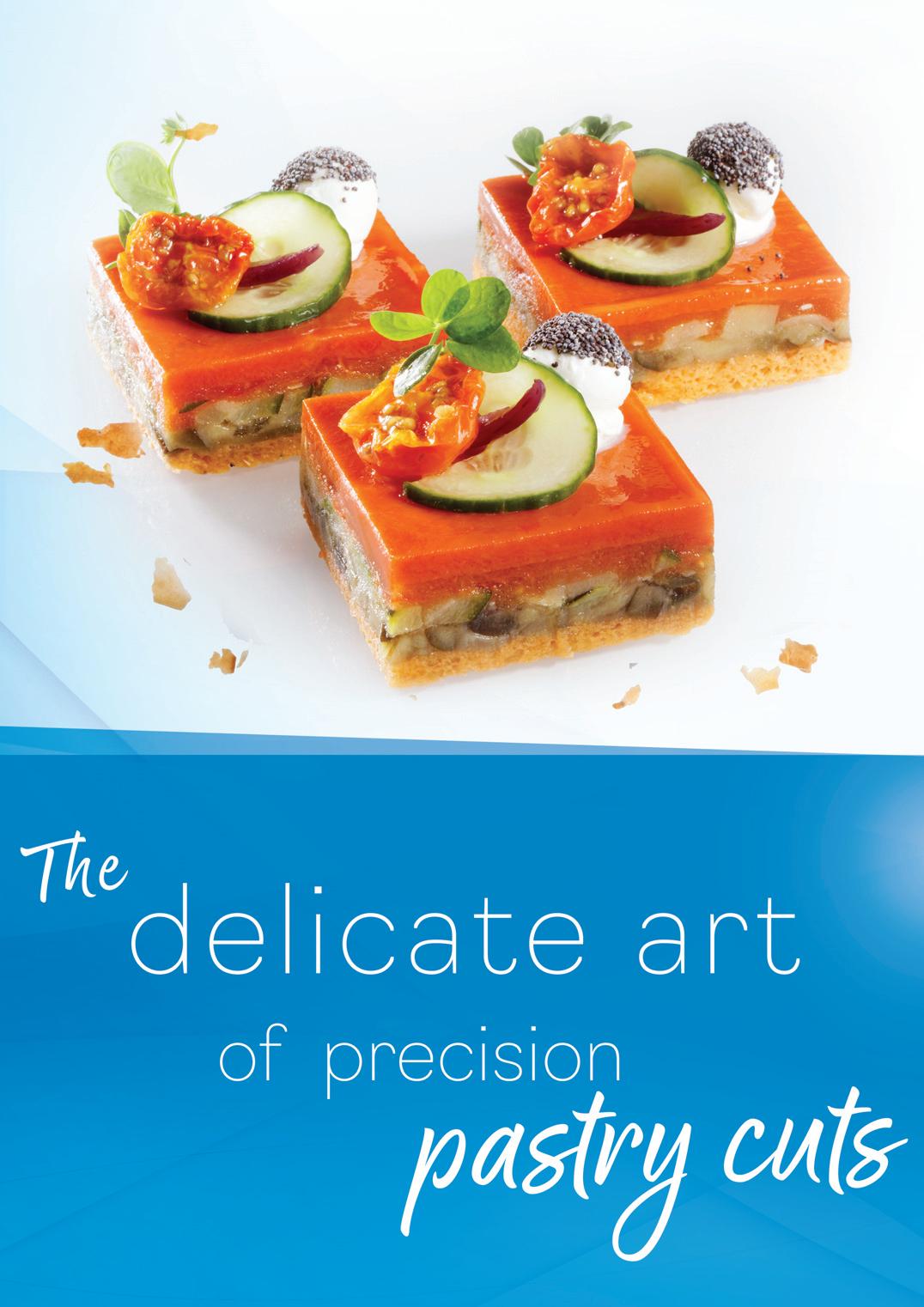

The delicate art of precision pastry cuts

POWERED BY INSIDE FOOD & DRINK

POWERED BY INSIDE FOOD & DRINK

HYDROPROCESS is a leading specialist designer and manufacturer of ultrahigh-pressure equipment up to 7,000 bar. While the company provides solutions for various industries, its famous ChefCut waterjet cutting machine is its most well-known and loved product, used by pastry chefs, caterers and other food industry professionals across Europe and beyond. Sales Developer Fanny Aznar sat down with Richard Hagan to discuss how ChefCut is revolutionising the way pastry chefs design, decorate and present their mouth-watering wares.

IN2 006, husband and wife team

Michèle and Philippe Dereims established HYDROPROCESS with the goal of designing a compact waterjet cutting machine dedicated to fine food artisans.

Prior to HYDROPROCESS’ arrival on the market, waterjet cutting machines were bulky and impractical for use by artisans who regularly have only limited workshop space. Consequently, waterjet cutting

technology was largely limited to use by large industrial clients. HYDROPROCESS set out to change that.

Between 2006 and 2011, the HYDROPROCESS team developed several waterjet cutting machine prototypes in its factory in Chalon-sur-Saône, Burgundy, France, until finally launching the first ever com pa ct waterjet cutting machine on

the market in 2011. Christened ChefCut, the new machine was developed specifically for the food industry and marketed at pastry chefs, catering firms, chocolatiers and similar artisans. With its compact dimensions and ease of use, ChefCut soon found success.

The machine’s successful launch spurred HYDROPROCESS to further refine it. This led directly to the 2015 launch of the second-generation ChefCut machine which featured noise-reduction enhancements and improved software.

Five years later in 2020, the latest - and current - generation of ChefCut, CC3507, was launched. The most accomplished machine released by the company thus f ar, CC3507 is comfortably the most compact and silent waterjet cutting machine on the market, whilst also offering the best performance. Built using the highest-quality parts from closely vetted vendors, every ChefCut machine

is put through a rigorous, 20-hour testing process in ChefCut’s factory before delivery to the customer.

The efficiency and productivity improvements offered by ChefCut have been shown to deliver substantial improvements t o customers’ turnover and operations. Additionally, its compact and silent technology is minimally disruptive to the store’s operation and at the end of the workday, it requires only 10 to 15 minutes to clean.

While HYDROPROCESS offers customers bespoke machinery solutions, ChefCut is its offthe-shelf machine offering and is the company’s primary market. The machine is available in two models: one has a single cutting jet while the other has two. The dual-jet model is able to operate both

jets simultaneously to rapidly create complex cuts.

ChefCut has found ready success with its target market and according to Sales Developer Fanny Aznar, the main reason is ChefCut’s flexibility: “ChefCut can cut almost any product you can find in a pastry and chocolate shop, such as pastries – both fresh and frozen – chocolates, confectionery, marshmallows, cake, and almost any other food products, including savoury items. And thanks to its high-pressure waterjet technology and its advanced software, users can even cut these products into any shape they want.

“Where traditionally physical blades would have only allowed for geometric shapes like squares, rectangles and triangles, the jets on ChefCut allow for complete flexibility in shape cutting as well as faster and more precise cutting than a human is capable of.”

Ms Aznar explained that while ChefCut is in daily use by industrial clients, including major multinationals such as Mondelez, its artisanal clients are equally important: “Amongst our artisan clients, we have customers ranging from those with one shop to some with over 30 shops. Our clients include

prestigious craftsmen and women awarded the Meilleur Ouvrier de France, as well as world champion pastry and chocolate chefs, and lots of artisans highly recog nised in their own fields.”

ChefCut enables users to be more productive and efficient by quickly producing high-precision cuts and complex shapes directly on the machine’s screen via software that is intentionally programmed to be easy to use. “We understand that pastry chefs don’t usually prefer to work on computers,” said Ms Aznar, “therefore we’ve designed the software to be easy to use and a pleasure to work with . The custom designs aspect of the software is quite simple, too.

“We have two modes. One cuts according to standard template shapes, where the second mode - creation

mode - allows the user to draw any shape they want, and the software then takes care of the programming of that shape. This mode is particularly useful for specific designs for particular seasons, such as Christmas and Easter.”

ChefCut’s software is a real point of pride at HYDROPROCESS. Developed in-house, the software continues to be actively maintained by a developer on the staff. Despite the software already being extremely refined, improvements are still occasionally pushed out based on customer feedback, ensuring that ChefCut customers are always able to extract the maximum value - and the maximum fun - out of their ChefCut machine.

In 2023, HYDROPROCESS launched MyChefCut, a free online space exclusively reserved for the use by, and benefit of, ChefCut customers.

This exciting new online space is a userfriendly database that includes a library of over 500 downloadable cutting program shapes sorted according to theme, a library of instructions and tutorials for using ChefCut and its software, and a HYDROPROCESS customer account with machine data and related documents pertaining to that customer’s specific machine. An interface for requesting quotes for machine consumables is also available, as is a revolutionary forum that allows the user to enjoy discussions with other members of the ChefCut community.

HYDROPROCESS is excited to announce that it will be attending Gulfood Manufacturing in Dubai in November 2023. A ChefCut machine will be present at the stand, alongside three

HYDROPROCESS staff members, to demonstrate ChefCut to any interested parties. Visitors are invited to either enjoy demonstration cuts on chocolate provided by HYDROPROCESS or to bring their own products for a cutting demonstration, by prearrangement with HYDROPROCESS.

Meanwhile, HYDROPROCESS’ engineers are working on some top-secret new products that the company expects to launch in the coming months. While Ms Aznar was not able to elaborate further, she concluded by dropping a few hints about what the market can expect from HYDROPROCESS going forward: “We’re always pushing the envelope to make the most efficient machine possible, as that’s what our customers are always asking for, while ensuring that our software is the best it can possibly be.” n