operator assistance.

H Series Harvesters… time to get ahead of the game.

It’s been a difficult time for Australia’s forestry and forest products sector as we head towards the end of 2025.

Many of our processors and manufacturers are fac ing serious challenges with rising energy costs and a still constrained housing and construction market.

The native hardwood in dustry continues to face op position from people igno rant of the role it can play in decarbonizing our economy while sustaining biodiversity, and the challenge of getting more production trees in the ground to meet future demand remains an ever-pressing issue on the plantation front.

O

Despite these difficulties, forestry enjoys strong bipartisan support at the federal level – a testament to the Australian Forest Products Association’s ongoing advocacy with the major political parties.

And the opportunities are growing for our sector as the Albanese Government seeks to drive down Aus-

tralia’s carbon emissions.

We know the trees we grow and the products we make are a huge part of decarbonising the economy – as such that remains a big opportunity AFPA is pursuing partnership on across the Parliamentary spectrum.

For growers, the everpresent challenge of getting more trees planted to meet demand in decades to come, continues.

The cost of land, skills

ur native industry has always had to fight for its right to exist and unfortunately that’s increasingly the case following the recent Great Koala National Park decision in NSW.

shortages, ensuring a rigorous carbon market and getting the right trees planted, in the right place, at the right scale is a constant focus of our Association.

The Support Plantation Establishment Program (SPEP) that AFPA advocated so strongly for in 2022 has been a success and we will argue for the Australian Government to further

the partnership with industry in getting more trees planted.

Our native industry has always had to fight for its right to exist and unfortunately that’s increasingly the case, following the recent Great Koala National Park decision in NSW.

Since the industry closures in Victoria and Western Australia, imported

and often dubious hardwood resource has filled the supply gap, which isn’t good for our economy or the global environment.

AFPA maintains that Australia needs a strong and sustainable native industry, because the demand for high-quality products is not diminishing.

The Australian industry is a world leader in environmental practice and forest management and it remains a critical employer in many regions.

Like with all manufacturing sectors and as alluded to at the beginning of this piece, processing and manufacturing in timber and wood fiber is being challenged by rising energy costs, red tape and imported products.

It’s critical that we keep our processing and manufacturing cogs in our supply chain strong. It is vitally important for our sovereign capability, employment and to promote the high-quality standards we are so proud of here in Australia. This again is a key area of focus for AFPA. Despite the difficulties and challenges, the outlook for forestry and forest products grown and made in Australia is excellent.

We’re a world leader when it comes to growing and managing forests and processing and manufacturing essential products.

As the world seeks to decarbonise, the demand for timber and wood-fibre is increasing – especially for timber and fiber resources produced sustainably.

AFPA looks forward to continuing to represent our sector proudly at the federal level and through our state-based associations.

I believe the difficulties and challenges we face are far outweighed by the opportunities we have to become even more important for Australia and the world in the future.

Aview frequently shared around the AFCA table is that everyone in the industry needs to do well in order for anyone to do well.

It speaks to the impor tance of partnerships and relationships, and how working together leads to much better long-term out comes.

The past year and more has been tough and it has been hard for anyone to do well. Housing construction has been flat which is the driver of the softwood market. Pulp and paper connects into general international trade which is being disrupted by the Trump tariffs. The woodchip market has also dipped.

The market stresses are being transmitted through the supply chain and forest services businesses have been squeezed by rising costs and limits on production. This is coupled with uncertainty created by governments through political and regulatory decisions, leading to high levels of stress across the industry.

Regarding government decisions AFCA was beyond disappointed by the announcement of the NSW Government for the creation of a full-size Great Koala National Park, particularly in light of the propositions put forward by the expert industry panel to maintain a sustainable industry and secure a park.

The decision is based on a series of flawed propositions, starting with that timber harvesting is detrimental to koala populations. A second one is that there is a looming tourism boom that will replace a productive forest industry as a driver of the regional economy for the Mid North Coast of NSW.

Koala population data collected by the NSW National Parks Service using drone surveys and thermal detections showed significant numbers of animals across the area with no differences between state forests and national parks. The timber industry and koalas have coexisted for more than a century and there is no evidence of a declining population.

Unfortunately, there is a lot of evidence of the negative impact on communities from decisions like this. Creation of the park will cause a 40 percent reduction in the wood basket across northern NSW and strip an estimated $730 million per year from the economy. The World Bank has identified that every dollar generated by forestry industries multiplies two and a half times through the economy, so the overall impact will be huge. You don’t have to look any further than Victoria to see the far-reaching consequences. In order to turn

off a sustainable native timber harvest from the state’s production forest resource, the government will spend upwards of $1.5 billion in worker support, business payments and local development strategies.

The past year and more has been tough and it has been hard for anyone to do well.

For an industry that was

directly contributing $800 million year on year to the state’s economy.

Meanwhile our forests still need to be managed. Former harvesting contractors in Victoria are now providing forest and fire services, but another group of contractors has been displaced as the planning capacity within the government struggles to keep up. Valuable skills and experience are likely to disappear and be very difficult to replace. Demand for the product has also not diminished and more timber is being imported. That means jobs and dollars are being exported. With global demand for timber and

wood fibre expected to at least triple over the next 25 years competition for available resources is likely to be fierce.

Which is also the reason we need to make sure Australian businesses are well positioned to ride through market shocks and take advantage of emerging opportunities. AFCA’s ForestFit™ Standard and Certification Scheme aims to do just that by ensuring the business foundations are solid while also embedding assurances for the supply chain about the sustainability of forest operations.

ForestFit™ is a global first as a certification designed specifically for forest services businesses regardless of size or scope of operation. With ForestFit™ alongside Responsible Wood/PEFC and FSC, Australia has delivered the world’s first fully certified supply chain for timber and wood fibre. This is a remarkable achievement and through AFCA we will be working with our industry partners on how to best capitalise on it.

Because we can all do well together.

The past twelve months have tested Victoria’s forest and wood-fibre industries in ways that highlight both our vulnerabilities and our resilience.

As we look ahead to the coming year — and with the next state election set for late 2026 — it is timely to take stock of the pressures we face, the progress we have made, and the opportunities we must seize.

Victoria’s housing market has slowed sharply, and with it demand for structural softwood. The combination of cost-ofliving economic impacts, reduced commencements, and a shortage of trades stretching build times has created a challenging environment. Inventories are high and prices have fallen by around 3% year-on-year for the past two years, eroding margins in an industry already grappling with

elevated operating costs. Some mills are running at around 80% capacity, and we have already seen the closure of some timber manufacturing lines such as those in Benalla. These shifts are not just numbers on a page — they mean real pressure on regional businesses, workers, and communities.

Adding to the domestic pressure are global trade dynamics beyond our control. The USA recently lifted its anti-dumping and countervailing duties on Canadian softwood lumber to levels of 35%.

In practice, this means Canadian exporters are seeking alternative markets for their product — and Australia is a natural target.

The threat of displaced imports into our market only heightens the urgency of ensuring a strong, resilient domestic industry.

At the same time, the export market for wood fibre has also dampened, underlining the importance of creating more value onshore.

Against this backdrop, VFPA has worked hard to ensure our sector’s voice is heard. We are engaging positively with all sides of politics and pushing a forward-looking agenda that highlights the new opportunities forestry can unlock for Victoria — from advanced timber manufacturing to carbon reduction and bioproducts.

Our policy agenda is increasingly recognised, reflecting the breadth of issues we carry — from housing supply and plantation expansion to protecting our existing plantation assets through stronger fire management, and the development of a by-products framework.

Our inaugural “Timber in July” event at Parliament House was a milestone, bringing together Ministers, Shadow Ministers, and MPs across the spectrum to experience first-hand the innovation and sustainability of our sector.

We hope this will become an annual fixture to

showcase the industry’s contribution to housing, jobs, and carbon reduction.

We’ve also hosted site visits from key Ministers to Colac and Portland, ensuring decision-makers see the jobs and technologies our industry supports.

These engagements matter: they build trust, foster understanding, and lay the groundwork for policy reforms we need in the years ahead.

One of the most pressing long-term issues remains plantation supply.

Victoria’s plantation estate has been broadly stable, but with demand for timber forecast to rise by more than 40% by mid-century, we face a projected fibre shortfall without significant new investment.

Land-use competition and regulatory barriers all make plantation expansion harder than it should be.

That is why VFPA has consistently called for government support to de-risk both softwood and hardwood long-rotation plantations.

We welcome the Victorian Government’s recent announcement of a new plantation establishment program, which will operate alongside the Commonwealth’s Support Plantation Establishment Program.

This is a constructive step forward — but both state and federal policies must be calibrated to address regulatory challenges, and tackle other bottlenecks upstream if we are to meet Victoria’s housing and climate goals.

This year we also released the Victorian Wood Fibre Roadmap, which highlights both the enormous opportunities ahead for next-generation products — from

engineered timber for homes, to green biofuels, biochemicals, and biomaterials — and the fact that Victoria’s forest products sector already contributes $9 billion annually to the state’s economy and supports 17,000 regional jobs.

We provide the ultimate renewable, capturing carbon while delivering affordable housing. With the right policy settings, Victoria can grow its plantation base, expand advanced timber manufacturing, and unlock the next generation of low-carbon products that our state will need in a decarbonising economy.

As just one key example of this effort, VFPA has invested this year in the Hardwood Manufacturing Feasibility Study, co-funded with the State Government through the Portland Diversification Fund. This project is exploring opportunities to expand hardwood manufacturing in western Victoria, opening up new potential for regional jobs and value-adding. With the export market softening, this work is particularly important in helping the sector diversify and capture more value through domestic processing.

Looking ahead, the next twelve months are critical.

For the sector, it will be a period of careful navigation through subdued housing demand, global trade pressures, and the ever-present challenge of securing new plantations.

For VFPA, it will also be a year of continued engagement, as we seek to ensure that forestry is central to political debate as we move closer to the election.

Despite current headwinds, we remain optimistic. This is a sector that has weathered many cycles before.

With strong advocacy, bipartisan political engagement, and a clear vision for growth, we can position Victoria’s forest products industry to be not just resilient, but a leader in Australia’s low-carbon future.

The past twelve months have rein forced an old truth: the more things change, the more they stay the same.

For the Tasmanian Forest Products Association 2025 has been a year defined by sustained activity, strategic advocacy, and a political environment that contin ues to demand vigilance.

Three election campaigns, negotiations over the management of the public forest estate, and persistent external scrutiny of native forestry have ensured that the sector remains firmly in the public eye.

The year opened with ongoing adjustments to Tasmania’s public estate, creating a complex policy landscape for forestry operators and policymakers alike.

From the outset, TFPA worked closely with members to develop a united approach to these negotiations.

By presenting a coordinated industry position, TFPA helped ensure that individual concerns were addressed within a collective framework—critical in a year where political uncertainty was the norm rather than the exception.

The first major political test came with the 2025 Federal Election. TFPA launched a focused advocacy campaign to secure recognition of the industry’s economic contribution and environmental credentials.

Engagement with candidates across Tasmania was intensive and deliberate, emphasising forestry’s role in delivering renewable timber products, supporting housing construction, and contributing to carbonpositive land management.

The effort produced tangible results. Both the Federal Minister for Agriculture, Fisheries and Forestry, Julie Collins, and the then Shadow Minister for Forestry, Jonno Duniam, provided clear statements of support for Tasmania’s forestry industry.

Their commitments reflected the effectiveness of the industry’s messaging and its ability to build cross-party consensus on the value of a sustainable, science-based forestry sector.

Barely had the federal campaign concluded when attention shifted to the Tasmanian Legislative Council election.

Once again, TFPA mobilised quickly to ensure forestry was well represented in the policy debate.

The result was encouraging: all successful candidates expressed support for our industry.

The pace of political change accelerated when a successful no-confidence motion against Premier Jeremy Rockliff in the House of Assembly triggered a snap state election -the third political campaign in just four months. The TFPA responded with a clear and disciplined platform built around four strategic pillars:

• Housing and Wood Products – highlighting forestry’s role in addressing Tasmania’s housing shortage and delivering renewable building materials.

• Community Awareness – promoting public understanding of the industry’s sustainability and its importance to regional economies.

• Climate Change and Fire Threat – emphasising the sector’s contribution to carbon management and

the need for active forest management to reduce fire risk.

• Timber Trees and Productivity – focusing on the long-term productivity and innovation required to meet future timber demand.

Both major parties responded with strong public commitments to the industry, demonstrating that forestry remains central to Tasmania’s economic and environmental agenda.

The post-election period brought its own challenges. With the crossbench dominated by left-leaning independents, the Liberal Party sought to secure support by offering to withdraw a proposed access of the future potential production forest

estate - an initiative originally created under the 2014 Tasmanian Forestry Agreement.

Labor declined to match this concession, reaffirming its position that traditional industries such as forestry and aquaculture must remain integral to Tasmania’s economic base. This decision, while principled, ultimately left Labor without the crossbench support required to form government.

The outcome marked the beginning of a new era in Tasmanian politics: one characterised by a finely balanced parliament and a crossbench with significant influence over key policy decisions. In this environment, the need for a strong, unified industry voice is greater than ever.

The TFPA remains com-

mitted to ensuring that future policy decisions are guided by evidence rather than rhetoric.

We continue to engage constructively with both Government and Opposition, providing accurate, science-based information on managed regrowth forestry, carbon outcomes, and the industry’s rigorous sustainability standards. Behind the scenes, TFPA is also investing in community education to counter misinformation and build broader public understanding of forestry’s role in climate resilience and regional development. While political dynamics will continue to shift, the TFPA’s mission remains constant: to represent and advance the interests of a sustainable, science-driven forestry industry that delivers lasting benefits for Tasmania and the nation. Change is inevitable. But with strong advocacy, collaborative leadership, and a clear strategic direction, the Tasmanian forestry sector will not only endure - it will thrive.

Mick Stephens CEO, Timber Queensland

Reflecting on the situation I reported on for Queensland last year I am pleased to advise that the political environment has taken a turn for the better since the state election held in October 2024.

The election of the new LNP Crisafulli Government has provided a solid footing on which to build a more secure policy framework for the industry to grow across the plantation softwood, native hardwood and cypress sectors and downstream manufacturing.

The Government has listened to our call for a comprehensive plan to remove productivity barriers and has put the forest and timber industry back at the forefront of strategic economic development.

The new Government has forged ahead with its commitment for a ‘landmark timber action plan’ to secure the local timber supply needed to build 1 million new houses and related public infrastructure over the next few decades.

A draft Queensland Future Timber Plan was released in August for public consultation with a number of key themes, including:

• securing sustainable timber supply for housing, construction and infrastructure and other industries;

• establishing supply chain competitiveness on an international scale;

• developing better regulation that the community sees benefits in;

• building and retaining a viable fit-for-purpose workforce in rural and regional economies; and

• modernising and innovating the Queensland forestry and timber industry through research, development and extension.

The 25-year timber plan will be underpinned by

5-year action plans with the first round of actions to be released in conjunction with the headline plan by the end of October 2025. Importantly, the plan is to be co-designed, co-invested and co-delivered by industry and the Government.

Timber Queensland has played a pivotal role in the provision of industry input into the draft plan including through the Timber Supply Chain Ministerial Roundtable established not long after the election.

We have provided a detailed submission with 18 recommended actions for regulatory and policy fixes, as well as our call for a world class, industry led forestry education and extension service.

This service would provide specialist advice and information to support best practice private forestry particularly targeting the better integration of native and plantation forestry with the beef sector and indigenous partnerships.

Key recommended actions include crown native forest resource security, a long-term right to harvest in private forests, accelerating uptake of innovation in timber manufacturing, targeted planting of new plantations, development of indigenous forestry, greater use of biomass in the bioeconomy, and carbon methods that recognise active forest management, amongst others.

In addition, the Queensland Government released a 25-year plan for the

broader

agricultural, forestry and fisheries primary industries sector, with the Prosper 2050 Blueprint.

Timber

Queensland and the industry will be taking the bull by the horns and leading the way to shape the future.

This Blueprint has the added goal to increase primary industries production to $30 billion by 2030 with the new timber plan to operate in parallel.

Through both these processes, the Government has clearly signalled the need to rebuild and boost the forest and timber industry as a critical sector for the state.

Timber Queensland has had a seat at the table where the industry is regarded as an important partner in addressing statewide workforce, infrastructure and regulatory needs.

Given these significant opportunities, we are in a unique position to express our leadership across the industry and with Government to put in place the

long-term policy and program settings necessary for sustained higher growth. For too long the industry has been neglected by successive Labor Governments and the Crisafulli Government has recognised the need to rebuild. Leadership also means not relying on others to manage and protect our forests for healthy outcomes and delivery of sustainable development goals.

Timber Queensland and the industry will be taking the bull by the horns and leading the way to shape the future.

The next 12 months will therefore be an exciting and busy time working with the Government on the implementation of the long-term industry plans.

Forestry in Australia sits at a familiar crossroad, though the stakes feel higher.

The risks, exacerbated by fragmentation of policy and responsibilities, are real. But the opportunity is just as real.

That is the work in front of us and it demands science, experience and partnership across all tenures.

We understand the headwinds. The continuing instability around forest settings, and a shrinking skills pipeline threaten our capacity to manage forests well, especially on the public estate. At the same time, short-term politics is too often crowding out long-term stewardship and consultation.

In particular, if Australia is serious about its new emissions target, we must fully embrace the role for forests. Australia cannot afford to base its climate future on myths and misplaced priorities.

To meet the target, reforestation alone will need to sequester more than 100 Mt of CO₂-e each year by 2050. That means up to 10 million hectares of new trees in just 25 years. At current rates, we’re at just 5% of what’s needed. A step change in policy is essential. We need more trained forestry capacity and new approaches involving local governments, farmers, Indigenous communities, NGOs, large private investors and the forest industry supported by effective extension services to enable forests to play their full role in climate action while delivering the timber needed to address the housing crisis.

At the Association level, our response is practical. Over the last year, Forestry Australia has focused on keeping our association steady and useful for members while the operating environment has become tougher. We took early, practical steps to reduce costs and rationalise where we invest. We were buoyed by the success of our Healthy Forests Symposium and the Forest

Carbon Summit, which both exceeded expectations on attendance, satisfaction and budget.

We have commenced development of our Professional Development Program to drive an offer that meets the needs of the sector. Through support from ForestWorks, we are leading a pilot mentoring program for women in the forest and timber industries under the Australian Government’s Forestry Workforce Training Program with feedback so far extremely positive. This is how we rebuild capability: one person, one team, one workplace at a time.

We also continue to strengthen our science policy work, including developing position statements and evidence reviews to support the sectors’ storytelling. We are investing in the Australian Forestry journal and have begun a strategic review to lift relevance, throughput and financial sustainability. This would not have been possible without support from FWPA and generous member donations. Forestry Australis understands advocacy is not an optional extra - its how we promote decisions that are informed by evidence, not ideology.

Another key initiative is Enhancing Native Forest Resilience, a tenure-blind carbon method Forestry Australia submitted under the ACCU proponent-led

process. Our method provides an internationallyaligned framework that is designed to enable broad participation across State forest agencies, national parks managers, First Peoples, private native forest landowners, community groups and notfor-profit organisations. Grounded in research, our proposed method highlights the potential of active and restorative forest management to increase carbon, enhance biodiversity, and build resilience. While not yet selected by the government for development, we are continuing progress, because integrity-first forest carbon is key to delivering on key national and forest sector interests.

We also continue to focus on safeguarding an independent, professional, member-led voice for the forest sector. More than a hundred people volunteer time and expertise to Forestry Australia each year. To every member who presents a webinar, mentors a colleague, writes or reviews a paper, or turns up to a field day: thank you. Looking ahead, Forestry Australia will continue focus on:

• Active, adaptive management across all tenures. From cultural burning and climate-smart silviculture to farm forestry and targeted restoration, we need implementa-

tion at landscape scales, planned transparently, monitored, and adjusted as conditions change. This is as important in conservation reserves as it is in production forests.

• Evidence-based, respectful debate. Australia needs environmental literacy that treats forests as complex systems, not as symbols. Our role is to keep bringing science and operational experience to the table and to make space for different perspectives to be heard and tested.

• People and pathways. We must rebuild the skills pipeline. Our new professional development initiatives will be a start and we will keep

expanding them with partners.

• The long-game. An independent association, thoughtful evidencebased advocacy, peer networking and quality events, and member-led committees may sound unglamorous, but they are what keep the profession going.

Forestry Australia is a professional association of more than 1,100 members working across forest, fire and land management and tree growing throughout Australia. Our vision is that Australia’s forests are healthy, resilient, and managed inclusively and adaptively to provide a broad range of values and benefits for society.

In 2023-24, the volume of logs harvested fell by 6.0% compared to 2022-23. This was primarily driven by smaller harvests of pulp logs from the hardwood plantation estate.

While the volume harvested dropped, the log price index for all logs increased slightly by 0.1% in nominal terms. Overall, this contributed to a reduction in the nominal GVP of total logs harvested by 5.3% to $2.28 billion in 2023-24 (9.1% decrease in real terms).

The volume of production from hardwood plantations decreased by 15.9% to 7.1 million m3 in 202324. The gross value of production also decreased by 17.9% (21.2% in real terms) to $656 million. Most notably for hardwood plantation log harvest, the volume of hardwood woodchips for export decreased by 15.4% from 2022-23. These changes reflect developments in international woodchip markets with Australia facing increasing competition from Vietnam in our key export markets. Indeed, the value of exports of forest and wood products continued a declining trend with a reduction of 2.0% in nominal terms to $2.7 billion in 2023-24 (5.9% fall in real terms), with the

majority of this decline attributed to reduced export values of Australian woodchips.

The volume of production from softwood plantations stayed relatively steady, only decreasing by 0.7% in 2023-24 compared to 2022-23. The gross value of production for the softwood plantation estate in 2023-24 was $1.36 billion, a 1.2% increase from 202223 (2.9% decrease in real terms). This steady value and volume of production was achieved despite an easing in housing market conditions in 2023-24. Declining import values and volumes were the main adjustment mechanism for reduced demand for structural and construction wood products, rather than a reduction in domestic production.

The volume of native harvests (including native cypress pine) decreased by 1.4% between 2022-23 and 2023-24 to 2.5 million m3. Declines in harvest in Victoria and Western Australia due to the phase out of harvesting in public native harvests on 1 January 2024 were almost entirely offset by increased harvests in New South Wales and Tasmania. However, this is a significant fall compared to 2021-22 when the total volume of native harvest was 3.5 million m3. The fall

between 2021-22 and 202223 was largely driven by lower harvests in Victoria due to legal challenges . The gross value of production for native harvest slightly decreased by 0.2% to $274 million in 2023-24. Similarly, this is a significant fall from $372 million in 2021-22.

The rate of new plantation establishment eased in 2023-24 with 3,700 hectares of new plantations established (16.9% less when compared to 202223). The majority of these new plantations were softwood (3,500 hectares) with some hardwood plantation establishment (200 hectares). In 202324, the total area of commercial plantations was 1.71 million hectares, with 1.01 million hectares of softwood plantations and 0.67 million hectares of hardwood plantations, and the remainder of unknown species.

In 2023-24, the volume of plantation hardwood log harvest decreased by 15.9% to 7.1 million m3 compared to 2022-23, with the value of production declining slightly faster, by 17.9% (21.2% in real terms) to $656 million in 2023-24.

Australia’s hardwood planation estate is structured to supply woodchips to international markets. In 2023-24, 87%

of hardwood plantation logs harvested were pulp logs intended for export as woodchips.

The value and volume of production from Australia’s hardwood plantation estate have been declining sharply since 2018-19. While the economic disruptions from the COVID-19 pandemic marked the start of this decline, exports of hardwood woodchips have not recovered to pre-pandemic levels and continue to decline.

Woodchips are an important export commodity and in 2023-24 were worth $1.2 billion, or 43% of Australia’s forest and wood product exports. This was a 7.3% reduction (11.0% in real terms) in total export value compared to 2022-23.

China and Japan have historically been the major markets for exported Australian woodchips. Recently, demand from China has been in decline, partly attributed to slowing economic growth but also, a strategic shift within its domestic paper industry. Increasingly, Chinese manufacturers are seeking imported wood pulp from other markets rather than raw woodchips that Australia traditionally exports, because wood pulp offers greater processing efficiencies

and cost-effectiveness (ResourceWise 2024). In contrast, the Japanese market remains focussed on imported woodchips as the pulp and paper industry is highly integrated and reliant on imported hardwood woodchips due to the limited domestic availability of suitable feedstock (Margules Groome 2020).

Australia’s historical position as a major global exporter of woodchips is also increasingly being challenged by Vietnam. While Australian eucalyptus woodchips are generally regarded as superior to Vietnam’s acacia chips due to higher pulp yields, Vietnam has steadily increased in importance in export markets and currently accounts for over 60% of the Asia-Pacific hardwood woodchip market (Margules Groome 2024). Declining competitiveness and increasing volatility in global woodchip markets is affecting dynamics in the Australian plantation estate, with growers beginning to consider alternate options for their hardwood plantations (ABARES 2025).

Continued page 28...

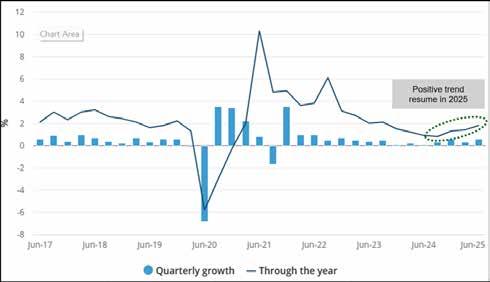

The latest national economic data, re leased by the ABS, shows that the Australian economy grew by 1.8% in the year to June 2025 (Fig ure 1).

While this remains below the longrun average of 2.7 per cent, the result was above market expec tations and represents an improvement on the 1.3% growth recorded in the previous quarter (in the year to March 2025).

Some indicators relevant to the Forestry and Timber industry also show encouraging signs. These include annual growth in Gross Value Added (GVA) across key related sectors such as Agriculture, Forestry and Fishing, Construction, Logistics, and Transport.

The upward movement in these areas suggests strengthening demand and activity that could support continued recovery and expansion within the Forestry and Timber sector.

Total Gross Value Added of Forestry Products

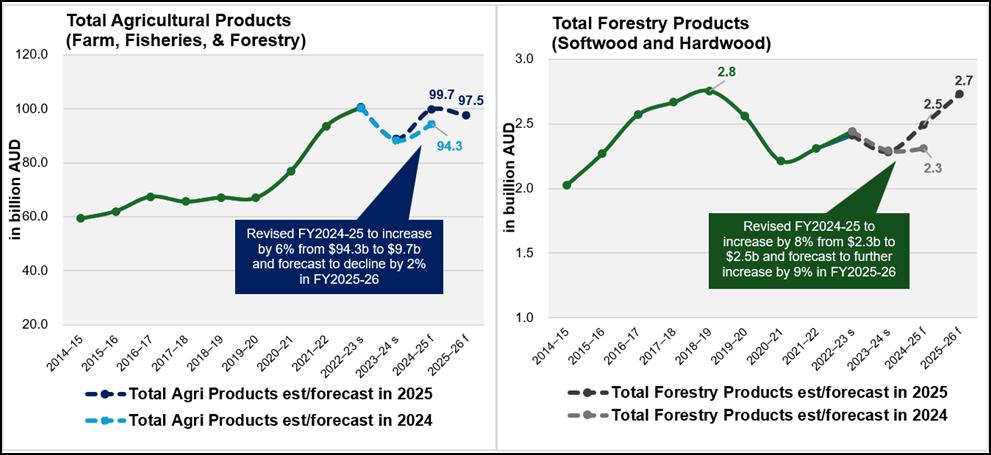

This ABS release complements the latest Gross Value Added (GVA) data in the Forestry Industry. The Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) has also released its Agricultural Commodities Report for the June quarter of 2025, providing updated estimates and forecasts for key sectors, including the forestry industry, for the financial years 2024–25 and 2025–26.

The report presents a revised estimate for the total value of agricultural commodities, which includes farm outputs (crops and livestock), fisheries, and forestry products. For FY2024–25, the total value is now estimated at $99.7 billion, representing a 6% increase compared to the previous estimate of $94.3 billion released in 2024. Despite this upward esti-

mation, the total value is forecast to decline slightly in FY2025–26 to $97.5 billion, a 2% decrease, largely driven by expected declines in the export values of livestock, livestock products, and crops.

Focusing on the forestry sector, the report shows a positive trend.

The total value of forestry products, which includes both softwood and hardwood, is now estimated at $2.5 billion for FY2024–25, indicating an 8% increase from the previous projection in 2024.

Over the next period, the value is projected to grow further to $2.7 billion in FY2025–26, reflecting a 9% year-on-year increase.

If realised, this would bring the total forestry value close to the sector’s peak of $2.8 billion

in FY2018–19, the highest annual value recorded over the decade between 2010 and 2020 (Figure 2). These revised figures highlight the continued importance and resilience of the forestry industry within the broader agricultural sector, particularly in the face of changing economic conditions and current dynamics in the global trade environment.

Construction, logistics, and

On the other hand, the construction industry, along with the logistics and transport sectors, has also shown signs of improvement.

These developments are highly relevant to the forestry and timber industry as demand for timber products is closely linked to these sectors. Structural timber products are essen-

tial materials for new residential and commercial projects. Moreover, timberbased packaging and pallets play a crucial role in supporting the movement of goods through growing logistics and transport networks.

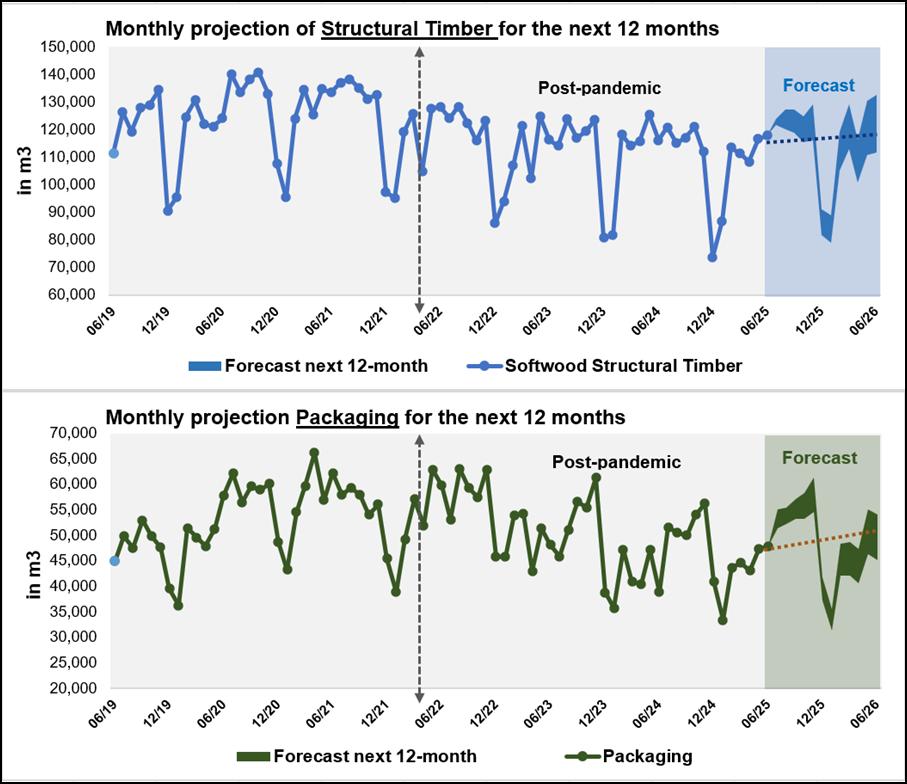

In terms of softwood structural timber, the data demonstrates a strong correlation between demand for this product and the level of residential construction.

Based on current and projected economic conditions above, including indicators from the Reserve Bank of Australia (RBA), analysis

by FWPA forecasts that demand for structural timber will increase by 2–4% over the next 12 months (FY2025–26).

This translates to a rise in volume from approximately 1.3 million m³ in FY2024-25 to around 1.35 million m³ by the end of FY2025-26 (Figure 3).

It is important to note that this projection is subject to the continuation of current economic trends and the accuracy of key macroeconomic forecasts.

continued

For packaging timber, this product benefits from the multiplier effect of increased economic activity, particularly through its use in logistics and the transportation of goods across various sectors. Recent data for the quarter from March to June 2025 shows a 7% increase in packaging demand, corresponding with the National Economic Data above.

Over the next period, packaging

timber is expected to follow a similar growth trajectory to structural timber, with projected demand increasing by 2–4% over the next 12 months.

In volume terms, this would see demand rise from approximately 560,000 m³ in FY2024–25 to around 570,000 m³ in FY2025–26 (Figure 3).

In summary, the latest national economic data indicate positive signs for the forestry and timber industry, with economic growth of 1.8% for the year to June 2025, supported by steady gains in construction, logistics, and transport.

These sectors are key drivers of timber demand.

Structural timber is closely tied to new housing and commercial building activity, while timberbased packaging and pallets benefit directly from rising logistics and distribution needs.

These trends indicate a positive market outlook and a supportive environment for timber producers and processors in the months ahead.

Disclaimer: Data and articles provided in the analysis are for informational purposes only. FWPA makes no guarantees regarding the accuracy or timeliness of the content. Readers are advised to verify any information, as all content is provided without warranties.

M.D. Wells

The forestry sector in Tasmania has long carried significance far beyond its economic contribution. It touches on environmental stewardship, regional livelihoods, and the future of a sustainable industry.

For many years it has been the subject of public debate, yet the industry’s trajectory today is increasingly one of renewal and resilience.

A shift towards balance sits at the centre of this change.

Balance between protecting the environment, growing the economy, and supporting jobs; between community expectations and the needs of downstream manufacturing; and between preserving natural assets and building sustainable plantations.

As the Chief Executive Officer of Mechanised Loging Pty Ltd (MechLog), Jillian Aylett Brown, observed:

“While the forestry sector will always be a political issue in Tasmania, the industry is working tirelessly to create the balance between community expectations, downstream needs for things like furniture manufacturing, and a long-term, sustainable plantation timber industry.”

Recent Federal initiatives have underscored the growing importance of forestry to Australia’s future.

Under the Support Plantation Establishment Program (SPEP), fifteen new projects worth a combined $19 million have been announced across the nation, with Tasmania among the beneficiaries.

This scale of investment is recognition of the challenges and opportunities facing the industry. Global demand for timber and fibre is expected to quadruple by 2050.

Further, timber products are increasingly essential to decarbonisation strategies.

The program is designed to ensure Australia has suf-

ficient, sustainably managed resources to meet both domestic and international needs.

For MechLog, the impact of such confidence in the sector is immediate.

“Training of new people, of all ages, coming into the industry is a priority for MechLog; and one that is bearing fruit,” Ms Aylett Brown said.

“The industry has shed its image of forestry practices of fifty or sixty years ago.

"The industry today is viewed as one that offers exceptional career opportunities to those considering a career in the forestry sector.”

Political discussions around the “Wood Bank” have been followed closely across Tasmania. Land was Initially set aside in 2014 as Future Potential Produc-

tion Forest; and viewed as a possible source of future supply.

Earlier this year, the government raised the idea of unlocking 40,000 hectares of this reserve, promising to deliver additional highquality sawlog exclusively to Tasmanian processors.

Following further community consultation, the Government decided to set aside the plan and instead place an emphasis on promoting greater on-island innovation in processing, while maximising the value of existing resources, including private forests.

While some in the sector viewed the change as disappointing, the outcome also demonstrates the willingness of government to listen to community expectations and work with industry towards shared objectives.

As Ms Aylett Brown commented: “It is pleasing to have a Minister in place who understands the forestry sector and has demonstrated a real desire to work with both sides of pol-

itics and the timber industry to maximise the sector’s contribution to Tasmania’s economy and wider community benefit.”

“One of the realities of Tasmania’s forestry industry in recent years has been the consolidation of operators. While some companies have exited or merged, service levels and industry output have remained strong,” Ms Aylett Brown added.

“Political stability and consolidation offered MechLog an opportunity.

"The company has expanded its operations, invested in its workforce, and broadened its service offerings to meet the needs of clients across the State.