TIDE

powered by Inside Marine

powered by Inside Marine

LD Tide is a joint venture between the French-owned Louis Dreyfus Armateurs (LDA) and the British-run Tidal Transit. The former has almost 170 years of experience in various maritime solutions, recently expanding into renewables. The latter offers transit services for the marine industry and is recognised as a specialist in offshore power. Gaël Cailleaux is Managing Director for Renewables at LDA, and Leo Hambro is Commercial Director at Tidal Transit. They explained to Hannah Barnett how LD Tide is putting the wind in the sails of the offshore industry.

Situated off the coast of Brittany, the Saint-Nazaire wind farm is set to supply approximately 20% of the domestic electricity consumption of the Loire-Atlantique region for the next 25 years. Following an international call for tenders, developer Eolien Maritime France (EDF-RE & Enbridge) and GE contracted LD Tide to produce three innovative Crew Transfer Vessels (CTVs) for the farm. They will transfer technicians between the coast and the farm for maintenance of the electrical substation and of the wind turbines in their operating phase.

Though LD Tide is an Anglo-Franco endeavour, it is also fundamentally French. “We managed to have a French design and a French shipyard to deliver the boat,” said Gaël Cailleaux, LDA’s Managing Director for Renewables.

The CTVs sail under the French flag and their innovative design was entrusted to Mauric, a naval architecture firm based in Nantes.

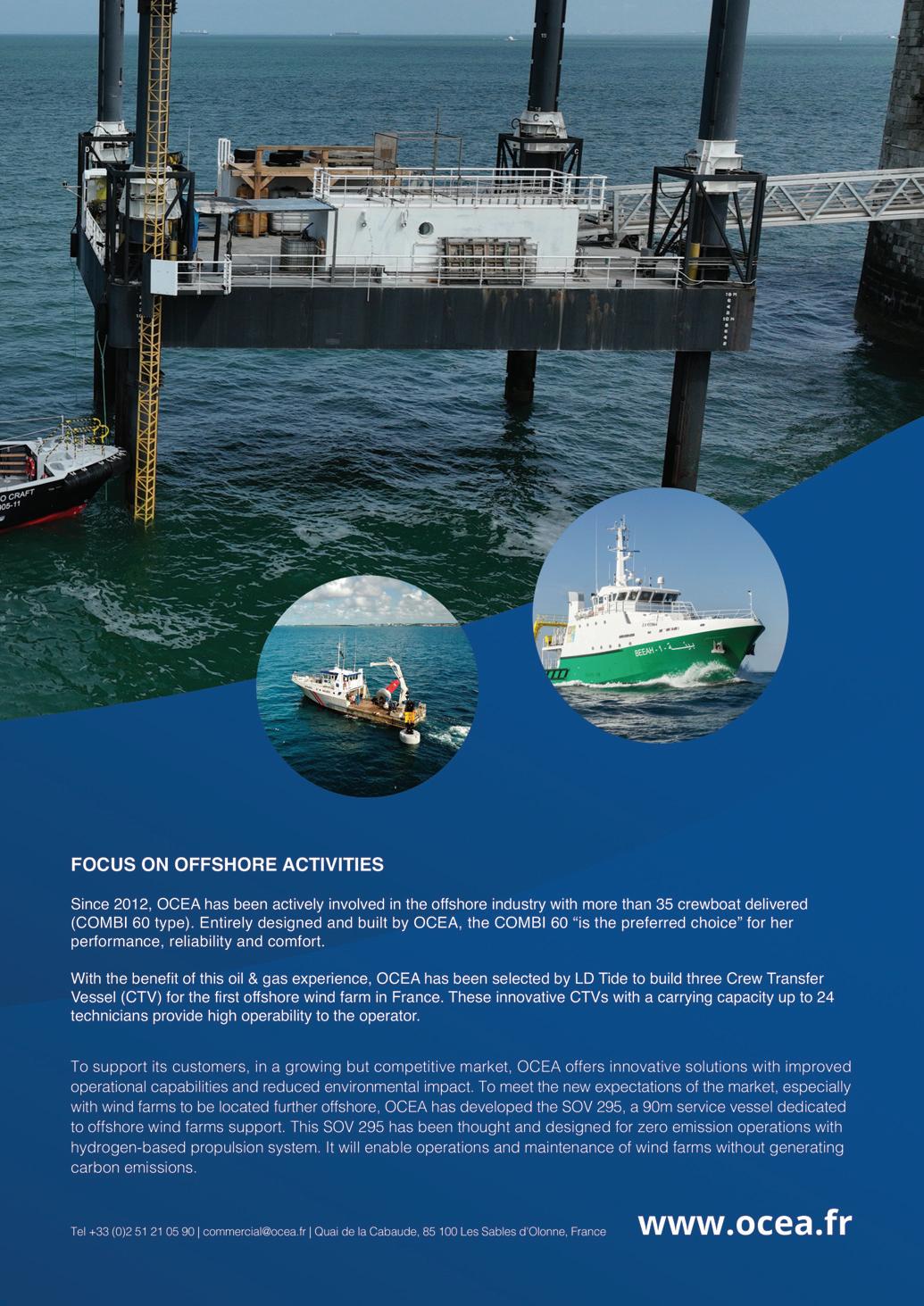

Construction was carried out by French shipyard OCEA, a market leader in the production of aluminium ships.

Mr Cailleaux said that this regional focus was beneficial in securing the bid: “We had a plan to develop activities locally. All our crew are from the area. We’ve managed to do that because we’ve secured long-term contracts of more than five years. That gives us visibility. We said if we have a long contract, we can commit to develop local activities with local people. And that is what we did. We have an integrated innovation and engineering team within LDA who worked closely with the ship designer and shipyard.”

One of the strengths of the LD Tide project has been the tools brought to the table by both sides of the venture.

“We felt that our experience in renewables in the small boat market would help bring LDA further into this industry,” said Leo Hambro, Commercial Director at Tidal Transit. “And then it

started to gel, we had some really fruitful conversations about our experience. Tidal Transit has predominantly worked with Equinor, RWE and Siemens. We have excellent coverage of the market in terms of existing contracts.”

Similarly, LDA subsidiary Louis Dreyfus TravOcean, which specialises in cable trenching, was able to contribute expert knowledge at the production stage.

“They’ve developed an innovative solution for the Saint-Nazaire wind farm,” Mr Cailleaux said. “The sides were too rough for jetting or mechanical trenching, so we laid the cable with mechanical protection. We provided this alternative solution and delivered the project earlier this year, ahead of schedule. It’s a great success. We’ve gained the confidence of new customers with our capability to provide them with pioneering, cost-effective solutions. This is how we’ve entered the renewables market as EPCI contractor, after many years of operating as trenching services provider.”

Operating the Saint-Nazaire wind farm are some of the world’s biggest energy firms. One CTV vessel is contracted to French-based

energy conglomerate EDF, the other two by GE. According to Mr Cailleaux, they proved very valuable clients: “Both have been very supportive and assertive on some of the features of the vessel. They were thorough about quality and performance. They’ve also offered long-term contracts, which allowed us to take risks on the design.”

And there is plenty about the CTVs design that is cutting-edge. Mr Hambro explained that LD Tide vessels are ‘not a standard commoditised CTV design’, but something that reflects years of experience in the market.

“At Tidal Transit we’ve had MAN engines in our in our boats since we started,” Mr Hambro said. “We’ve even gone out and bought second-hand boats because they had MAN engines in them. We wanted to make sure that the CTVs continued to use MAN engines because they have been bulletproof for us; not only reliable but extremely efficient.

“These boats are diesel hybrids with options to further decarbonise when the availability and density of batteries increases. But they already have the ability to charge the battery.”

As well as considering its long-term sustainability, LD Tide is also taking the immediate environment of the CTVs into account.

“We’re dealing with the Bay of Biscay, which is not the nicest of places to have to sail every day,” Mr Hambro explained. “The weather conditions are much rougher than the coastal environ -

ments in the North Sea. We've had to build something that's stronger, more capable than other CTVs in the market. So that's why we've gone for a tank of a model. And to make the tank efficient, we have the hybrid engine and the Foil Optimisation and Stability System which is a key part of the Mauric design. This increases not only comfort for passengers, but also the efficiency of the vessel.”

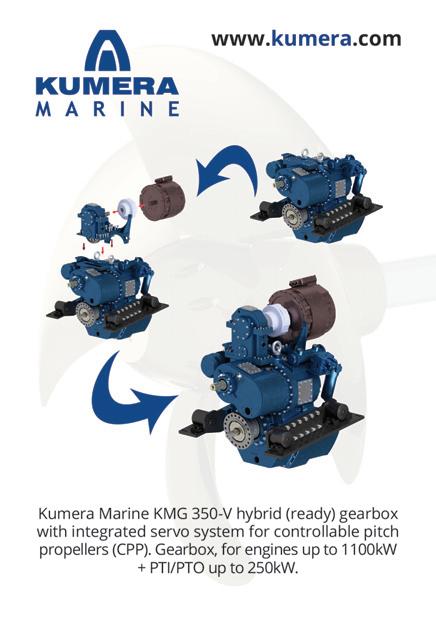

Being adaptable has proved a key element in the LD Tide venture. “Our business in the UK uses fixed pitch propellers and water jets,” Mr Hambro said; “Whereas going into the French market and the Bay of Biscay, we've looked into Controllable Pitch Propellors (CPPs). We've combined the best engines with the most advanced CPP system and made life a bit more complicated for ourselves, rather than using the more standard fixed pitch propulsion systems.”

Both Mr Cailleaux and Mr Hambro were excited about the future of the industry, and LD Tide’s place within it.

“Every time I open a paper, I see something about offshore wind,” Mr Hambro said. “We're selling shovels into a market that produces the real goods. The potential for growth in the vessel sector is enormous. There are about 320 CTVs in the market, with the projection of getting to 550 by 2035. And by 2050 they're talking about 800 or so.”

This is a very exiting environment for innovation, Mr Cailleaux added: “We have an electric hybrid solution ready to go, and a more advanced design to push further the operating limits. The hull, the material, the propulsion, the fuel (Methanol or Hydrogen), all aspects of these vessels are innovative. This is the future. By providing these types of solutions, we hope to convince the customer that the extra pennies they pay now will be a solid foundation to save on future operations and their CO2 emissions.”

As this is also an initiative that began at the start of the Covid pandemic, it does not seem too extreme to suggest the sky is now the limit for LD Tide.

“During the first lockdown we managed to win tenders with GE and EDF for 12- and five-year charters respectively,” Mr Hambro recalled. “We managed to negotiate with the shipyard, get the design work agreed with the naval architects and the clients, and get the money together to start delivering. It’s been a phenomenal couple of years. If we can endure what we have endured, then I’m very excited about the potential of what we can achieve in this market.”