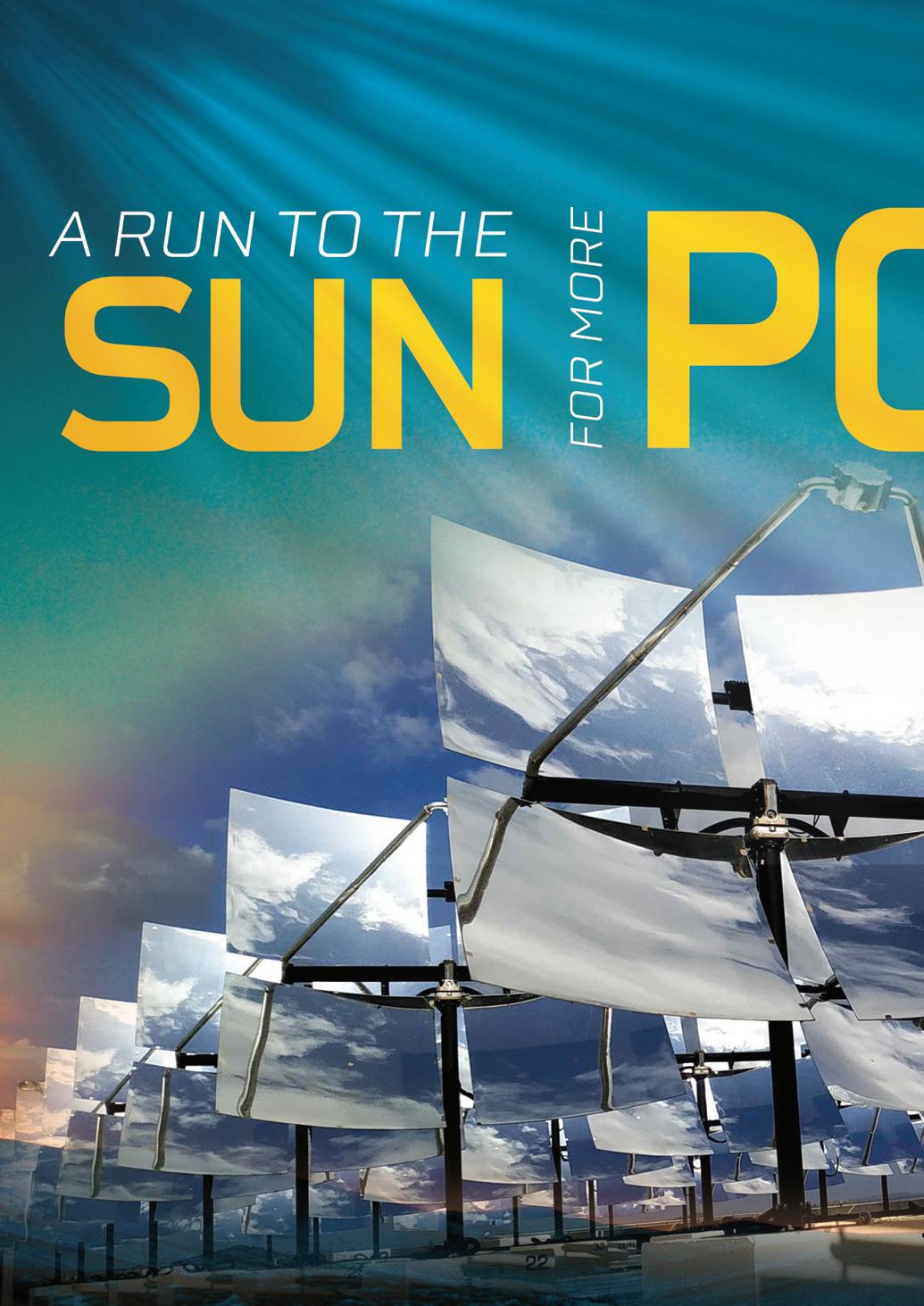

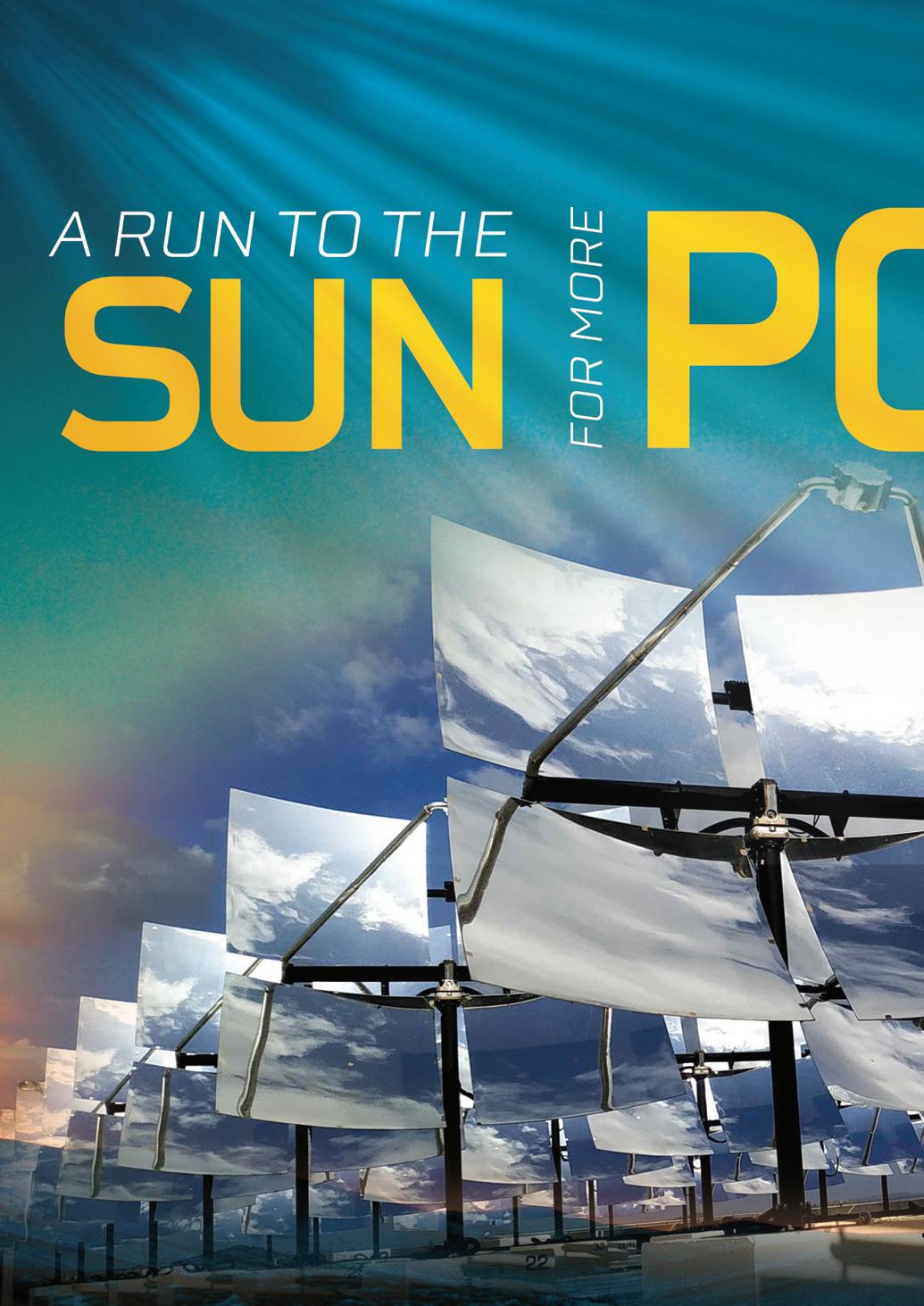

RIOGLASS SOLAR A RUN TO THE SUN FOR MORE POWER Powered by Inside Sustainability inside-SUSTAINABILITY.com

314 Inside sustainability

RIOGLASS SOLAR I PROFILE

Rioglass Solar is a global leader in designing and manufacturing optical concentrated solar power and concentrated photovoltaic components

Andy Probert spoke to Jeroen van Schijndel, Chief Sales & Marketing Officer, about the company’s business development and diversification into related service fields.

Within 15 years, Rioglass Solar has become an industry leader in developing key optical components across two market segments: CSP (Concentrated Solar Power) and CSH (Concentrated Solar Heat). The former means producing electricity with solar energy, while the latter involves supplying heat to industrial and other processes with solar energy through concentrated sunlight. This is also known as SHIP – Solar Heat for Industrial Processes.

Having completed its largest-ever contract for the world’s biggest CSP Plant in Dubai, supplying mirrors and receivers

for the 3x200MW Parabolic through Units of the Noor Energy 1,950MW CSP Hybrid Power Plant – Phase IV of the Mohammed bin Rashid Al Maktoum Solar Park, Rioglass Solar has become the torch-bearer for setting industry standards.

Now, from its HQ in Brussels and with operations across Spain, the company is diversifying its business. This means supporting customers’ smaller industrial applications for heat and light solutions and developing different types of technical and maintenance services for clients.

“Rioglass Solar thrives on innovation,” said Chief Sales & Marketing Officer

Inside sustainability 315

RIOGLASS SOLAR I PROFILE

Jeroen van Schijndel. “Our expanded service offerings mean we can offer a 360-degree approach to clients.”

Innovation pioneers

In CSP units, oil is heated to nearly 400 degrees and later converted into steam to drive a turbine. The oil heating decomposition process creates hydrogen in a vacuum of the receivers, which can be destroyed over time and become less efficient.

Rioglass Solar has developed an online and continuous measurement system to measure the dissolved hydrogen in the HTF oils used in CSP. The tool helps measure and monitor not only this value continuously and online, but also quantity preventive and predictive maintenance to reduce the values.

“We have implemented the solution at 14 CSP plants on three continents and it is being rolled out further as clients see the advantages of monitoring this value over time,” said Mr van Schijndel. “This value was never considered in the design process for a CSP plant, but operators now plan to build in this tool from the beginning.”

Patented technology has also been designed to inject a specific gas into the vacuum, which neutralises the hydrogen and enables the tube to operate for the rest of its lifetime without further problems and to increase the solar field efficiency. “That solution has since been implemented in over 40,000 products worldwide,” Mr van Schijndel said.

Other innovations have included increasing the reflectivity of mirrors by

improving coating and reducing glass thickness, plus developing new coatings and coating processes for the receiver tubes for next-generation CSP technologies.

“We have created higher precision glass bending processes to boost the intercept factor of our mirrors,” Mr van Schijndel continued. “This is as well as finding new technologies to bring overall costs down and introducing, for example, improved heliostat mirror mounting and canting methods to improve the optics of Central Tower plants.”

Rioglass Solar has also devised groundbreaking drone thermographic technology for inspections to monitor heat emissions to detect problems and deviations, and opto-mechanical aspects of collectors in the solar field.

316 Inside sustainability

“Our technology for drone inspections is more precise than anything on the market,” Mr van Schijndel explained. “We are expanding that for transmission lines and PV plants. In detecting early deviations in the field, we can immediately work on preventative and corrective maintenance as part of an integrated package which means more added value for customers.”

The company also supports solar field inspections looking for deviations in components that need to be repaired, corrected or replaced. Welding services to replace valves, pumps or ball joints have also been developed, as well as new technology to test the efficiency and durability of ball joints.

“Our dedication to innovation plays a key factor in the competitiveness, productivity,

and sustainability of Rioglass Solar,” said Mr van Schijndel. “These services are offered on many continents with various customers, but it is one of continual expansion. They now account for over half of our business.”

Continual evolution

These services further complement and consolidate Rioglass Solar’s excellent reputation within its industry. Now employing 111 people, it has offices and factories in Europe, North and South America, South Africa and the Middle East.

Having supplied more than the equivalent of 4GWe of mirrors and more than 5

Inside sustainability 317

RIOGLASS SOLAR I

GWe of receivers delivered worldwide, Rioglass Solar is the world’s leading provider of CSP receiver tubes or heat collector elements (HCEs) and glass mirrors.

Its products are the best on the market: the tempered mirrors boast low breakage rates, the highest specifications for geometry and reflectivity, and the highest absorption rate available. Its receiver tubes for linear CSP applications are built and tested for extreme environmental conditions and comply with strict standards for power piping, plus boiler and pressure vessels.

Rioglass Solar’s experience came to the fore when it landed its largest contract for the DEWA CSP Plant in Dubai, which uses CSP and PV solar technologies. It supplied high-performing PTR 90-4G receiver tubes and 8.2 Parabolic Trough mirrors for all three parabolic trough CSP units; each with a capacity of 200MWe. The complex will provide clean energy to 320,000 homes in Dubai while reducing annual carbon emissions by 1.6 million tonnes.

The innovative tempered Parabolic Trough mirror technology from Rioglass Solar has been utilised by customers worldwide for its high performance optically and mechanical resistance, where it reduces cost from an O&M perspective. More than 4GWe of these mirrors are operational and have been adapted to different trough designs and other CSP technologies.

Expansion and challenges

More and more CSH technology is now being used to replace fossil-fuel based industrial heat processes.

New CSH projects are coming to the fore due to the reliability of these solar power technologies over other emerging renewables.

“We have a clear advantage: other renewable technologies are cheaper but intermittent,” Mr van Schijndel explained. “CSH is more complex; but thanks to an integrated thermal storage technology it can supply electricity or heat 24/7 and avoids expensive backup systems for the evening and night hours and is more manageable. The challenge is to make customers more familiar with the CSH technology. But it is a proven technology and provides many solutions especially when the thermal storage is considered an integral part of the energy transition. It can also be easily hybridised with PV systems.

“There are many new complexities that the industry needs to consider when searching for renewable technologies. Each industry has different needs, from

318 Inside sustainability

PROFILE

food and beverage to concrete and steel, and there is never a one-size-fits-all solution. Sometimes hybrid solutions are the best option to transition to renewables.

“For CSP, Rioglass Solar is working hard to expand its range of solutions and services to meet clients’ requirements. One of our main R&D projects is to be able to work at higher-temperature processes. If the temperatures cycle is higher, then there are more efficiencies, making the technology cheaper.”

Transparency and trust remain fundamental pillars in maintaining Rioglass Solar’s long-term customer relations and have deepened further with its service offerings. “Working so closely together, you can profit from the engineering knowledge of both and develop new technologies,” Mr van Schijndel continued. “That was the case for the hydrogen measurement tool.

“On the CSH side, alternative energies are coming to the fore due to the increased volatility in fossil fuel costs and availability, and the business risks operators are exposed to. Renewables are not the cheapest yet, but we can give industry clear visibility on the cost of installation, maintenance and service: and the sun and wind are free resources for power, and thus a foreseeable cost.

“Rioglass Solar’s technology and service advancements have positioned it at the forefront to enable it to provide greater support to best work together and provide for our customers,” Mr van Schijndel said, in conclusion. “We aim to maintain our leading position as the largest supplier of products – focusing intensively on R&D with a strong patent portfolio – and to expand our new package of services to clients to provide more comprehensive solutions.” n

Inside sustainability 319