THE FINE BEDDING COMPANY SEWING IN SUSTAINABILITY Powered by Inside Sustainability inside-SUSTAINABILITY.com

62 Inside sustainability Established ness that pr Managing D Laura Keay innovation, i

FINE

PROFILE

THE

BEDDING COMPANY I

in 1912, The Fine Bedding Company is a fourth-generation busirovides premium bedding through sustainable manufacturing. Director Claire Watkin and Head of Marketing and Ecommerce discussed the company’s passion for sustainability and in conversation with Antonia Cole.

Throughout its long history, The Fine Bedding Company has continuously adapted to the evolving market by staying flexible and proactively taking advantage of new opportunities. As gaps in the market opened, the company developed new machinery and technology, inserting itself as an industry-leading innovator in bedding.

Constantly improving its product range with new innovations, The Fine Bedding Company utilises technology to increase the efficiency of products. The cuttingedge fibre technology Smartfil has the same thermal efficiency as a premium down duvet with a lighter and more breathable feel. Also, the company’s sonic seam technology uses ultrasonic waves to neatly seal fabric edges, reducing waste by up to 5%.

The company employs around 170 people and generated £28 million in

turnover last year. Its eco-factory produces approximately 55,000 duvets and 100,000 pillows per month and there are plans to increase these figures by evolving current software and machinery.

Thinking into the future has always been at the core of The Fine Bedding Company’s operations. The company accomplished a world-first with a duvet made entirely out of recycled PET bottles in 2018 and is continuing to push the boundaries of sustainable bedding, working with partners to stay at the front of the market and making new innovations accessible to customers.

“We’re always developing new technology and finding ways to increase the efficiency of our operation,” said Managing Director Claire Watkin. “We have two new projects coming out next year that we’re very excited about.”

Inside sustainability 63

Inside sustainability 65

THE FINE BEDDING COMPANY I PROFILE

Moral fibre

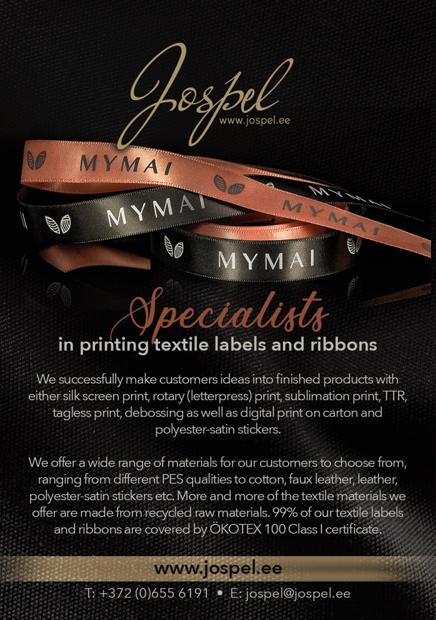

The Fine Bedding Company’s eco-factory is based in Tallinn, Estonia, a country with a substantial environmental focus. With over 2,200m2 of manufacturing space, 3,000m2 of warehousing space and connections to cargo routes, the company is well-equipped to develop and manu facture bespoke products that promote sustainability.

At its factory, the company uses 100% renewable energy and has 42 energy monitors to observe usage and effectiveness of machine upgrades in terms of efficiency. It also recycles 100% of the waste produced.

There are many innovative ways in which the company recycles waste material from production. One of which being that excess fabric is sent to a company in Lithuania that re-purposes it to make cuddly toys. Calibrated scales are also used to measure materials throughout the production process and recycled raw materials are utilised in new designs to limit waste.

All of the cotton used in the factory comes from the Better Cotton Initiative, a group promoting improved cotton farming standards across the globe. The Fine Bedding Company also uses post-consumer plastic waste and transforms it into fibres to be used in bedding. Recycling procedures at the factory are Global Recycle Standard approved and certified, attesting to high levels of environmental sustainability within the company.

66 Inside sustainability

“As well as establishing environmental policies within our operations, it is also important for us to integrate sustainability into our workforce,” explained Ms Watkin. “We have green teams, in both the UK and Estonia, that create employee-led environmental initiatives.

“There’s a lot of passion for sustainability throughout every level of the company and so, we are using the TIMWOODS framework to identify and limit waste across the business.”

Nights to remember

The company also helps customers to be more sustainable by creating environmentally conscious products. Through the use of premium materials, technologically advanced production techniques and informed designs, The Fine Bedding Company is able to create long-lasting and high-quality bedding.

This reduces waste as it means that customers can keep their bedding for longer, minimising the amount of bedding that ends up in landfill. The company is also working on an initiative educating consumers on how they can recycle bedding to limit their environmental impact.

“There are some incredible people down the supply chain that really want to make a difference and we are working with them to make developments in materials, fabrics and fibres,” said Head of Marketing and Ecommerce Laura Keay. “170 tonnes of bedding get disposed of as general waste every day in the UK, which is a huge amount.

Inside sustainability 67

“This is mainly low-quality bedding that only lasts a couple of months before it has to be replaced, which is damaging to the environment. We are changing this standard and promoting the use of long-lasting premium bedding.”

The Fine Bedding Company has created sustainable options that improve sleep quality. There are multiple products that help solve typical sleep problems including allergies, temperature and breathability, but the most popular product is the Night Lark Coverless Duvet.

This duvet has no cover, and so there is no duvet cover replacement struggle. The entire duvet can be put in the washing machine, allowing for convenience and accessibility, whilst still retaining quality and durability.

HeiQ, a global leader in material innovation, developed a four-in-one allergy treatment that The Fine Bedding Company uses in bedding to create products targeted at those with allergies It is

not chemical based and targets the four most common allergens, making it an effective and sustainable solution.

Dream teams

As a certified B Corporation, the company is constantly striving to improve sustainability. It has spoken in B Corp panel talks, participated in volunteering opportunities and connected with charities to improve environmental awareness.

The Fine Bedding Company has been working with Montcalm hotels to provide sustainable bedding, giving the hospitality sector better access to environmentally friendly options.

“As a B Corp, it is our job to educate and communicate about sustainability,” explained Ms Keay. “We’re holding ourselves publicly accountable. With the accreditation comes a lot of work, as we must constantly improve. We choose to provide impact reports because were confident in what we’re doing and want to be fully transparent.”

All of the company’s suppliers have been audited for social compliance and environmental targets using the Higg Index. Through site visits and open communication, The Fine Bedding Company is able to work with suppliers to build relationships founded on the common goal of sustainability.

“Our fibre supplier Huvis is doing great work in terms of sustainability, it has a low carbon footprint and is very forward-thinking,” said Ms Watkin.

68 Inside sustainability

FINE

I PROFILE

THE

BEDDING COMPANY

The Fine Bedding Company Managing Director, Claire Watkin.

“By choosing suppliers whose values align with our own, we are able to build long-standing relationships and can work together to improve the industry.”

The company has lots of new innovations that it is working to bring to the market including more efficient technology, recyclable materials and waste reduction techniques.

“Going forward, our biggest impact will be through the companies we’re working with,” concluded Ms Watkin. “We are altering the course of some major companies through education and access to our sustainable products, leading to a more environmentally conscious world.” n

Inside sustainability 69