Pattyn Group develops automated solutions to pack, weigh, fill or count products for industrial use. Since 1952 the company has gradually expanded into many different industries, and is now the global market leader in industrial box-lining solutions. VP of Sales Stefaan Lips explained more to Hannah Barnett.

Th e Belgium-based Pattyn Group is something of a pioneer. The company was founded in 1952 by Jean Pattyn, who originally installed cinema projectors. When he received a request to automate a weighing and filling machine for a local candy company, he created his innovating ‘Doseur-peseur’ which laid the foundation for the company that it now is today.

“Today we are a turnkey solutions provider,” said Stefaan Lips, VP of Sales. “We provide customers with a fully integrated solution that extends from the products coming off the line, to the palletised boxes.”

The company has maintained its market leading position by investing in automation and by establishing a strong working relationship with its customers: and with 500 employees across seven divisions, Pattyn is a company with plenty to offer.

A brief history

While the company may have started in 1952 in the garage of Jean Pattyn, it was not until 1960 that the construction of the first fully automatic industrial scales for confectionary started.

approached by Unilever to create a bag-inbox solution, with a filler for oils and fats,” Mr Lips explained. “It was then that the first automation for packaging was developed. In the last 30 years we have expanded our bag-in-box and weighing technology offerings to many different industries.”

The company has evolved into sectors including nuts, bakery, fresh fruit and vegetables, solid chocolate, caps and closures, and even outside of food and beverage altogether into tobacco and pharmaceuticals.

An international partner

These days, Pattyn is an international powerhouse. It has seven divisions worldwide including a subsidiary in North America which opened in 2010, with just two employees running day-to-day operations. “Today, we have a team of 50 colleagues in the States. This fast growth has shown us that the proximity and our customer intimate approach is definitely the right strategy,” Mr Lips said. “Last year, we also established Pattyn Asia in Kuala Lumpur, with a team of service

“We provide customers with a fully integrated solution that extends from the products coming off the line, to the palletised boxes”

engineers and salespeople covering the whole of Southeast Asia, China, Korea and Japan.”

Another arm of the group is the Pattyn film division. The company’s acquisition of GMP in Barcelona has allowed it to specialise in the production and commercialisation of high and low-density polyethylene film, bags and sacks, and lamination of special complex film, enabling them to work with their customers on specific and complex packaging solutions.

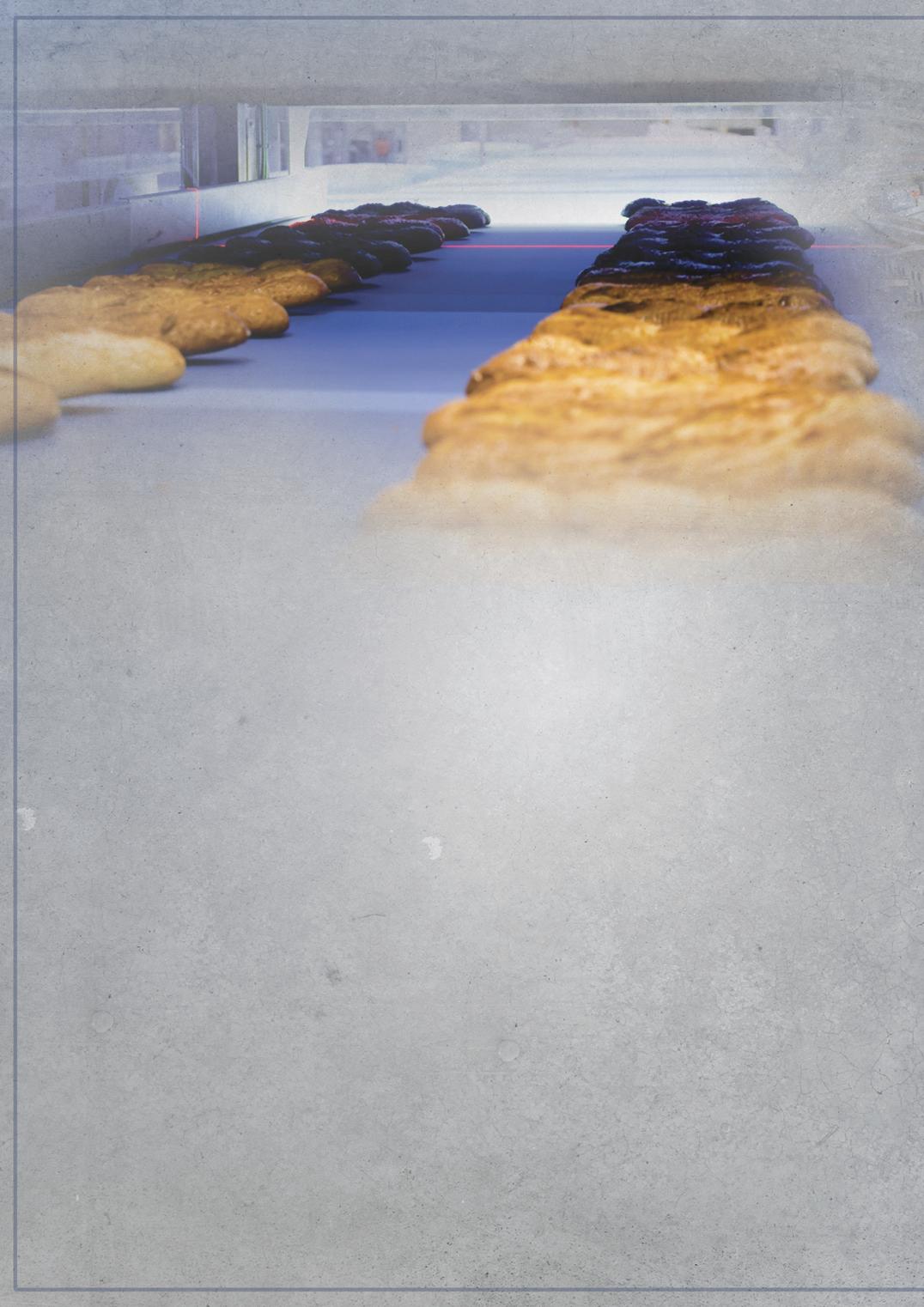

To continue the growth of the company, a significant acquisition came a decade ago when Pattyn acquired the majority stake in the French company De La Ballina Industrie (now Pattyn France); a specialist in bakery solutions.

This acquisition has enabled both companies to provide complete solutions to count, weigh, organise, control, fill and pack bread or pastry products into lined cases. These include semi-automated and fully automated lines with artificial vision, such as the vision-counting system ArgoCount-31.

“We have vision inspection on the frozen bread, meaning we can count and review the quality of different bread and pastry products,” Mr Lips explained.” We have also strengthened this competence with the acquisition of Visionerf, a company specialised in 3D Vision technology.”

Automated solutions that Pattyn provides to its customers every day increase the efficiency and productivity of the packaging process. The vision system

ODICE

Becker is your trusted partner for customised industrial vacuum solutions. With a global presence and 135 years of experience, Becker provides innovative solutions that enhance the efficiency of your installations. Our extensive experience ensures superior reliability and reduced maintenance expenses. Choose Becker for unparalleled quality and exceptional service.

MAKE IT BECKER.

editorial mention

detects – at high speed and with high precision – defects, contaminants, functional flaws and other irregularities in manufactured products.

Innovating for the future

Expansion continues at Pattyn with investments in facility additions. Currently, in Bruges, plans are underway for the current assembly area to double in size. These renovations will be completed by the end of 2023.

“In terms of new machinery, we typically focus on adding robustness into the processes by allowing user-friendliness and accessibility for the operators, remote connection and data sharing,” Mr Lips said. “That is the direction a lot of our innovation is heading in today.”

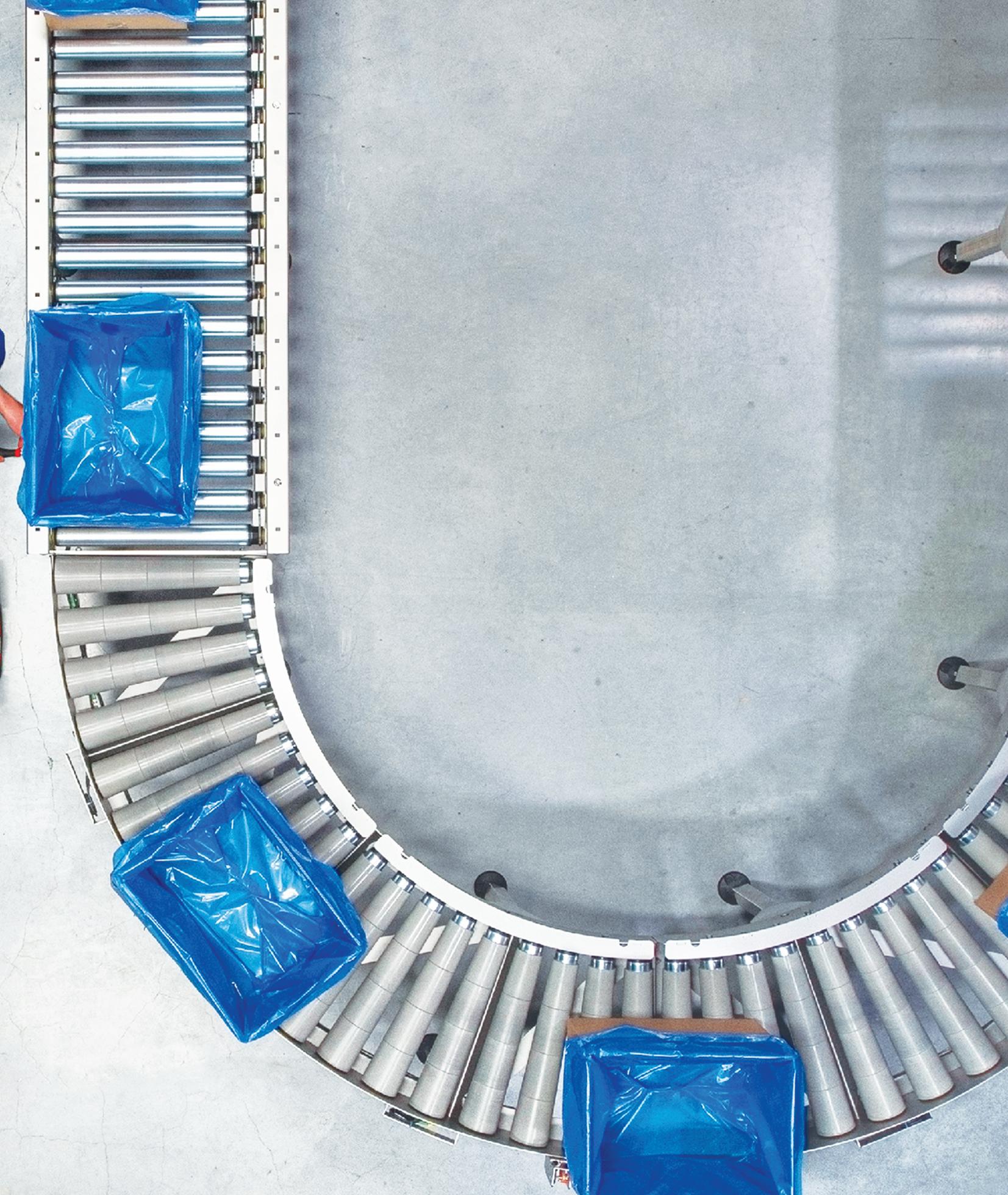

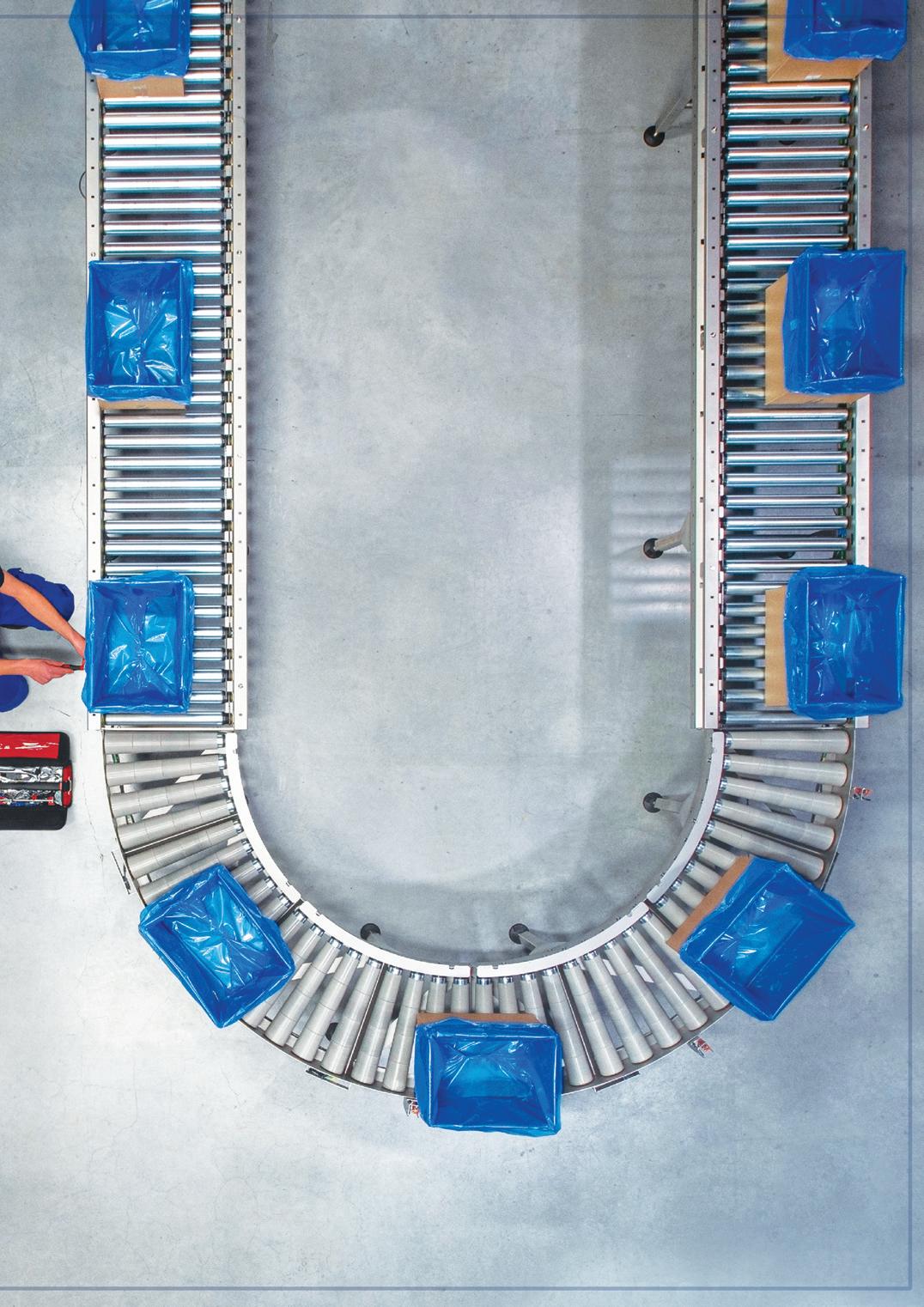

The company outclasses its competition by providing fully integrated turnkey solutions, which includes the automated moving of products from one machine to another.

“Our solutions are optimised to work in a seamless manner because we’ve actually programmed and integrated them ourselves,” said Mr Lips. “This is where we excel; in the engineering skills and integration we offer. We see a lot of the competition focusing on just selling machines or externalising programming & design.

“But we have carved our own niche by giving the customer the full flexibility on the consumables they want to use: and we focus on providing them with the best possible packaging line.”

The worry-free journey

Pattyn’s operations and ethos are defined by its customer focused slogan: ‘It’s all about U.’

“It means that we want to unburden our customers as much as possible,” Mr Lips explained. “From the sales phase, over the management of the project and later,

t he aftersales service, our people will speak the language of the customer and provide them with the best possible service and solutions.”

Alongside excellent customer service, for a company with longevity such as Pattyn, a long-term relationship with its suppliers is equally crucial. But what is the secret?

“We don’t shop around,” said Mr Lips: we stick to a number of bigger suppliers and build lasting partnerships with them. That way we can innovate, keep a consistent standard of quality and grow together with our suppliers.”

Representatives from Pattyn are set to be networking with both customers and partners alike at the world’s largest food exhibition, Gulfood Manufacturing, which returns to Dubai in November.

As Mr Lips reflected, the benefits a change of scenery can bring to

business conversations should not be underestimated: “Events like Gulfood allow us to interact with our customers in an environment that is not purely operational, and we can discuss longer term plans or new developments. Gulfood has always been very good at bringing us into contact with new people too. We get to network with a lot of potential clients from the Middle East and India.”

For Mr Lips, it is the opportunity to travel and meet potential clients around the world that keeps the job so thrilling. “Customers all over the globe can have very different expectations due to the industry and culture in which they are active,” he concluded. “I like working to find different solutions for different customers. There is no ‘one-size-fits-all’ and that really excites me.” n