In 1974, Stuga Machinery entered the fenestration industry under the name Thomas Engineering. Pioneers of CNC machine tools and automated machinery, the company became renowned for its ZX series, which is still being produced today. Managing Director Ed Williams discussed the success of this product line and gave insights into the important efforts Stuga is making to improve its sustainability. Reporting on the company is Imogen Ward.

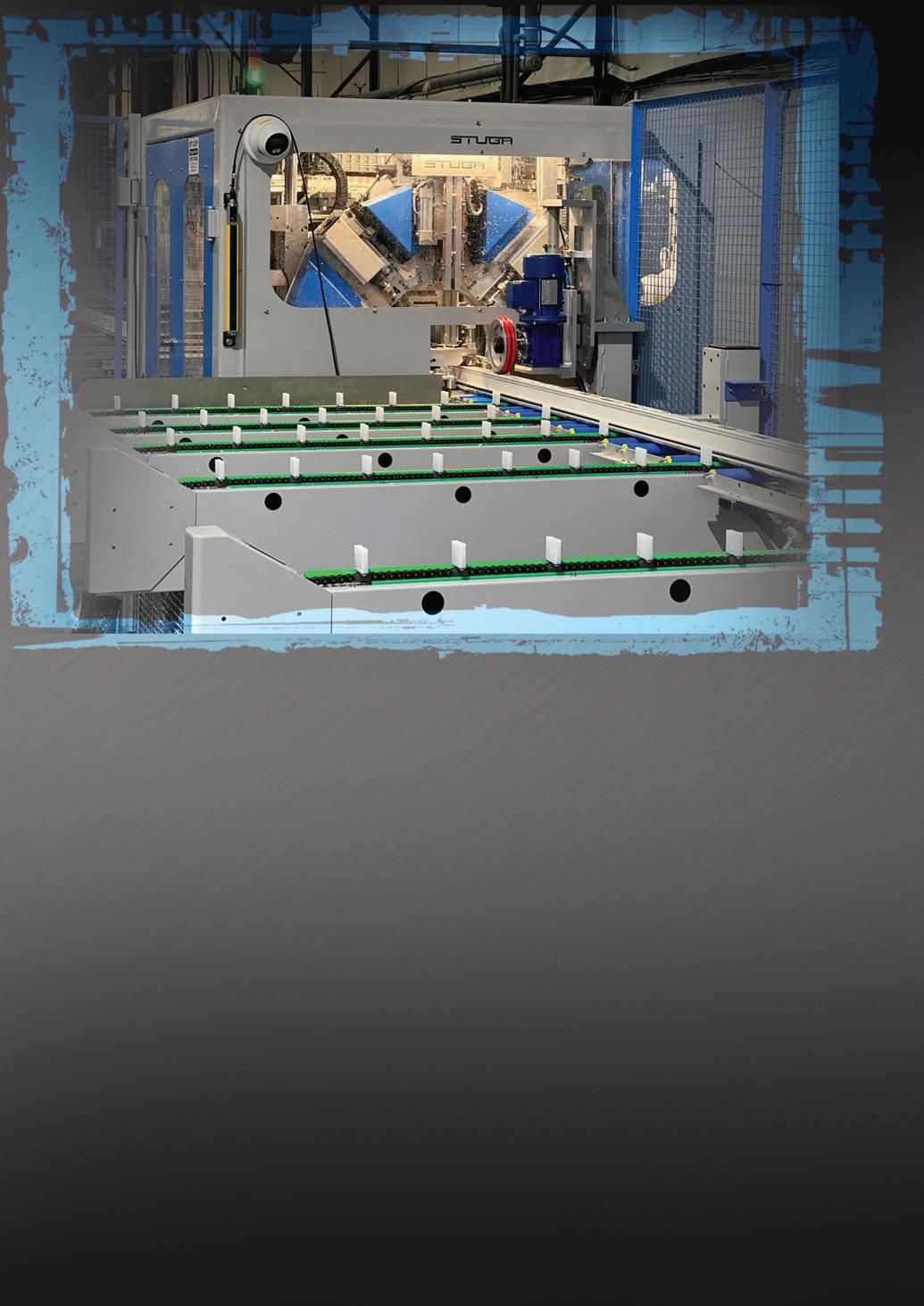

The fenestration industry was revolutionised by the creative heads at Stuga Machinery, seeking ways to overcome huge consumer demand for uPVC products as the industry moved away from traditional steel/aluminium and wooden frames. Since bringing the world-renowned ZX series sawing and machining centres to the market, Stuga has continued to develop its designs to improve the automation of critical fabrication processes and retain its competitive edge.

“Our latest model in the ZX line of machines has an optimisation feature that minimises waste,” Managing Director Ed Williams said. “It does this by looking ahead at the other orders in the programme queue and cutting the plastic profile into required sizes. The designers were working to a clear brief to reduce waste and the response of the industry to the final solution was very positive.”

All Stuga’s machines are designed and developed at the company’s manufacturing centre in the coastal town of Great

Yarmouth, Norfolk. With over 35 years’ experience in the fenestration industry, Stuga continues to bring innovative products to the market. The reputation for reliability and service has not gone unnoticed, and earlier this year the company was purchased by Stürtz Machinery.

After Stürtz’s takeover in February, the parent company highlighted a need for more factory space. This led to the more recent expansion of Stuga’s factory. This resulted in production space doubling and enabled Stuga to substantially increase its manufacturing capacity. As an added bonus of the expansion, Stuga has enough room to display Stürtz machines in-house Although the Stürtz products are manufactured in Germany, having these display models enables Stuga to complete demonstrations for clients, creating additional marketing for these products within the UK.

Stuga is renowned for its ZX series of automated machines. Designed by Gareth Green, the ZX machine innovated the production of windows, reducing labour whilst improving manufacturing times and cost effectiveness.

“Gareth patented and developed a rotary ring system for the machine,” Mr Williams explained. “The ring incorporates multiple tooling stations and is capable of carrying out multiple machining functions simultaneously. This tooling ring improves the speed of machining in an extremely cost-effective way. It would cost our competitors considerably more to achieve the same production levels.”

The most recent model in the ZX line was developed with an optimisation feature. The ZX5-S assesses cutting and sawing profiles using computer-based intelligence,

which results in a more economic process. “Having analysed real production data,” Mr Williams said, “it shows that this system can save up to 5% on the overall consumption of profile, due to the decrease in waste material.

“Plastic profile can cost between seven and twelve pounds per metre, and a company could be using hundreds of thousands of metres per year. If, for example, a large company uses five million pounds worth, a 5% saving of that would be quite substantial. Even a smaller company that only spends 50,000 pounds would make significant savings.”

The company also offers additional machinery, including the entry-level AutoFlow-2 Sawing and machining Centre, an in-line solution designed to appeal more to start-up and lower volume output businesses. The AutoFlow-2 can produce around 400 windows per week.

Just like all Stuga products, this machine is built with high-grade components that increase its reliability. As a result, the company has to replace fewer parts; this

reduction in spare part consumption is better for the environment and helps save customers money too. Stuga’s dedication to the environment is also evident in the company’s ICC SME360X Certification following an environmental impact assessment.

Stuga’s machines are durable and withstand the test of time. The company’s confidence in the products is highlighted through its refurbished machinery programme. This option became available a decade ago and helped improve customers’ environmental impact, offering an alternative option to buying new

“We buy older machines from our customers who purchased them 10-15 years ago,” Mr Williams said, “then we strip the machine down to its chassis and replace all the old electronic and mechanical OEM components. This includes the servos, drive motors, sensors and bearings. Sometimes we even add new functions to the machines, but we are effectively selling customers a refurbished as-new machine. This

means companies can purchase a Stuga machine for considerably less than the list price of a new like-for-like system.

“We are prolonging the lifecycle of these machines, upcycling them and encouraging machinery recycling. New businesses tend to start with very manually oriented production processes, but eventually, they reach a point where the volume of orders is too much to keep good quality control with the workforce they have, whilst maintaining output demand. At that point , automation is the most sensible path to go down, but small businesses don’t have access to unlimited funds; our refurbished machines are the perfect solution, allowing smaller businesses to stay competitive in a huge market.”

As part of this service, the company offers a 12-month warranty for parts and labour. This highlights Stuga’s confidence in these ‘as-new’ machines.

Since becoming a subsidiary of Stürtz, Stuga has set out goals for diversification and expansion of product capabilities. Stuga are already selling and servicing the entire portfolio of Stürtz equipment, including welding and corner cleaning, logistics and handling solutions.

This purchase also benefits existing Stürtz customers – there is already a large instal lbase in the UK market – giving them access to a vast array of first-class engineers who are based across the UK and offer the very best machine maintenance. “We have 11 engineers,” Mr Williams said, “who carry out planned maintenance and breakdown repairs.

“Having this structure in place is really important for Stuga because, as they say, a sales representative can sell the first machine, but the reliability of the product and the service support provided is what

keeps customers coming back. Previously, Stürtz didn’t have reliable UK representation, so the Stuga acquisition helps tackle this critical challenge.”

As part of its investment into expansion, Stuga is also adding new members to the workforce. Mr Williams is bringing an array of business strategies to the company which will set about delivering sustainable and profitable growth – including the immediate objective to build a sales and technical team that can sell and support the range of Stuga and Stürtz products.

The company hopes to continue working with its long-standing suppliers who are local to the business, Stuga has maintained these relationships since the 1990s, regarding them as critical.

“Stuga has always designed its own parts, but the manufacturing of those –the metal parts anyway – has always been completed by our local supply chain,” Mr Williams concluded. “We like the fact that we have these great relationships with fabricators around the Great Yarmouth area.

“Gareth always liked the idea of working within the community and helping keep businesses alive and afloat, especially during the 90’s when the automotive industry was collapsing. It works both ways, when Gareth approached the local manufacturing companies, they threw their arms around the business and really supported us too, they have ever since.”