INDUSTRIAUMBRA’s commitment to developing unique products follows its creation from the merger of two Italian paper industry heavyweights. Now, with a focus on developing sustainable solutions, the company has teamed up with Canadian-based Competitive Green Technologies. INDUSTRIAUMBRA’s Industrial Director Nicolò Fiorucci and Corporate Unit at Industriaumbra Dr Giulia Bendolini explained more, in an exclusive interview with Inside Sustainability. Report by Imogen Ward and Colin Chinery.

Working in partnership, INDUSTRIAUMBRA and Competitive Green Technologies have developed a new and exciting facility that is set to position the companies in a unique position within the market.

“Together, we have established a new company, the CGT Production Center srl, within the green core of Italy,” Corporate Unit at Industriaumbra Dr Giulia Bendolini explained. “This investment is set to position INDUSTRIAUMBRA as a natural sustainable industrial manufacturer that is unlike anything the market has seen before.”

“Having completed 2023 with a turnover of over €27 million, and so many exciting developments on the cards, we have a very busy year in front of us,” INDUSTRIAUMBRA’s Industrial Director Nicolò Fiorucci added, in support.

Four years ago, INDUSTRIAUMBRA was founded from the merger of two major Italian paper sector businesses, Brefiocart and fisadorelli.

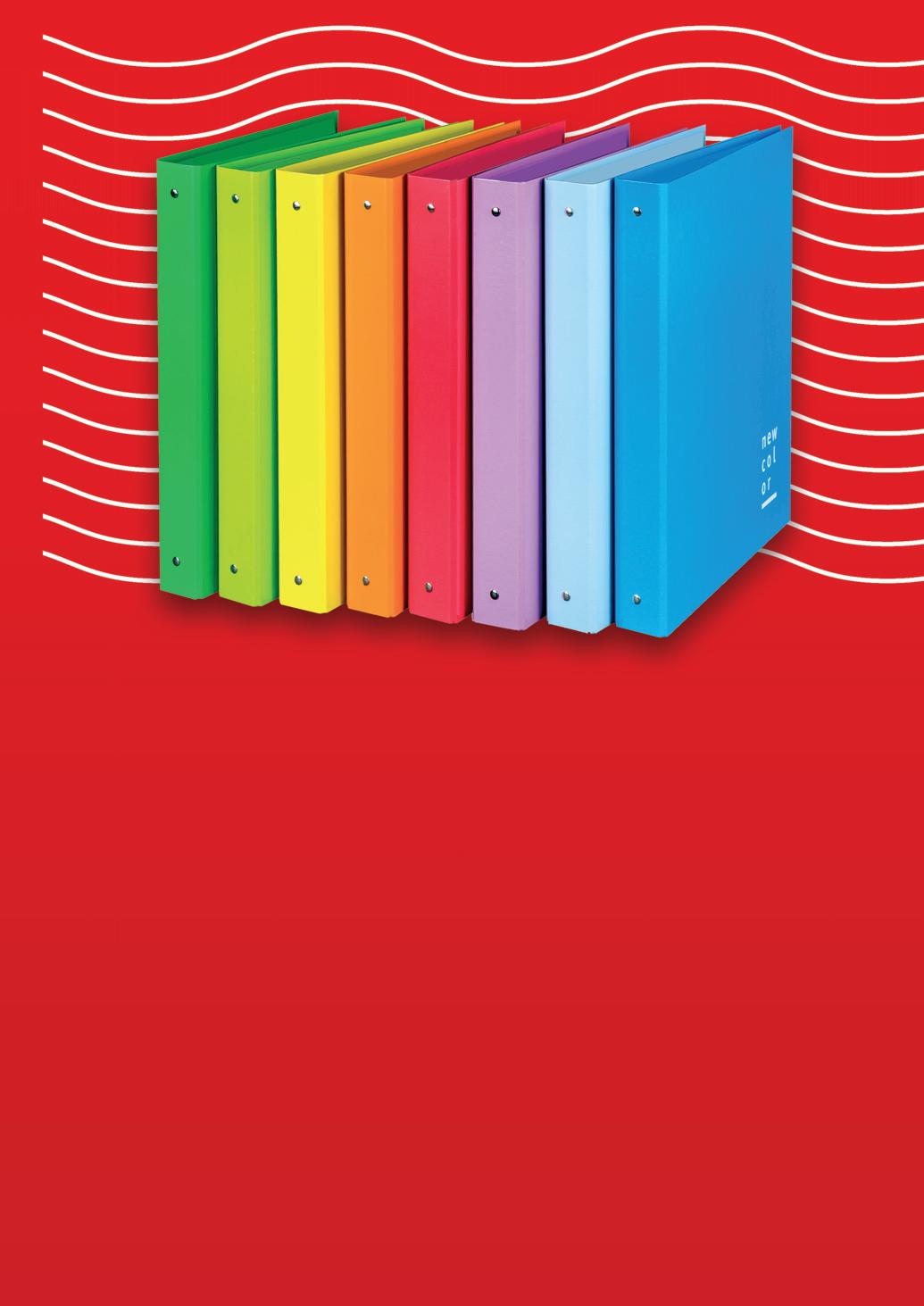

Launched in 2003, Brefiocart had a long tradition in the production of paper products for office archiving and school sector material. A capacity to integrate production and commercial specialisation, along with a development strategy based on specific national market needs, rapidly established it as market leader.

Meanwhile, fisadorelli was founded in 2011 from a collaboration between Fisa, an historic paper converting company in Umbria, and entrepreneur Alessio Dorelli. This company grew to become an international award-winning European reference in the sector of material for points of sale.

With an inherited undisputed leadership in domestic and international markets, INDUSTRIAUMBRA launched in 2020 under a consolidated management, and enhanced industrial abilities aimed at uninterrupted innovation. Today, the company maintains a core emphasis on sustainability, which is fitting for a company based in Umbria, an inland region often called Italy’s Green Heart.

INDUSTRIAUMBRA has also gone on to gain an impressive award-winning status.

“INDUSTRIAUMBRA recently won the Best Supplier award from HH Global, the world leader in tech-enabled creative production,”

said Mr Fiorucci. “They look for suppliers that can provide first-class designing services and product development, and INDUSTRIAUMBRA ticked that box.

“We recently designed, developed and produced a beverage dispenser for Coca-Cola for the 2024 Paris Olympics. This machine is 100 per cent sustainable and every component is recyclable. This drink fountain is meant to impose the use of re-usable glasses, in order to eliminate the need for traditional single use beverage containers such as bottles or cans.

“Coca-Cola is so happy with these machines that it plans to re-install them in various places after the Olympic games are over.”

With its focus remaining on sustainability, INDUSTRIAUMBRA has developed a growing partnership with CGT.

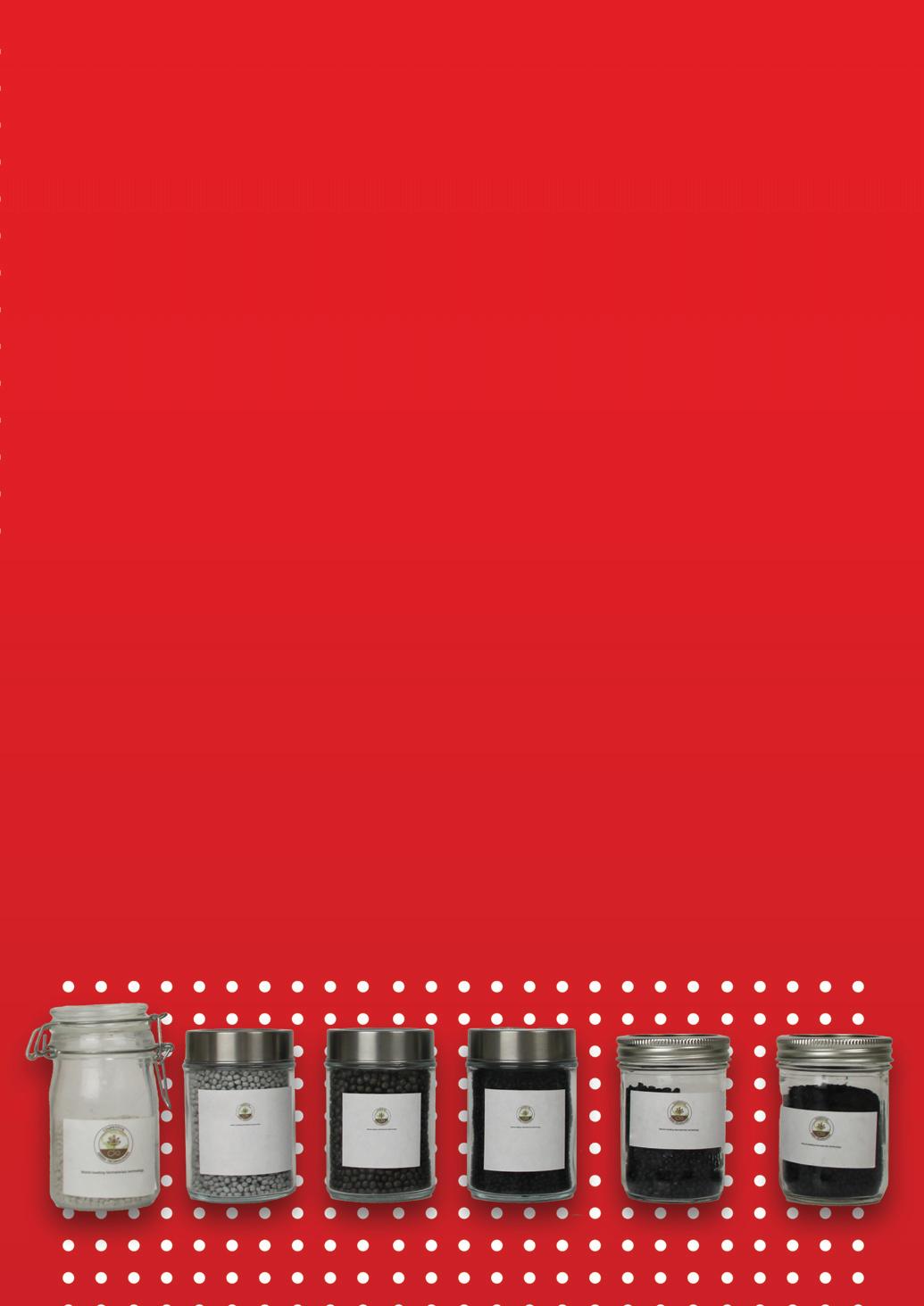

Ranked among the ten best bio-composite resin manufacturers in the world, Ontario-headquartered Competitive Green Technologies’ founding vision is to popularise biomaterials in the quest for a greener planet. Today, it is the leading producer of bio-composite resins and biopolymers for a range of commercial products, including coffee pods, food packaging and lightweight automotive parts. This collaboration led to the creation of a new company – the CGT Production Center – focused on the production and commercialisation of bio-composite resin and biopolymers.

“The CGT Production Center’s objective is to create a European point of reference in the production and commercialisation of the innovative raw materials of Competitive Green Tehchnologies, based on a ten-year

exclusive licence,” said Dr Bendolini. “We work with the development team at the research University of Guelph BDDC in Ontario, which is our collaborator in implementing new technologies. One of my goals has been to collaborate with the Vice Presidents of Industriaumbra and CGT to invest in innovation, byproducts, and the circular economy in this new plant in Sigillo, Italy.”

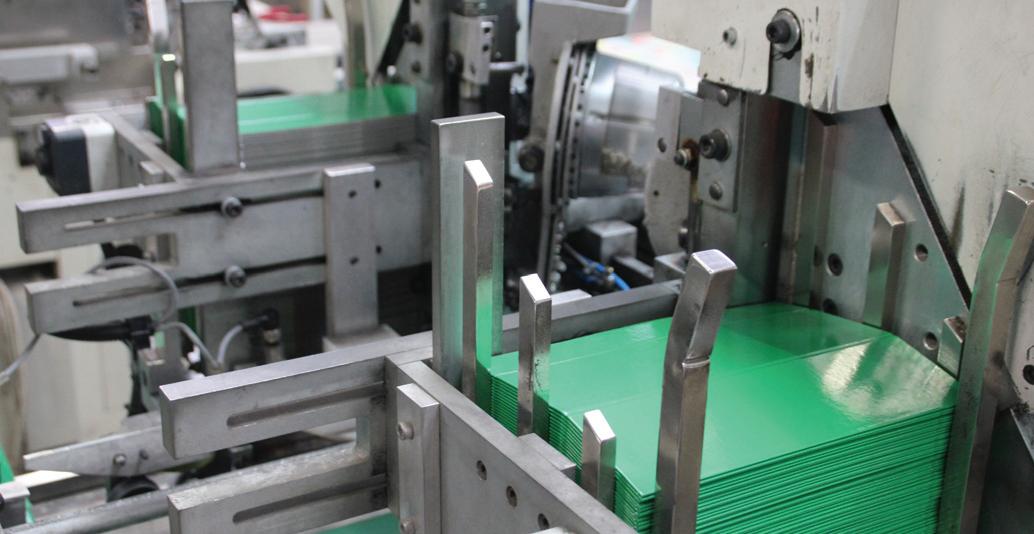

With a twin-screw extruder in place, the CGT Production Center now has a

5,000-tonne per year production capacity, but an upgrade is expected in the near future.

“Our extruders allow us to make compostable products using bio-composite sourced from non-edible food waste and, until today, over thirty-five variants of biomass – none with an edible background – have already been sourced,” Dr Bendolini continued. “Our products do not create any microplastics, which makes the product much easier to dispose of at the end-of-life

s tage. This is our own unique way of contributing to the environment, and it is a great way of getting our customers to partake in a more circular economy.”

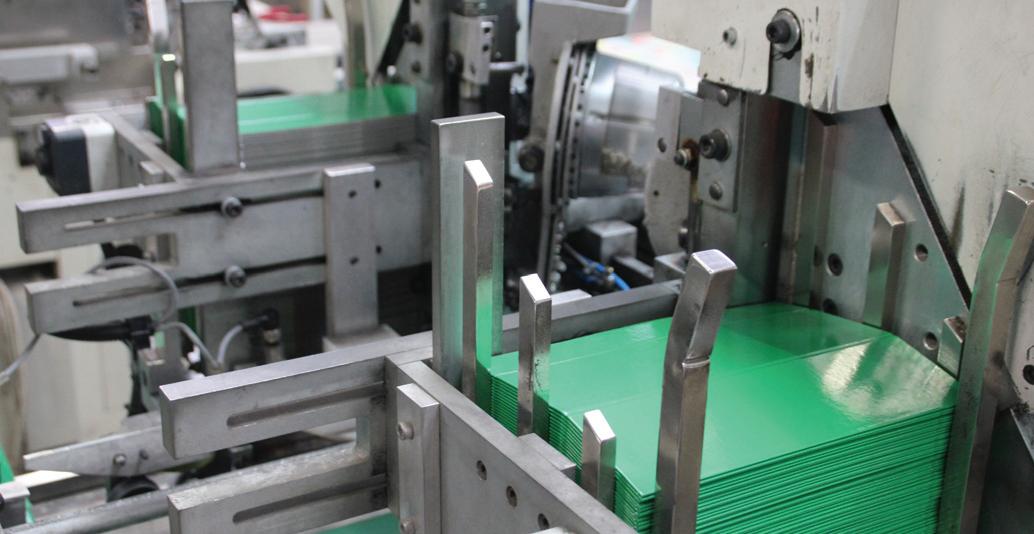

Meanwhile, INDUSTRIAUMBRA’s threestage corporate construction programme is nearing completion, according to Mr Fiorucci: “The first phase, completed two years ago, was about harmonising the processes, creating organisational efficiencies and a single and specific standard for the new organisation.

“The second phase, finished some three months ago, was a physical one; creating new physical processes using effectiveness and efficiencies for production. We also invested heavily in a new 35,000 square metre premises. We moved all machinery and production systems into this single unique plant, where we have invested in green technology for energy production. “

As part of this development, the company has also worked hard to eliminate plastic. INDUSTRIAUMBRA no longer uses PVC labels on its products: instead it has opted for

a paper-based alternative. The company is also experimenting with the use of bioplastics, which it hopes to implement in the near future.

“We are also focused on transitioning from animal-based glues to a plant-based alternative that will be much better for the environment,” Mr Fiorucci continued. “We are fully committed to ensuring our operations are sustainable, after all, we did start a new company with green in its name.”

The third and final stage of INDUSTRIAUMBRA’s corporate construction programme relates to the development of a harmonious corporate culture.

“We are determined to create a single corporate culture,” said Mr Fiorucci. “It’s going slowly and is very challenging and demanding, but we are confident that the process will be a success.

When discussing his time at INDUSTRIAUMBRA Mr Fiorucci was very reflective. “I take my role very seriously when it comes to the development of our people and their potential,” he said, in conclusion. “I am constantly thinking of ways to help our people grow, and I am determined to teach them the real meaning of improvement and enjoyment.” n