Based in Palma de Mallorca, PURE Superyacht Refit provides professional and specialist superyacht refit management services, tailored to fit clients’ needs. Owner Nic Clarke discussed PURE’s services and innovative business model, in conversation with Hannah Barnett and Antonia Cole.

With over 20 years of experience in professional yacht racing as a team manager, boat captain and sailor, Owner of PURE Superyacht Refit Nic Clarke has an extensive knowledge of the marine industry. Mr Clarke saw the increasing demand for specialist refit services and used his expertise to found PURE in 2007, a leader in the service of superyachts.

The company is based within the open Servicios Técnicos Portuarios (STP) facility in Palma de Mallorca. This means that PURE is able to offer clients a range of highly skilled contractors to fit individual project needs.

STP consists of 102,000m2 of hard standing area for 80 hauled vessels up to 67m & 1000 tonnes and 60,000m2 of berthing area for 60 vessels to a maximum of 110m LOA. There are six travel lifts ranging from 30 to 1000 tonne maximums and seven keel pits accommodating deep-draft sailing yachts of up to 67m.

Despite being a small company with three permanent staff members, PURE accounts for a high percentage of Mallorca’s superyacht refit business. Palma de Mallorca has many skilled nautical professionals and sub-contractors from around the world, giving PURE the ability to provide a high-performance

service, regardless of language barriers or weekly working hour constraints.

Pure also offers refit accounting services, providing detailed status reporting of the refit as it progresses. Thus, allowing captains, owners, management companies etc. to be completely informed.

“One of the benefits of working with PURE is that we don’t take every project that comes along,” said Mr Clarke. “We take on projects that are challenging and require the advanced involvement and expertise that we are able to offer.”

Exceeding expectations

PURE determines the scope of work required and establishes a realistic timeframe. The company then organises designs, berthing or haul-out options, suitable skilled contractors, plus work lists and budgeting to meet client and project requirements.

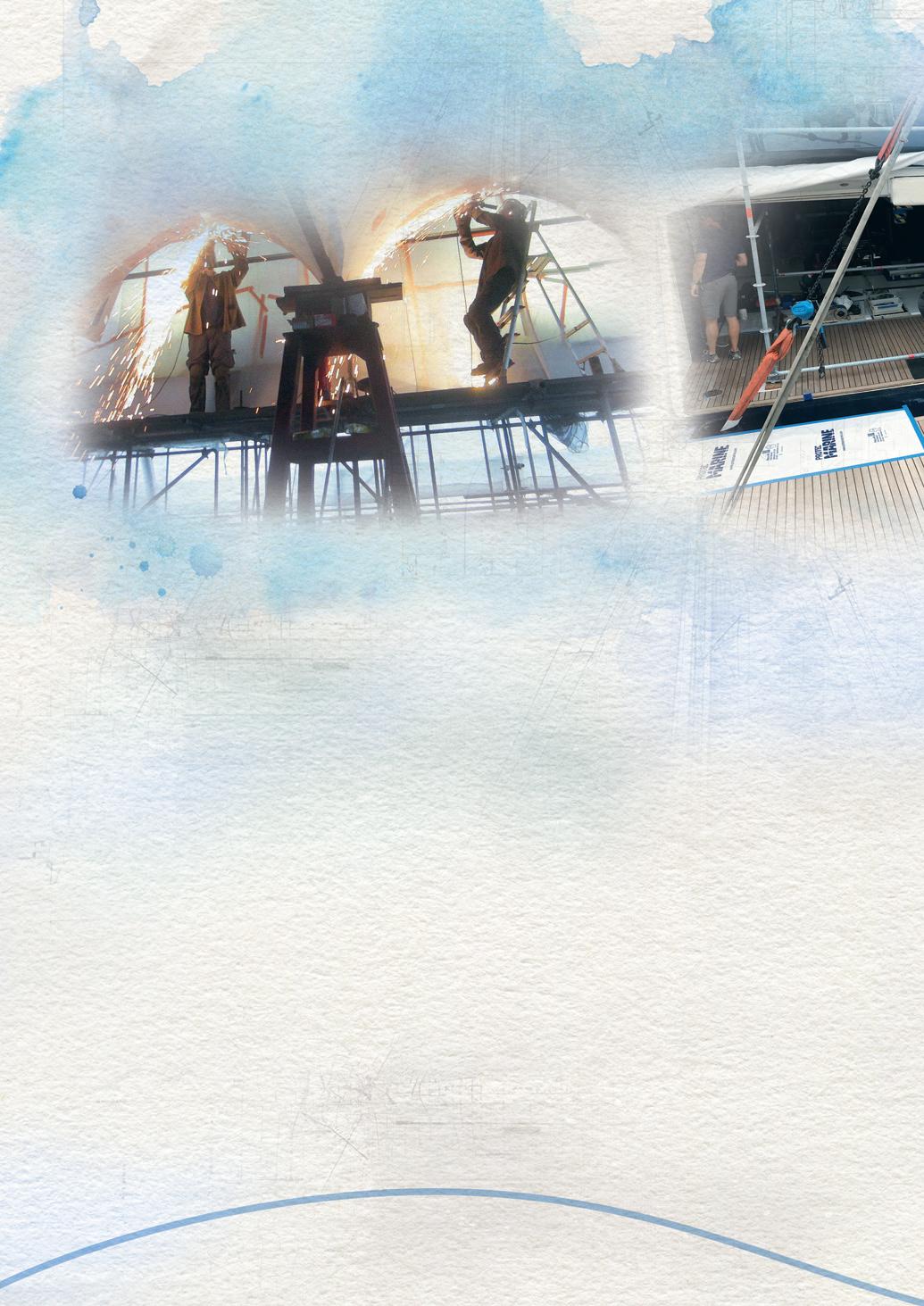

The company’s first project in 2007 took a 52m 650 tonne motor yacht out of the water, before cutting 2m square openings into either side of the hull/engine room, then removing and replacing generators, exhausts and engine management systems. A 1.3m swim platform hull extension was constructed and the project was completed with teak deck replacement and full, four colour paint re-finish, making it a nearly €5 million project.

“Projects like these, that exceed expectations, are what have put us on the map,” explained Mr Clarke. “Our ability and determination to achieve the incredible is what makes our clients confident that PURE will meet and deliver their needs.

“We have no problem cutting holes into the bottom or sides of vessels if required, as it is often more efficient and less intrusive. We go that extra mile to deliver exceptional services as efficiently as possible. Our standards are high and we meet them with every project.”

As a qualified engineer and professional skipper with experience in shipyards world-wide, Mr Clarke has the knowledge to interpret client requirements to a greater degree. This expertise allows PURE to complete all projects to the level of quality that the customer envisions.

“I’ve got very high standards for our work,” said Mr Clarke. “I am confident in the fact that if I accept something, then the client will accept it too. We don’t waste our clients’ time, so we make sure to get it right.”

PURE begins project management around three to six months before the vessel arrives, in a process it calls ‘pre-fitting’. This means that preparations are made so when the vessel does arrive, the company can begin work immediately and clients receive their services quickly and efficiently.

“The initial three weeks after the vessel arrives are critical to the successful completion of works in the allotted time period,” explained Mr Clarke. “Through preparation and access to skilled crews and

sub-contractors, we are able to deliver refit services that are guaranteed to satisfy our clients.

Abundant abilities

The company operates out of the STP boatyard, a unique public facility that allows independent contractors to deliver works, whilst STP provides berthing, hauling and occupation services. There are no contactor relations through STP, so there are no surcharges for choosing subcontractors as there would be in a private shipyard.

This business model allows clients the freedom to choose contractors that mee t their individual needs without excess charges. Based within STP, PURE is able to provide clients with the best possible contractor options, tailored to suit skill requirements and price points.

“Whether it’s someone from across the world or someone local, our clients have the opportunity to use whichever

contractor they want,” said Mr Clarke. “For example, a lot of our clients have systems in their properties that they want to replicate in their vessel, such as audio-visual set-ups. We can assist in access into STP for the specific company, providing they submit the required documentation, to come and carry out the desired works without any additional surcharges.

“This model means that we can meet specific requirements for our clients and can bring in the specialised skills from a range of industries to develop the vessel into the client’s vision.”

With Palma de Mallorca as PURE’s main location, the company has access to large numbers of highly skilled craftsmen across all superyacht services and trades. With access to a large workforce, PURE is able to complete projects quickly and deliver significant upgrades that exceed expectations. Over the last 17 years, the company has managed painting over 30 vessels.

One of PURE’s recent projects involved transforming an 82m industrial vessel into a leisure vessel/toy carrier with a helicopter pad, a basketball court, a golf simulator room, a bar and more, all within three weeks. This highlights PURE’s capabilities as a company to achieve the almost unachievable.

Collaborative connections

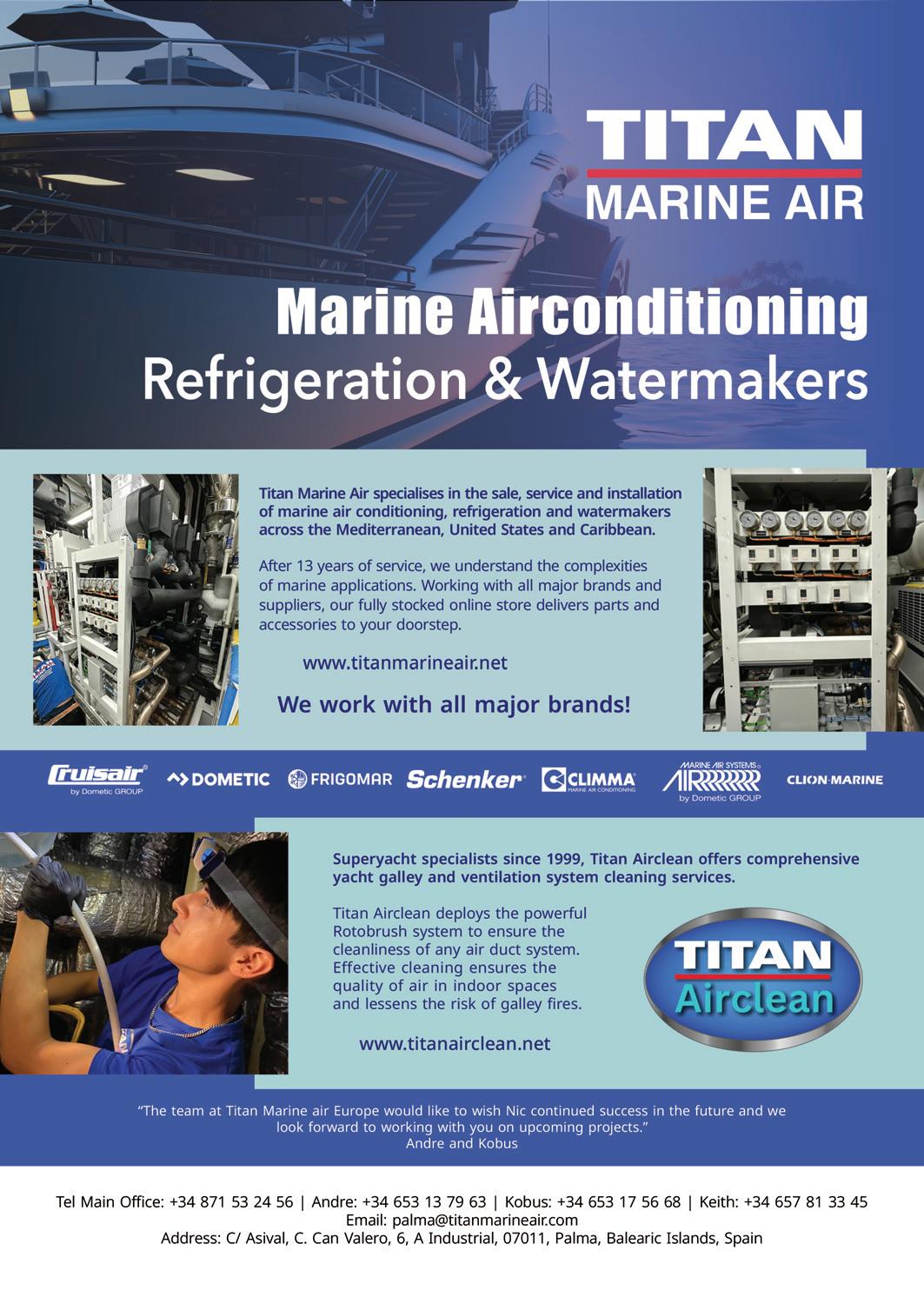

PURE has built long-standing relationships with partners across the industry, so that it can trust that projects are being completed to a high standard and on time.

“We work with some really good companies,” explained Mr Clarke. “They understand how we work and allow us to succeed. We all see the importance of going out and getting the work done as soon as possible. With our distinctive handson approach, we are well positioned to anticipate client and contractor needs and plan well in advance. Being proactive

instead of reactive allows for a smoothrunning operation.”

PURE often finishes projects ahead of schedule, meaning that clients have the ability to have more works or services added to the project within the original allotted time frame. The company’s focus on efficiency means added convenience for the client, as well as more business for partners and suppliers.

Going forward, PURE hopes to maintain this management system, but to expand into other facilities. The company will be able to create teams and work on vessels in different areas, increasing PURE’s project capacity.

“I like to succeed,” concluded Mr Clarke. “Taking what seems like an impossible project and turning it into a reality is rewarding. I am passionate about the industry and what we do, which shows in the projects that we deliver.” n