John White Managing Director

John White Managing Director

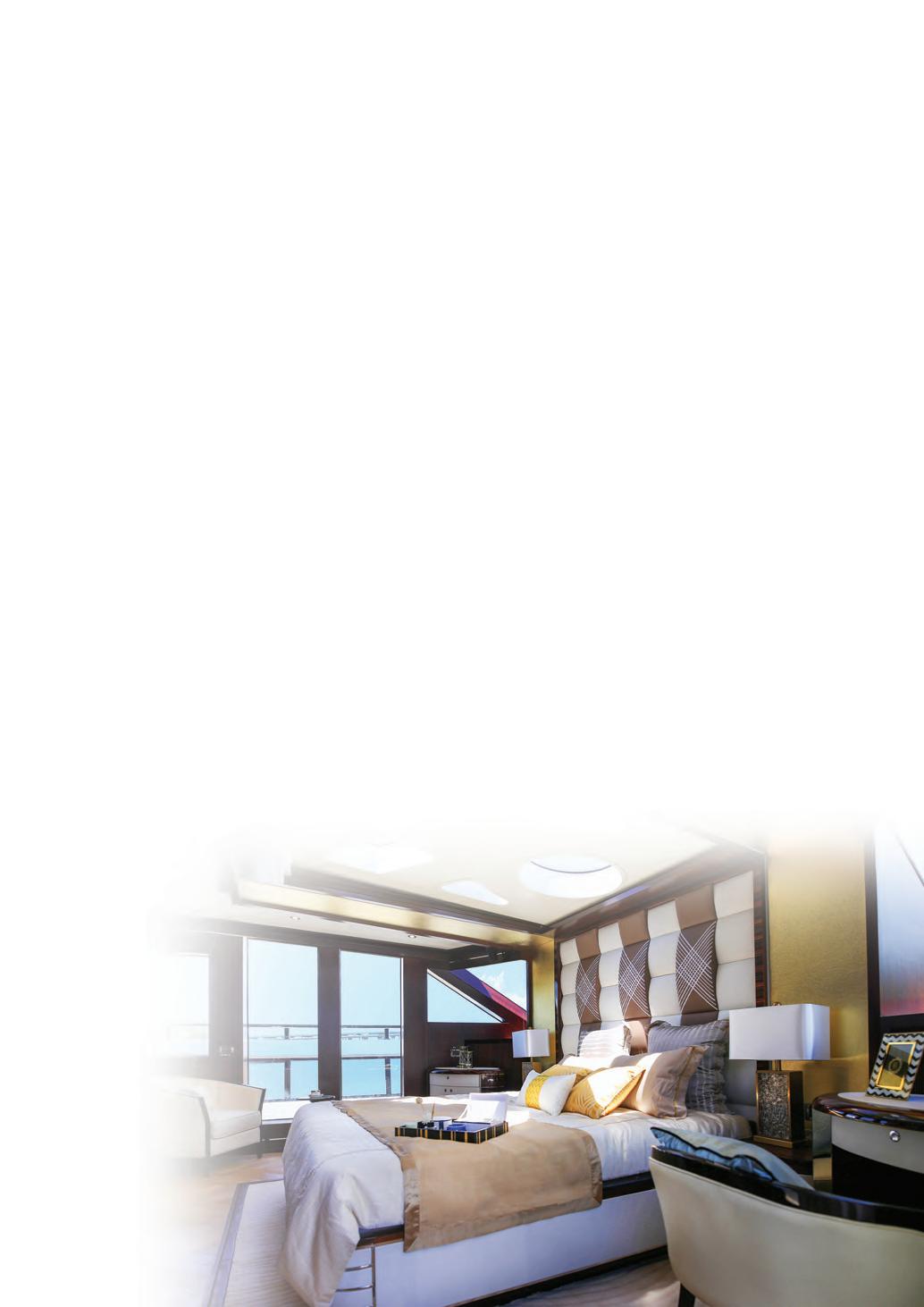

Managing Director John White squeezes so much content into a small porthole.

Welcome, dear reader, to your latest edition of Inside Marine.

My Editor just popped into my office to give me some guidelines for this piece. As usual, there is so much exciting content that trying to cover it all within the meagre number of words he allows me is a challenge, but here goes…

This edition brings you coverage of four exciting maritime-related events (Europort, Breakbulk Americas, ADIPEC and Silicone Expo) with which we are official media partners with. Therefore, given how popular this section has become, be sure to take some time to find out more about them and the many exhibitors, especially if you are considering a visit!

As if that were not enough, you will also be pleased to find a focus on the specialised support vessel industry: those unsung heroes working hard behind the scenes in support of the often show-stealing larger vessels and fleets. For example, where would those leviathan tankers and cargo ships be if it were not for the comparatively tiny tugboats guiding them in and out of port? Well, quite simply, either stranded outside of the port or causing havoc within it !

There’s more… we should always find time, (and Inside Marine is always pleased to do so), to showcase those involved in crew welfare. This vital area of the industry helps to keep our fleets afloat and is, of course, of paramount importance.

Finally, in keeping with our slogan ‘Seven Seas – Five Oceans – One Voice’, we bring you, as always, a vast array of other maritime articles, advertisements, news, views, and snippets of interesting and informative content for your reading pleasure.

I think I have just enough space left to wish you all fair winds and following seas n

To have your company’s latest product, technology or concept included in Inside Marine, contact us today.

Decarbonisation is a hot topic within the maritime industry. ADIPEC 2023 will facilitate global dialogue on critical energy and climate issues, foster meaningful partnerships and inspire credible solutions towards securing a cleaner, more affordable and sustainable energy future.

Managing Director

John White

Finance Director

Filomena Nardi

Editorial Manager

Phil Nicholls

Editorial Assistants

Imogen Ward

Hannah Barnett

Feature Writers

Andy Probert

Romana Moares

Richard Hagan

Colin Chinery

Business Development Manager

Darren Foiret

Research Editors

Jeff Johnson

Mark Simmonds

Judi Wheaton-Mars

Ginelle Lorenzo

Natalie Martin

Dane Coady

Becky Scrivens

Jamie McBride

Sam Ransome

Sales Director

Richard Brightmore

Sales Manager

Helen Leisi

Project Managers

Alexander Paterson

Tony Ingrouille

Kym Hamilton

Chris Renicar

David Earl

Connor Doddington

Lisa Smith

Carl Millican

Art Director

Ian Spencer

Art Editor

Philip White

Webmaster

Michael Stamp

Designers

Sarah Jones

Georgina Harris

Events Manager

Jasmine Lodge

Events Executive

Matthew Spalding

Marketing Executive

Adam White T: +44 (0)1493 445121 +44 (0)1502 566216

E: media@insidepublication.com W: www.insidemarine.com

Latest developments from the Brazilian industry

Petrobras, the major Brazilian energy company, has achieved a significant milestone in its new commitment to sustainable ship recycling with the successful conclusion of the auction for the disposal of a floating offshore platform in Brazil.

The sale of the floating unit P-32, which has operated in the Marlim field of the Campos Basin, took place at the start of July 2023. In a collaboration supervised by Petrobras, the steel company Gerdau S.A. and shipyard Ecovix have been entrusted with the responsible and environmentally sound recycling of the platform.

“This decision marks the first time a commercial vessel at the end of its lifecycle will be dismantled in Brazil,” Nicola Mulinaris, Senior Communication and Policy Advisor of the NGO Shipbreaking Platform, said. “This significant move not only paves the way for the development of a recycling industry in Brazil, but also sets an important precedent for the shipping and oil and gas sectors, encouraging other ship owners to adopt similar strategies for capacity building.”

Over the next five years, Petrobras is expected to retire at least 26 units, with a projected investment of USD 9.8 billion allocated towards decommissioning activities. Just a few months ago, the oil

and gas giant announced the adoption of a new policy mandating the recycling of vessels only in facilities equipped with dry-docks or impermeable surfaces with drainage systems.

This off-the-beach stance places the company among an increasing number of responsible ship owners – including competitors SBM Offshore and Shell –that are choosing facilities with infrastructure enabling the safe and environmentally sound management of their end-of-life assets.

“After years of selling numerous old vessels for dirty and dangerous shipbreaking on the shores of South Asia, Petrobras has finally committed to environmental stewardship by unequivocally disavowing such practices, Ms Mulinaris concluded: “Moreover, the company’s decision to opt for a domestic solution, leveraging the state-of-the-art infrastructure available in Brazil, showcases that it is possible to find alternative and better solutions to beaching.” n

Latest developments from the UK’s industry

Babcock International has successfully completed maintenance works for the Royal Research Ship (RRS) Sir David Attenborough at its Rosyth facilities.

Babcock welcomed the RRS Sir David Attenborough (SDA) to Rosyth in early June with works to the ship including upgrades to the vessel’s gas detection system, helideck netting and draft sensor vent pipework, as well as assistance with planned maintenance, defect rectification and general logistics support.

The maintenance was supported by around 20 expert Babcock tradespeople, including apprentices.

Designed to support science in extreme environments, the SDA is one of the most advanced polar vessels in the world, with the maintenance carried out by Babcock allowing the vessel to continue operating efficiently and safely as it embarks on its next global operation.

The SDA is the second Royal Research Ship to visit Rosyth as part of the newly agreed Natural Environment Research Council (NERC) contract, part of Babcock’s £45 million contract to maintain the UK’s fleet of scientific research ships. Babcock will also support NERC to review, identify and

adopt technologies and solutions to reduce ship emissions.

“The UK’s fleet of scientific research ships carries out invaluable work at both polar regions to allow us to further understand changes in our climate,” Sean Donaldson, Managing Director, Babcock’s Rosyth facility, said. “To operate effectively in those regions, it is essential that each vessel is perfectly maintained. That’s where Babcock’s expertise and long history of successfully maintaining complex assets is invaluable.

“Our flexible and efficient recent work on the vessel bears testament to the fact that we deliver when it counts most, and we are proud to play a part in this fantastic UK scientific programme.”

RRS SDA is a one-of-a-kind polar research ship that is set to transform the UK’s polar research capability. A floating laboratory, the ship will enable world-leading research in Antarctica and the Arctic over the next 30 years, allowing scientists to investigate the important issues we face as a society, including climate change, future sea-level rise and threats to marine biodiversity. n

Latest developments from the Australian industry

AAL Shipping (AAL) recently completed the successful transportation of critical Toshiba-built power station components on a single shipment from China and Japan to Queensland, Australia.

The units were carried for global logistics provider DB Schenker and are to be used in the repair of the Callide Power Station as part of a USD 200 million project to fix damaged turbines. The components will also return one of Queensland’s newest and most vital coal-fired power plants to full capacity, after failures had resulted in mass power outages from the NSW border to the north of Cairns.

AAL was selected for the project due to its long-standing relationship with DB Schenker, a history of strong performance on Toshiba cargoes and the reliability of AAL’s monthly ‘Asia-East Coast Australia Liner Service’ on which this latest cargo was shipped.

Initially consisting of a 270-tonne transformer and 600CBM of accessories, the cargo was loaded onto AAL’s 31,000 deadweight mega-size A-Class heavy lift MPV ‘AAL Singapore’ in the Port of Shanghai and was due to be discharged at the Port of Gladstone in Queensland,

with the trans former offloaded to barge and then transported to shore.

“Whilst loading the transformer in China and before her sailing to Gladstone, our client requested if the AAL Singapore could deviate to Yokohama in Japan and load other critical accessories for the same project, which we were happy to do,” Chris Yabsley, Chartering Manager, AAL Australia, said. “AAL was then further engaged to harness our vessel’s heavy lift cranes and transfer a large 276-tonne generator stator from wharf laydown to a waiting barge, which we again executed seamlessly.

“All these components were then transported via road to the Callide Power Station in central Queensland for the final 100 kilometres of their journey, having travelled a total distance of nearly 9,000 kilometres. The project was completed on time and without issue, to ensure vital works at the power station can go ahead without delay.” n

Latest developments from the Dutch industry

The Dutch Minister of Infrastructure and Water Management, Mark Harbers, attended an event celebrating the completion of the enlargement of the Twente Canals.

Agreat recognition for the work of consortium Van Oord – Hakkers –Beens, who worked on the final phase of the enlargement of the Twente canals in recent years.

The Twente canals are an important logistical connection for the transportation of goods by water. By enlarging the waterway, the ports of Almelo, Hengelo and Enschede are more accessible, and larger vessels can sail through more safely and smoothly. This boosts regional economy and makes water transport even more attractive.

The Van Oord – Hakkers – Beens consortium was commissioned by Rijkswaterstaat, the executive agency of the Dutch Ministry of Infrastructure and Water Management. The consortium was responsible for enlarging the canal, replacing the sheet piling over a length of 35 kilometres and applying a self-sealing layer at the bottom of the canal. The consortium also created 13 kilometres of nature-friendly riverbanks.

During project execution, the Twente canal remained accessible and in use at

AS A CONSORTIUM, WE ARE PROUD TO CONTRIBUTE TO THE OBJECTIVE OF THE TWENTE CANAL PROJECT: THE IMPROVEMENT OF THE ACCESSIBILITY OF THE WATERWAY

“

all times whilst 80 pieces of floating equipment worked on the canal. The project paid a lot of attention to sustainability: part of the sheet pile walls, and the dredged material, were reused on projects in the area.

“As a consortium, we are proud to contribute to the objective of the Twente canal project; the improvement of the accessibility of the waterway,” said Ronald Schinagl Managing Director for Van Oord Netherlands. “In cooperation with Rijkswaterstaat and all other stakeholders, we got the job done with limited disruption and an eye for sustainability.” n

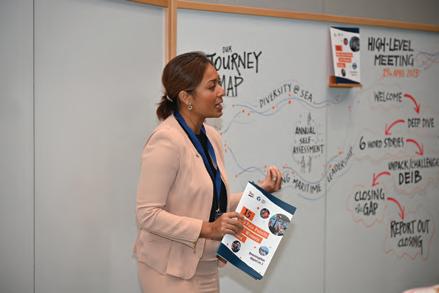

An overview of All Aboard Alliance’s efforts to improve conditions for women seafarers.

Interviews with 115 anonymous women seafarers from all ranks form the basis of a multi-year effort by the All Aboard Alliance to improve living and working conditions for women at sea. Report by Phil Nicholls.

The new qualitative study from the Global Maritime Forum and the All Aboard Alliance contains a wide spectrum of perspectives from women seafarers who address the challenges they experience at sea, from ill-fitting safety gear to slower career progression and harassment.

The key pain points

From the anonymous interviews, the All Aboard Alliance has identified 15 key pain points which fall into four broad categories, the first being the difficulty of succeeding professionally at sea. This category referenced being perceived as less competent than male coworkers, not having equal access to training or tasks onboard and

having to outperform male peers to get respected or promoted.

Another category of key pain points involves how social relations onboard can be especially challenging for women at sea. This involves feeling isolated or unsupported because of their gender, the concern for gossip or rumours, power abuse or sexual harassment and sexual misconduct onboard.

The third group of pain points relates to systemic employment challenges at sea. The seafarers highlighted the lack of family planning options, such as maternity leave or sea-shore rotation programmes, resulting in many women having to choose between a career at sea or starting a family, in turn

pushing women seafarers to find employment elsewhere. This category also covers service contracts at sea being too long and how many companies are still not willing to recruit women seafarers.

The final category relates to the physical conditions onboard. This describes the lack of access to female sanitary products onboard or a lack of access to adequately fitted Personal Protective Equipment, such as boiler suites or fire gloves. The concerns in this area also noted the lack of access to designated women’s changing rooms or bathrooms onboard vessels.

Some of these pain points were already known, but the detailed accounts are very valuable. The study itself contains a selection of the quotes recorded to illustrate the pain points.

“We need to make life at sea more inclusive to women seafarers,” Su Yin Anand, Head of Shipping at South32 and Co-Chair of the All Aboard Alliance, said; “but now that we have a better understanding of what the pain points are, we can work together to address them. We do not

An overview of All Aboard Alliance’s efforts to improve conditions for women seafarers.

want them to leave their careers at sea because we need them – and we need many more.”

The qualitative Diversity@Sea study covers such a wide spectrum of the industry and looks broadly at the problems that face women working at sea.

On average, women at sea amount to less than 2% of the total seafarer population.

“These issues must be addressed,” said Mikael Skov, Co-Chair of the All Aboard Alliance. Mr Skov is also CEO of Tanker operator Hafnia – which in 2022 launched its Maritime

Cultural Lab aboard four of its vessels, with crew matrixes consisting of at least 50%

women – to learn more about the cultural nuances and impact of a more diverse crew.

“First of all, we must address these issues because it is the right thing to do,” Mr Skov continued. “Secondly, because the maritime industry is changing rapidly, and more advanced skills are needed –ones which require us to look holistically at the full talent pipeline to identify the best candidates – for the maritime sector to thrive and grow.”

It is important to note that many of the key pain points identified in this study –such as bullying and harassment, feelings of isolation and long contracts keeping seafarers from their families for many months – are also considered as pain points for many male colleagues.

The interviews were the first part of a pilot project conducted by the All Aboard Alliance. The study covers women of all ranks, from captains to deck hands, and in many types of ships, with most of the women interviewed being from Asia (63%) and Europe (25%).

“The study provides us with the direction we need to develop adequate measures to find solutions to each of these challenges, and not, to decide which of the measures to test in the pilot project later this year,”

Susanne Justesen PhD, Project Director, Human Sustainability at Global Maritime Forum and co-author of the report, explained. “The maritime industry needs female seafarers, and it is important that we work collectively to develop and test ways to make work life onboard more inclusive for everyone.”

In the next phase of the project, to be launched in Q4 of 2023, selected vessels from within the All Aboard Alliance with higher-than-average numbers of women officers and crew members onboard, will test the co-designed measures and solutions in an action-research approach. The goal is to identify which of the proposed solutions are most impactful in addressing the 15 key pain points for female seafarers, and thus what will best help the All Aboard Alliance in making a career at sea not just

inclusive, but also attractive to more women seafarers going forward.

The Global Maritime Forum and the All Aboard Alliance hope that the Diversity@Sea report will help spread awareness of the major challenges experienced by women at sea and that many will join this mission to identify adequate and sustainable solutions for each of the 15 key pain points. A career at sea must made be more inclusive to become attractive to women seafarers and everyone interested in pursuing a career at sea.

Read the Diversity@Sea report, 15 Key Pain Points for Women at Sea, here: https://cms.globalmaritimeforum.org/w p-content/uploads/2023/04/All-AboardAlliance_Diversity@Sea-report-no.-1_15key-pain-points-for-women-at-sea.pdf

The All Aboard Alliance brings together senior leaders from across the maritime industry, united by a collaborative drive towards increasing diversity, equity, and inclusion in all organisations, at sea and onshore. The All Aboard Alliance is supported by Founding Knowledge Partners: Global Maritime Forum, Diversity Study Group and Swiss Re. The Alliance was established in 2021 and currently has 36 member companies. n

Latest innovations from the marine industry

HAV Design has been chosen to develop another methanol-fuelled offshore wind service operation vessel (SOV) for ESVAGT.

VHADesign will deliver both the ship design and an integrated equipment package including propulsion system, engines, propellers and positioning system.

“We are humbled and delighted to be awarded yet another assignment from our long-term customer, who is the leading SOV operator,” said Gisle Vinjevoll Thrane, Vice President of Sales at Norway-based HAV Design. “ESVAGT sets extremely high standards for project execution, safety, environmental features and cost-efficiency of operations. As such, the company is a customer that makes us an even better supplier.”

The newbuild hybrid vessel is of HAV 833 SOV design. The vessel will be equipped with a methanol-electric propulsion system, including a battery pack that allows very low to zero-emissions operations. The SOV is 93 metres long and 19.6 metres wide and can accommodate up to 124 people.

The main purpose of the SOV is to safely transfer technicians and spare

parts to and from wind turbines and offshore substations.

The vessel will be constructed at Cemre Shipyard in Turkey. Upon completion, the vessel will become an integral part of Ørsted’s UK East Coast Hub.

This is the 11th SOV that ESVAGT is developing together with HAV Design. ESVAGT is a provider of safety and support at sea and a market leader within offshore wind solutions. The company has a fleet of more than 40 vessels and approximately 1,100 employees offshore and onshore. It is recognised as the market leader and largest operator of SOVs in Europe. n

A unique e-learning programme that puts positive wellbeing in the hands of seafarers was launched in July by international maritime charity Sailors’ Society.

With funding contributions from Norden and Trinity House, the fun, interactive platform with animations, podcasts and quizzes is being offered free of charge and works on- and offline to ensure seafarers everywhere can access the charity’s award-winning Wellness at Sea programme.

Available on a phone, tablet or laptop, it provides seafarers with tools and resources they can apply to daily life. It is designed to educate and empower seafarers to make the changes they need to see a positive impact on their health and wellbeing, allowing them to live a happier, healthier and more fulfilling life at sea.

Six modules cover a wide range of topics to help seafarers manage mental and emotional strain, improve personal and professional relationships and look after their finances and physical and mental fitness. Everyone who completes the course is awarded a certificate.

“We are so proud and excited to launch this platform today,” Sailors’ Society CEO

Sara Baade said. “We think this is a game changer in getting wellness coaching into the hands of all seafarers, wherever they are and whether they have good connectivity or not. This platform brings together our many years of expertise and experience in providing practical solutions to maritime welfare.”

Fibre optic sensor-based and digitally connected Hull Stress Monitoring Systems improve safety and optimise Condition Based Maintenance.

Light Structures AS, the world-leading supplier of fibre optic condition monitoring systems based on Fibre Bragg Grating technology (FBG) and its Dubai headquartered partner Elcome International LLC have been contracted to provide precision SENSFIBTM Hull Stress Monitoring Systems for 10 Offshore Supply Vessels (OSVs). All of which are owned by a major Middle Eastern-based offshore support services provider.

The project is due for delivery and installation on all 10 OSVs by August this year. The SENSFIBTM system has been selected for the retrofit project and is designed to provide instrumentation that fulfils requirements under the new SMART Structural Health Monitoring (SHM) notation. It will also follow ele -

ments of the Hull SMART notation from Bureau Veritas (BV)

Both notations provide a framework for the use of structural stress and fatigue monitoring data as part of a Condition Based Maintenance programme. As a result, significant OPEX savings are expected to be made by reducing the number of drydock visits during an average vessel’s lifetime if onboard instrumentation can deliver compliant, verified data.

Precision measurements from unique SENSFIB fibre optic sensors on board all 10 OSVs will be made available digitally to ensure that the latest hull stress and fatigue data is always available for informed maintenance decisions. Light Structures will also provide comprehensive annual reports for all vessels based on the collected data, supporting a long-term monitoring approach to ensure operational safety and to help extended the vessels’ operational life. n

Thefinal day of Maritime Safety Week

2023 saw the launch of a new partnership to improve safety in commercial fishing. The partnership was established between The Seafarers’ Charity and the National Federation of Fisherman’s Organisations (NFFO) and formalised by a Memorandum of Understanding aimed at ensuring collaboration on a range of industry-led initiatives to improve fishing safety.

The new partnership sees The Seafarers’ Charity and NFFO utilising their specialist skills and resources for the broader benefit of the commercial fishing sector. The Seafarers’ Charity is a leading maritime funder of safety initiatives and welfare services for people working at sea. The Charity brings its funding resources, collaborative approach and convening powers to the partnership, which will be informed by the NFFO’s representation and specialist knowledge of the fishing industry in England and Wales.

The formalisation of a partnership builds on The Seafarers’ Charity co-funding with the NFFO of their Risk, Safety & Training Lead post held by Charles Blyth. The post

has already been co-funded by the two partners since May 2022 and the Charity recently agreed a further two-year funding commitment into 2025.

In addition to funding this key role, the two organisations committed to collaborating on various initiatives and projects that will contribute to raising awareness and understanding of safety management practices.

The Seafarers’ Charity has been improving the lives of seafarers and their families for over 105 years. Through grants and fundraising, the charity brings about truly life-changing impacts for many who work –or have worked – at sea, and their families. Alongside this, it also uses funding collaboration, research and advocacy to tackle the root causes of seafarer hardship and disadvantage in the UK and around the world. n

seven seas, five oceans, one voice

A selection of event previews and quotes, followed by interviews about ADIPEC, Silicone Expo USA, Breakbulk Americas and Europort.

02-05 October 2023

ADIPEC 2023

ADIPEC is an international platform convening global energy producers, consumers and innovators to accelerate game-changing solutions and transformational progress for the future of energy. Hosted in Abu Dhabi by ADNOC, ADIPEC builds on its 39year legacy of innovation and evolution for the entire energy ecosystem.

[click here] for weblink

20-21 September 2023

World Offshore Week

World Offshore Week is the #1 mega-show bringing together all industry stakeholders impacting the offshore oil and gas sector. This leading platform is the focal point for the offshore industry to discuss best practices and latest solutions in transforming the future of offshore energy.

[click here] for weblink

11-15 September 20

London International Shipping We

London International Shipping Week important international shipping an world. Having grown consistently s become an even bigger event in 2023, host attracting thousands of international indus

[click here] for weblink

November 2023

roport, organised in the world port city Rotterdam, is the international maritime eeting place for innovative technology ex shipbuilding. With an average of 25,000 al visitors and 1,000 exhibiting companies elongs to the world’s largest maritime d knowledge sharing B2B platforms.

12-14 March 2024

For nearly 40 years, global maritime professionals have come together to meet, network and do business at CMA Shipping. Across a packed three days, CMA Shipping offers opportunities to learn from industry leaders, source products from established and emerging brands, and take advantage of enviable networking opportunities. here] for weblink

[click here] for weblink

023 eek

(LISW) is one of the most nd maritime events in the ince 2013, LISW is set to ting hundreds of events stry decision-makers.

Why not give your event exclusive coverage to thousands of readers and connections globally? Contact us: media@insidepublication.com

Inside Marine asks the experts about their personal experience in the industry

What benefits do you see from attending industry events and conferences, either face-to-face or online?

I prefer face-to-face interaction. If it’s a course or seminar, it can be online, but when you’re talking about industry events and conferences, the personal discussions are far better than online. When you’re online, there are often a lot of things that are not discussed. In face-to-face events, you achieve a lot and get lots of meetings done. We came back to industry events last year, and since then, we’ve been attending conferences worldwide, non-stop.

Diego Aguilar, Founder & CSO, E-NAV Offshore

Today, we live in a globalised world. Attending exhibitions and conferences allows us to reach better agreements with suppliers, strengthens the relationship between companies and customers, thereby building alliances with shared experiences, innovations and good practices.

“Germán

Schacht, Business Development & Marketing Manager, ASENAV

“Having face-to-face meetings will always trump meeting people over the internet. In fact, I think that people have lost that sense of personal feeling in recent years. It is extremely important to meet clients and new people face-to-face and stay ahead of industry trends.

Cherif Khoury, Chartering Manager, Blue Fleet Group

Based on my experience, I value faceto-face interaction much more than I value online. Industry events are important to share views, and to put a face to the nameotherwise, you talk a lot to people digitally, but never get to meet them and understand who they are and how they really think. At a recent exhibition that we attended, it was great to share views about the industry’s direction and future challenges. You can’t do that via email, because human conversation is so dynamic. I also think it’s easier to influence key decision-makers when you have the opportunity to see them face-toface and talk to them.

Francesca Trotta, General Manager, Iblea Ship Management

“The maritime industry is a very traditional ecosystem and a lot of what we do is built on personal trust. Meeting customers and potential customers face-to-face gives us the opportunity to discuss what we stand for. It gives us an opportunity to come out of our offices, meet our peers, discuss opportunities and challenges together. The growth we’re seeing is attributable to, the conferences and events we’ve been to and therefore we try to be at all the shipping conferences.

Sanjeev Wewerinke-Singh, Founder and Managing Director, Varuna Marine Services

“

“

When you’re face to face, there’s always that extra opportunity because you’re seeing the face and gaining that extra content from the conversation. Having a cup of coffee together gives you the opportunity for a bit more interaction; it’s much more natural. You can pick up the small details and read the room.

“

Justin Bijenhof, Marine Sales Manager, Wouter Witzel

It’s hugely beneficial because, generally, you learn something you’d never learn from an email or a telephone conversation. When you sit down with people, they tend to relax and open up; conversations are broader. We often mention things when we’re talking to people, and opportunities arise as they realise that we can do various other things – beyond what they’d assumed about our capabilities.

Things tend to come up in conversation and they lead to unexpected opportunities. That’s the great thing about industry events: you get much more open conversations that lead somewhere that both parties can benefit from. Also, selling is about relationships, so it’s important to go and meet people and enhance those relationships.

Mark Phare, Group MD, Teignbridge Propellers

We would love to hear your answers, so send an email over to our Editorial Manager, Phil Nicholls, and share your thoughts with all our readers.

media@insidepublication.com

Event Director Will Maley explains the show to Inside Marine.

Taking place in Detroit on 4-5th October, Silicone Expo USA is the one-stop shop for buying industries to find silicone solutions. One of the organisers, Event Director Will Maley shared with Inside Marine’s Jasmine Lodge what attendees can expect.

Looking ahead to Silicone Expo USA on 4-5th October, what do you see are the benefits to businesses of attending the show?

Attending Silicone Expo USA provides businesses with the opportunity to meet with industry professionals and showcase their products and services. It is an ideal platform for networking and gaining insights on the latest developments and trends in the industry.

How has Silicone Expo USA evolved since the last show? What is new for this year?

Silicone Expo USA has evolved in quite a large way with the addition of our co-located event Tape & Functional Film Expo, following its successful launch in Europe in March 2023. Not only this, but

we are working closely with Visit Detroit to create an immersive experience inside the hall to showcase why Detroit is the perfect host city for the event.

What visitor and exhibitor numbers are you targeting this year?

We’re aiming to have 130+ exhibitors, 90 guest speakers across two conference tracks and 2,000-2,500 attendees visiting. Based on the turnout from our debut European event in Amsterdam, I believe this is an achievable target.

What can visitors expect from their trip to Silicone Expo USA?

Visitors can meet with 130+ exhibitors showcasing their latest silicone technologies and solutions. Our conference also offers a platform of thought leadership, where visitors can benefit from a variety of topics presented by our speakers. This year, we will be incorporating an essence of Detroit within the hall to create a more

Event Director Will Maley explains the show to Inside Marine.

rounded experience. Be sure to grab your self a Coney Island hot dog while enjoying the Motown Band!

What benefits can companies expect to gain from exhibiting at Silicone Expo USA?

Exhibitors can expect to have high level conversations with corporate executives looking to source their bespoke silicone solutions. The beauty of this show is that it is completely dedicated to silicone. People will be in attendance looking to meet new suppliers for their projects.

Looking at the companies already booked for Silicone Expo USA, can you share any previews about the trends and developments on display this year?

We have a great line-up of companies already booked for Silicone Expo USA. There seems to be a lot of talk within the industry about the improvement of sustainability throughout all aspects of manufacturing. I think this year we will see new advancements in this space across our conference and exhibition.

Are there any other special aspects of Silicone Expo USA that you would like to include in this feature?

This year, we are planning a giveaway for anyone who registers by mid-September. The details are being finalised, but it involves an exclusive Detroit experience, sponsored by Visit Detroit. Tune into our social media platforms to find out more about this in due course.

untington Place, Detoit, USA 4-5th October, 2023

www.silicone-expo.com

What do you consider to be the main industry challenges the maritime sector faces for the future? How far do events such as Silicone Expo USA go in helping companies overcome such difficulties?

The maritime industry – along with most other industries – faces hurdles within the supply chain. Trade shows, such as Silicone Expo, can offer a bridge between suppliers and buyers looking to network and gain new business opportunities that help to alleviate these issues.

Tell me more about your conference programme: who do you have lined up to speak and what topics are high on the agenda?

We are in the process of building the agenda now with our Call for Speakers programme. We expect more of the same quality from our previous events, with sessions dedicated to manufacturing and new applications. We are pleased to have Dow as our headline sponsor for the conference, as they endeavour to share new information about sustainability within the space.

On a personal level, what aspect of Silicone Expo USA are you most excited about?

As we are a UK based company, we do not see our American representatives as often as we would like. It is always nice to reconnect with people who are passionate about the industry. The team and I have worked tirelessly to deliver a great show. I think we are all excited to see our hard work come to life. n

Christopher Hudson, President of dmg events, explains the show to Inside Marine.

Hosted in Abu Dhabi by ADNOC, and taking place from 2-5 October 2023, ADIPEC is an international platform convening global energy producers, consumers and innovators to accelerate game-changing solutions and transformational progress towards decarbonisation and the future of energy. Christopher Hudson, President of dmg events, organisers of the show, shared with Inside Marine what visitors can expect.

ADIPEC has evolved considerably over the years. Today, we build on our nearly 40year legacy of innovation and evolution with a bolder vision, and stronger purpose to support the energy industry and wider

ecosystem in its efforts to transition towards greater sustainability. Under the overarching theme, ‘Decarbonising. Faster. Together’, ADIPEC 2023 seeks to unite industries to accelerate the urgent action and game-changing solutions needed to decarbonise quicker and future-proof the global energy system.

For four days, ADIPEC will convene some of the brightest minds from across the energy value chain and beyond –including government, private enterprise stakeholders, technology, academia

United Arab Emirates 2-5th October, 2023

www.adipec.com

and finance – to ignite the innovative and disruptive thinking needed to tackle the world’s most pressing energy challenges.

And with ADIPEC 2023 taking place less than two months before the UAE hosts the 28th United Nations Conference of Parties (COP28), our event is uniquely placed to offer a global stage to address some of those critical issues from across the energy ecosystem and focus on moving the needle forward towards securing sustainable energy for all.

ADIPEC consistently strives to be a force for transformation and leadership, offering a platform for the industry, by the industry. Through continued discussions with key industry stakeholders – including the ADIPEC 2023 Executive Committee – we have iden tified specific challenges the energy industry needs to be advanced, including reducing methane emissions, supporting the decarbonisation of heavy industries and facilitating finance and investment in low-carbon energy and clean technology.

Reflecting this, ADIPEC’s themes and programme have been designed to bring together the ideas, ambition, technology and capital needed to address some of these critical issues and drive energy progress on the path to net zero. They are focused on facilitating collaboration and innovation, to enable diverse actors to unify around a common cause and empower them to share ideas, co-operate and build the momentum needed to create the energy system of the future.

These key industry challenges will be addressed across 10 strategic and technical conferences and more than 350 sessions, where more than 1,600 speakers

United Arab Emirates 2-5th October, 2023

www.adipec.com

will share diverse perspectives and approaches, forge collaborations and explore the strategies and innovations critical to accelerating a cleaner, more secure energy future.

How is ADIPEC responding to industry needs in this rapidly changing and challenging energy environment?

ADIPEC’s central focus on decarbonisation reflects the need for energy and related sectors to reduce their carbon emissions in support of the global energy transition. As part of our commitment to that, we have developed enriched conference and exhibition offerings to enable a secure and sustainable energy future.

This includes the new ADIPEC Decarbonisation Accelerator; a specialised exhibition area that enables organisations to showcase their game-changing projects and solutions driving decarbonisation at scale. Within the Accelerator, a dedicated Start-up hub will host pioneers presenting groundbreaking technologies that drive the future of decarbonisation and accelerate energy progress.

Complementary to that, we have introduced the new Decarbonisation Connect

initiative to facilitate connections on the show floor by showcasing exhibitors’ decarbonisation strategies and innovations through dedicated spaces and presentations. To increase engagement, we are also developing the Decarbonisation Guide, featuring exhibitors' decarbonisation products and solutions and a schedule of exhibitor presentations during the event.

Recognising the importance of the maritime sector – which supports the transportation of 90% of all traded goods –ADIPEC 2023 has broadened its focus on the wider maritime and logistics industries. We have launched a dedicated hall to host our expanded Maritime & Logistics Zone and dedicated Maritime & Logistics Strategic and Technical Conferences. The zone will connect the global maritime and logistics supply chain with leading experts in energy and technology driving lower-carbon solutions while maintaining sustainable

Christopher Hudson, President of dmg events, explains the show to Inside Marine.

growth, while the conferences will gather industry leaders, regulators and decisionmakers from across the shipping and logistics supply chain to engage in technical and strategic dialogue around decarbonisation and digital innovation.

These new offerings, alongside our expanded youth programme, Hydrogen Strategic Conference and all new ADIPEC Awards categories, support the global energy transition by focusing the wider industry’s attention on key needs and issues. Proof of ADIPEC’s responsiveness and relevance to industry’s needs can be seen in the fact that we had our highestever number of submissions for our Technical and Downstream Technical Conferences, and a record number of submissions for our ADIPEC Awards.

What are the top-line issues for energy and energy-related companies this year?

Energy industry volatility, climate change- related commitments, persistent global conflicts, and record levels of inflation are among some of the many challenges currently being faced by the global energy ecosystem. At the same time, energy and its related industries, like manufacturing and transport, face growing pressure to reduce emissions outputs – through improved efficiency and use of cleaner fuels, secure investment for research and development for cleaner products and services, and to ensure the continuity of the company’s commitment to sustainability through training and development of its workforce.

While the issues faced by the energy ecosystem are manifold, as an inclusive platform convening countries, governments and policymakers ADIPEC has created an event programme and setting to enable participants to engage in inclusive dialogue, foster collaboration

Abu Dhabi, United Arab Emirates 2-5th October, 2023

www.adipec.com

and work collectively to find solutions. Some of the timely topics of focus in our conference programme include reinforcing regulatory systems to guide and accelerate emissions reduction, decarbonising end-use and heavy industries to facilitate discussion and resolution, and navigating safety and sustainability for hydrogen.

In the same vein, we have introduced all new ADIPEC Awards categories reflecting topics of importance to a sustainable and inclusive energy transition, like hydrogen, decarbonisation at scale, clean-tech and sustainable energy for the developing world. Like previous editions, the awards focus on celebrating the pioneers in industry who are implementing the projects and programmes that are helping to scale up, innovate, and support the changes needed in the energy sector and beyond.

What can visitors expect to see on the show floor at ADIPEC 2023?

More than 2,200 companies from across the entire energy value chain will exhibit at ADIPEC’s 15 exhibition halls, which include four specialised exhibition areas – the Decarbonisation Accelerator, Maritime & Logistics Zone, Digitalisation in Energy Zone, and Manufacturing & Industrialisation

Exhibition & Conference. Additionally, the 30 dedicated country pavilions at ADIPEC 2023 will highlight each country’s latest innovations and best practices, offering a platform for global collaboration and innovation.

ADIPEC’s strategic conference programmes have been curated to focus on important topics like hydrogen, decarbonisation, manufacturing and industrialisation, diversity, equity and inclusion (DEI), and the development of future leaders. The technical conference programme has been designed to demonstrate cutting-edge technical and engineering insights that will drive ideas, overcome challenges, create new value and highlight innovation. n

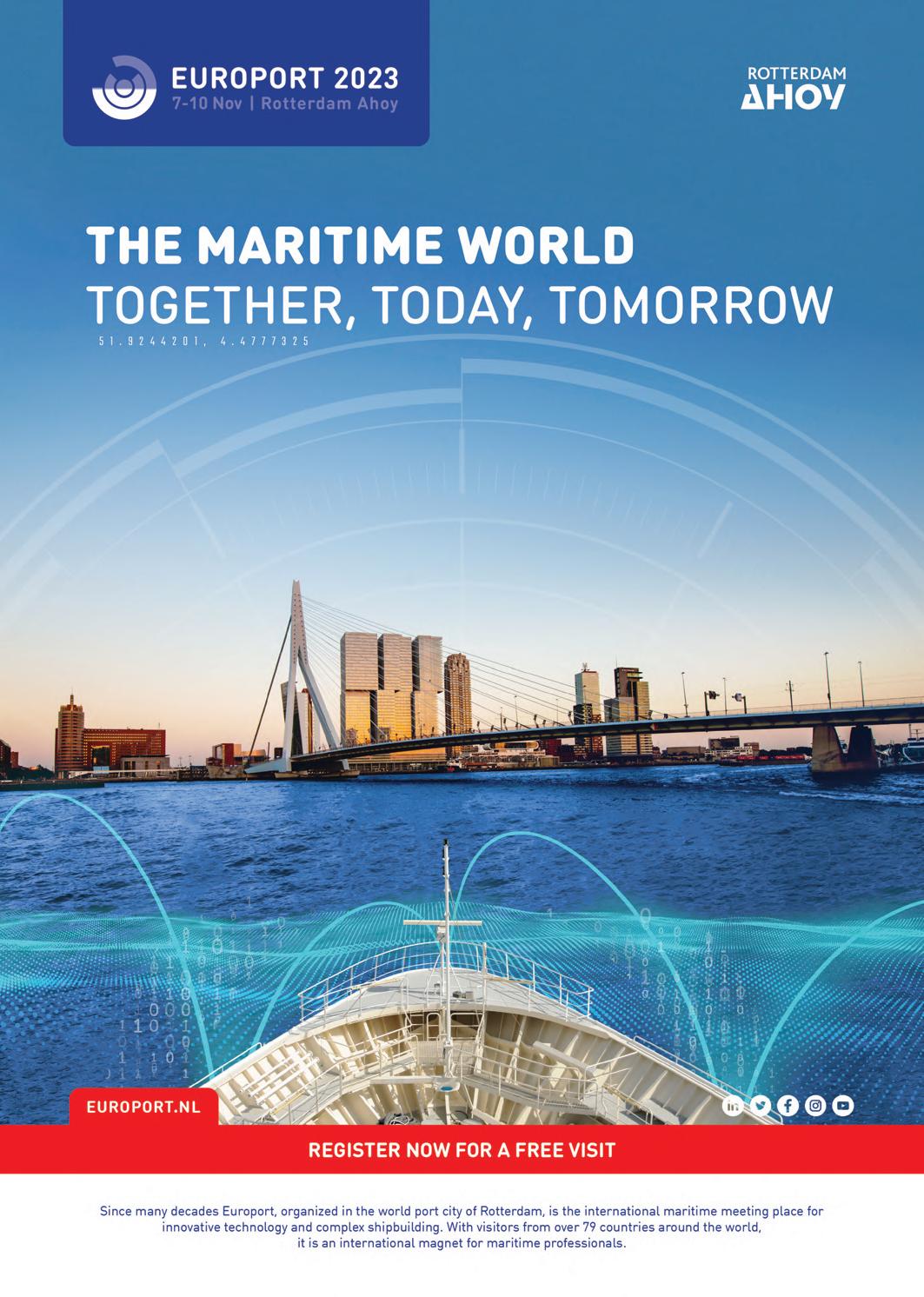

Director Europort Raymond Siliakus answered questions for Inside Marine

Held in Rotterdam on 7-10 November, Europort 2023 is the international maritime meeting place for innovative technology and complex shipbuilding. Director Europort Raymond Siliakus offered Inside Marine an insight into what visitors will experience at the show.

With Europort coming up on 7-10 November 2023, what would you say are the advantages for companies attending the show?

For many decades, Europort has been the exhibition and meeting place where the industry gets together to connect, cooperate and innovate. Europort is held in Rotterdam, the Maritime Capital of Europe, and one of the leading maritime cities in the world. Within a range of 200 kilometres, Europe’s largest ports, offshore and dredging contractors, superyacht builders and shipyards are active, working closely together with high-level research centres, equipment suppliers and numerous ship owners. And every two years these stakeholders come together at Europort along with visitors from all over the world. Therefore, it is safe to say that Europort belongs to the world’s largest maritime meeting and knowledge-sharing B2B platforms.

Rotterdam Ahoy

7-10th November, 2023

www.europort.nl

Last time, we were very fortunate that Europort could take place despite Covid. However, there were still some travel restrictions, mainly from continents other than Europe. Nevertheless, we had a very successful event, with many satisfied visitors and exhibitors. This year, we see that Europort's appeal extends again beyond Europe, with the return of the Chinese and South Korean pavilions, for example. In addition, we see that the world is changing even faster with all the digital developments and the emergence of AI. Hence this year, for the first time, we have a Digitalisation Area where frontrunners in digital transition and smart connectivity are concentrated and can get visitors connected most effectively.

How many exhibitors and visitors are you expecting this year?

This edition, we will again aim to make the best use of all available space in Rotterdam Ahoy. That means we can expect more than 1,000 exhibiting companies and approximately 25.000 professional visitors. Looking at the current status of the floor plan, we are well on our way to achieving this goal!

What might a visitor expect from a trip to Europort?

A trip to Europort promises a diverse and enriching experience for visitors, with exhibitors showcasing the latest products, technologies and services. Visitors can witness the latest advancements in automation, digitalisation, sustainable solutions and other transformative technologies that are shaping the industry's future.

Europort not only focuses on the professional aspects, but also offers a social side that enhances the overall experience for visitors. Europort organises various social events, receptions and networking

Director Europort Raymond Siliakus answered questions for Inside Marine gatherings, offering attendees a chance to relax, socialise and engage in informal discussions.

Overall, a trip to Europort provides an excellent opportunity to explore the latest trends, forge new connections and gain insights into the maritime and offshore industry while enjoying the vibrant atmosphere of Rotterdam.

What are the benefits of attending Europort as an exhibitor?

Europort belongs to the world’s largest maritime exhibitions and, as such, attracts a highly focused international audience of industry professionals, including shipbuilders, shipowners, equipment manufacturers, suppliers and service providers. This focused environment ensures that companies can engage with relevant stakeholders and potential customers. It allows maritime companies to showcase their products, solutions and expertise to an international audience.

Can you offer any predictions about new technology and developments for the maritime industry among the companies exhibiting this year?

Digitalisation will have a growing impact in all aspects of shipping and vessel technology. Ongoing digital innovations will help to counter major industry challenges in the field of energy efficiency, reducing the carbon footprint, cyber security and smart use of scarce human resources –especially with the disruptive revolution of Artificial Intelligence, of which I believe we have only seen the beginning.

In what ways do events like Europort help companies overcome challenges in the maritime industry?

Europort brings together industry professionals, experts and thought leaders from around the world. Through conferences, seminars and workshops, attendees can exchange knowledge, share experiences and discuss challenges and solutions. This knowledge exchange enables companies to gain valuable insights into emerging trends, best practices and innovative approaches, helping them tackle industry challenges more effectively.

Furthermore, events like Europort offer a comprehensive overview of the current state and future direction of the maritime

Rotterdam Ahoy

7-10th November, 2023

www.europort.nl

industry. Through keynote speeches, panel discussions and presentations, companies and visitors gain insights into market trends, regulatory developments and emerging challenges. This knowledge equips companies with the necessary information to adapt their strategies, identify potential risks and seize opportunities in a rapidly evolving industry landscape.

What part of Europort are you personally looking forward to the most?

The beauty of exhibitions in general is that they truly connect people and cultures from all over the world. In a world that becomes more and more divided and polarised, exhibitions play a fundamental role in literally bringing people together.

Exhibitions focus on opportunities and cooperation, on mutual ambitions, shared values, and synergy. This certainly applies to Europort where industry peers from more than 90 countries are expected to get together to connect, cooperate and innovate.

What can visitors expect from this year’s conference programme?

We have defined four key topics to lead the Europort 2023 agenda: Energy Transition, Digitalisation, Ship Finance and Human Capital. These themes will be deeply explored in the exhibition and during the many conferences, innovation pitches and networking events. Europort offers an exceptionally in-depth programme in close cooperation with national and international industry partners, innovators and pioneers. And it will be fun too, with plenty of occasions to make the trip enjoyable and memorable.

Is there anything not covered so far that you would like to share with our readers?

Yes: visitors should make sure they get inspired by young entrepreneurs and their visions. It is crucial that everyone visits the Rising Stars Pavilion, where a selection of 21 promising start-ups will showcase the newest insights. n

Marketing & Media Director Leslie Meredith previewed the event for Inside Marine

Running from 26th to 28th September in Houston, Breakbulk Americas is the only exhibition devoted to the project cargo and breakbulk industry in the Americas. Marketing & Media Director Leslie Meredith summarised the Breakbulk Americas experience for Inside Marine. Questions by Jasmine Lodge.

How has Breakbulk Americas evolved over the years?

The event has a long and rich history spanning more than 30 years, beginning when containerization was first introduced. At the same time, modularization – building huge components like drilling rigs in pieces where manufacturing was cheaper and then assembling them at the jobsite – opened new transportation opportunities, leading to what has become a major part of the transport and logistics of project cargo.

It is not unusual to see components manufactured in multiple countries and then shipped separately to the project’s location.

The complexity and unique aspects of every job demand expertise from all people involved in a project including the project owner and EPCs, the global forwarders, spe cialized transporters, ports, equipment providers, and related service providers. This evolving and ever more complex supply chain is represented at Breakbulk Americas.

What can visitors expect from their trip to Breakbulk Americas?

Nowhere else will you find the variety of companies that are on the exhibition floor and walking the aisles. Last year, 2,240 companies were represented from

59 countries, united in a common purpose: to renew business relationships and make new ones. Everyone is looking for business, but they all know business starts with relationships.

In addition to exceptional networking, participants can enjoy the Main Stage sessions scheduled for Wednesday and Thursday. In the early days, most sessions focused on handling traditional breakbulk cargo, but today you’ll find a wider variety of topics –from project outlooks by sector and region

to sustainability, new regulations, and digi talization – factors that impact the cost and efficiency of project development.

What visitor numbers are you targeting this year?

We learned during Covid that we could get our work done remotely, over email or a video call. We also learned there was no replacement for face-to-face interaction. In fact, Breakbulk Americas attendance

Marketing & Media Director Leslie Meredith previewed the event for Inside Marine

surged 39 percent in 2022 compared with 2019, due to the enthusiasm for meeting again in person. There is not a more efficient way to network with reputable industry companies than over the course of two-and-a half days at the George R Brown Convention Center in Houston. More than 5,000 visitors are expected at this year’s event.

Are there any special aspects of Breakbulk Americas that you would like to include in this feature?

Breakbulk Americas sets itself apart with two special programs: one for cargo owners who are the decision-makers when it comes

to new project contracts, and Education Day, designed to attract university students into the business of project cargo.

Our Breakbulk Global Shipper Network includes members from the world’s largest energy companies, EPCs, industrial manufacturers, and mining and metals firms. Houston is home to many of these companies, making Breakbulk Americas the top event for BGSN members.

At the other end of the spectrum are students who are interested in joining the industry. For more than 15 years Education Day has provided a solid introduction to the world of project cargo, and given students a chance to meet executives from different sectors – for some,

Houston, USA

6-28th September, 2023

americas.breakbulk.com

Education Day has led to a career filled with challenges and travel. This year we expect to host about 200 students from schools throughout the region.

What do you have planned for the conference agenda at Breakbulk Americas?

This year’s program features a ‘double header’ with an industry sector review of mining, oil and gas, renewables and manufacturing, followed by a panel that will discuss the readiness of the breakbulk sector to respond to shifts in demand and services for these four types of projects. We will also do a deep dive into projects across Latin America, as well as new projects that will revitalize the Gulf of Mexico as we move further into the energy transition.

One of the most exciting things we see at Breakbulk, is the spontaneous formation of industry work groups following a panel discussion. These groups tackle challenges that came to light during the panel, and then come back to the stage to report their progress along with industry developments. At Breakbulk Americas, last year’s air cargo solutions group featuring CargoLive, Airbus, and Antonov will return to the stage this fall. Breakbulk is more than just an event, it is a catalyst for industry solutions.

Alongside the formal aspects of Breakbulk Americas, how are you supporting the more social side of the event?

We also recognize that casual networking can be just as important as scheduled meetings. All participants are invited to Tuesday’s Welcome Reception on the show floor, followed by an after-party at The Rustic, sponsored by Port of Houston. d-ship Carriers will host the annual Women in Breakbulk breakfast at the Marriott on Wednesday morning to give female attendees the opportunity to make new connections and discuss career issues.

From Tuesday until Thursday, participants will have the full Breakbulk experience: friendly networking, exceptional business insights, and the opportunity to be a part of the industry’s original Breakbulk event. n

seven seas, five oceans, one voice

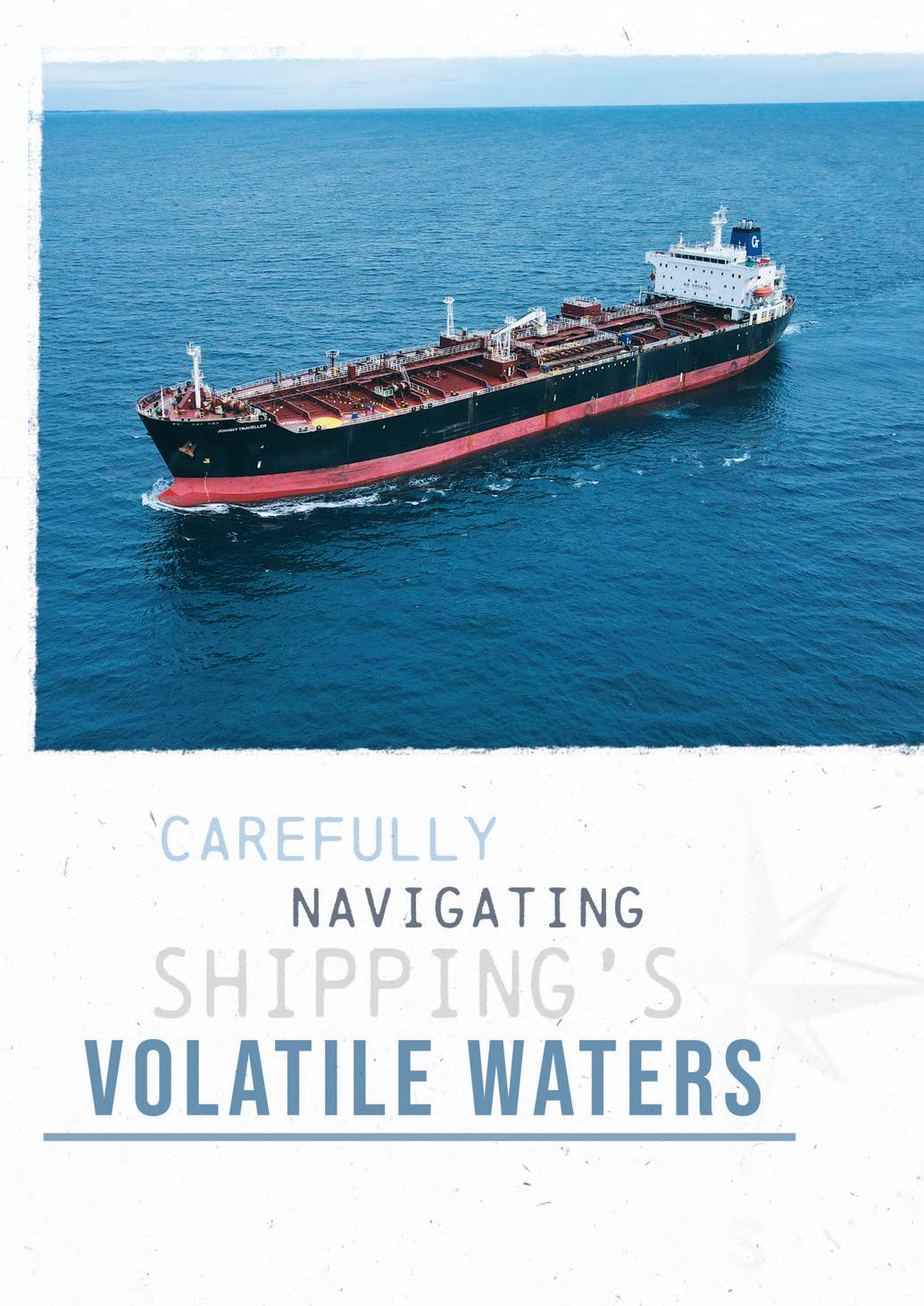

An introduction to specialist support vessels, with a special report, news and a photo feature, followed by the company profiles for: tideman boats us rem offshore e-nav offshore tug malta tor group

An overview of how the National Oceanography Centre conducts research cruises

Jon Short, Senior Project Manager at the National Marine Facilities, National Oceanography Centre (NOC), and Helen Oldridge, Head of Scientific Engineering, lead teams of highly skilled technicians on board NOC’s fleet to fulfil science research missions efficiently and optimally.

The National Marine Facilities (NMF) operates two world class, multidisciplinary, deep ocean research vessels, RRS James Cook and RRS Discovery, alongside the National Marine Equipment Pool (NMEP) to deliver the UK marine science programme, which supports a world effort to better understand our ocean.

Modern research projects are rarely single nation affairs, with participants joining from institutions around the world, and collaborations with international partners increasingly the norm. This was

particularly evident during Covid-19, where, after a brief pause in 2020, most research programmes resumed with a focus on the recovery of data and deployed assets between research vessel operators. Fast-forward to 2023: normal service has resumed with NMEP equipment and technicians deployed globally, and the research vessels operating in four of the five oceans this year.

Oceanography covers a vast range of research areas, each asking different qu es tions and so requiring different data and methods of collection. A multidisciplinary cruise requires a range of different platforms, instrumentation and equipment from the NMEP that spans the range of engineering disciplines, skills and experience to deliver. NMF’s mission is to do just that. Four groups converge to ensure the success of research cruises. The Programme Management team create the schedule for the RRS James Cook and RRS Discovery, alongside managing each

individual research cruise within the programme. Research Ship Operations comprises the mariners and base support staff delivering the day-to-day operation of the research vessels.

The Scientific Engineering team is responsible for the maintenance and operation of equipment within the NMEP. Finally, the marine autonomous and robotic systems (MARS) team is responsible for the maintenance and operation of the autonomous platforms requested by the scientific team.

Producing the marine facilities programme is a complex process that must consider the geographic, temporal, and technical requirements of funded projects whilst minimising ‘passage legs’ (periods where a ship is transiting between two locations without carrying out a science project) to maximise the efficiency and capacity of the programme. This efficiency gives the maximum ‘science bang per carbon buck’ and helps deliver carbon emissions targets.

The project manager forms the bridge between the technical and scientific teams, ensuring the right person and equipment is in the right place at the right time to collect the data.

When a project manager is assigned, their first task is to meet with the Chief Scientist (CS) to review and discuss their original application. These may often have been submitted several years beforehand and the objectives may have evolved along with the technology available to support them. They revisit the simple but key question: ‘what are you trying to achieve?’

Of course, everyone wants more than the time, budget, equipment, deck space or berth limitations allow, so the project manager’s task is to find the best combination of equipment and skills to meet the aim.

As with most projects, the execution rarely looks exactly like the first draft of the plan, with complications inevitable such as diplomatic clearance delays, freight issues, supplier lead times and technician availability. These are mitigated firstly through an early and iterative planning process; but mostly by making sure the cruise priorities across the full programme year are understood, so an action to assure a positive result for one project does not have unintended negative consequences on another.

The assembly of the correct technical team onboard is arguably the most telling factor of cruise success. This requires

An

overview of

a del icate balance, so that the operations can be carried out safely and adhering to the relevant working time directives, but also keep as many onboard berths as possible free for the science party.

Consideration is also given to ensure that the team, drawn from multiple engineering disciplines, have complementary skills. A decision is taken assigning the Senior or Lead technician role, who then assumes overall responsibility for the NMF-supplied equipment and personnel onboard.

The project manager attends the mobilisation, assuming the responsibility for commissioning the requested equipment onboard the vessel. They liaise closely with the Captain and the Chief Officer to make sure that the ship’s staff know what is

required of them and that all operations are carried out safely and efficiently.

This can be a complex operation – often involving local contractors – to bring large pieces of plant equipment on board the vessel. To this end the PM will produce a ‘port programme’; a document that details all of the mobilisation operation with an accurate timetable.

The vessel will sail on the research cruise once the Captain of the vessel is happy that everything is secure and safe for going to sea and the PM and Chief Scientist are happy that all of the science gathering equipment is working.

While the ship is performing the science, the PM will prepare for the demobilisation. This is the reverse of the mobilisation and

includes liaising with appointed ships’ agents and local customs to prepare any freight that urgently needs to come back to the NOC – this is minimised however, to limit carbon and financial costs.

Change is coming: not necessarily in what science is done, but in how it is achieved. Fossil fuelled shipping has a high carbon output, with emerging low-carbon fuels having lower energy density. Therefore, the next generation of research vessels are likely to accommodate fewer personnel as the space required to hold fuel increases by two to three times, impacting marine, technical and scientific teams.

With the emergence of LEO satellite connectivity bringing reliable, high speed, low latency internet connection at sea, the opportunity for remote participation increases significantly. By streaming data in real or near real time, scientific teams ashore can actively participate in cruises.

Similarly for technical support, live participation from ashore in terms of fault finding, and even remote operation, becomes more feasible. Over the next few years, this type of scientific and technical participation will be explored to find what can be achieved safely, without impacting the quality of

science delivery. This will be a cultural shift, working on the principle that ‘if your job is working on a computer, then you should be doing it ashore.’

As we move towards Future Marine Research Infrastructure, data collection that can be done effectively using autonomy –that is currently done using the vessels – will gradually transition to these platforms as the fleet and capability expands. This leaves the vessels to be prioritised for the data collection that cannot be done using autonomy.

In this +Ship model, the first question is ‘can this be achieved using an autonomous platform?’ Autonomy is not the silver bullet for decarbonising marine research, but it is an important capability that allows the ves sels to be prioritised for the research that genuinely requires world class, multidisciplinary, deep ocean research vessels for the foreseeable future. n

Workboats has announced the sale of a new 15m ProZero vessel to Nord University in Norway. This acquisition marks a significant milestone for Nord University's commitment to expanding and enhancing its research capabilities within the blue sector.

The 15m ProZero workboat will provide researchers and students with improved opportunities to expand and advance their studies. It is expected to contribute to technological progress, empowering students and researchers to engage in high-quality teaching and research activities.

This acquisition is part of Nord University’s historic investment in the blue sector. With the ongoing construction of the Blått bygg campus in Bodø, set to accommodate the Faculty of Biosciences and Aquaculture from the fall of 2024, and the recent christening of the coastal research vessel

‘Prinsesse Ingrid Alexandra’ (PIA) in April 2023, this new vessel represents another significant addition to Nord University’s marine infrastructure.

According to Skipper Morten Krogstad, the new 15m Prospero Workboat is a clear improvement that complements the

existing fleet. He emphasised that Nord University's campus in Bodø is now the ideal place to study marine and fisheries sciences.

The ProZero 15m vessel represents an advanced maritime solution, designed with versatility and efficiency in mind for various marine applications. Constructed using high-quality composite materials, it ensures durability and longevity while meeting regulatory standards.

The vessel incorporates robust features for enhanced functionality and protection, including large fender lists for docking and mooring operations. Its interior and exterior are set up to meet the university’s specific needs in regards of equipment, such as winches and cranes to handle water and seabed samples, and the layout is configured to ensure the best possible workflow when students are on board. n

North Star’s second hybrid-propulsion service operation vessel (SOV) is set to be mobilised three months earlier than planned to support SSE Renewables with a new scope of work at the Dogger Bank Wind Farm.

The first of the firm’s new offshore wind fleet, the Grampian Tyne, was blessed in June at an event held at the Dogger Bank O&M base in Port of Tyne. The second SOV, the Grampian Derwent, (which is a larger ship with increased accommodation capacity and helideck), has recently been delivered to North Star in Vietnam.

The new award with SSE Renewables will see the UK’s leading infrastructure vessel support firm aiding the construction and commissioning stage at the initial phase of the wind farm’s development, located

130km off the Yorkshire coast. This will allow the ships to then dovetail straight into scheduled long-term charters to carry out operations and maintenance (O&M) related in-field vessel activities for the development partners. The wind farm is a joint venture between SSE Renewables (40%), Equinor (40%) and Vårgrønn (20%).

North Star has a proven track record of successfully building multiple vessels simultaneously on time and on budget. The 135-year-old business also has a robust £127 million finance package in place to fund its Dogger Bank SOV fleet newbuild programme, which will result in four of its hybrid-electric ships being operational in field by 2026; each on a 10-year minimum term charter agreement. n

This stunning photo (copyright Boskalis) shows the BOKA Vanguard loading the Carnival Vista, attended by a small fleet of support vessels. BOKA Vanguard is a state-of-the-art semi-submersible heavy-lift ship, owned and operated by Dockwise BV. For

mething interesting to show the business world? We are always looking for beautiful and interesting visuals of ducts, innovations, buildings and technology. Get in touch and start promoting your company to the global market. media@insidepublication.com

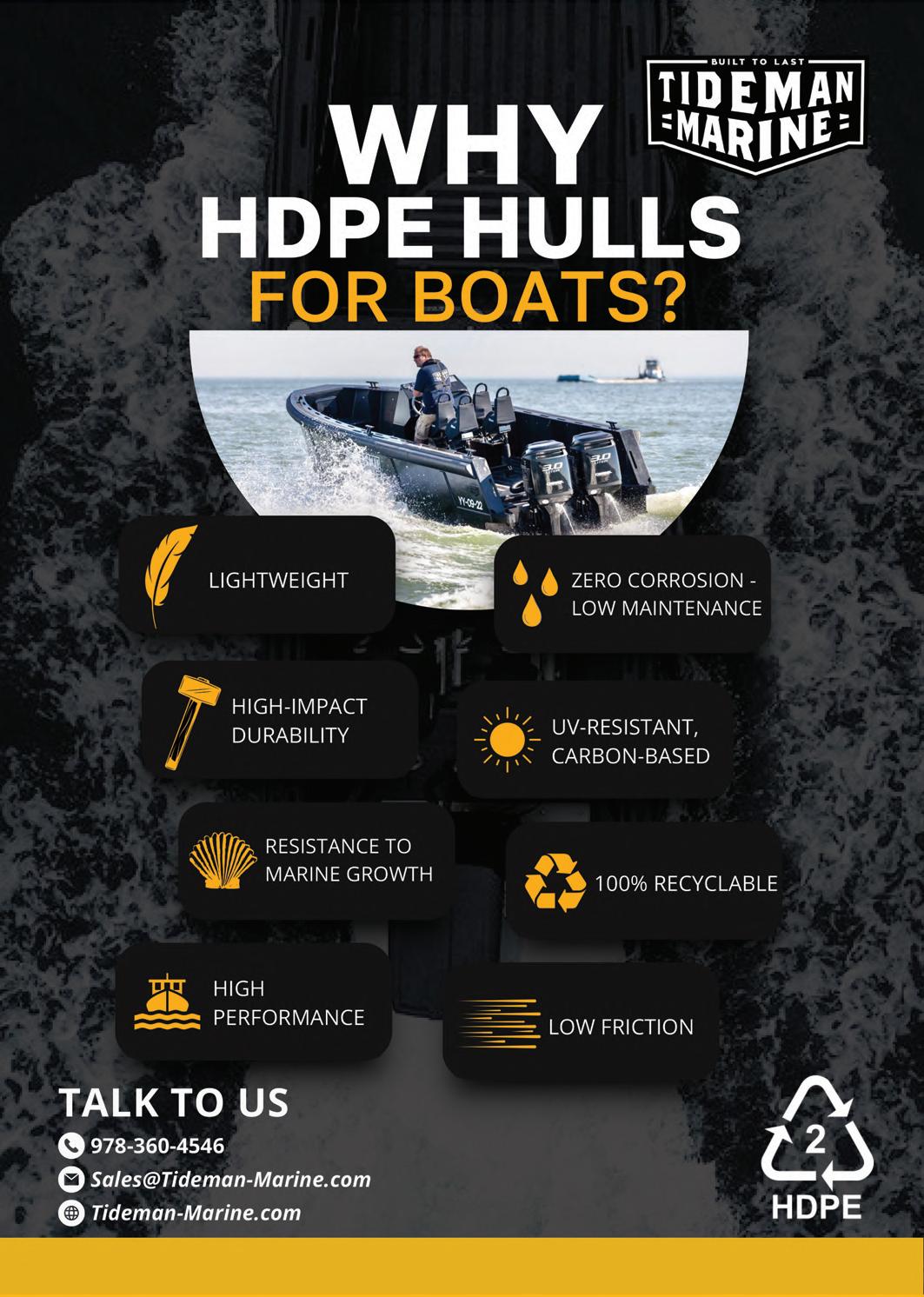

Tideman Boats US manufacturers high speed, virtually indestructible, HDPE hulls and other marine components for the North American marine market. It is an offshoot of Tideman Boats, the Dutch company pioneered by Bruno Tideman. The vessels manufactured by Tideman are especially beneficial in shallow waters and rocky coastlines. Hannah Barnett spoke with Sales and Business Development Manager Matt O’Sullivan to learn more.

The distinguishing feature of Tideman Boats US is summed up by four letters, HDPE: the company fabricates hulls in this durable, lightweight, high-density polyethylene material.

Sales and Business Development Manager Matt O’Sullivan extolled the virtues of working with HDPE: “The material has been used in boat building for decades. It’s very sound for welding and is sledgehammer – impact tough. It’s in a class of its own.”

HDPE means low maintenance, no bottom paint, less dense than water and virtually indestructible.

Bruno Tideman, founder of the Dutch company Tideman Boats BV, discovered the use of HDPE while working as an aluminium boat builder. For years, he tested it out, proved it and never looked back.

Bruno explored bringing Tideman to the North American market in early 2021. By February 2022, after forming a joint venture with Yacht Eco, LLC, an innovative partner, and United Plastic Fabricating (UPF), a thermoplastic fabrication company with over 35 years in the industry, Tideman Boats US was born.

“A perfect match bringing UPF and Tideman Boats BV together to form Tideman Boats US,” Mr O’Sullivan reflected. “It’s been excellent partnering with Bruno and his experience, bringing the pioneering legacy built in Europe onwards into North America. Equally important is the strategic investment and plastic fabrication expertise UPF brings to the table, as the majority owner of the Tideman Boats US joint venture and the sole supplier of the Tideman hulls.”

One key element separating Tideman Boats US from its Dutch roots is that this operation focuses specifically on the fabrication of bare hulls. This means the

“THE PRODUCTION OF HDPE USES 1/5 OF THE CARBON FOOTPRINT THAT ALUMINIUM DOES.

IT’S ALSO 100 PERCENT RECYCLABLE: NO WASTE ”

com pany partners directly with boat builders all over North America, from its two fabrication facilities in Wisconsin and Florida. Tideman hulls are manufactured in UPF’s facilities, by leading experts in thermoplastic design and fabrication.

“We are part of the supply chain,” Mr O’Sullivan explained. “So instead of being the boat builder, we are supplying a part of the boat, the bare hull. The boat builders take our HDPE hull and perform the vessel outfitting, the aluminium work, rig propulsion, marine electronics et cetera, then deliver the boats to their customers. Most often an HDPE hull with aluminium outfitting above deck: the best of both worlds.

“We chose not to compete against the existing boat builders, but rather to partner alongside, offering aluminium and fiberglass boat builders a Tideman HDPE hull to work with and supply their customer’s demand.”

When it comes to partners,

Mr O’Sullivan acknowledged a few including Metal Shark in Louisiana, Waypoint Marine in Massachusetts and LMM Boats in Washington State. He also referenced partners in Florida, North Carolina and Canada as part of the expanding network.

“We want boat builders to order our hull like they would a Yamaha or Mercury outboard,” he continued. “We’re part of the

supply chain and deliver hulls fast. Our own supply chain and labour is both simple and has depth. We use Rochling HPDE and have over 100 welders on staff.

Bruno Tideman’s vision was to build a safe and robust work boat that would last. So the company’s signature vessel, the RBB (Rigid Buoyancy Boat) is built for exactly that.

“The Tideman RBB hulls are designed for utility and performance on the water,” explained Mr O’Sullivan. “The material itself is less dense than water (it floats) and exhibits zero corrosion, coupled with

versatile aluminium outfitting above deck, creating an outstanding vessel overall.

Additionally, the environmental sustainability of HDPE is a significant selling point for the future. According to Mr O’Sullivan, the production of HDPE uses 1/5 of the carbon footprint that aluminium does: “It’s also 100 percent recyclable: no waste. ”

Tideman Boats US is in a good position to provide the material and labour for hulls in North America. The company delivered its first RBB 700 hull for a boat that went to Hawaii last year. Another RBC 900 hull went to a workboat delivered to California. There were a handful of other RBB hull sales last year, as well as building a few custom marine vessels, including a project completed for General Dynamics.

“Partnering with Metal Shark has been very significant for us,” said Mr O’Sullivan. “They are one of the best boat builders in the world. We’re excited to recognise the synergy. The best workboats and patrol boats in the future will combine aluminium and HDPE, once customers in North American understand the benefits.”

Going forward, the company is overcoming obstacles and offering its innovative HDPE materials to the wider market.

“One challenge is getting the material widely recognised,” said Mr O’Sullivan. “People are beginning to understand that it works, is safe and reliable. We have so much interest in this product, and everybody recognises how cool and innovative it is.

But it’s also new to North America. We are about 10 years behind Europe on this front.

Part of the company’s quest for wider recognition will come from classification by regulatory bodies. Mr O’Sullivan highlighted the United States Coast Guard and the American Bureau of Shipping (ABS) as entities that can help bring HDPE to the mainstream. “DNV in Europe now recognises HDPE, having put it into their small craft rules in 2022,” he said. “We need more support in the US to recognise HDPE as a viable and safe material for hull building, and to have HDPE take its seat at the table with steel, aluminium, and fiberglass.”

The other exciting development around the corner for this innovative and everevolving company is that Tideman Boats US will soon be called Tideman Marine.

“This is something we’re all excited about,” revealed Mr O’Sullivan. “It focuses on the fact that Tideman builds hulls in North America: our RBB bare hulls, custom hulls and vessels, and other innovative marine components as the industry grows.”

There is no doubt that Mr O’Sullivan is highly passionate about the HDPE hull technology and the strategic growth opportunity, and he has the industry experience to back it up.

“It's a privilege to build on Bruno’s legacy in Europe here in North America,” he concluded. “It’s remarkable to consider what is happening within the industry. The innovation of utilising HDPE f or marine vessels, the simplicity of it, the way we can utilise this material and wha t it brings to the industry is truly gamechanging. These are boats that don't dent. They don't need bottom paint. They perform incredibly on the water, resisting impact, lowering fatigue. It's a revolution of the industry. I am pleased to be a part of that.”

n

Rem Offshore is a new company with older roots. Since beginning operations in 1978 in service of the Norwegian fishing industry, the fleet today provides offshore support vessels worldwide, with a main office in Fosnavåg, on the west coast of Norway. Ronny Pål Kvalsvik, CCO, explained to Hannah Barnett more about what the company does.

Rem Offshore prides itself in being a pioneer in several different offshore markets, while continuing to build its presence throughout the industry.

The company’s fleet is built up with well-known designs bought on the market. With a new build recently added and another due next year, Rem Offshore is expanding to include high-specification vessels fitted with cutting-edge technical capabilities.

Strong partnerships 2023 has already been a good year for Rem Offshore. It has signed contracts for several PSVs, established on market terms. This ensures that the company will

maintain high fleet utilisation during the next year.

These include contracts for Rem Cetus and Rem Insula, which were extended for one year with Apache North Sea Limited in the UK sector, and the company values this continuing relationship.

“We have been working with Apache for a while,” Ronny Pål Kvalsvik, CCO, said. “The contract extensions show trust in our organisation and satisfaction with the performance of our vessels. We have had several contracts with the company and this is one of our key customers in the UK market.”

At the same time, Rem Arctic has been awarded contracts with Well Expertise (DNO Norge ASA and Wellesley Petroleum AS) supporting Deepsea Yantai and Neptune Energy. Rem Commander has been awarded a 14-well plug and abandonment contract with Spirit Energy North Sea Oil Limited, which is estimated to last ten months.

It is clear that Rem Offshore is reaping the benefits of multiple closely forged ties with its partnership network. “It’s aways good when you have a track record working

with a customer,” reflected Mr Kvalsvik. “To ensure longevity, you need to establish a good relationship and agree on what you need to deliver. That is very important. And that is why the majority of our clients come back to us.”

One of the jewels in the Rem Offshore crown is Rem Energy, a CSOV offshore supply ship built in 2021 to sail under the Norwegian flag.

Rem Offshore has a five-year contract with Siemens Gamesa and Rem Energy has proved a vital element in the evolution towards working in renewables.