What More UK is on a mission to become Europe’s biggest manufacturer of metal bakeware and cookware, plus plastic housewares. To make this dream a reality, the company has invested in itself and its people. Director Tony Grimshaw explained more, in an exclusive interview with Inside Sustainability. Report by Imogen Ward.

Wh at More UK has experienced a wealth of success in the UK market. Perhaps known most notably for its incredibly popular plastic storage boxes, Wham, the company is also a major player in the metal bakeware and cookware sectors. Holding the title as the third biggest manufacturer of plastic housewares in Europe, the company is going for gold. To achieve first place status, What More UK is on a journey of growth, business development and education.

“The demand for our products grows as quickly as our commitment,”Director Tony Grimshaw explained. “Because of this, we have an ongoing dedication to investment. We continue to invest in new products, our infrastructure, our customer and supplier relationships, and our people.”

What More growth

In line with What More’s ambitions for growth, the company has made several key acquisitions in the last two years.

In a bid to have total control of the entire value chain, What More initially acquired Canteen Smithy, a mould manufacturer, in 2022.

“After starting our bakeware and cookware division in 2016, it became apparent that we needed to produce a whole new catalogue of products,” said Mr Grimshaw. “To allow for this, £1 million was invested in an onsite toolroom. Our product designers went berserk and soon outstripped the toolroom’s ability to manufacture the required moulds. So, when Canteen Smithy came up for sale, we purchased it without a second thought.”

Following the success of this acquisition, What More went on to purchase metal solutions manufacturer, Firsteel, i n 2023. According to Mr Grimshaw, this was a natural decision due to the company’s reputation as the best coil

coater of rolled steel and other metals. As one of only two businesses in the UK and five in Europe with this capability, it is no wonder that What More made the leap to invest.

“It made sense to complete the supply chain with the purchase of Firsteel,” Mr Grimshaw continued. “The acquisition of these two companies has afforded us complete control from the drawing board to the oven. We can now proudly say that not only are What More’s products made in Britain, but all our raw materials are too.”

With the company stretching vertically along the value chain, a decision was made to expand its manufacturing and distribution facility in East Lancashire, UK.

“We operate out of 500,000 square feet of real estate,” said Mr Grimshaw. “The surrounding land is currently being cleared, and foundations are being laid to increase this by another 100,000 square feet.”

What More green

All of What More’s growth has been accomplished strategically and responsibly with its environmental impact accounted for at every stage. This has been a consideration since the company first opened its doors 24 years ago.

“We have always recycled our owngenerated plastic waste,” Mr Grimshaw explained. “We designed a number of black item products that specifically enabled us to do this such as dustbins, seed trays and builders’ buckets. Over time, the demand for these products increased and very soon surpassed the waste levels that we produced internally. This required us to find another source for the waste, and with the increasing demand for recycling, our recycled ranges of storage products were born.”

The company’s RECYCLE range of storage solutions is made from recycled industrial waste and was launched in 2019, alongside What More’s other sustainably focused line, Upcycle, which

is manufactured from recycled single-use plastic waste.

“Both ranges received recognition at European level, they came in the top three at the European Recycling Industry Awards, and nationally in the UK Recycling Industry Awards,” Mr Grimshaw said.

In line with this commitment, What More has been spending a lot of time working with schools to encourage recycling across the board.

“It’s not just about plastic, recycling of all materials needs to be actively encouraged,” Mr Grimshaw explained. “We spend a lot of time opening our state-ofthe-art facility to schools and colleges to

spread this message. It also gives us the opportunity to show the difference between our products and single-use plastic.

“After all, single use plastic is drastic; What More plastic is fantastic.”

What More collaboration

What More is always keen to work with students to help develop their passion for the industry. Eight years ago, the company took the next step and established its own apprenticeship scheme.

“We learnt the true value of apprentices when we first established our scheme all those years ago,” said Mr Grimshaw. “We now have a rolling cadre of apprentices

that join the workforce after their training . They take with them the knowledge gained from What More’s engineers and the valuable skills they pick up during their time at college. Each one of these apprentices has contributed and enabled our unprecedented growth. So, when we took over Firsteel, introducing a similar scheme was a no-brainer.”

Everyone at Firsteel has been very receptive to the newly initiated apprenticeship scheme. With a high staff retention rate and an average length of service of more than 30 years, What More felt the need to retain the valuable knowledge of the current workforce before they retired and took it with them. Currently, there are three apprentices working on their qualifications with Firsteel, with vacancies for a further two.

“What More is the UK brand and market leader,” said Mr Grimshaw. “We are continually developing our products, our relationships with customers and partners, but most importantly our staff. Without our staff, we are nothing. They help us stand out in the industry, providing the world with quality products made in Great Britain. Products that –through innovation, advanced manufac -

turing techniques and a workforce that cares – are world leading and affordable.”

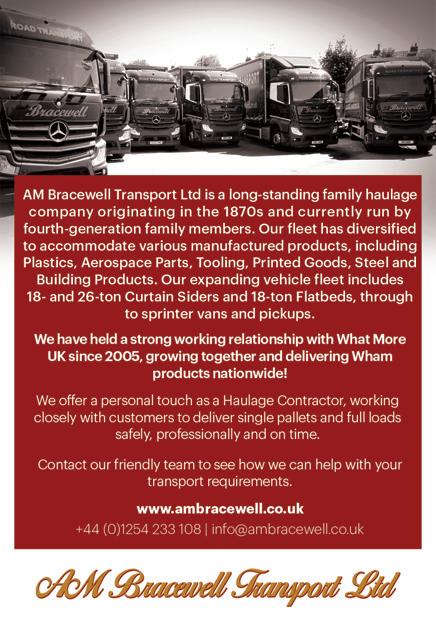

Of course, staff are not the only people that What More relies upon when it comes to success. According to Mr Grimshaw, the company greatly depends on the r eliability of its suppliers: “Our ongoing aim is to work in harmony with our suppliers. Just like our staff, they are an imperative ingredient in our success. We depend on their innovation, ingenuity and ability to bring new ideas to the market.”

As What More looks to the future, it intends to explore more growth opportunities, which includes the international market. The company has already exported to 75 countries across the world and looks set to continue.

“Exports are always in our plan,” Mr Grimshaw concluded. “From design and product development to services, 18 per cent of our turnover comes from this market. So, we would love to develop this area further, whilst continuing to grow our presence in the UK market.

“It has been a pleasure to watch the entire company progress from its humbl e beginnings, with the backing of an amazing group of employees. Our mission to become number one is achievable because of this brilliant team.” n