Having built solid foundations over 60 years ago, Lisnave has developed a reputation for world leading excellence when it comes to ship repair. Now, with the renewables sector growing rapidly, the company is looking to expand its presence in this area. Commercial Manager Luis Braga divulged the latest news, directly from Mitrena Yard in Portugal. Report by Imogen Ward.

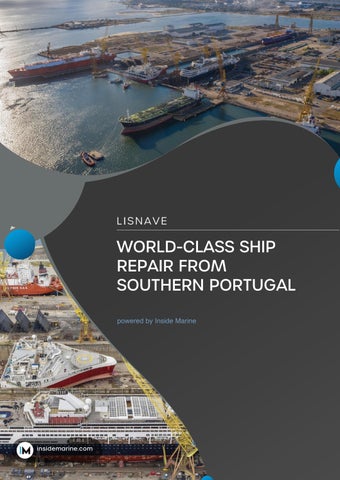

i th 1.5 million square metres of land, Lisnave sits upon the river Sado estuary in Southern Portugal. The yard is perfectly located to meet the needs of vessels travelling through the Mediterranean Sea and across the Atlantic Ocean.

“Our facility has huge potential due to the large area, location and extensive waterfront,” Commercial Manager Luis Braga said. “We have major investments on the table, not only to improve the efficiency of our repair work, but also for activities relating to the renewable offshore energies and ship recycling.”

Future-proof facilities

Originally located on the north bank of the Tagus estuary, Lisnave relocated to the south bank in 1967 and to its current

location in 2000. Since then, the company has upgraded its facilities several times. “We have six graving docks, two of which are VLCC size, one Suezmax and three that accommodate Panamax vessels,” said Mr Braga. “The three Panamax docks are the newest and are controlled via a hydro lift system. It was a Portuguese engineering project, which uses similar mechanics to the Panama Canal.

W“The gates elevate the water level so the vessel can cross from one side to the other; once the water has been drained out it looks just like any other graving dock.”

Lisnave’s yard is also home to more than ten workshops, including piping, mechanical, steel and a whole host of smaller complementary spaces. With these impressive facilities, the company can achieve an abundance of repair-related activities.

“Surface treatment is something that we do to every docked vessel,” Mr Braga explained. “Every five years, clients want their vessels looking beautiful again. Furthermore, the removal of marine growth from the hull results in big fuel savings and lower GHG emissions. So, having blasting

and painting capabilities in-house is a must. We also have a huge steel department, where we can renew any kind of steel, affected by corrosion or damage. We even complete retrofits and upgrades too.”

One of the biggest retrofits currently on Lisnave’s books is a bulk carrier conversion. With previous experience in vessel conversion, the company has been tasked with changing the vessel into a juice tanker. During this project, Lisnave will install several juice tanks inside the ship’s cargo holds. “The juice tanker is a major retrofit project that will require some transformation of the ship,” Mr Braga said. “We are already in the planning phase and there is a lot of engineering underway.”

Sustainable shipping

The word sustainability is rife across the maritime industry. With EU emission regulations becoming stricter, Lisnave has been awarded a number of

up-g rade projects, to ensure customers remain compliant.

“We have upgraded several cruise vessels so that they could reach emissions levels below tier three,” Mr Braga said. “We installed selective catalyti c reactors, which allow the vessels to sail in the regions with the strictest regulations.”

2023’s schedule is already filling up fast for Lisnave, with seven cold-ironing projects underway. Several bulbous bow replacements are also on the horizon: intended to reduce drag, these retrofits will improve fuel efficiency and reduce the vessels’ carbon emissions.

Having previously manufactured newbuilds until the 1990s, Lisnave still has a large newbuilds area that it is eager to repurpose. With the demand rising for more environmentally friendly projects, the company hopes to make the most of these facilities. “Our goal is to continue with what we are doing,” Mr Braga said. “Ship repairing will remain our core business, but we have a large

area – about a third of our facility – that is currently underutilised. So, we would like to see that dedicated to work within the renewables sector.”

As part of its commitment to ESG, Lisnave also has a high waste recycling rate. All waste produced at the shipyard is sent to licensed processing companies, around 90% of which is either recycled or recovered.

“We believe in promoting a circular economy,” Mr Braga explained. “In line with that philosophy, we donate all our used grit – a residue produced from

“WE WILL ALWAYS STRIVE TO PUSH OURSELVES WITH NEW AND CHALLENGING PROJECTS THAT IMPROVE OUR CAPABILITIES”

blasting activities – to the cement industry, where it is used to manufacture cement. This is then used in a large por tion of Portugal’s infrastructure. We follow the best waste management practices and abide by the latest technical solutions to continually improve recycling rates.”

Enthusiastic employees

The company has also been promoting awareness for the current climate crisis. In November last year, employees at Lisnave planted a 50 square metre Miyawaki micro-forest on its premises. Featuring 23 different native species,

the forest was designed to improve air quality and help offset carbon emissions.

“The forest is very symbolic; it’s one of the ways we are trying to raise awareness,” said Mr Braga. “Everybody at Lisnave shares this mindset. We have also installed a solar panel park capable of generating one megawatt, which currently covers around 5% of our energy consumption.”

Not only does Lisnave provide its employees with opportunities to volunteer within the community, but it also offers all staff in-house training. The yard even has its own school, running numerous courses throughout the year providing vocational education for

aspiring individuals. This facility has helped the company overcome one of the biggest challenges currently faced across multiple sectors.

“Finding skilled labour seems to be a recurring issue across the whole of Europe,” Mr Braga said. “That’s for all industries, not just ship repair. Although Lisnave is not an exception, we have our own training school inside the shipyard that has helped mitigate that challenge. We are always giving young people the opportunity to become part of the Lisnave Family.

“ Those who attend our school are also not bound to Lisnave; some stay and some go. We never know if they are going to settle: it is a long and

expensive process, but it’s essential because, without it, our numbers would be much lower.”

Despite the recent challenges, Mr Braga is confident in the future of the business: “I have worked at Lisnave since 1995. I have witnessed history being made. We have always stuck through the tough times and made it out the other side. I got to watch as the company rose to its market leading position. Now, more than 70% of our business comes from returning customers, whom we are very committed to.

“We will always strive to push ourselves with new and challenging projects that improve our capabilities,” he concluded “I think that’s the best mindset to have.”