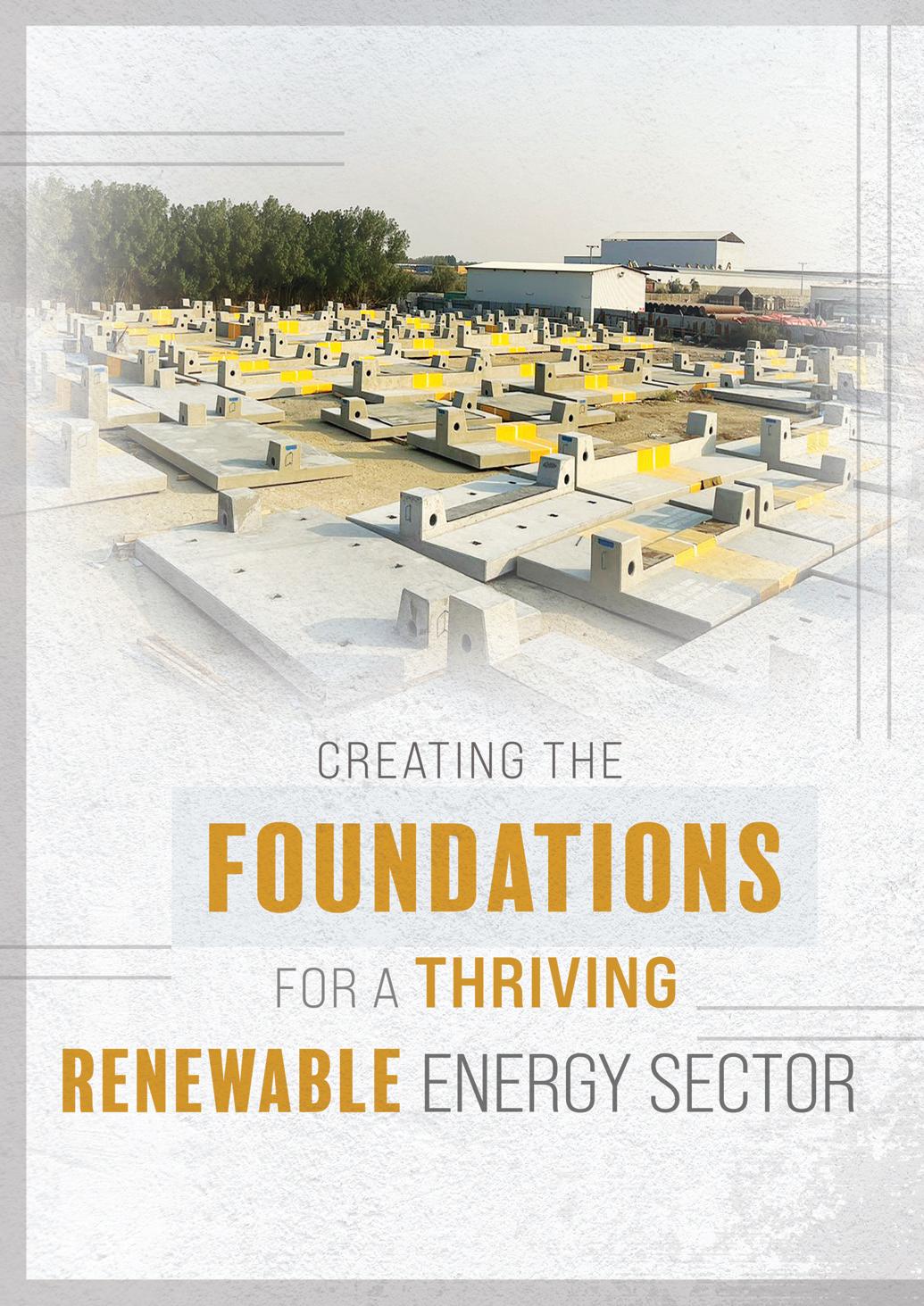

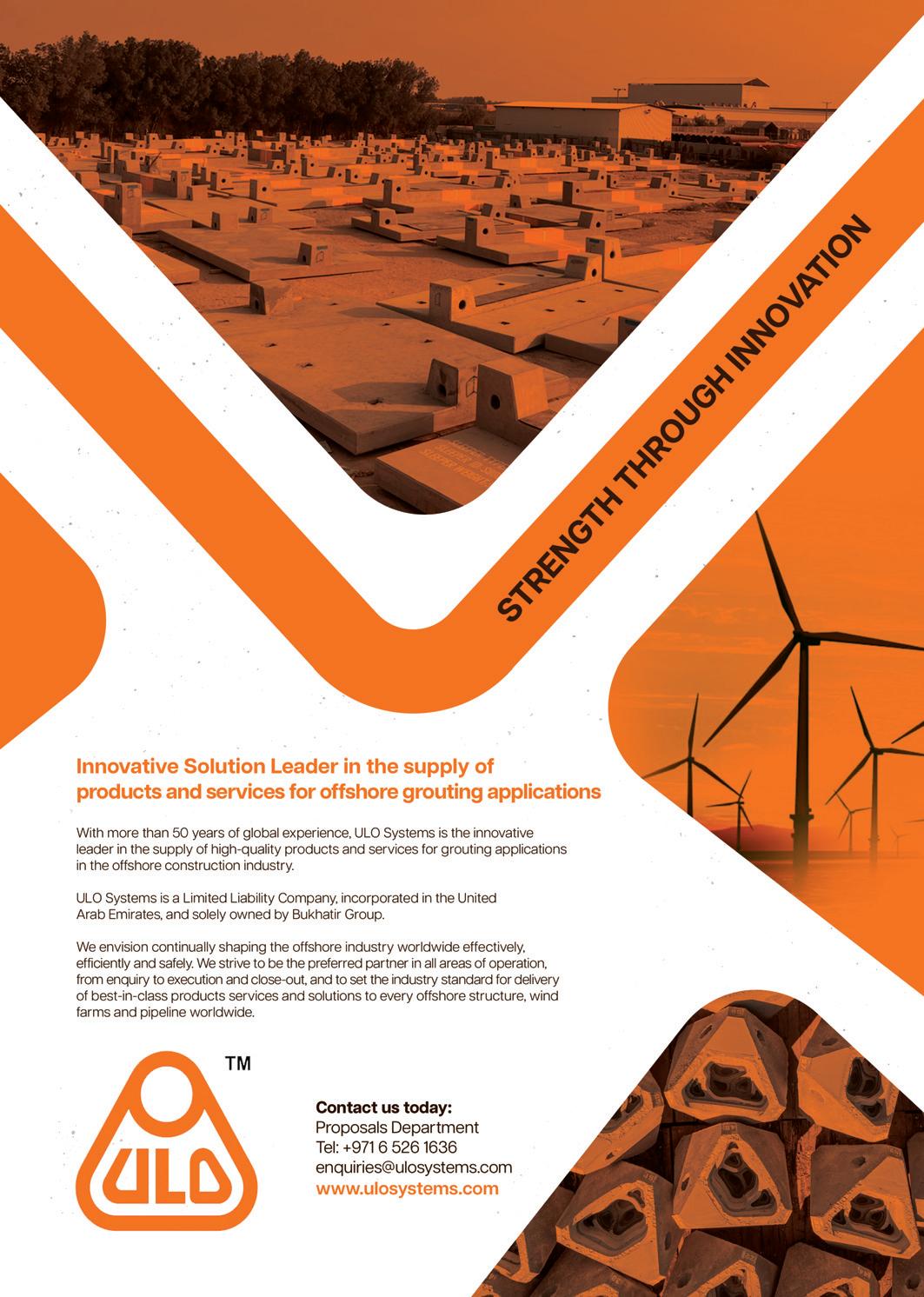

ULO Systems, an innovative solution leader with over 50 years of experience, initially provided foundation grouting solutions to the offshore oil and gas sector, and is now rapidly pivoting to supply renewable energy clients. ULO Systems has a comprehensive range of offshore grouting solutions for every possible foundation type as well as fabric formwork, flexible interlocking concrete mattresses and reinforced precast concrete crossing supports, in addition to a wide range of products and services to serve various oil, gas and renewable energy offshore operations.

The UAE-based ULO Systems can count itself as being in the right place at the right time with the right solutions, as demand for sustainable renewable energy sparks an uptick in the need for more offshore wind farms. Throughout construction, operations and maintenance, the extreme and hazardous environmental conditions and operating parameters are constant issues faced by the industry.

Having been a mainstay of the offshore energy sector for 50-plus years, ULO is

exploring new frontiers and securing projects as it becomes a pivotal player in fast, efficient, safe grouting of wind farm foundations. Its professional, bestin-class proprietary grouting equipment and DNV-approved operational methods are proving highly transitional.

“Since 2022, we have returned to pre-Covid levels of business in the windfarm and oil and gas sectors,” said General Manager Gregory Sauvage.

“Traditional energy is also seeing greater investment in expanding existing

installa tions and new fields in Qatar, UAE and Saudi Arabia.”

However, with the offshore wind market capacity expected to reach 600 gigawatts, fifteen-fold its current market, ULO is harnessing the expansion potential from Asia to Europe and the Americas.

“Offshore windfarm projects now account for 40 per cent of ULO’s income stream, compared to 20 per cent two years ago,” Mr Sauvage said. “It is a marke t that will only get bigger as more projects

come to the fore. We are also keeping pace with R&D and investment in more innovative equipment as we anticipate the growth in bulk grouting.”

Quicker turnarounds

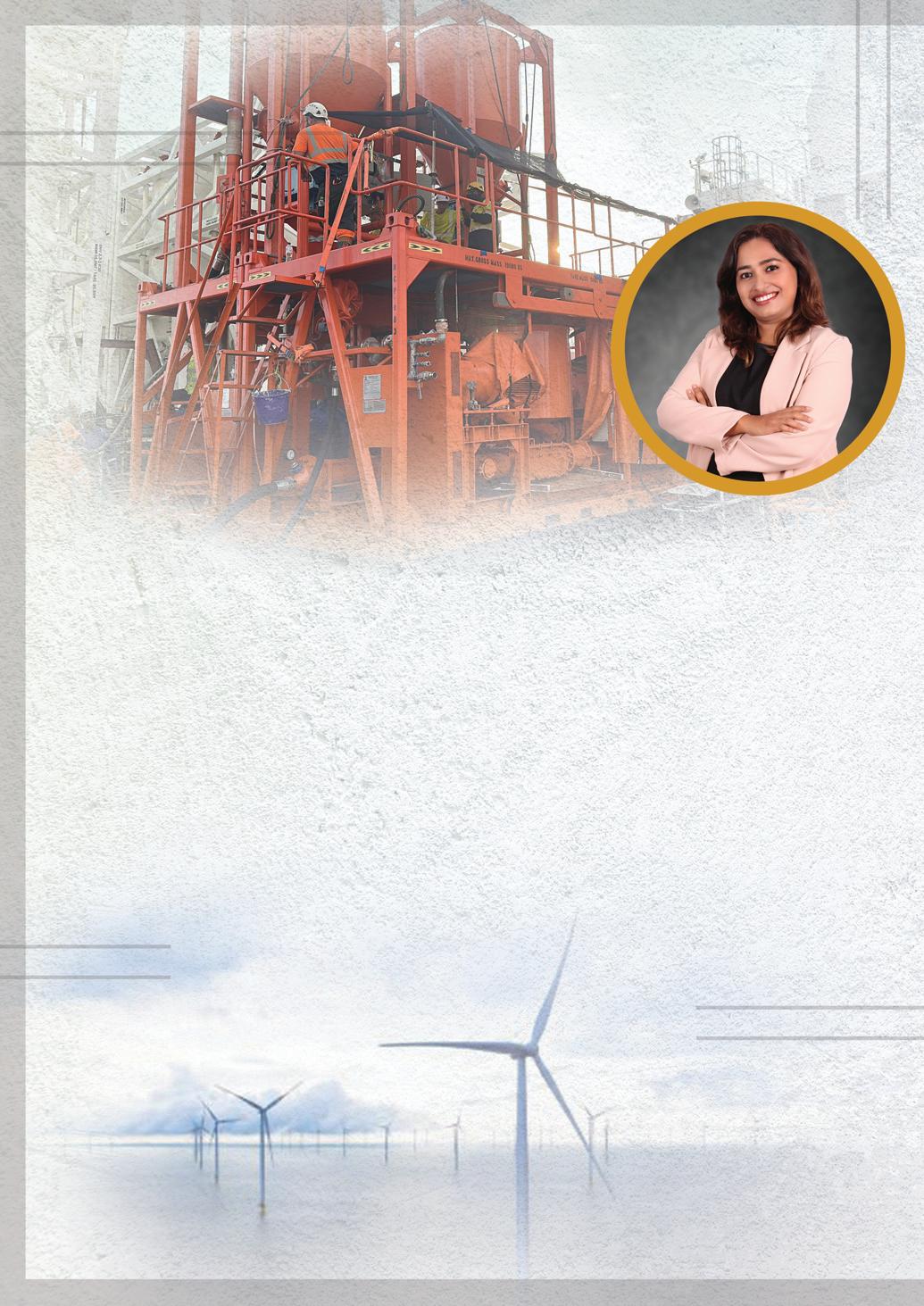

In 2020, ULO worked on a 950-megawatt offshore wind farm at Moray, East Scotland, grouting 103 substructures over six months. The project featured ULO’s new-generation recirculating jet mixer (RJM) and high-capacity pump to

significantly reduce grouting time. The RJM can enable grouting five times faster than traditional mixers and has a capacity of up to 120 cubic metres an hour for standard OPC.

ULO unveiled a new and even more compact RJM1 unit in 2023 which has been put into operation on several projects, including its first offshore wind contracts in Taiwan. “One of our recent projects in Taiwan involved the grouting of 52 jacket foundations,” Zena Zeyad, Head of Project, said. “This was realised within a challenging timeframe of 103 days, signifying an overall

impressive rate of one jacket installation every two days. Our team’s resilience and adaptability enabled it to navigate several challenges and ensure the project’s successful execution.”

The installation compared favourably with recent European projects, where large-scale projects were installed at a rate of 1.75 days per jacket, according to Mr Sauvage: “We achieved our targets in Taiwan despite harsh wind, typhoons and other challenges. Reaching these remarkable sequences and offshore output has never been seen in Taiwan

and will assist in accelerating offshore wind farms deployment.

“It clearly validated how development in new equipment and teamwork at all levels help our clients deploy their offshore wind installation faster, save costs and deliver on target. It was a great achievement for the ULO team and further demonstrated the effectiveness of our RJM concept.”

Such impressive results, Mr Sauvage explained, had helped secure a string of other RJM1 bookings and another set of contracts in Taiwan.

Sustainability focus

Since 2012, Abu Dhabi has been home to the International Renewable Agency (IRENA), and the UAE has become a pivotal player in the growing renewable energy segment. ULO Systems has taken the lead in sustainably focused solutions.

“ULO’s strong commitment to sustainability objectives is being achieved through a two-pronged approach: on raw materials and process change.” Rilsa Raphael, ULO’s QHSE Manager responsible for environmental factors, said.

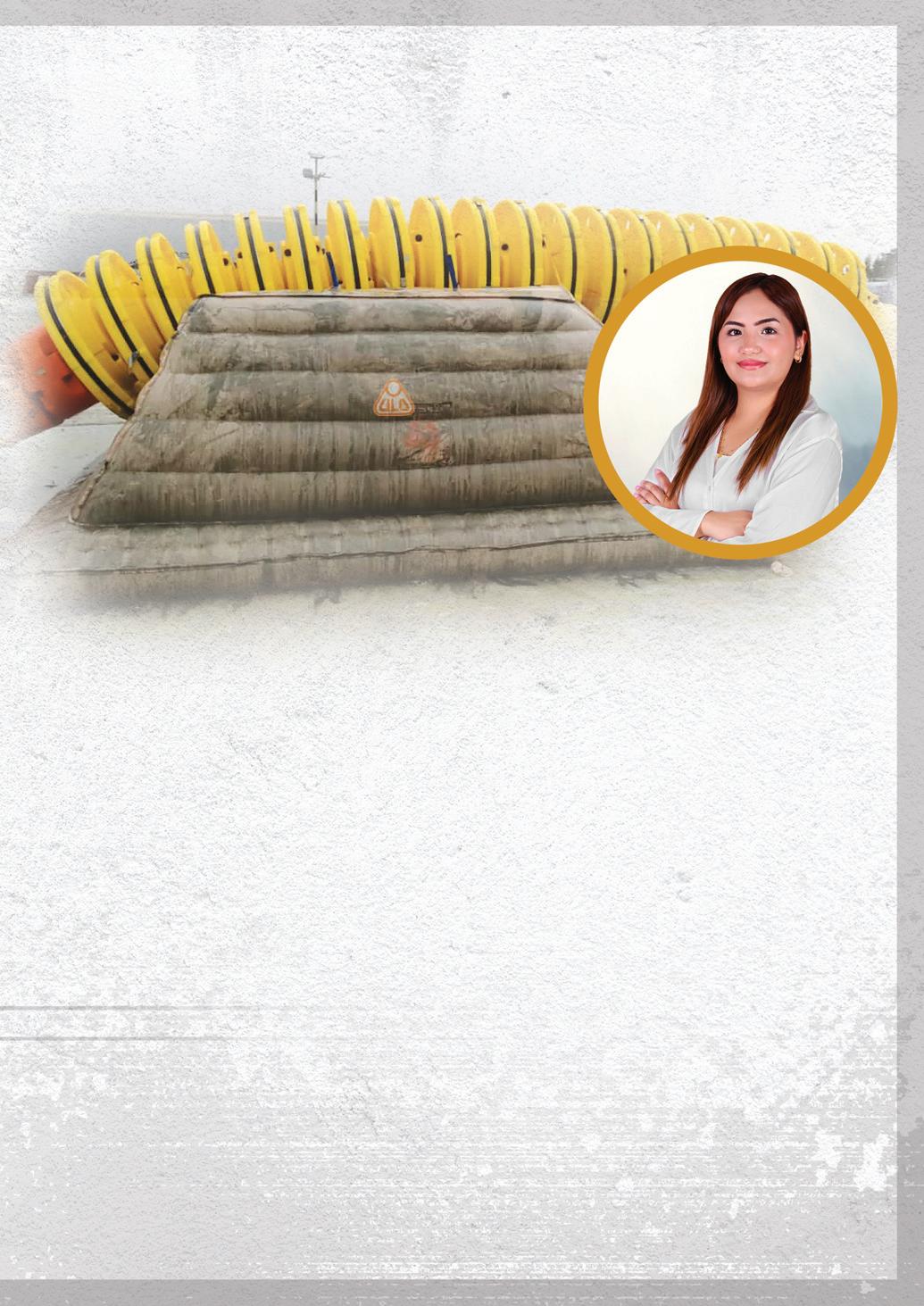

The company has invested in sustainable raw materials; seeking alternatives to the plastic traditionally used in its fabric formwork. “We are actively working on fabric formwork made from natural fibre,” Ms Raphael continued. “This will, in turn, address environmental concerns and meet client demands for eco-friendly solutions to minimise plastic-based waste in the oceans.”

The fabric formwork is an effective sub-sea solution that helps stabilise pipelines and rectify free-standing ones. This formwork displaces water and excess fluids during the curing phase, allowing the formwork to develop and maintain its full strength and shape, providing long-term support in every application.

Amongst other materials initiatives, its sustainable approach led to collaboration between ULO and ECOncrete in exploring the adoption of its marine concrete technology to replace traditional concrete used in its current concrete mattresses.

“This transition will not only contribute to thriving marine life but also accelerate the growth of marine ecosystems and align with our commitment to environmental preservation,” said Ms Raphael.

“Essentially, the mattress will be a living, thriving ecosystem for marine life.”

Addressing its processes, she high-lighted how the company was transitioning to a moulded system for its concrete mattresses: “Previously, we used recycled plastic shelves to encase concrete mattresses that remain in the system for its entirety.

“We plan to adopt a new approach to de-mould the recycled plastic shelves. This means making more concrete mattresses by significantly reducing the consumption of plastic. In the long run, we will significantly reduce the plastic and our carbon emissions.”

Embracing change

ULO Systems employs 80 people, with a pool of 120 offshore personnel to meet peak season work demands. It has a yard in Hamriyah Free Zone, near Sharjah, in Dammam in the KSA and maintenance logistics facilities in Singapore, the Netherlands, and in the US.

It receives exceptional support from its parent company, Bukhatir Group, one of the UAE’s largest and most diversified business houses, with interests spanning from North

America to North Africa and South Asia. ULO Systems is setting up new business in Saudi Arabia as major offshore works are coming from Saudi Aramco.

“We are developing different services, and Saudi Arabia is fast expanding in all our markets,” said Mr Sauvage. “The energy industry is also investing heavily and growing in Europe, Asia and the US. Globally, the market is strong, and ULO Systems is handily placed to continue driving forward. We continuously invest in our equipment and evaluate our products and processes to be more carbon efficient and minimise plastic usage.

“We adopt a visionary approach to anticipate customers’ requirements and challenge our processes to be cost-effective. It is about finding a perfect balance, keeping pace and our eyes wide-open.

“Our suppliers’ achievements are critical to us, and we maintain a transparent and collaborative approach, while clients expect us to be deadline driven, with zero mistakes,” he concluded. “Our DNA is to be flexible: we never say ‘no’ to customers’ challenges and always bring solutions to the table. We learn from every project and take those experiences into the next one to ensure ULO Systems is always improving.” n