Tradeprint was established in 1997 and has grown into a full web-to-print business, acting as a partner for thousands of aspiring companies. Following its success in the print sector, the company is exploring the potential of sustainability in a myriad of ways. Hannah Barnett spoke to Sales & Customer Success Director - Sustainability Lead Anthony Rowell to learn more.

When it comes to improving its environmental footprint, Tradeprint has a lot going on. With a path to net zero by 2040 in mind, the company is investing in energy-reducing infrastructure and equipment, exploring lower emissions substrates, and seeking more sustainable shipping options.

“I look at sustainability as being the right thing to do, for the greater good,” said Anthony Rowell, Sales & Customer Success Director – Sustainability Lead. “So we collaborate with anybody, even competitors, on sustainability initiatives and work with industry groups like the British Printing Industries Federation, where I chair the environmental forum.”

Conscientious decisions

Tradeprint has been measuring its environmental footprint for some time, with data stretching back roughly six years. “This has enabled us to look forward, set targets and develop a pathway to be more sustainable, said Mr Rowell. “Sustainability is at our core, and it doesn’t stop there; we

really value our people and have gone as far as hiring a Head of People & Culture to support our employee-centric goals.”

Nowadays, Tradeprint has 160 employees, is approaching a £20 million turnover and operates from a 40,000 square foot site in Dundee. The company remains dedicated to small but significant changes, like converting all its lighting to LEDs; but as the business grows, so too does its impact.

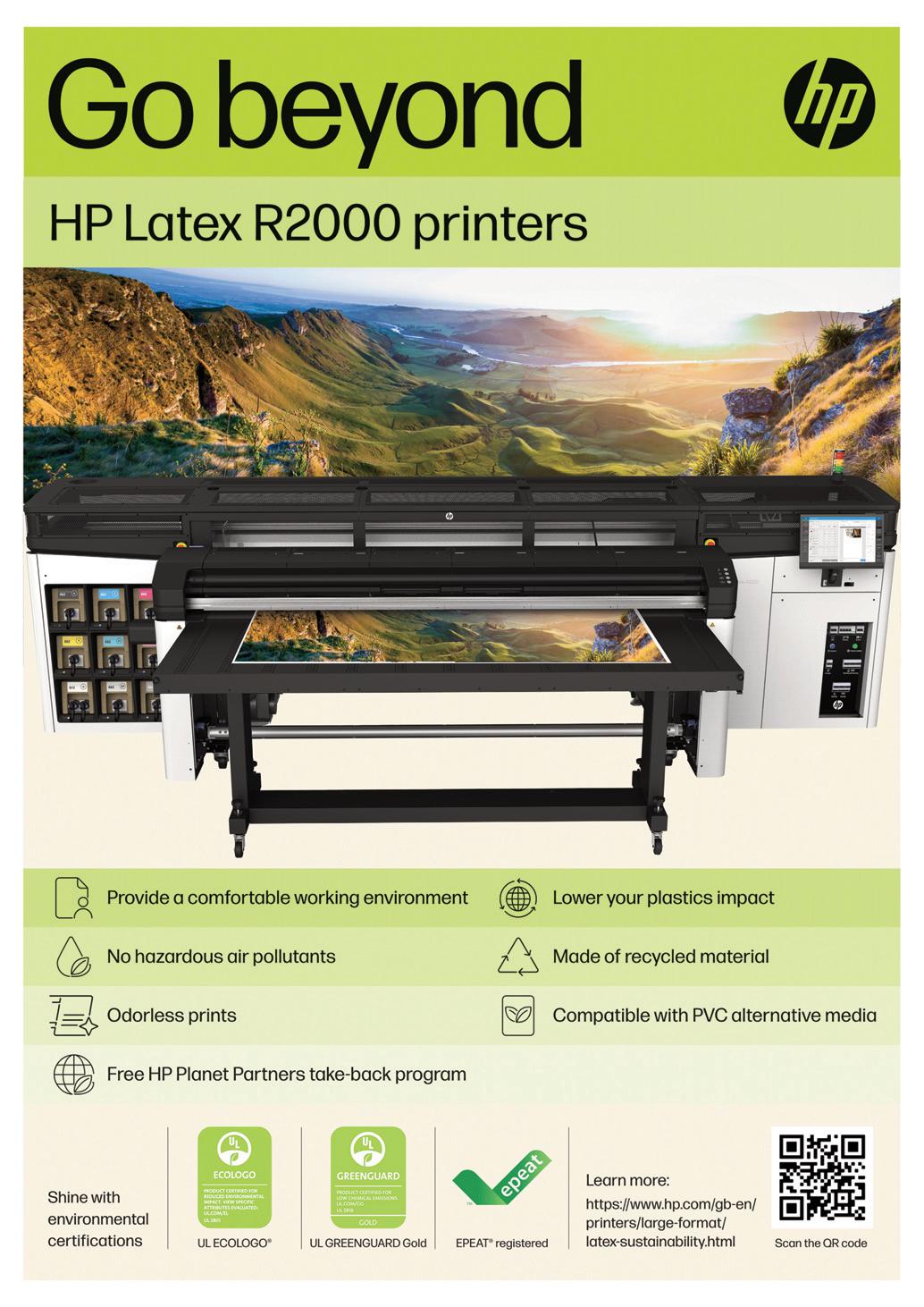

“We’ve got to work twice as hard to mitigate the impact of our expansion,” Mr Rowell explained. “We acquired a company out of liquidation in 2022 and doubled our footprint, going from 20,000 square feet to 40,000. That allowed us to install more LED lighting, invest in some additional state-of-the-art equipment and had the happy co-incidence of inheriting an HP Latex Wide Format printing kit that uses HP Latex Water Based Ink.”

The Tradeprint team are pioneers of mass customisation, leveraging

technology to optimise production flows and keep print costs at a competitive level. This has contributed to the international success of parent company Cimpress.

“When they acquired us in 2015, Cimpress recognised that we had a really good approach to commoditising print,” said Mr Rowell. “Mass customisation is all about collecting similar jobs, ganging them together and driving economies of scale. As well as mass customising leaflets, flyers, booklets, posters, letterheads and other small format products, we’ve applied our skills and leveraged our expertise by applying it to Wide Format Printing. Driving those economies of scale and bespoke manufacturing flows enables us to be very competitive in the signage and display space, especially on-line.”

The path to plastic-free I n 2020, Tradeprint committed to improving the profile of its plasticbased packaging, in line with targets set by the New Plastics Economy Global Commitment and EU Plastics Pact. This includes the elimination of problematic plastics.

“It’s exciting, because we’ve already introduced some PVC-free substrates,” said Mr Rowell. “We also focus on what’s recyclable: not all

plastic is bad at the end of the day. We sometimes have an opportunity to support our customers sustainability ambitions. For example, we collected corrugated plastic at the end of a recent campaign, had it chipped and it was subsequently recycled into some low-grade plastic that can be used for plant pots –a great circularity concept.”

Amongst a number of projects and initiatives, perhaps one of the most significant is Project Hulk, so-called “because its big and it’s green,” according to Mr Rowell. The project focuses on the transition from PVC to PVC-free materials. One of the challenges is that, due to being composed of multiple substrates, PVC-free materials can be harder to recycle. They also must meet the same printability and durability of PVC.

As this area of development is still in its early days, there are few reasonable alternatives on the market. Because of a lack of demand, PVC-frees are also traditionally more expensive. Tradeprint is striving to close that gap by leveraging

Tradeprint visits Number 10.

Anthony Rowell recently contributed to a roundtable discussion on Sustainability and Innovation at 10 Downing Street. Meeting with the PM’s Special Advisor on Manufacturing and Industry, Mr Rowell highlighted the huge contribution the printing and paper industry makes to the UK’s economy, while showcasing Tradeprint’s collaborative efforts to promote sustainability.

its group size, with a global tender to help drive the price to the point that can be accepted by customers.

A truly circular economy

Mr Rowell described recycling in the printing sector as “in a constant battle against greenwashing.”

He continued: “We are on a steep learning curve regarding sustainability, and it can be very complicated, so, making the right decisions is sometimes challenging. We want to be sure we can support any claims with evidence so we are not accused of greenwashing.

When we started printing on PVC-free, the material suppliers had claimed that the

material was recyclable. Technically, it is; but they couldn’t confirm where we could recycle it. After further investigation, we decided to re-think our strategy and we are looking forward to the result of the global supply tender so we can have confidence we are making the right choices.”

Tradeprint has an almost obsessive approach to waste. In 2021, Mr Rowell conducted a full cradle-to-grave analysis of the company’s waste streams. He discovered that Tradeprint sent less than half a percent of waste to landfill.

“Normally, printers would claim 100 per cent landfill avoidance if it was over 99 per cent,” he said. “But we don’t make that claim because we’ve still got work to do. We

have recently signed up to the FESPA-UK & Reconomy Sustainability Partnership, which supports the adoption of improved waste stream management to ensure we are pushing waste as high up the waste hierarchy as we can, whilst optimising the opportunity to increase revenue from our waste. Almost all waste has a value if managed in the correct way.”

Future proof

Tradeprint is also a proud member of Two Sides, a not-for-profit which provides verifiable information about the sustainability of paper; encouraging forest certification schemes, the use of recycled fibres and the elimination of waste going to landfill.

“Two Sides helps to dispel myths and reduce greenwashing,” said Mr Rowell. “Print is a really sustainable industry because we recycle our waste paper and work only with paper suppliers that are involved in responsible forestry with environmental labels like FSC and PEFC.”

The company was recently honoured for its work with an Independent Printing Industries Association Sustainability Advocate Award. “Winning felt like recognition for what Tradeprint has been doing in the industry; an external endorsement on the internal action we have been taking,” said Mr Rowell.

Tradeprint is now focused on decreasing its Scope 3 emissions and is working closely with suppliers in order to do so. This involves collaboration, discussion and education. As t he company has been measuring its carbon footprint since 2016, it has the valuable resource of data, along with a centralised sustainability team to collate it.

“We recognise the importance of sharing knowledge, making sure our suppliers engage with us and understand our vision,” said Mr Rowell. It’s the right thing to do, because it helps them on that journey, too.”

Indeed, for Mr Rowell, life at Tradeprint has proved an inspiring and meaningful vocation.

“If anybody is looking for an exciting career, printing is a brilliant business to consider because of the sustainability: plus we’re really innovative,” he concluded. “More than 10 per cent of our workforce are software developers, for instance. The pace of change is fast, the technology’s amazing and we’re a really diverse employer, with colleagues all around the world. It’s great to be part of a global business and I get a lot of satisfaction out of knowing that we’re making a difference.” n

If you’d like to learn more about Tradeprint’s approach to Sustainability, contact Anthony Rowell: arowell@tradeprint.co.uk.