STREAMLINE YOUR PACKING AREA

PROTEGA PACKING ENVIRONMENT

PROTECTING PRODUCTS, ENHANCING BRANDS

BE MORE ECO-FRIENDLY

PACKING INTEGRATION

UK MANUFACTURING

Are you looking to increase your despatch output and reduce your costs? Or simply improve the environment that your team is working in?

Many retailers are citing that speed of packing is their main constraint at peak times. Integration helps you to remove the waste of your scarcest resource – time.

IMPROVE CUSTOMER EXPERIENCE

100% RECYCLABLE & BIODEGRADABLE PAPER

Our Protega team have over 25 years experience helping companies across multiple industries, to speed up work flow and design integrated solutions. This can improve operator working comfort as well as increase productivity.

From the beginning we work with you to make sure we have an in-depth understanding of your pick, packing and despatch requirements. Following the information gathering phase we offer proven ways of streamlining your processes.

SPEED UP THE PACKING PROCESS

Which includes maximising the storage and positioning of supplies and equipment. In many cases we have been able to virtually double the output of a packing area by reducing operator movement whilst enhancing working environment.

WHY INTEGRATE WITH PROTEGA

All of our products are manufactured in the UK, taking our customers sustainability to the next level and providing a service like no other.

Secure Supply Chain

Designed in the UK

Manufactured in the UK

Low Carbon Footprint

FSC Certified Expert aftercare and training

100% Recycled and recyclable paper packaging

FSC CERTIFIED UK MANUFACTURER

Leading the way in eco-friendly packaging and seamless packing integration.

At Protega we provide you with viable, cost effective alternatives to nonsustainable packaging.

Our sustainable packaging range is complemented by our design and manufacture of integrated packing systems. This includes bespoke workstations and conveyor systems, which will help you streamline your operation as well as make your packaging more sustainable.

We are a fully accredited, FSC certified company with over 40 years combined

experience working with clients from a multitude of industries.

Throughout this time we have developed a reputation as packaging experts, and have worked closely with hundreds of companies all over the UK.

We are continuously innovating along with our customers to find smarter and faster ways to pack to increase your daily despatches by at least 50%.

OUR INTEGRATED

PACKING

SYSTEMS ARE BEING USED IN SOME OF THE UK’S LARGEST RETAILERS.

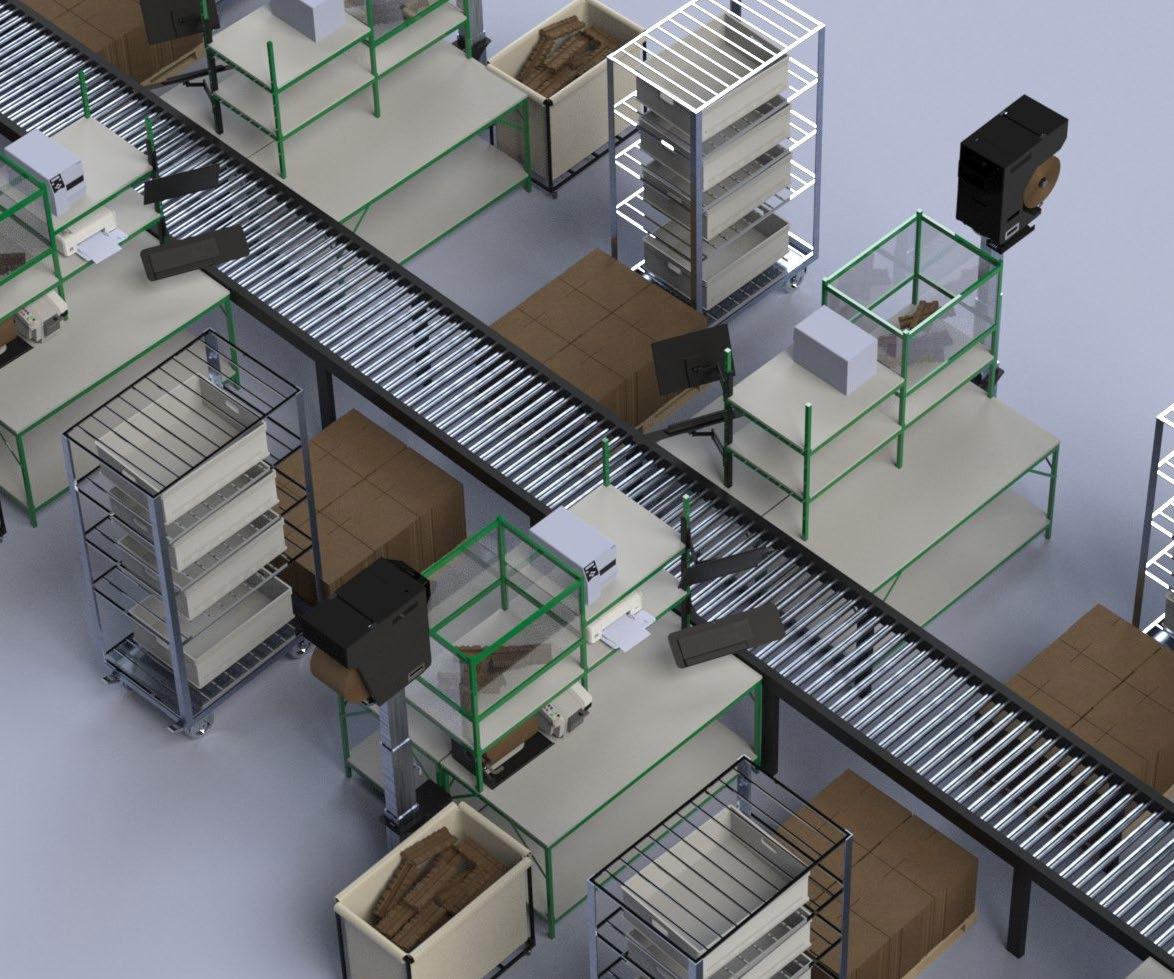

INTEGRATED PACKING STATIONS

Improve warehouse efficiency with a seamless integrated packing area, all manufactured in the UK .

Are you looking to increase your despatch output and reduce your costs? Would you like to do this within your existing space and with the same number of packing staff?

The requirement for each packing workspace varies considerably from company to company.

Our design team will work with you to get an in-depth understanding of your pick, pack and despatch requirements.

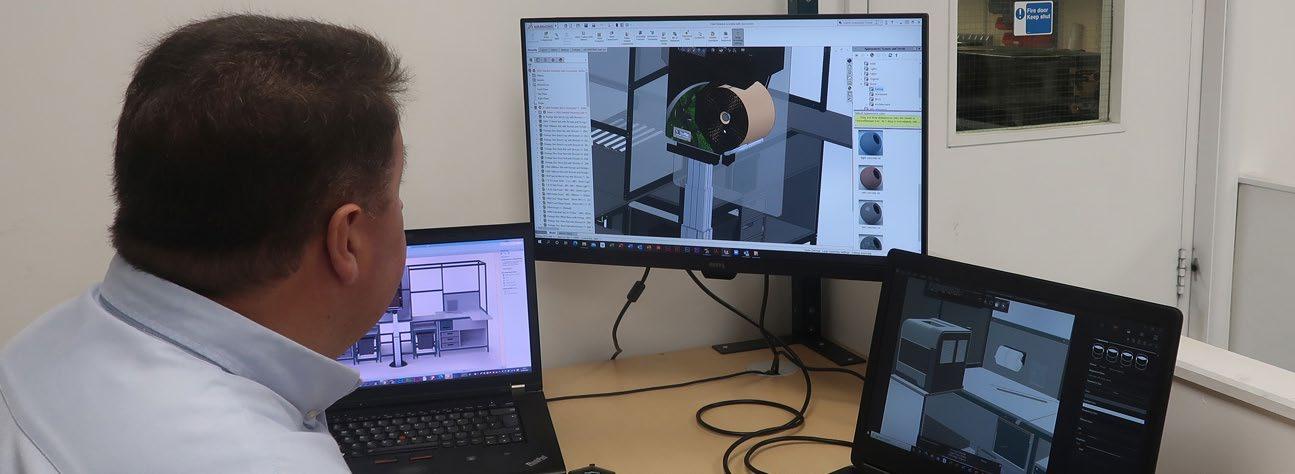

At Protega we take the process from concept through to

completion using our Solid Works CAD design package which enables us to provide you with visualisations of your customised design.

We will help you create the optimal packaging environment, which will speed up your processes, and positioning supplies and equipment within easy reach of your packers.

We design individual workstations to integrate packaging machinery and replenish systems, keeping parcel flow optimised during peak times.

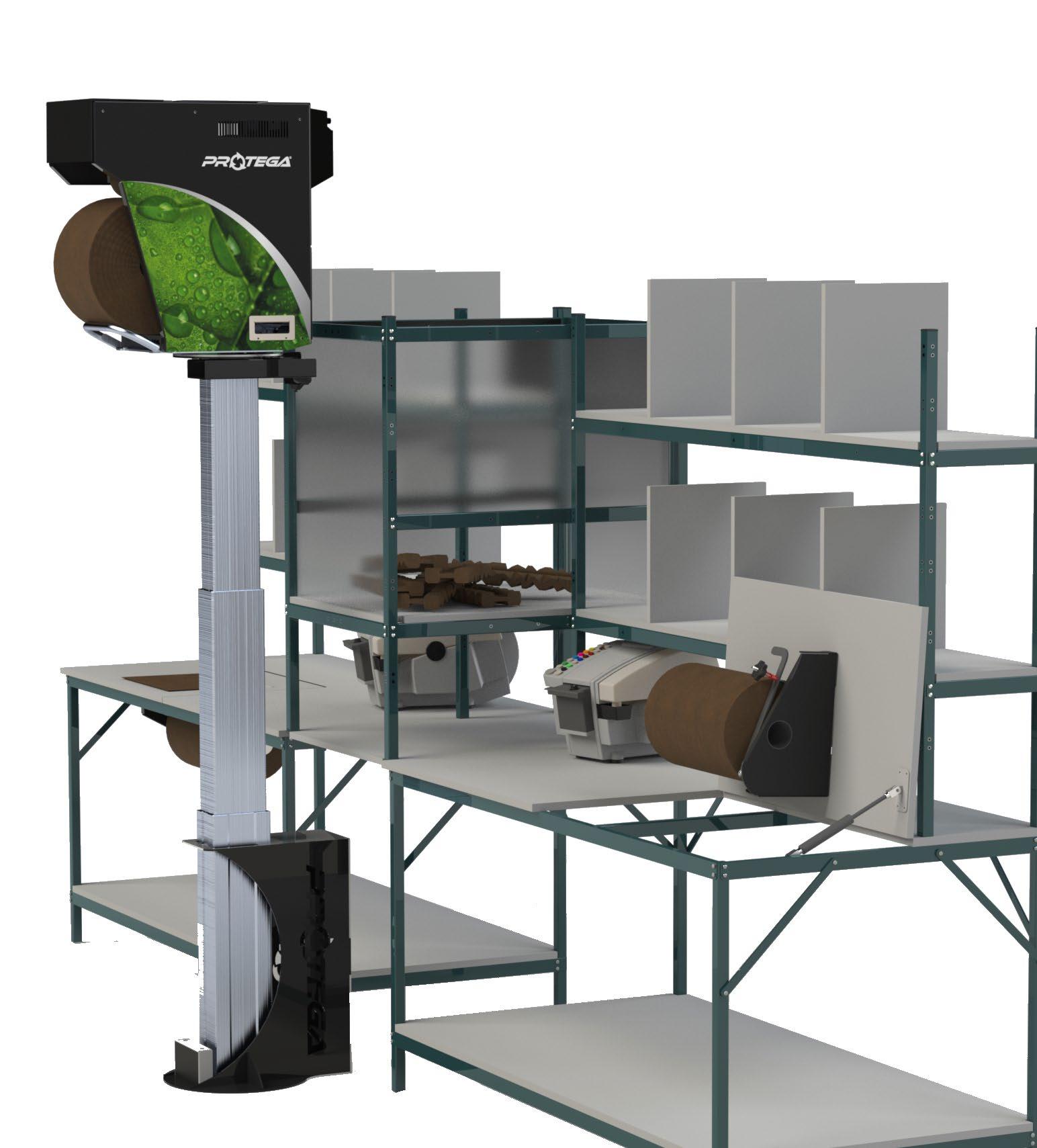

Hexcel Dispenser

Overhead Hopper

Protega 125 Machine

PACKING STATIONS

Storage Area

With over 40 years experience helping companies across multiple industries to speed up workflow and improve operator working comfort to increase productivity.

Height Adjustable Stand

PROTEGA DESIGN PROCESS

Consultation and CAD design, a bespoke integration system to fit your operational requirements.

Protega Global focuses significant effort and investment in the development of new innovative ideas, to create an eco-friendly packing range enabling you to pack both smarter and faster. Our research and development capabilities allow us to bring ideas to reality.

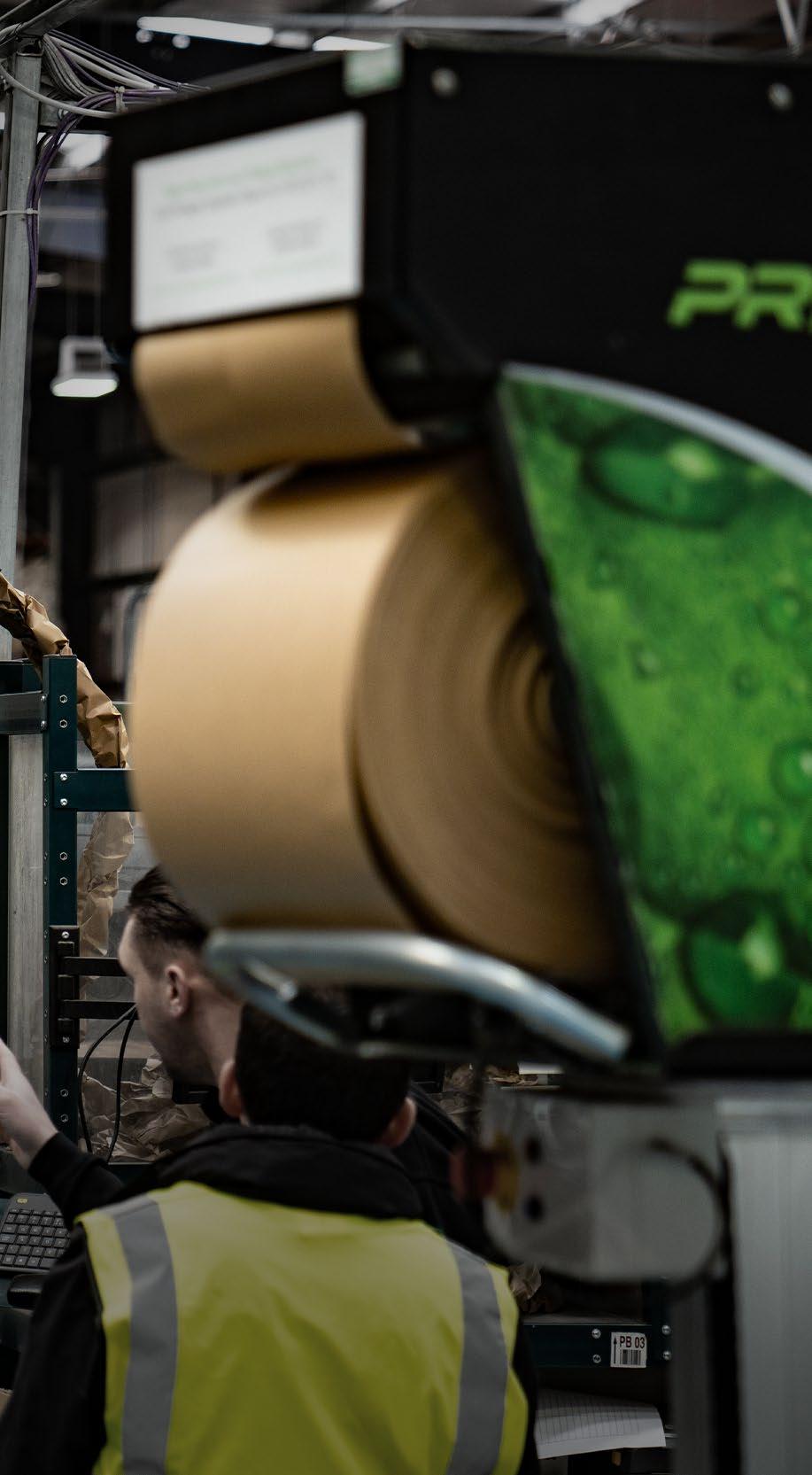

Our paper void fill machine has been designed and built by Protega Global in the UK to rigorous quality standards, providing you a machine that is compact, efficient and cost effective.

About the design process.

We carry out an initial survey to gain an operational overview of your organisation. We look at workflow, materials handling and packing requirements and configure an efficient and safe work area.

CAD designs show what the finished project could look like, and, subject to input from all project stakeholders and agreement on the final design, a fixed cost will be given.

A VIRTUAL FIRST LOOK AT YOUR PACKING AREA

Bringing your packing area to life in the design process, helping you visualise the future of your operation.

Once we have combined our suggestions and your requirements, we begin creating a concept. We work with you all the way through to a finished product using our Slidewords CAD design package.

Enabling you to see your bespoke bench designs and packing area in the virtual world. At this stage we are able to place your equipment and supplies into the CAD visual, creating your typical packing scenario. This will allow us to check you have sufficient space for a more efficient day to day warehouse operation.

“We have always struggled with space in the warehouse, especially during peak. Protega helped us get a clear view of how to improve our efficiency,

the CAD drawings made this process very simple for us”

PROTEGA MANUFACTURE PROCESS

A bespoke design to fit your businesses needs and improve your warehouse efficiency.

Our team of technicians at Andover UK do not believe that ‘one size fits all’. In close consultation with our customers we produce and customise our Protega machines and packing stations to fit your business needs.

We have created a machine which we can adapt to your unique packing environment, by elevating above your packing line, integrating into your workstation or by customising the controls. Our Production capabilities vary from packaging benches, conveyor systems, storage systems, all of which can be combined with our sustainable packaging materials.

PROTECTING PRODUCTS ENHANCING BRANDS

TRULY SUSTAINABLE

Paper is the most sustainable option when it comes to packaging; it does not rely on the extraction of oil, is widely recycled and is truly biodegradable. At Protega we use 100% paper recycled products wherever possible, which has a lower carbon footprint than virgin paper. Protega Global has a strong sustainable ethos and innovates to bring the best paper protection products to the market. Any businesses considering switching from plastic void fill packaging can do so with confidence with Protega.

With our compact and efficient systems, we can help make your switch cost neutral; whilst improving pack speeds and increasing protection.

“Protega helped us hit our carbon targets, buying from a UK manufacturer meant we were no longer shipping our packing equipment from overseas.It’s also a great benefit to have a reliable supply chain during these uncertain times.”

PROTEGA INSTALL PROCESS

A seamless installation process that guaruntees a simple set up.

Our in-house installation team will work with you to minimise disruption and ensure a smooth transition to your new packing and despatch area.

TRAINING & MAINTENANCE

Our journey doesn’t end there, we pride ourselves on our after-care and maintenance.

We are passionate about helping others, going the extra mile to ensure you obtain the maximum gain from your switch to Protega packaging.

Before and after installation we will support your team with training in best practice of the Protega paper machine and associated equipment and materials. We will ensure your team are equipped with the techniques to maximise speed of packing, minimise waste and reduce potential breakages and damage.

UK Design and manufacture holds great benefits for our customers, not least that we are able to provide locally based preventative maintenance for all of our Protega machines.

In addition, our field based engineers are on call to respond to any service requirements should the need arise, within 24-48 hours.

Your eco-friendly alternative to plastic bubble wrap.

Hexcel Wrap really needs to be seen to be believed! It is supplied as a flat sheet which then becomes three dimensional simply by stretching it. It can be effortlessly wrapped around products and the layers build up to offer protection as good as plastic bubble!

Hexcel is dispensed from a small manual tensioning device which can be deployed anywhere, without the requirement for electricity. Hexcel wrap is easy stretch and easy tear. Once stretched around the product you simply tear the paper, and the paper interlocks on itself. No need for adhesive tape! Not only does this reduces plastic use but also reduces pack times by up to 50%. Unlike any other paper bubble wrap with no adhesive tape required, making it easier for your customers to unwrap the products too!

Stats:

Benefits:

Interlocking feature, no tape required!

Surface protection for fragile products

100% recyclable and biodegradable

Manufactured in the UK

PAPER BUBBLE WRAP

PACKING SOLUTIONS

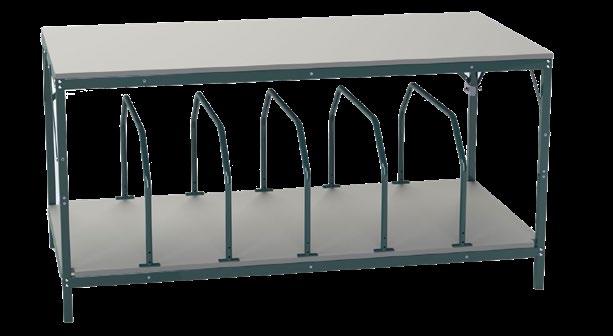

HEXCEL BENCH

Increase efficiency with the integrated Hexcel bench.

The use of Hexcel Wrap – a paper alternative to bubble wrap – has been made even easier with the development of an integrated dispenser. Housed under the bench, the Hexcel paper is simply passed through a pair of rollers and dispensed onto the bench at the optimal position for the packers.

This design maximises the usable area of the bench, and dramatically increases efficiency. To reload, a section of the bench lifts up and allows rolls to be placed easily and ergonomically.

SAVE SPACE, SAVE TIME, SAVE MONEY

INDUSTRIAL & ELECTRICAL RETAILER - UK

Protega services provided:

UK manufactured Paper Packaging

Protega Paper void-fill machines

Packing Stations with overhead hoppers

CHALLENGE:

Using an overseas packaging provider, causing supply chain issues with Brexit and the Pandemic.

SOLUTION:

Protega design and manufacture all of our products in the UK, reassuring our customers that their supply chain will be uninterrupted.

“We had endless problems with sourcing packaging during 2020 and needed a resolution that would guarantee a secure supply and support throughout our busy periods. Protega went above and beyond to give us exactly that.”

ECOMMERCE FOOD AND CONDIMENTS SUPPLIER

Protega services provided:

Integrated Hexcel benches

Bespoke packing stations

Protega Paper void-fill machines

CHALLENGE:

Delay in despatches due to increase in online orders.

SOLUTION:

Implemented seamless packaging solution to speed up packing times and improve warehouse efficiency. Including new packing benches with integrated Hexcel dispensers, Protega machines on elevated stands, weight scales and conveyor.

“Protega helped us get back on track with weekly despatches during 2020 and 2021. We saw a 50% increase in online orders during the pandemic and needed to find a solution that could help us get more orders out the door.”

INTEGRATION PRODUCT RANGE RETAILER - UK

HPB299 - Hexcel Integrated Benchno Shelf

HPB299/S - Hexcel Integrated Bench with Shelf

With the Hexcel Dispenser fitted below the bench surface, wrapping becomes more efficient and the available work space is increased

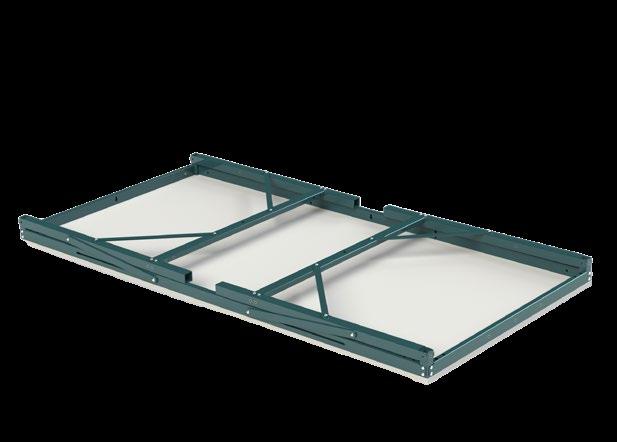

HRB299/S - Hexcel Integrated Bench with Opening

Lower Height Mini Packing Bench800 x 600mm - The Mini Bench helps with the handling of large and heavy

SRB299/S - Packing Bench with Opening

This style of bench allows a storage trolley or lower height bench to be stowed underneath for an uncluttered packing area.

Paper Cushion Storage Trolley

Designed to share between two benches for the most economical solution

SUH269 - 1800 x 700 x 1180 Hopper and Shelf Unit

As with the shelf unit, this Hopper Unit is shared between two benches, providing an overhead supply of paper cushions for maximum efficiency.

SPB299 - 1800mm x 900mm x 900mm Packing Bench

Suitable for all packing areas needing a robust packing surface.

FPB299 - Folding Version

Useful for additional peak requirements.

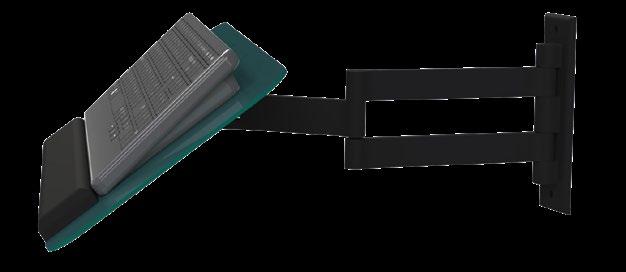

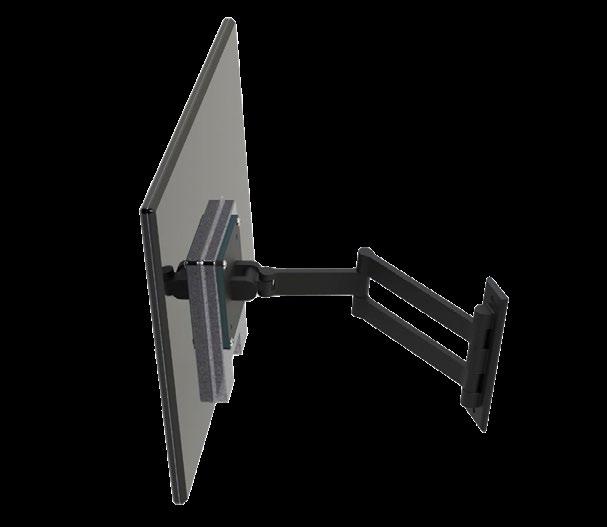

PMB22 - Monitor Bracket - 2 way position and angle adjustment

PKS22 - Keyboard Shelf Bracket - 2 way position and angle Adjustable.

SUS269 - 1800 x 700 x 1180 Upper Shelf Unit

LH300 - Label Roll Holder - 300mm wide PCD300 - Carton Storage Dividers - set of 5

SUS269 - 1800 x 700 x 1180 Upper Shelf Unit

LH300 - Label Roll Holder - 300mm wide PCD300 - Carton Storage Dividers - set of 5