Hodge Clemco is a leader in manufacturing and supplying abrasive blasting and surface treatment solutions that have become quality marques in various industries. Sales and Marketing Manager Liam Davis spoke to Andy Probert about the company’s recent acquisition by the US-based SurfacePrep, and ambitions to consolidate its global business.

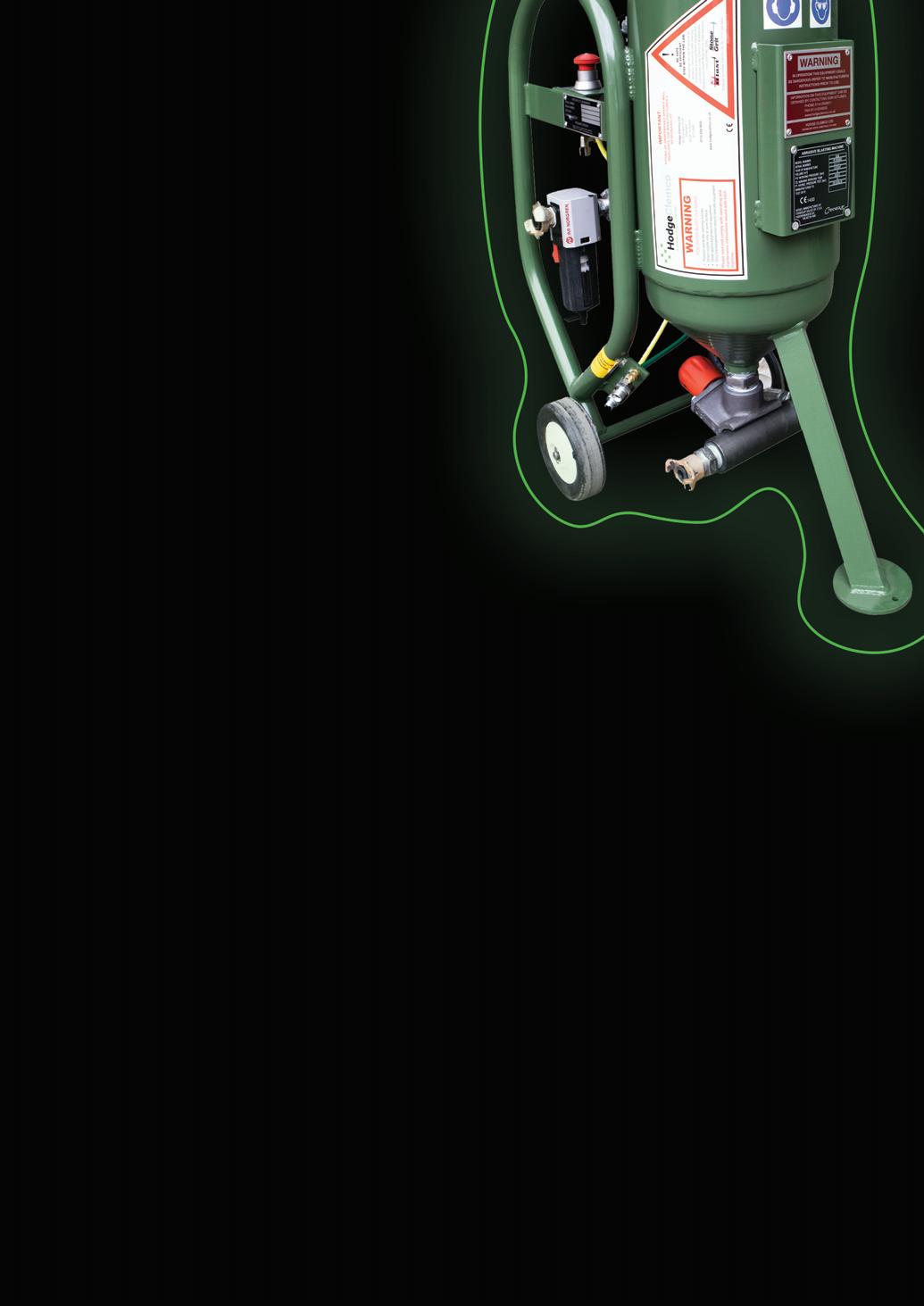

For nearly 65 years, Hodge Clemco has consistently been the leader in manufacturing and supplying abrasive blasting equipment and surface treat ment solutions to the UK industry. From its smallest blast pot to large, containerised bespoke acoustic or weatherproof blast rooms, the Sheffield-based company has developed innovative blasting technology that fits clients’ needs.

“Whether bespoke or standard, Hodge Clemco works hard to design and manufacture equipment that is fit for the job,” said Liam Davis, Sales and Marketing Manager. “The company is highly active across different industries where the primary threat is corrosion, whilst also supporting other applications such as polishing and peening. The equipment is designed to transport abrasive media at a high velocity towards the component or structure, to achieve the desired surface cleanliness and/or profile required.

Delivering the perfect surface preparation for the protective coating to then be applied therefore providing protection for many years, whether it’s a gas pipeline, an oil rig platform or a wind farm component.”

The company has consolidated its market footprint in the UK through strategic acqu isitions over the last decade. However, in 2021, Hodge Clemco became part of SurfacePrep, a group of companies with facilities across the US, Canada and now the UK, considerably strengthening its hand and brand presence.

“These are exciting times as Hodge Clemco continues to maintain its leading position in the surface finishing industry in the UK and abroad,” said Mr Davis.

The company’s comprehensive product portfolio covers every solution for abrasive blast cleaning; from portable units, hand blast cabinets and shot blasting equipment to a full range of recyclable abrasives and abrasive recovery services. Hodge Clemco is also renowned for its full blasting training, equipment servicing, abrasive reprocessing and disposal, and blasting substrate inspection equipment.

The company also has a team of qualified service technicians and installation engineers across the UK to ensure it can provide a total service solution offering for its equipment. It also provides a recycling service where spent abrasives can be reprocessed rather than being shipped to landfill.

Hodge Clemco was launched in 1959 and was part of the Samuel Hodge Group, a diverse engineering group founded in 1897 around the marine industry. The company jointly formed Wolverhampton Abrasives as part of a venture with IMI to produce and market abrasive materials before Wolverhampton Abrasives became a subsidiary in 2007.

With changing markets, the popularity of site blasting techniques reduced in favour

of fixed installations which can be environmentally controlled and offer lower running costs. Hodge Clemco rose to the challenge, developing innovations to cater to this growing trend and installed for clients including the Ministry of Defence, Rolls Royce and Airbus.

In 2015 Samuel Hodge acquired Dinnington-based Mac'Ants Abrasives, a supplier of abrasives and blast materials and one of the world's largest specialist plastic media manufacturers. This enabled Hodge Clemco to offer an expanded range of abrasives, from plastic media and aluminium oxides to garnets, silicon carbides and anti-skid materials, to complement the Hodge Clemco market leading expendable abrasive range, JBlast.

Hodge Clemco opened a state-of-the-art abrasives facility at Dinnington in 2019. The investment in the 3,500sqm unit expanded its ability to manufacture and hold stocks of abrasive media in the UK, such as plastic media, garnet and aluminium oxide.

Now as part of the SurfacePrep group, Hodge Clemco acts as an independent subsidiary and a dynamic stepping stone for its new parent group into the UK and Europe. The group has also bought a clutch of similar companies, including a powder coating specialist, to offer strategic locations across the UK.

Hodge Clemco, which employs around 80 people, predominantly caters to the UK market, while 10% of its business – mainly on the abrasive media side – is exported worldwide; to Europe, the USA and the Far East.

“With a diverse portfolio, featuring over 50 different blast machines,” Mr Davis said, “as well as wet and dry solutions,

offshore specific portable machines , fixed installations, and the consumables, Hodge Clemco is the real benchmark for the blasting sector.

“The company has seen year-on-year growth, and for 2023 we are facing another successful year. Our order book looks healthy, and plenty of projects are in the pipeline.

“Another element of the business consolidation will be the hiring and renting of equipment as market trends emerge. SurfacePrep will enable Hodge Clemco to increase its product portfolio and complement the subsidiary companies working under the parent group.”

One of Hodge Clemco’s specialisms is designing and manufacturing in conjunction with leading fabrication maintenance companies for the offshore industry. “We also design and manufacture ATEX-rated products to work in restricted zones which could have an explosion-risk,” Mr Davis continued.

For turnkey solutions, the company recently designed a unit for the marine industry, and specially fabricated, to it through the hatch opening on ships and boats. The blast machine is used to carry out abrasive blasting on internal areas. The closed-circuit blast head allows for blasting and recovery of abrasive and eliminates airborne abrasive and dust created from blasting.

Hodge Clemco has also manufactured a closed-circuit blast system for Tods Defence in Dorset. The system is being used to blast large sonar pods on the front of submarines and warships.

“While the company continues to steer through the current economic climate, there is now more poor-quality, sub-standard competition in the market with cheap alternatives, rather than trying to maintain the qualities that Hodge Clemco attests to,” Mr Davis said. “Our products can be differentiated because they are well-engineered and made to last.

“We like to build good long-term customer relationships based on honesty, integrity and reliability while offering value-formoney machines, abrasives and services. A stand-out for Hodge Clemco is working as a partner and building solutions that fit their purpose. It goes to the heart of SurfacePrep’s motto of ‘delivering results beyond the surface’.”

He added that in maintaining its quality approach, Hodge Clemco is primed to exploit the premium-standard range of products sourced from SurfacePrep. This includes the RockRidge Abrasive garnet,

predominantly used in blasting offshore rigs, jackets and pipelines, as well as for waterjet cutting applications.

Hodge Clemco offers a recycling route for spent media from the abrasive blasting processes, according to Mr Davis: “While the main avenue is to landfill, our company offers to collect it on a waste transfer license and, depending on its condition, it can be reprocessed and supplied into other applications and processes, such as furnace linings or for ship ballasts.

“Not only is it a green, environmentally friendly approach, but it also helps customers remove their waste media and supply that product to others for their applications. It offers a second life for the waste while saving money and protecting the planet.

“It is a service that is growing rapidly year on year, and one which Hodge Clemco is proud to offer.”