A distinguished company within IC Holding, Treysan was established in 1975 in Ankara, Turkey. Treysan serves a range of industries – including the oil and gas, mining, construction, electrification and communication/control systems sectors – whilst also working with a number of military organizations and relief organizations by providing a wide range of products with customised special solutions. Jordan Yallop reports.

Pioneering prefabricated steel company Treysan produces quality products able to withstand many years in difficult conditions.

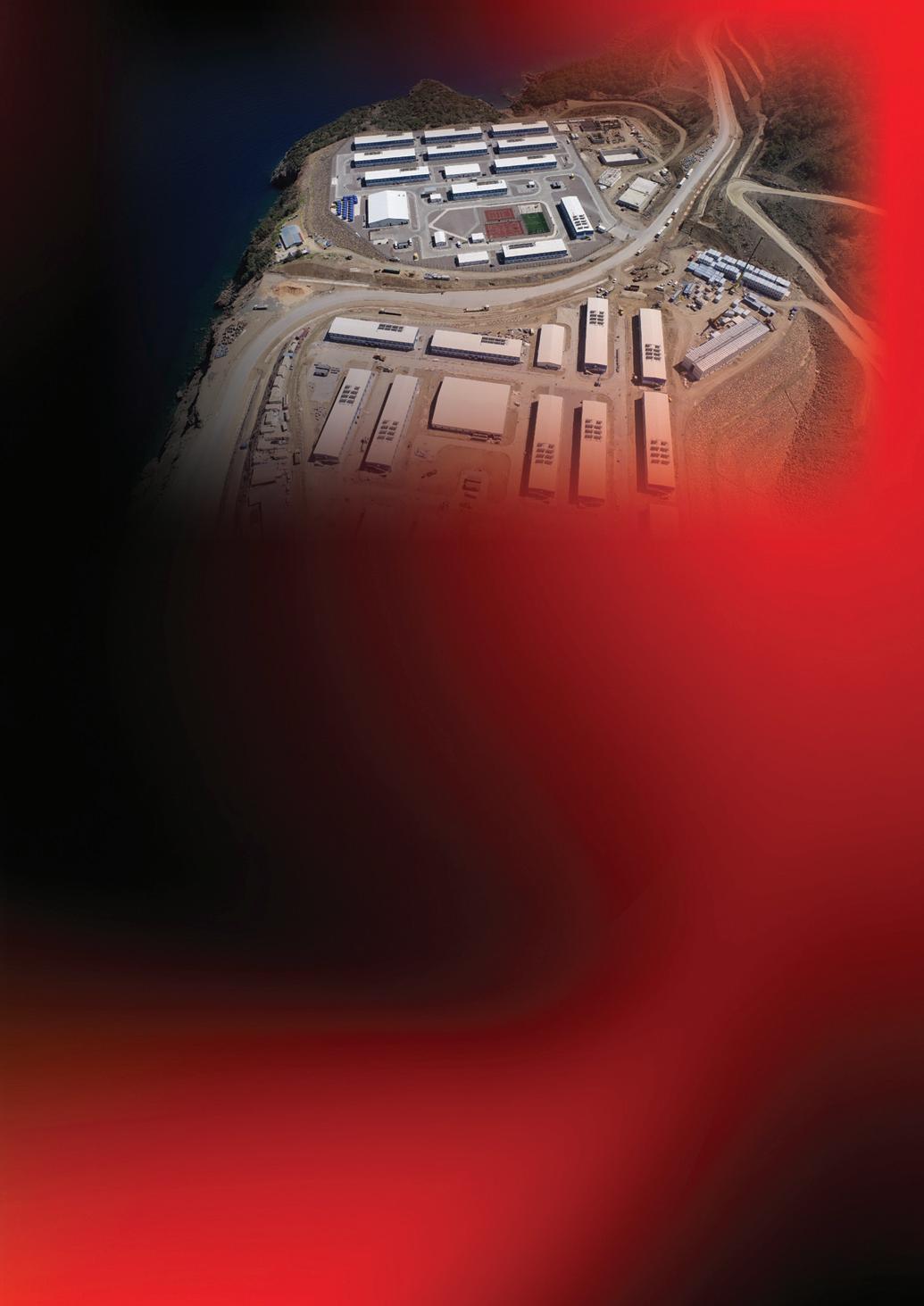

The Turkey-based business has built a reputation as solid as the products it builds. Be it mobilisation camp solutions, containerised units, prefabricated panelised system buildings, pre-engineered buildings, warehouse and workshops, Treysan’s customised design and supply approach continues to win the business many orders for other specialised builds too, including drilling camps, E-houses, substation containers, control rooms and LERs, secondary plant supports and permanent structures.

In addition to top quality products manufactured in its high-tech plant in Turkey, Treysan also provides services in design, engineering solutions, installation, after sales-service, logistics, furniture and equipment supply and commissioning to fulfil client expectations in every phase of its projects.

Treysan enjoys recognition among a number of the most reputable global brands and exports around 75% of its production to foreign markets. To date, the company’s strong global reach spans more than 80 countries, in five continents. The company says that it is deeply honoured by global offering and is motivated to continue pushing the limits as a global brand with high customer satisfaction and solution-oriented suggestions.

Treysan designs and supplies prefabricated and containerised solutions that meet all kinds of needs in different geographical regions at the same time.

Treysan’s head office in Turkey is complemented by a branch in Kazakhstan. In both locations, top quality production and customer satisfaction have been the main principles since the early days.

Senem Sirma, Business Developer said: “Treysan is one of the leading factories of its sector, consisting of 60,000 sqm with nine production halls that produce at international quality standards with its high technology machinery.”

For over 45 years, Treysan has been involved in many valuable projects and has constantly renewed itself. The company aims to serve clients’ interests right from the initial stages of project development to the final stages of product release. Through the local market, and extensive international experience, Treysan aims to offer top-notch products and service expertise to meet each client’s business targets and generate value for all involved.

Senem Sirma said: “Being a pre-approved supplier to most of the world’s leading EPC companies and our ability to develop projects pecific designs have made us a preferred brand in front of our competitors. The trust that our company gives to its customers with our factory, production capacity and financial strength is reinforced by IC Holding company behind it. Our flexibility to adapt to technical and commercial conditions for every geography and the satisfactory services we provide to our clients from the tender process to delivery always distinguish us from the competition.”

Treysan saves time thanks to its special panel production system. With its advanced production capabilities, Treysan designs and manufactures its special panel system buildings in accordance with international and local standards and makes them ready for use in a short time.

The company has mastered the art of adding value to project sites and turning them into functional, fully equipped living areas.

“ We have built permanent and temporary mobilisation camp facilities for employees on project sites used for many different sectors such as oil and gas, pipeline and mining in different harsh climates from hottest to coldest, from MENA to CIS,” said Senem Sirma. “In addition to basic needs such as accommodation, dining halls, laundry, hygiene areas and recreation areas, we also meet requirements such as office buildings, clinical buildings, steel warehouse structures, steel shelters and security cabins with our project-based design and production system.

“Moreover, we are always ready with our fast-track solutions to provide relief in sheltering need in emergency cases such as postnatural disaster and refugee housing. We supply temporary housing to meet urgent humanitarian needs such as accommodation and hygiene units in very short time.”

In recent years, the business has taken its place in large oil and gas pipeline projects, carried out work on a terminal station and renewable energy projects. In particular, its e-house, substation and central control room solutions and solar inverter station container products – where control and power units are placed – have proved particularly popular.

“We have specialised in e-house production by developing our product portfolio,” continued Senem Sirma. “We took our place in international oil & gas and pipeline projects with our projected based design substation, central control room and SCADA telecommunication containers.”

Steel manufacturing is one of Treysan’s core businesses: offering quick and cost-saving alternatives for a wide range of sites, Treysan’s pre-engineered steel buildings are ideal in terms of their flexible dimensions, speedy production and easy dismantling or relocation –suitable for installation in any area of the world as well as over longer periods of time. Secondary steel manufacturing with high quality engineering solutions is also supplied.

Treysan presents fast-track custom designs for a wide range of products to ensure easy installation and transportation. The building components are shipped to a construction site as ready to assemble, pre-assemble or in a flat pack. Thanks to Treysan’s years of experience and ultimate pre-engineering capability, components are designed for simplicity of assembly to save time, and both labour and machinery costs.

“Instead of being a temporary solution, Treysan products are considered real assets for construction companies and investors owing to their long-lasting design and multiple use capabilities,” said Senem Sirma. “Treysan delivers exactly what is promised, helping clients in their projects from design to start up.”

Treysan has been particularly busy within the MENA and CIS regions over the past decade, involving itself in a number of important energy efficiency and energy security projects. Treysan, which has been involved in prestigious projects especially with EPC camp facilities and permanent steel buildings in the past, is constantly expanding its product range and is able to find innovative solutions to all of its customers’ needs.

Whilst the company’s logistics advantage increases its chances in MENA and African countries, Treysan also delivers products to many projects in Europe and to America every year.

“In addition, we have an active role in CIS region with our branch office registered in Kazakhstan,” Senem Sirma said. “With our fast and permanent solutions specific to projects, the area where we have been the most intense for the last two years has been the permanent steel structures of investments such as refineries, nuclear power plants and private seaport and airport operations.

Treysan meets a wide range of needs with practical, competitively priced and durable products that can be installed in any kind of environment, and the company goes one step further in its own sector.

“We have a wide working area with our wide product range. Our temporary and permanent steel solutions are solutions to our customers’ requests.”

All engineering and design is carried out with in-house technical staff and all structural components are manufactured at the company’s production facility. Treysan’s experienced teams work on the company’s land area totalling 60,000 sqm with production carried out in the 19,200 sqm plant certified as per international standards.

Pioneering the way as a responsible sector leader in Turkey, Treysan is also ISO 9001 – 2000 certified, highlighting the company’s commitment to high environmental standards. Operating according to practices which pay the utmost attention to environmental protection and minimum energy consumption, Treysan has obtained certifications for its Environmental Management System (EMS) according to EN ISO 14001:2015, as well as for its Occupational Health and Safety Management System (OHMS) according to ISO 45001:2018.

Treysan has recently invested towards minimising or eliminating waste by utilising the region’s natural sources effectively and implementing new technology to prevent pollution.

Senem Sirma said: “Regularly, innovations are made in our internationally approved certified production halls that will provide

cost and production time advantages within the framework of our long-term investment plan. In addition, we make innovations and investments for our sustainability efforts.

“We have new investments for our sustainability efforts. With a zero-waste policy, waste recycling procedures are followed in our production halls. Our carbon footprint measurement studies are continuing.”

When talking about the future of the company Senem Sirma said: “Treysan benefits from being in Turkey. We comply with project deadlines on time by creating a supply chain from different continents for raw materials. In addition, owing to our logistics advantage, we save time with fast shipping solutions to three continents.

“We are much more hopeful for the future with our strong stance i n the sector in the post-pandemic period. Ongoing and newly launched projects will provide a movement for all sectors. We continue our efforts to take part in projects by closely following the investments in the region and supporting our customers from the design stage.

Senem Sirma concluded: “ADIPEC is a great organisation to follow investments in the region and reach our new clients. With our know-how and pioneering existence in the prefabricated sector, high-capacity technological manufacturing facility and experienced engineering services, we are ready to serve in a huge variety of prefabricated and containerised production solutions.” n