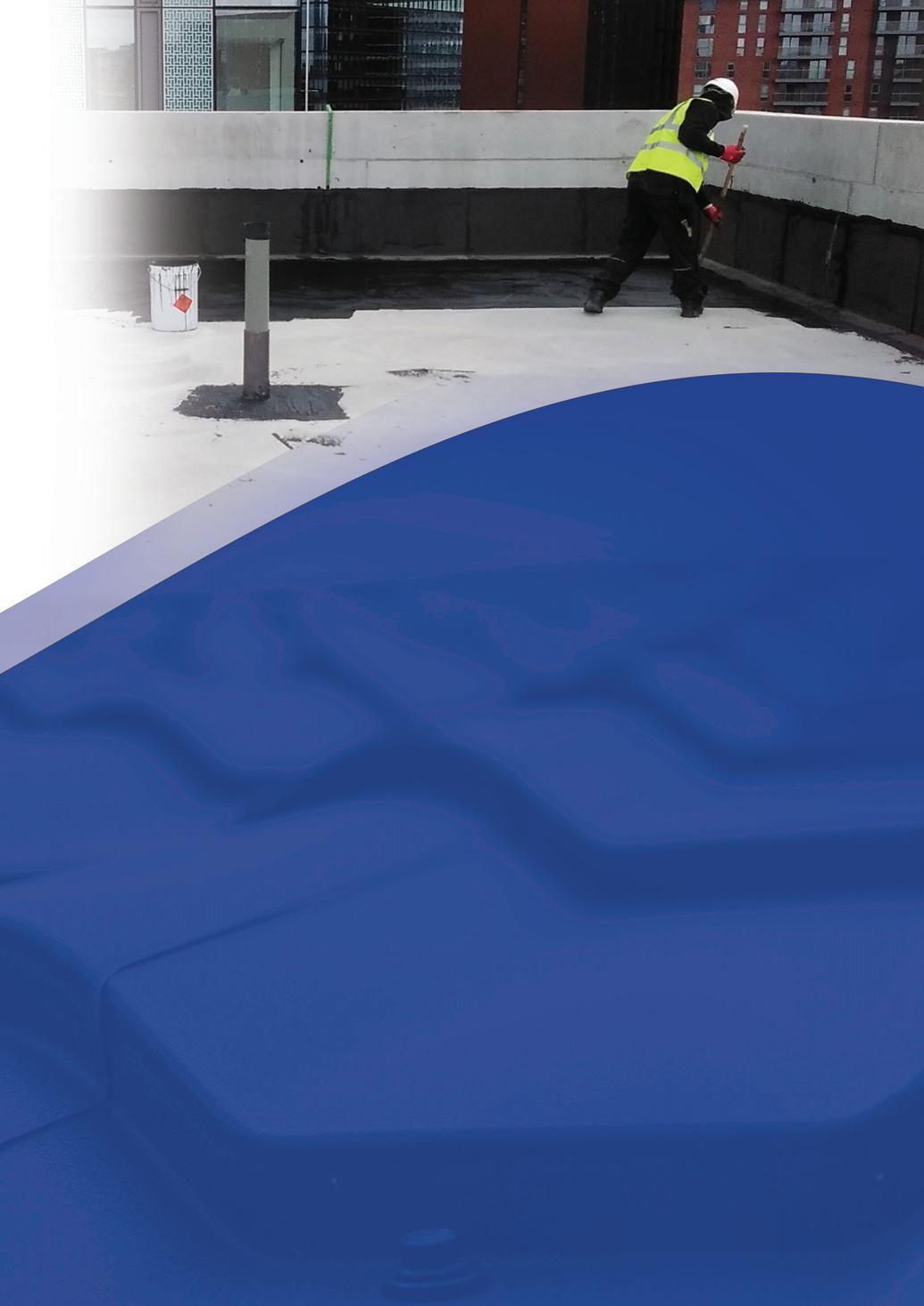

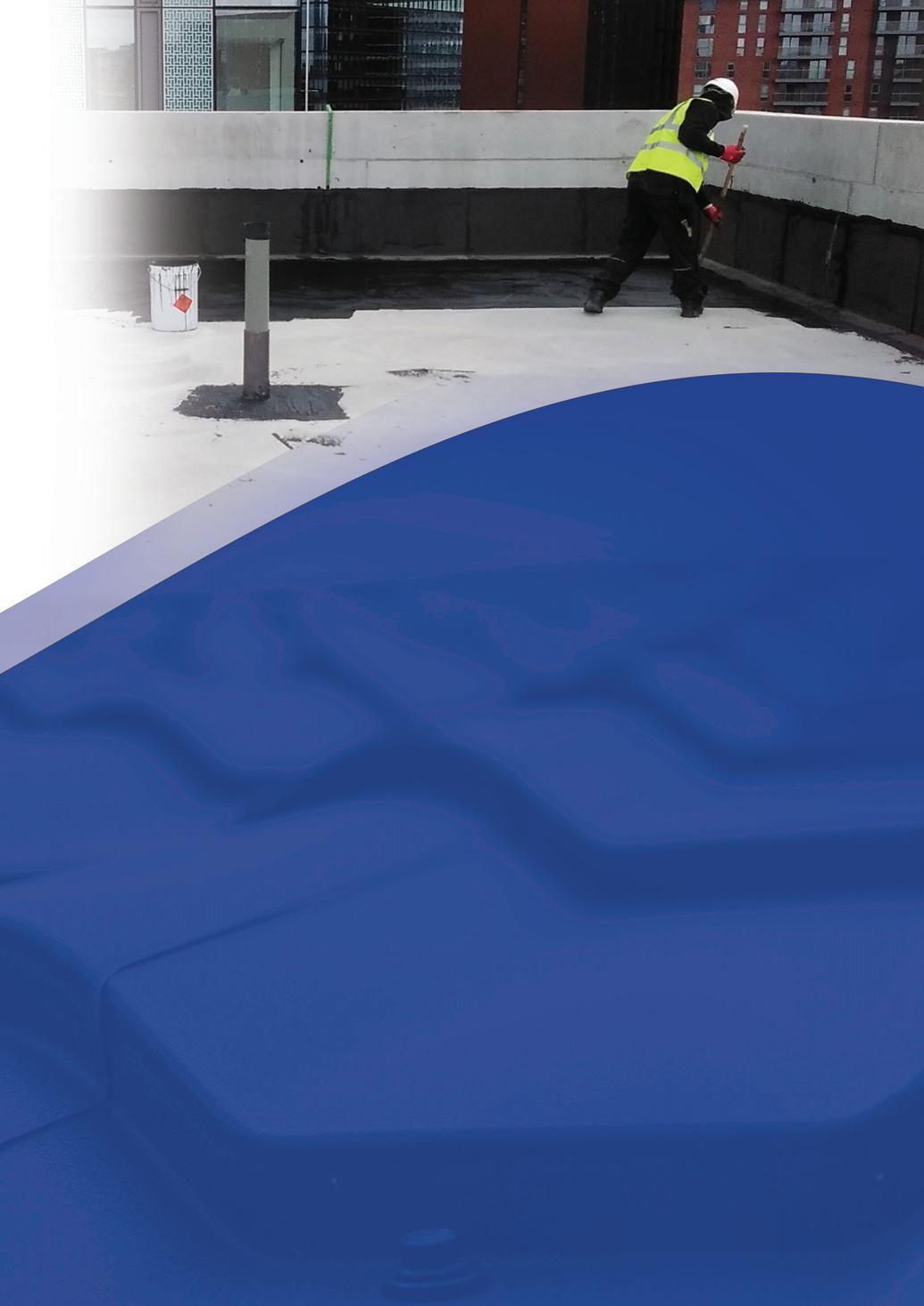

LRL ROOFING FLAT ROOFING SPECIALISTS THAT KEEP EVOLVING Powered by Inside Sustainability inside-SUSTAINABILITY.com

LRL Roofing Solutions was established in 2003 as Liquid Roofing Ltd, with the primary goal of delivering high-quality liquid applied roofing systems. The company has since evolved into the bituminous sector, which now accounts for around 65% of the market. Hannah Barnett spoke to Sales Director Chris Rea and Marketing & Communications Coordinator Joshua Ford to learn more.

When Liquid Roofing Ltd changed its name to LRL Roofing Solutions, this reflected the company’s intentional move towards the bituminous sector. This shift has proved beneficial; not only did it complement the way the market

was going, but it also allowed the company to be more flexible than ever.

“We can offer any roofing system for a flat roof,” said Chris Rea, Sales Director. “We try and provide the right solution for the client on every project, not just the most cost-effective one. We’ll give them different choices,

168 Inside sustainability

LRL ROOFING SOLUTIONS I PROFILE

while also suggesting the best option and the reasons behind that. We are service driven.”

A change of focus

LRL’s rebrand in 2019 was in part due to the appointment of a new MD, Rob Richmond. Mr Richmond came from a felt background and saw an opportunity in the market.

“Initially, anything to do with liquid coatings was our bread and butter,” said Mr Rea. “Our rebrand reflected that the industry changed. We went from a lot of liquid projects to bituminous, hot melt and different roofing systems. Though we still do a lot of liquid coating jobs, the labour that we have now are

predominantly felt operatives who install bitumen membranes.”

As a result of this change, LRL doubled in size and to accommodate that recently moved to a bigger HQ, in Eccles, Greater Manchester. Growth was supported by an £11 million turnover in 2023.

On site, the company uses a mixture of directly employed labour and subcontractors, working with large tier one companies like Morgan Sindall and Kier Construction, as well as directly with clients.

LRL has dedicated itself to working closely with its supply chain to develop safe installation methods for bituminous services, incorporating enhanced fire watches and flame-free detailing. Mr Richmond was an instrumental part of the Safe2Torch

Inside sustainability 169

LRL ROOFING SOLUTIONS I PROFILE

guide line panel, a National Federation of Roofing Contractors (NFRC) campaign, seeking to significantly reduce the risk of roof fires when using gas torches.

The scope of sustainability

LRL is striving to improve its environmenta l credentials. This is a non-negotiable when working with large constructions companies.

“We want to be at the forefront, by reducing our carbon footprint and using more local suppliers, where possible,” said Mr Rea. “We have several electric vehicles already, though not yet the vans that we use on site due to cost, but we are looking into solutions for that.”

Marketing & Communications Coordinator Joshua Ford explained how a carbon reduction course, in partnership with Manchester Metropolitan University and

the European Funding Initiative, has given the company further insight and direction.

“I went on the course to get more understanding about our Scope 1, 2 and 3 emissions,” said Mr Ford. “It has enabled us to tackle the easier, ‘low hanging fruit’ changes first. One thing we’ve done is created a new project coordinator position. She investigates managing projects in a more environmentally friendly way, such as organising labour transport as efficiently as possible, choosing the routes and grouping people up. And then we will move on to more long-term measures.”

One bigger picture solution in the works involves a process whereby two quotes are given for each job: one per specification, then another, carbon neutral option.

170 Inside sustainability

“We don’t know whether that’s physically possible yet,” Mr Rea explained. “There are various systems on the market and some insulation boards are lot more environmentally friendly than others. So, we are working with manufacturers and the big main contractors to develop a solution that others haven’t managed yet.”

LRL has already been recognised for its sustainable work. A notable Jodrell Bank project with Kier Construction and Bauder

Flat Roofs won a 2023 NFRC award in the green roof category.

“It’s basically a dome covered roof with a sedum blanket system which blends into its surroundings and, obviously, takes in CO ₂ and gives out oxygen,” said Mr Rea. “That was a really interesting project to showcase what we can do.”

Another significant venture took place at Wythenshawe Forum, a live community building housing various retail, medical,

Inside sustainability 171

leisure and educational facilities, with a main transport terminus located on-site. Construction took place during Covid, which meant battling with different restrictions. Working closely alongside Bauder, LRL successfully installed a new single-ply bituminous roof system, as well as completing removing a flat-to-pitch roof conversion. The energy-efficient roof is now covered by a 20-year manufacturer’s guarantee.

Working partnerships

Keen to see improvement internally as well externally, the company recently went through Lean Six Sigma training to increase the efficiency of its workforce.

“I’ve worked with a lot of very good con tractors, and many of them don’t necessarily want to grow or change,” said

Mr Rea. “But we’re trying to progress and grow naturally. Plus, we’ve got a wide range of knowledge within the office because we’re all from different backgrounds. If someone doesn’t have an answer, someone else may well do. It’s a really strong, productive team.”

LRL also works closely with a network of partners and suppliers, maintaining a mixture of local and wider-reaching partnerships to achieve optimal success.

“Relationships are very important,” said Mr Rea. “For example, to grow in the northeast, we need contacts in the northeast. But we work with all the major suppliers too; Bauder, Alumasc, IKO, Garland. And then on the liquid side, we’ve got Polyroof, Centaur, and Sika who also do bituminous We’ve got strong partnerships with all the suppliers and we’re not completely reliant

LRL ROOFING SOLUTIONS I PROFILE 172 Inside sustainability

on manufacturers to generate enquiries for us, we go out and do that ourselves as well.”

To continue to deliver to a high standard, the company is focused on sustaining a skilled ongoing workforce. “Securing the work isn’t necessarily the hard bit, it’s delivering the work,” Mr Rea explained. “We can win X million pounds worth of work, but we need the team in place to be able to deliver it.”

As a result, LRL has established relationships with various colleges to find the roofers of the future, with Rob Richmond already running sessions in Manchester and North Wales.

“It’s to show that there are opportunities and good progression routes within roofing,” Mr Ford explained. “For Rob, that’s key. Personally, I didn’t know any thing about roofing when I started here as an English graduate. But now, it excites me being part of modernising the roofing industry while communicating that to our clients and potential employees.”

For Mr Rea, motivation lies in the everdeveloping nature of the industry. “I’ve been with the business more than 18 months, and I’ve seen the company evolve in that time,” he concluded. “We have moved to new offices; plus, turnover and project delivery has been going in the right direction. It’s exciting to see where we can go and our continuous improvement. It’s all about changing the smallest things to enable a larger result.” n

Inside sustainability 173

Sales Director Chris Rea (right) picking up an award at the Morgan Sindall Supply Chain Awards.