The portfolio at RETOS VARNSDO covering new machines, overha tancy services, plus the deliver accompanying documentation. a milestone anniversary and his important to his family. Report b

ORF is focused on horizontal boring mills, auls, partial or medium repairs and consulry of spare parts, accessories and the . Managing Director Jan Müller discussed s goals for this business which is so by Phil Nicholls.

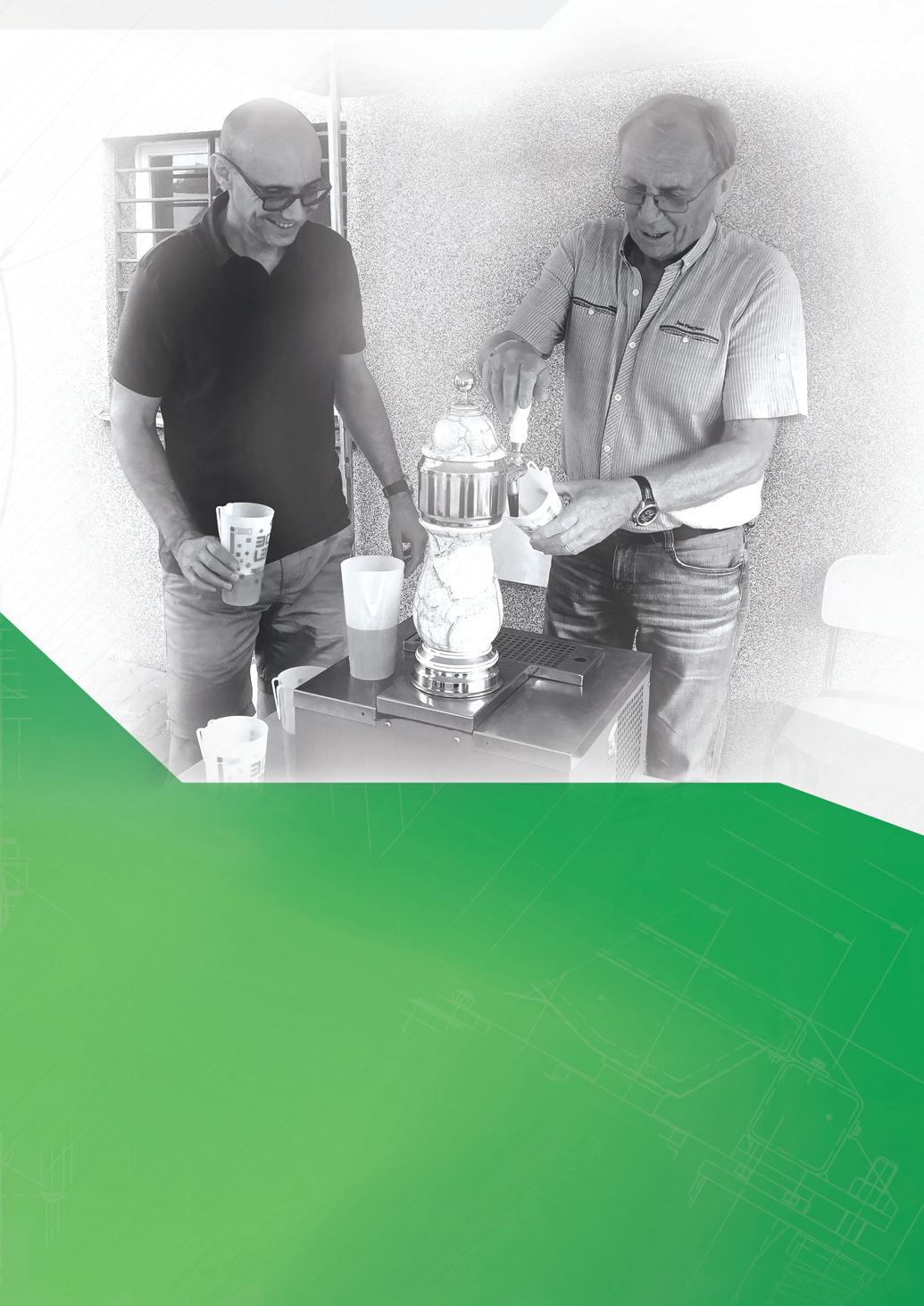

IN2023, RETOS VARNSDORF celebrated its 30th anniversary. Throughout its existence, the company has maintained a strong family atmosphere.

“Working at RETOS is about creating something with real value: not money, but products, a brand,” explained Managing Director Jan Müller.

“We are keeping alive the family tradition. My grandfather designed horizontal boring mills for his whole professional life at TOS VARNSDORF. My father was a fitter and later th e

founder of RETOS, and CEO for twenty years. Today, even my children work for RETOS during their holidays.”

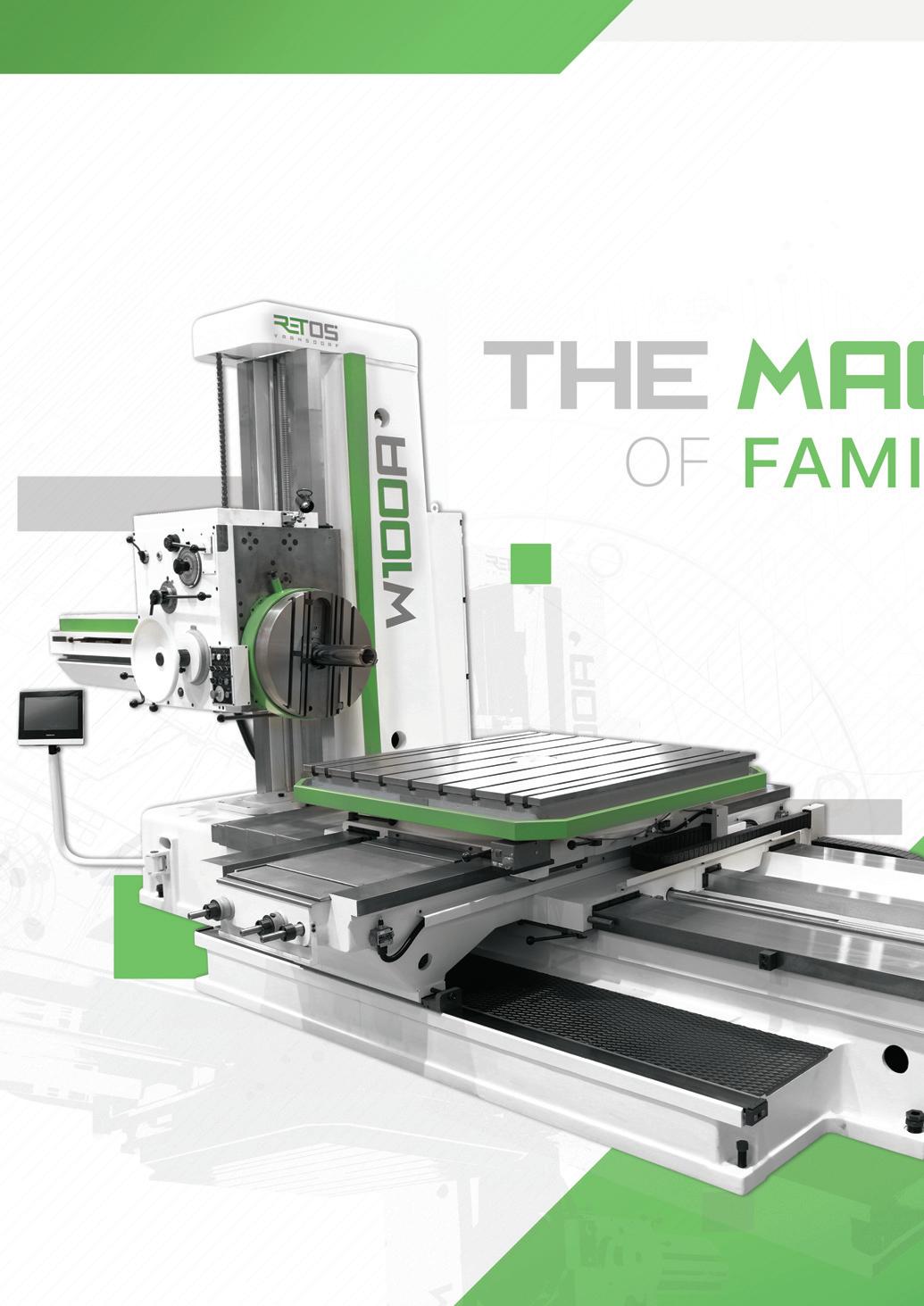

The original retrofitting department of TOS VARNSDORF was split off in 1993 and founded as RETOS still focusing on repairing horizontal boring mills. Over t ime, the company steadily invested in new technology and gradually presented itself as a producer, instead of only bein g a repair company. The major change came in 2016, at the point of release of the brand-new product line RET10XP, the company rebranded. This resulted in a new logo, company colours, machine designs and commercial product names

Last year’s big anniversary was a wonderful opportunity to reflect on the company’s achievements. “We simply let people know that we are here,” said Mr Müller. “We had a garden party for ou r staff and local partners, which was fun. At the International Engineering Fair in Brno, we gave an illustrated presentatio n about our history.”

The company continues to use the original facilities at Varnsdorf in the Czech Republic. RETOS has two photovoltaic power stations installed on the roof, with a total power of 25kW, plus a new installation adding a further 150kW to the tota l generation capacity. The company has about 85 employees, plus another ten external co-workers.

RETOS has a strong focus on the Western Europe market, where the company produces, overhauls or sells approximately 35 machines a year. This delivers an average turnover of about €8 million.

An international portfolio

The team at RETOS produces a range of high-quality machines in its distinctive branding of green, white and grey. This portfolio is in addition to an extensive range of spares and accessories. The experienced engineers at RETOS also offer after-sales services for RETOS machines, both in the Czech Republic and abroad.

“My goal, every single day I go to work, is to help build an even better version of RETOS”

Even with such a diverse portfolio, the company continues to juggle the competing market demands, according to Mr Müller: “The market wants the impossible combination of German quality for Chinese prices.

“What sets us apart is that we cover all the design, production, sales and service activities, including spare parts even long after the warranty period. No matter if it is a new, overhauled or used machine, our customers have all they

need in one place and can rely on us to deliver satisfaction.”

The availability of an extensive selection of spares at RETOS is a huge step towards helping customers achieve sustainable operation through the overhaul of their machines. Notably, the manual production of gears at RETOS is quite a rarity. This is more than necessary, considering how many of them are needed for just one headstock of the conventional W100A boring mill.

“To repair, in comparison to producing new heavy machines, is very environmentally friendly,” Mr Müller explained.

“Regarding the range of new machines, the only way of reducing the carbon footprint is to optimise the design, the energy intensity and technological management – so as not to waste energy, tools or coolant liquid.

“We supply machines for long-term service. It is common for our machines to serve the customer for 20 years, and then, after an overhaul, last for a further 20 years.”

Building a better future

The recent anniversary was also an opportunity for RETOS to acknowledge the support of suppliers as part of its 30-year history.

“The challenging market means that we are all in the same boat,” said Mr Müller. “Suppliers should support RETOS, just as the producer should support the customer. Certainly, suppliers are very important for our success. For example, some of the specialised mechanical parts are things we are not able to produce alone.”

Mr Müller acknowledged that the biggest challenge for RETOS involves finding the right product for the future. Even though there is a large degree of innovation in the company’s product line, the core product is still a machine tool.

“The competition with the Asian market is growing more intense, year by year,” he continued. “We have also been affected

by supply issues, especially regarding electronic components. At RETOS, we will continue to produce as much as we can using our own knowledge, resources and facilities.

“This distinct combination of traits helps us to be more resilient to the ongoing market fluctuations.”

Looking towards the next 30 years, Mr Müller was clear about his goals: “My personal dream as Managing Director is stability for RETOS. Our broad target is to maintain growth in correlation to that of the general economy.

“At the 30 years party, there were three generations of my family in attendance,” he said, in conclusion. “Yet, my family is not the only one with a tradition of working in this company. It is fulfilling to see how knowledge and traditions are preserved at RETOS.

“Every generation also brings new ideas as it struggles to keep pace with an ever-changing world and makes its own contribution to progress. Sometimes, this creates pressure. My goal, every single day I go to work, is to help build an even better version of RETOS.” n