Vol. 9, No. 3 JUNE / JULY‘19 Front Cover Story Pages 24-25

West Coast Edition For WA, OR, & CA

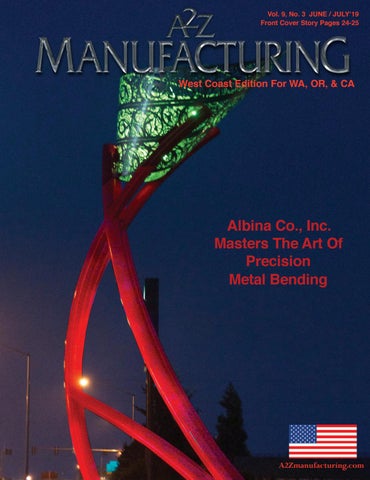

Albina Co., Inc. Masters The Art Of Precision Metal Bending

1 • JUNE - JULY ‘19 A2Zmanufacturing.com

A2Z MANUFACTURING WEST COAST •

Vol. 9, No. 3 JUNE / JULY‘19 Front Cover Story Pages 24-25

West Coast Edition For WA, OR, & CA

Albina Co., Inc. Masters The Art Of Precision Metal Bending

1 • JUNE - JULY ‘19 A2Zmanufacturing.com

A2Z MANUFACTURING WEST COAST •