ON OUR WAY TO A GREENER FUTURE

ON OUR WAY TO A GREENER FUTURE

PROTECTING PRODUCTS, ENHANCING BRANDS

ELIMINATING PACKAGING POLLUTION.

We are a team focused on helping customers reduce their reliance on plastic, and become more sustainable and efficient in their packing process. Initiated by customer led projects, Protega have become known for producing user friendly and cost effective void fill solutions.

Protega manufacture their equipment in Europe, entirely from locally sourced parts. Together with the Hexcel that we manufacture in-house, and the Protega paper, all is European manufactured reducing businesses carbon footprint and providing a secure supply chain.

PROTEGA ARE FSC® CERTIFIED AND ALL PRODUCTS SUPPLIED HAVE CERTIFIED CHAIN OF CUSTODY

WE MANUFACTURE OUR MACHINERY AND MATERIALS IN EUROPE

A TRACK RECORD OF REDUCING BREAKAGES BY UP TO 50%

88,000 SQ FT WAREHOUSE

LOCATED IN THE UK

“WE INNOVATE TO BRING SEAMLESS AND SUSTAINABLE PACKAGING SOLUTIONS TO FIT YOUR BUSINESSES NEEDS”

We strive to bring the most cost effective, sustainable packaging solutions.

Protega are focussed on helping businesses become more sustainable in their packaging. This includes eliminating plastic packaging, and reducing the amount of packaging required to protect goods in transit.

Protega also helps customers find ways to offset rising packaging costs by speeding up the pack process, with integration and standardised packing methods.

UK Address

Ascent 100, Stephenson

Close, East Portway Ind Est, Andover, SP10 3RU

United Kingdom

Germany Address

Protega DE GmbH, Alte Ziegelei 5, 51588 Nümbrecht

At Protega we provide you with viable, cost effective alternatives to non-sustainable packaging.

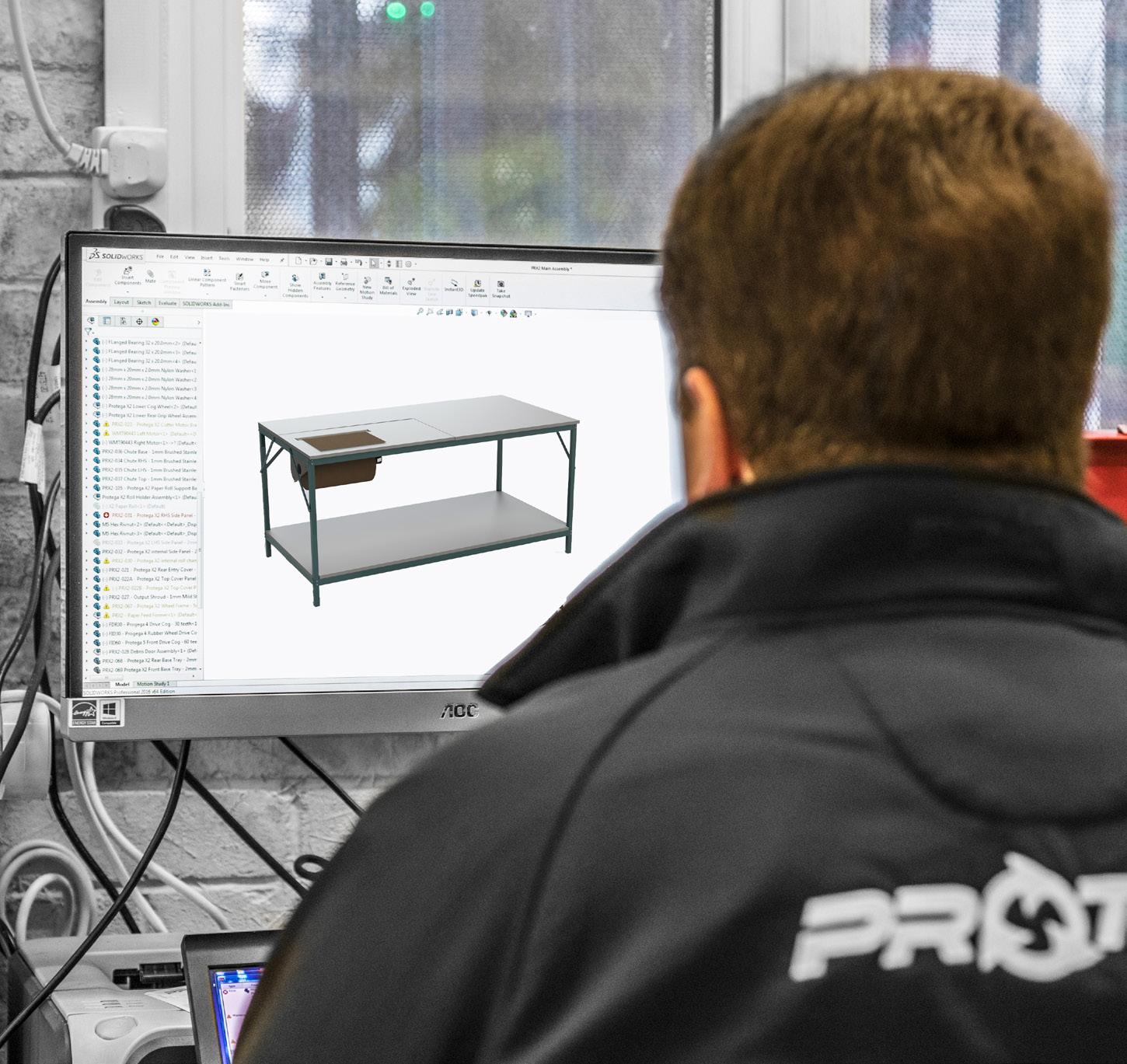

Our sustainable packaging range is complemented by our design and manufacture of integrated packing systems. This includes bespoke workstations and conveyor systems, to help you streamline your operation as well as make your packaging more sustainable.

We are a fully accredited company with over 40 years

combined experience working with clients from a multitude of industries. Throughout this time we have developed a reputation as packaging experts, and have worked closely with hundreds of companies all over Europe.

We are continuously innovating along with our customers to find smarter, faster ways to pack and create eco-friendly packaging that will excite your customers, bringing them back to you again and again.

As the Director at Protega DE GmbH I know how critical it is to have a reliable and relatable supplier, who understands your needs and consistently delivers innovative solutions. I will be leading the team throughout the contract.

Overseeing all operational areas of Protega to include CEX despatch, HexcelPack UK production and Protega machine and integrated packing bench production.

Delivering procurement and commercial support, will be developing a robust strategy from the contract set up and hold negotiations with key partners to optimise competitive pricing and a seamless supply chain.

I will hold day to day responsibility of your account ensuring customer service is of the highest standard. Working closely with our distributors and ecommerce brands directly I know the importance of communication so you will always have a direct line through to me.

Overseeing a team of skilled technicians, who are on call for all your service & maintenance requirements.

Taking the lead from your Account Manager I will ensure quality, stock and delivery requirements are all met and of the highest standard.

Whilst supporting every area of the business, I deliver first-class support to our key accounts and project manage new product concept opportunities.

In line with our company values, we drive continues improvement by constantly upskilling and training our staff, and offering development opportunities.

RICHARD STEEDMAN Director CLIFF JENNINGS Supply Chain FALLON PETFORD Commercial Manager GREG BALL Operation & Transport Manager ANDY REYNOLDS Service Engineer ADAM TUFFIN Operations Manager ORELLA DIFFEY EA to DirectorEuropean manufactured eco-friendly packaging solutions.

Paper Voidfill

Compact paper cushion machines that can be integrated into any packing environment.

‘Hexcel’ Honeycomb Paper

The eco-friendly alternative to bubble wrap.

Integrated Packing Stations

The ‘Protega Protect’ is a unique desktop paper machine producing high volume ‘on demand’ protective paper packaging.

The footprint of the slimline Protega machine is not much larger than an office printer and fits easily into even the smallest despatch area. Alternatively, it can be placed on a height adjustable stand and integrated into a packing line.

One unique feature is that the paper rolls are prefolded. This means they are easier to handle than traditional wide paper rolls, enabling the machine to be manufactured to a very small footprint of only 635mm x 360mm and at a weight of only 50kg.

About the product:

Small footprint

Lightweight design

Available in FSC®

Environmentally friendly

Certified Kraft, White & Black

100% sustainable

Slimline & compact design

Desk or floor stand mounting options offer unrivalled versatility

Protega is passionate about offering you the most sustainable packaging material - paper.

Our Paper is made from 100% recycled paper! Paper is naturally biodegradable and easily recycled via kerbside collections allowing your customers to play their part in reducing plastic.

Protega Paper is FSC® Certified and manufactured in Europe. This significantly reduces the carbon footprint and helps businesses reach their sustainability goals.

Protega Paper is the industries leading paper void-fill, ideal for protecting fragile and heavy products, as well as producing a very cost effective voidfill.

Lightweight

Ultra Strength

Use less void-fill

Designed to absorb impact

Made from 100% recycled paper

100% recyclable & Biodegradable

Available in FSC® Kraft, White & Black

The Protega paper machine produces a paper cushion equivalent to the strongest on the market, but within a much smaller footprint, and with optimal use of paper.

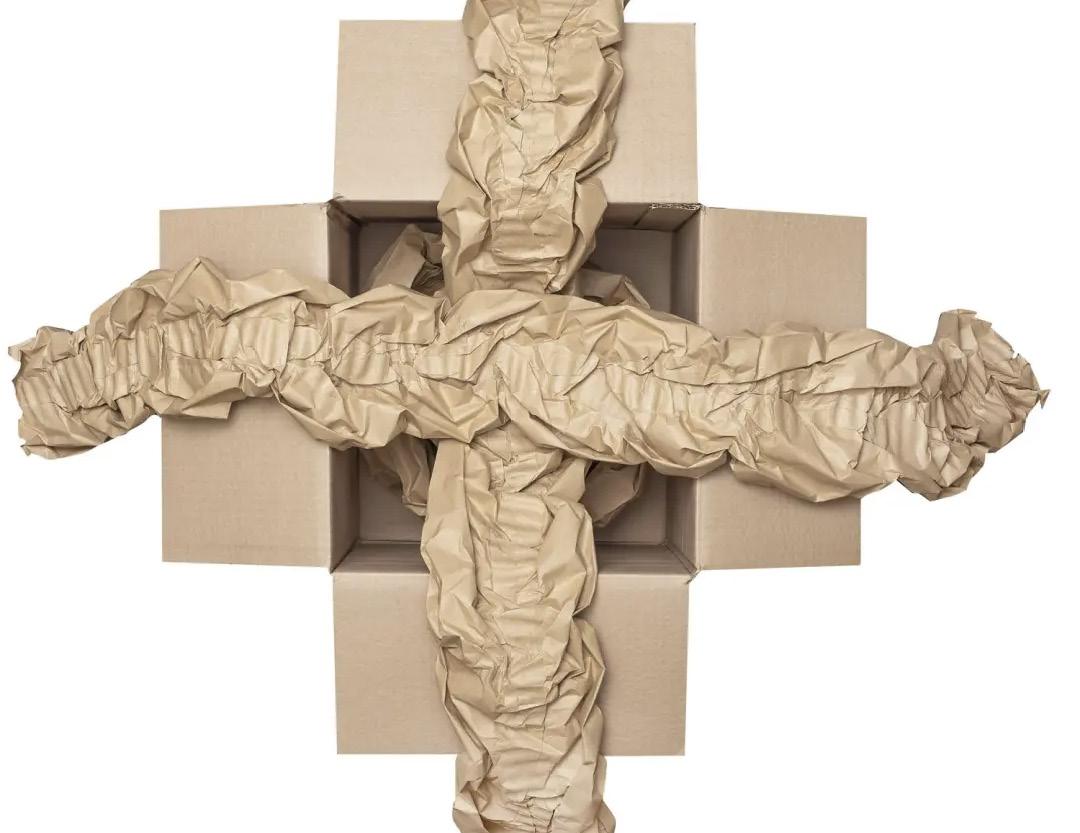

Ensuring you use the correct techniques with Protega paper cushioning can save you time, reduce wastage, and ensure you protect your goods correctly.

This method is an excellent way of minimising use of paper and avoiding total void fill within the box. Once a small coil is wedged between your product and the edge of the box it will remain firmly in place during transit.

Twisting the paper is an effective way of bulking up the paper to fill gaps and securing your products, at the same time as reducing paper usage.

Coiling is used to form a protective base on which single or multiple heavy products can be nested, and a further coil can be placed on top to give superior all round protection.

A quick and efficient way of providing all round protection for single items.

Protega paper is prefolded making it stable and compact to store and transport.

• Pallet Size: 1200x800x1300

• Pallet Weight: 490kg

• Pallet Qty: 32 Rolls

• Meterage per pallet – 9600 metres

We have designed the machine to be small enough and sufficiently light weight to move freely, with the ability to load in the back of vehicles.

On the rare occasion the Protega Machine becomes faulty, thanks to its lightweight design it can simply fit into one of our transporting boxes for collections and delivery.

PAPER BUBBLE WRAP

Hexcel Wrap really needs to be seen to be believed! It is supplied as a flat sheet which then becomes three dimensional simply by stretching it. Effortlessly it can be wrapped around products and the layers build up to offer protection as good as plastic bubble!

Stats: Packing Speeds

425m No tape 80% less

Per Roll (Unstretched) 254m

50% Faster

Benefits:

Interlocking feature, no tape required!

Surface protection for fragile products

100% recyclable and biodegradable

Manufactured in Europe

14

Speed up your packing processes during peak with our Fil-in-a-Box™ with HexaFil™, a variation of Hexcel wrap which is a quick void-fill solution that can be deployed without the need of power.

A simple way to reduce your packing times immediately! A smaller, portable and disposable version of our Hexcel Wrap, 100% recyclable, biodegradable and compostable Hexcel paper, with an intelligent box tensioning system to give you the perfect protection for your products.

The use of Hexcel Wrap – a paper alternative to bubble wrap – has been made even easier for retailers and warehouses with the new WrapPads™. Designed specifically for the Retail & Industrial market.

PAPER BUBBLE WRAP

PAPER BUBBLE WRAP

The use of Hexcel Wrap – a paper alternative to bubble wrap – has been made even easier with the development of an integrated dispenser. Housed under the bench, the Hexcel paper is simply passed through a pair of rollers and dispensed onto the bench at the optimal position for the packers.

This design maximises the usable area of the bench, and dramatically increases efficiency. To reload, a section of the bench lifts up and allows rolls to be placed easily and ergonomically.

SAVE SPACE, SAVE TIME, SAVE MONEY

Once agreement has been reached on a standardised pack process, we are happy to offer both face to face training and video training. Video training has been used very effectively by other customers, particularly those who employ a lot of temporary staff.

We can produce a customised video using your products and boxes, and this could become part of your induction programme for new starters.

WATCH ONE OF OUR TRAINING VIDEOS HERE

We will ensure your team are equipped with the techniques to maximise speed of packing, minimise waste and reduce potential damage.

European design and manufacture holds great benefits for our customers, not least because we are able to provide preventative maintenance for all of our Protega machines.

Currently in development, Protega are launching an online resource centre. Giving instant access to product images, videos, certification documents and much more

Every industry faces its own operational challenges, which drives us to bring new innovative solutions every year.

INCREASE DAILY DESPATCHES BY UP TO 50%

Do your customers relate to any of these challenges?

Protega services provided:

Integrated Hexcel benches

Bespoke packing stations

Protega Paper void-fill machines

CHALLENGE:

Delay in despatches due to increase in online orders.

SOLUTION:

Implemented seamless packaging solution to speed up packing times and improve warehouse efficiency. Including new packing benches with integrated Hexcel dispensers, Protega machines on elevated stands, weight scales and conveyor.

“Protega helped us get back on track with weekly despatches during 2020 and 2021. We saw a 50% increase in online orders during the pandemic and needed to find a solution that could help us get more orders out the door.”

Protega services provided:

European manufactured Paper Packaging

Protega Paper void-fill machines

Packing Stations with overhead hoppers

CHALLENGE:

Using an overseas packaging provider, causing supply chain issues with Brexit and the Pandemic.

SOLUTION:

Protega design and manufacture all of our products in Europe, reassuring our customers that their supply chain will be uninterrupted.

“We had endless problems with sourcing packaging during 2020 and needed a resolution that would guarantee a secure supply and support throughout our busy periods. Protega went above and beyond to give us exactly that.”

Protega services provided:

Protega paper void-fill

HexcelWrap

CHALLENGE:

Using excessive amounts of plastic packaging.

SOLUTION: Switched to Protega Paper and Hexcelwrap

“We have been cautious of switching to paper packaging because we mostly ship fragile products such as glass, but with customer demand of sustainable packaging it was time for us to make the leap.

Once we had started our trial of paper void-fill and paper bubble wrap it was an easy choice to make the switch, it came as a surprise to us when we actually reduced the amount of breakages in transit and the long term costs saved.”

We are always working towards a more sustainable future, for both us and our customers.

Paper packaging solutions are our speciality, with over 25 years of experience working with companies in a myriad of industries. From the start, we’ll work closely with your business to gain a thorough understanding of your needs – and find out how we can streamline your packing process.

We continue to improve our sustainability and are always looking for ways to reduce our environmental impact.

POWERED BY SOLAR PANELS

It’s estimated that 100 billion pieces of plastic packaging are thrown away by European households every year – a staggering 66 items per household per week (UK). Every day, around eight million pieces of plastic enter the ocean. That’s the same as a rubbish truck every minute. Consumers are becoming more environmentally conscious by the day and look to shop with retailers who are mindful of the planet.

USING GREEN ENERGY TO PRODUCE HEXCEL

TWICE THE RECOMMENDED AMOUNT OF ROOF WINDOWS, TO REDUCE ELECTRICITY USAGE

ELECTRIC CAR CHARGING POINTS

One of the easiest swaps is for businesses to move their transit packaging from plastic to paper. We have developed an extensive range of paper packaging products to replace plastic packaging entirely. This includes Hexcel Wrap, the first European-manufactured paper bubble wrap, and Protega paper void fill from FSC®-certified forests. Everything, from boxes to adhesive tape, is 100% recyclable and biodegradable.

NEW 2024 SUSTAINABILITY TARGETS SET

WHERE POSSIBLE, WE WILL ELIMINATE PACKAGING WASTE

T: +441264 598440

E: sales@protega-global.com

W: www.protega-global.com

Germany Distribution Centre: Protega DE GmbH, Alte Ziegelei 5, 51588 Nümbrecht

United Kingdom Distribution Centre: Protega

Global, East Portway Ind Est, Andover, SP10 3RU