IN2006, three budding engineers set out on a quest to evaluate the commercial viability of wave energy.

“Martin and Kristian had worked together on other projects, and they were inspired to develop a system that would have positive impact on the planet,” said CEO Michael Henriksen. “They decided wave energy had a very large, unexploited potential. I came onboard in 2013 after they have worked out of the garage in parallel with their day jobs for the first years to prove the Wavepiston concept they had developed.”

Wavepiston was officially founded in 2014. An intensive period of fund raising started, for both equity and public cofunding, and then finally in February 2015 after years of bootstrapping the first salary could be paid. From there, the company implemented stringent development and testing on its system.

“Wave power is a large, unexploited renewable energy source,” Mr Henriksen explained. “There have been several companies that have tried and failed in the past, but we feel now, with the transition

Over the last 18 years, the experts b have been working tirelessly to mar as a competitive option in the race Now, with its first full-size demonstra well underway, the company is gear commercialisation. CEO Michael Hen explained more, in an exclusive inter Inside Sustainability. Report by Imog

to greener energies, it is the perfect time to bring this technology to market.

“Experts say the theoretical potential of wave energy equates to the entire world’s current electricity consumption. To play our part in developing this segment, we are following three tracks for development: technology, projects, and testing and demonstration.”

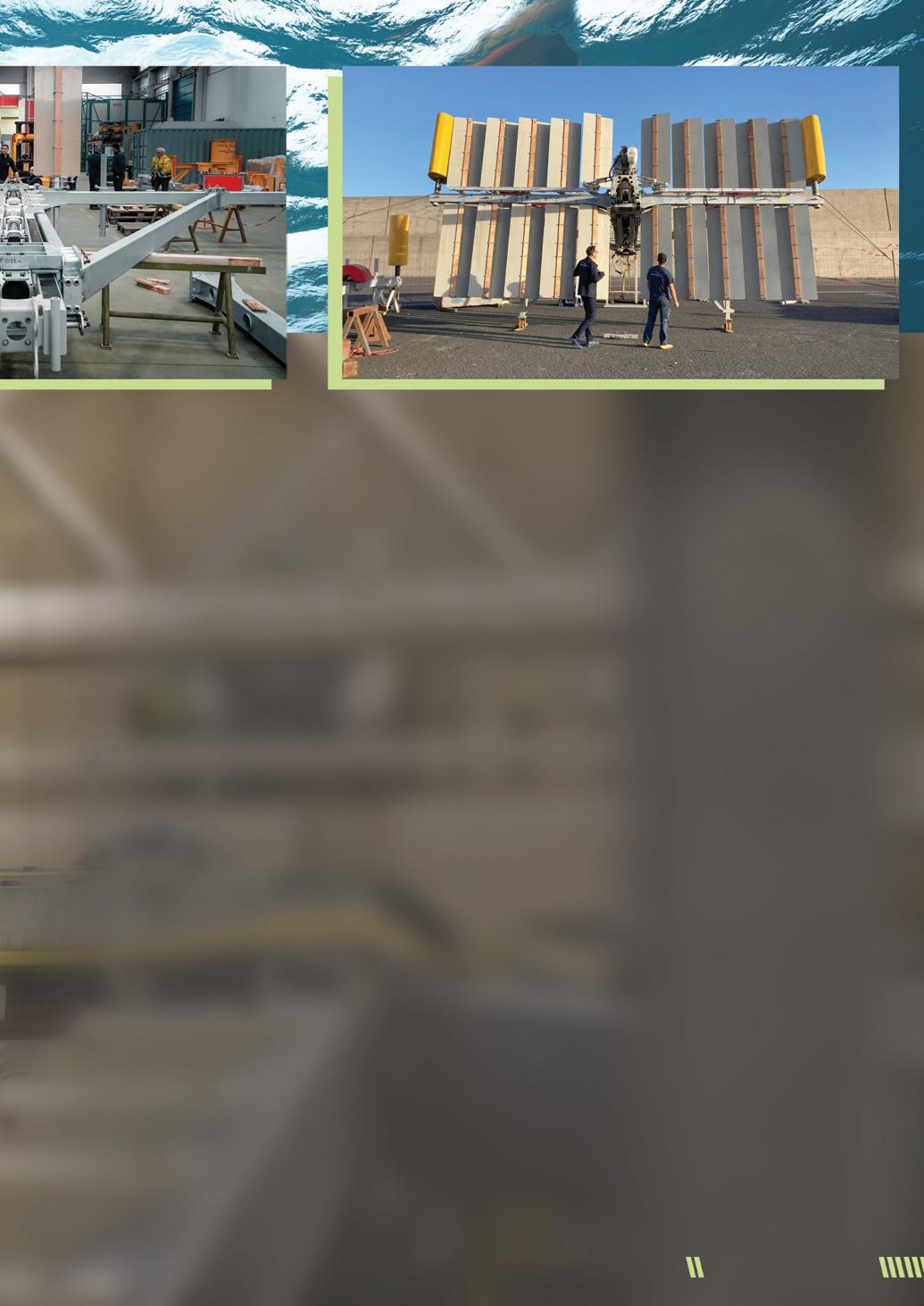

The Wavepiston system consists of a series of non-intrusive energy collectors attached to the Wavepiston WEC (the supporting line). These collectors are perfectly positioned to use the oscillating horizontal motion of waves and the subsequent mechanical energy to create a palpable source of usable energy.

Demonstrating effectiveness

Having previously run several small-scale trials, Wavepiston elected to run a fullscale demonstration project at the PLOCAN test site, Gran Canaria, to test the effectiveness of its system for power generation and seawater desalination.

ehind Wavepiston rket wave energy to greener energy. ation project ring up for nriksen rview with gen Ward.

The Competitive Wave Energy on Islands (CWEI) project consists of a supporting line of up to 20 energy collectors and a turbine generator. All going to plan, this project could be a critical step towards providing isolated islands with a consistent supply of clean power and water, with CWEI expected to produce 547,000kWh per year.

“Before we start offering this technology on a global scale, we really want to focus our efforts on creating a positive impact locally, by reducing energy prices and ensuring access to clean water.”

Mr Henriksen explained. “At the same time, we seek to protect these islands from the volatility of energy prices –taking fossil fuels out of the equation.”

With the first energy collector having been tested in the water and six more to come, Wavepiston intends to run data collection throughout 2024, before implementing any system upgrades in 2025 and 2026.

“The results we get from 2024 will be a really good indicator for what improvements we need to make, before we take the system commercial in 2027,” said Mr Henriksen. “The results so far have been positive and have really helped us to understand the dos and don’ts of installation and data collection.”

The road to commercialisation

To successfully market the Wavepiston system as a commercially viable product, several changes need to be implemented to make it cheaper, lighter and more robust. Currently, the system’s wave energy collectors are the most expensive element of the build. To overcome this cost, Wavepiston is running a project on Composites, Hybrid Testing, and Simulations for a Disruptive Wave Energy Collector (COHSI-WEC).

This project, which was awarded a grant of DKK15.6 million from the Energy Technology Development and Demonstration Programme (EUDP), will see Wavepiston replace key steel components with lighter fibre-reinforced polymer alternatives. If successful, these new components will make production costs much lower, making scalability a more likely scenario.

“To successfully meet our 2027 commercialisation target, we are currently implementing a project in collaboration with DTU and Aalborg University, focused on adapting our energy collectors,” said Mr Henriksen. “We developed our protypes using steel components, which worked well to demonstrate the technology, but it is not an ideal material for the final product.

“We started developing the new polymer components last year, and they are now going through wave tank testing. The completed energy collectors should be ready for full-scale offshore testing next year.”

Developing partnerships

Wavepiston is also running a second project in parallel to COHSI-WEC, which will help advance the system’s journey to commercialisation. The SHY project is set to advance wave energy through the development of key components for a seawater hydraulic power-take-off system. The company will also establish an advanced control strategy at the same time to help reduce energy costs and minimise environmental impacts.

This project has just received €4 million in funding from Horizon Europe and is supported by partners Maynooth University,

DTU, FibronPipe GesmbH, LESER GmbH & Co Kg, Julia F. Chozas, Applied Renewables Research, Marine Systems Modelling, and Plataforma Oceánica de Canarias.

Whilst these projects are underway, Wavepiston is also focused on several other pursuits to progress to the next stage of commercialisation.

“We are also placing the foundations for future project development, by establishing collaboration agreements with project developers and partners,” said Mr Henriksen. “We must do this in parallel with our current projects because there is no time to just sit and wait. Project development, permissions and agreements can take up to five years to implement.”

None of Wavepiston’s work would be possible without the help of key suppliers and partners. The industry innovator is grateful for the contribution of every single company, including mooring expert Delmar, which has been a prominent player in ensuring the mooring of the Wavepiston system.

Another key partner for Wavepiston has been TCDL Steel; it has been involved since 2021.

TCDL Steel is also a trusted supplier of components to the Wavepiston wave energy system and an important partner in giving input to the optimisation of its piping system. TCDL Steel has supplied the drill-pipes and the specialised subs that are the backbone of the Wavepiston Wave Energy Converter string. They are a highly professional supplier and deliver high-quality items at a competitive price.

Wavepiston has also enjoyed creating new relationships, especially when it comes to the SHY project, where is has been able to work alongside Austrian safety valve manufacturer LESER for the first time.

“We also recently collaborated with major energy conglomerate Shell,”

Mr Henriksen explained. “The company was interested in witnessing the potential of wave energy.

“Wave energy is beginning to garner the attention of these larger players, and it is an area of the market that could become very interesting in the mid- to long-term.”

As Mr Henriksen looked to the future, he made it clear that the road ahead was not going to be smooth: “Although there is an increasing amount of investment going into wave energy, there is still push back.

If we stay on the track for renewables, we will get there, but the sector requires significant support to successfully commercialise these different technologies.

Advancement doesn’t just happen by itself; it requires a lot of active involvement and funding before it can go global.

“I love being a part of a company that is having such a positive impact on small communities, and I can’t wait to witness this evolve into a global enterprise that has a major impact everywhere.” n