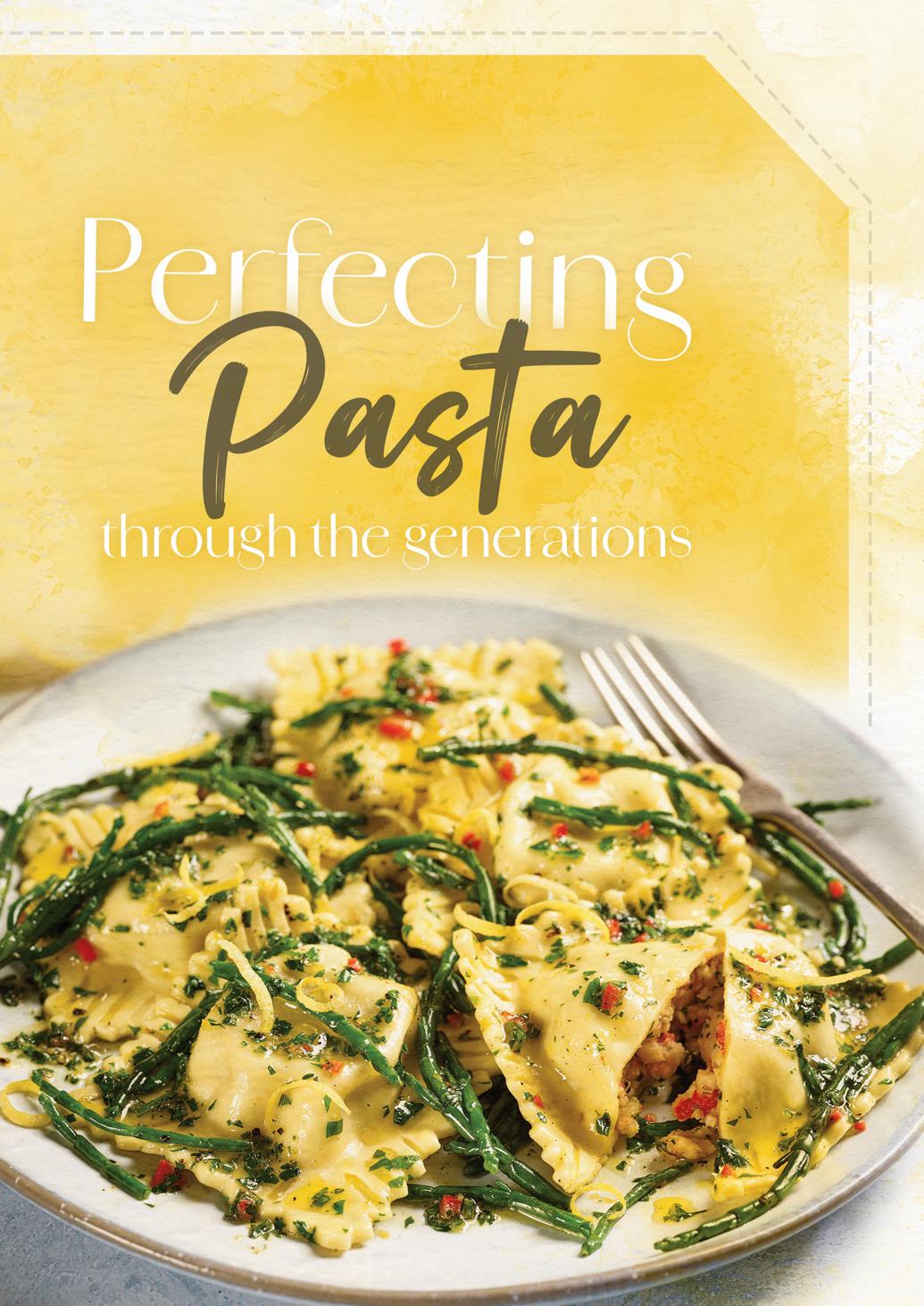

Ugo Foods Group is a fourth-generation family business which prides itself on innovation and never compromising on quality. Hannah Barnett spoke to Charlie Ugo, Group Operations Director, and his brother Freddie, Head of Corporate Social Responsibility, to learn what makes this forward-thinking family firm tick.

There are businesses run by families and then there are family businesses.

Ugo Foods Group is the latter. A large measure of its enduring success is down to the company’s strong commitment to moral values and innovation, as passed down from its original founder.

“It’s not just about producing highquality food, we want to make a better impact on the planet,” said Head of Corporate Social Responsibility, Freddie Ugo. “That’s our philosophy. A lot of that comes from being a family business. It started with our great-grandad. He passed it down to our grandad, Leo, who passed it down to our father, Paul, who still works here as Chairman. And then there’s me and Charlie.”

Innovators from the start

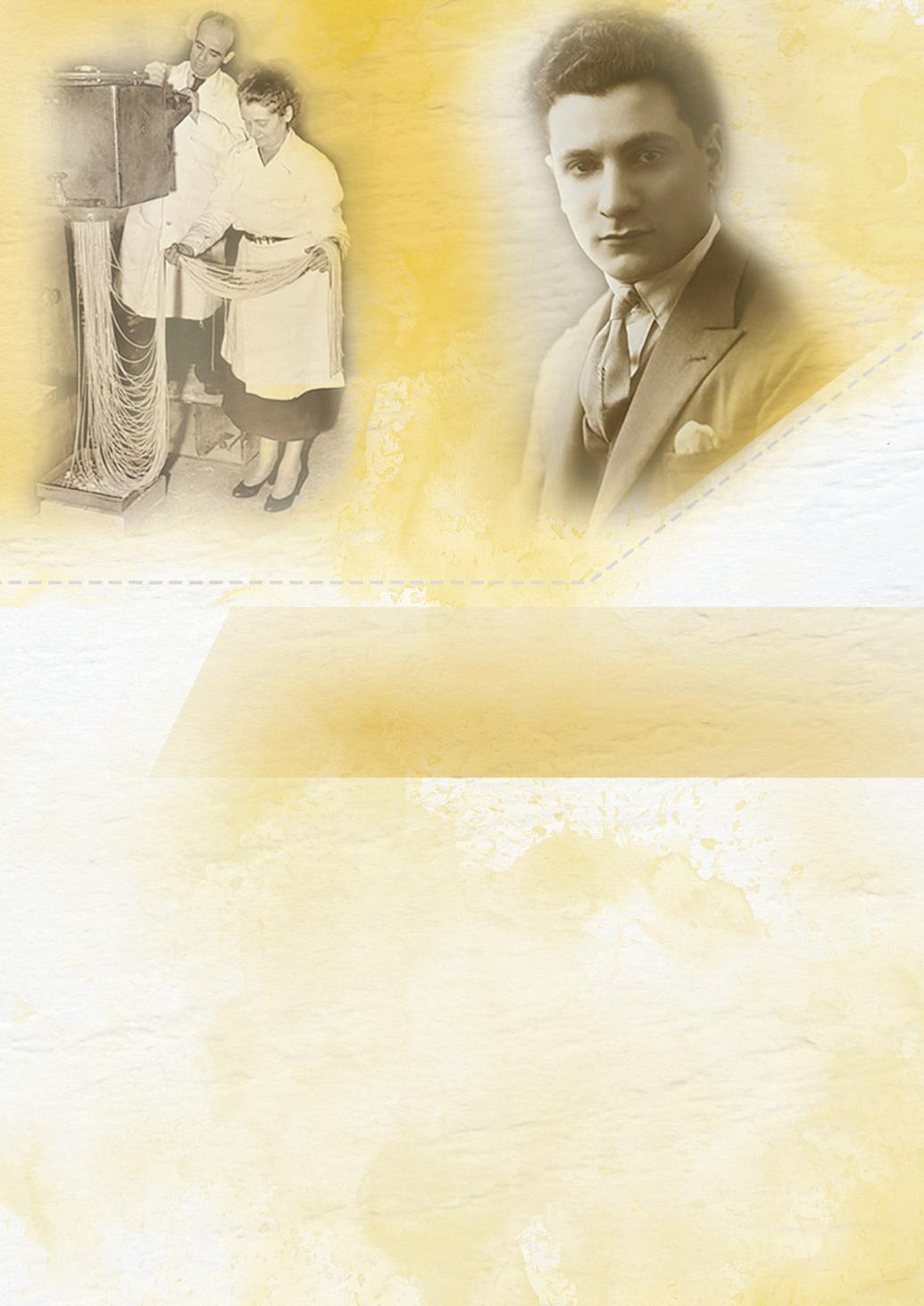

Ugo Foods Group is infused with the values and vision of its founder, Luigi Ugo He emigrated to the UK from Italy in the

early 1920’s and began selling paper bags of homemade pasta, not a wellknown product in the country at the time.

In 1929, Luigi opened his first delicatessen on Gerrard Street, Soho, and began making fresh pasta in the window of his shop. Another man, who was trying – and failing –to source noodles for a Chinese restaurant, spotted this activity.

“Nobody was making noodles in the UK at the time,” Group Operations Director Charlie Ugo explained. “This man eventually ended up teaching my great grandfather how to make noodles and opened his Chinese restaurant next door. Gerrard Street is now the centre of Chinatown. So, we’re quite proud of our part in that history.”

As a result, Ugo Foods Group spent much o f the interwar period producing Chinese cuisine. There was a fundamental shift in focus following the Second World War, and the company began manufacturing dried and fresh pasta once more, supplying

high-quality shops like Selfridges, John Lewis and Harrods. Innovation and new cuisines fit for the UK palate followed in abundance.

“We brought gnocchi to the UK and developed the first gnocchi machine using fresh potatoes rather than dried,” said Charlie Ugo. “We also produced organic and wholewheat pasta for the first time in the UK in the ‘60s. We even created a gluten free solution in the early ‘90s. A lot of the period from the ‘60s onwards was about innovation and how we could create a bespoke, unique product offering for the UK. We started experimenting with lots of different fillings and flavour profiles.”

Ugo Foods Group now produces 500 million parcels of pasta a year from its HQ in Hertfordshire, accumulating a turnover of £25 million.

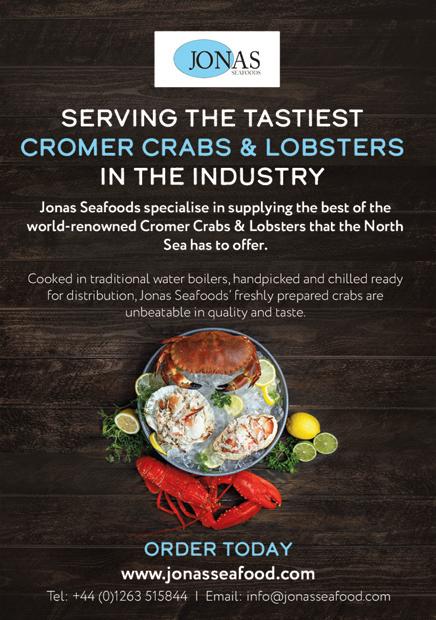

The company continues to innovate and its Cromer Crab and Crayfish raviolo

As seen on TV

Ugo Foods Group recently appeared on BBC TWO’s Inside the Factory. In the episode, Charlie Ugo showed Gregg Wallace an innovative machinery process that makes the company’s popular Cromer Crab and Crayfish raviolo so delicious, while Cherry Healey took a trip to Norfolk to meet the ingredients suppliers.

recently won a Gold Q Award; the ultimate accolade, bestowed on products which are truly outstanding.

Ugo Foods Group remains committed to using the highest quality ingredients in innovative ways, like a semolina-blend flour base for pasta dough.

“The semolina has a large grain size, is very yellow and high in protein, which allows us to create quite a unique dough,” explained Charlie Ugo. “This means we can reduce our egg content versus competitors, lowering our carbon footprint, while still having the texture and flavour expected.”

Socially aware sustainability

As a conscientious company run on family values, it is no surprise that Ugo Foods Group is keen to minimise both its environmental and social impact.

“Something that sets us apart is that we have a lot of charitable commitments that actually make a direct impact,” said Freddie Ugo. “We don’t just give a pot of money and say: ‘go ahead and use it,’ we like to be involved.”

This includes a partnership with the European Nature Trust, helping to preserve wildlife and ecosystems in Italy. A local hospice, Keech, for terminally ill

children, is supported with fundraising initiatives and by inviting residents to the factory to learn pasta making.

On the environmental side, Ugo Foods Group has almost eliminated scope 1 and 2 emissions by moving to renewable energy sources and replacing refrigerants. The company has also developed a semi-bespoke system for its triple-layered boiler to significantly increase efficiency and reuse waste heat as part of a reclamation system.

“We’re directly involved in the sustainable measures we go for,” Freddie Ugo explained. “We’re doing our due diligence, but we actually care about it. And that also comes across in the ingredients that we buy. There’s been multiple occasions where we’ve changed supplier because we realised there was either an ethical or an environmental issue with them .”

The company works closely with suppliers; sourcing ingredients as locally as possible and prioritising partners that are focused on carbon

reduction. In particular, Ugo Foods Group highlighted ethical flour millers, Wildfarmed.

A pint of pasta

Both Ugo brothers are particularly passionate about the eradication of waste where possible. As a result, company wastage has significantly reduced in recent years; but it cannot be entirely avoided due to vital quality control processes. Of course, Ugo Foods Group has multiple innovative solutions to mitigate this.

One partnership with a notable celebritychef-turned-farmer, involves feeding pigs uncontaminated scraps, thereby reducing food waste and the emissions usually derived from animal feed. Though successful it is not a consistently reliable solution to excess waste, due to variation in demand.

The next step involved even more innovation, when the novel idea of brewing beer from pasta was raised.

“We didn’t know whether it was even possible,” said Charlie Ugo. “We did

some early-stage trials with pots and pans in the kitchen to see if we could create fermentable sugars. This took maybe a year and a half to advance to a point where we had a good quality product. We have since patented that process throughout Europe and the UK, and we’ve launched applications globally.”

And with that, Beyond Belief Brewing Co. was born. The process involves using surplus fresh pasta as a base malt replacement, saving 2/3 of a litre of water and over 110 grams of CO 2 for every pint.

After nearly a century of innovation, Ugo Foods Group is not the kind of business to rest on its laurels. The company recently introduced fully recyclable packaging, investing hundreds of thousands into

converting its machines as a response to feedback from customers.

And there is plenty more to be done, according to Freddie Ugo: “We’re in the process of getting B Corp status. We’re signing up to the Science Based Targets Initiative to set a verifiable carbon emission reduction goal. We’re working with various consultancies to do lifecycle assessments of different products. Carbon accounting is a very collaborative thing, and we are trying to make it more accessible to smaller producers.”

This scope of innovation, as always, extends to the products themselves too.

“We are trying to do what we have always done: bring new things to the UK, just like our great-grandfather did,” Charlie Ugo concluded. “So, of course there is plenty coming up in the new product development pipeline.” n