Hays Hydraulics and CA Engineering are a match made in heaven. The two companies operate side-by-side, having carved out their niche within a diverse range of sectors. Director Cameron Steel explained more, in an exclusive interview. Report by Imogen Ward.

Business partners Cameron Steel and Andrew Milne were both employees of Aberdeen-based Hays Hydraulics when they became inspired to set up their own business. Determined to make their dream a reality, the two coworkers established CA Engineering in 2012.

“I had been at Hays for three years when we decided to take the plunge and set up CA Engineering,” Director Cameron Steel explained. “We really wanted to give it a go with a business that was both similar and different to Hays. CA was definitely focused more on plant construction, and we successfully built it up as the years progressed.”

Following seven years of successful growth, CA acquired Hays. Now, both com -

panies are operating with a close-knit team, Hays with 12 employees and CA with 11.

“We worked tirelessly to build CA from the ground up and have really enjoyed diversifying the company’s presence in various sectors,” Mr Steel continued. “We began the company with a focus on plant work and eventually diversified into marine, alongside oil and gas. This transition aligned perfectly with Hays’ expertise, and an acquisition felt like the perfect step forward.”

Today, CA also offers fleet support, HGV diagnostics, repairs and recoveries, whilst also providing its services for thirdparty businesses as well. The company has a large fleet of onsite mobile hose

manufac ture vans; six at CA and a further six at Hays. It also maintains three lorries and one recovery wrecker at CA.businesses as well.

“We work anywhere that requires hydraulic which covers many different types of industries,” said Mr Steel. “We recently started doing work in the renewables sector, which is an area that Hays is exploring as well.”

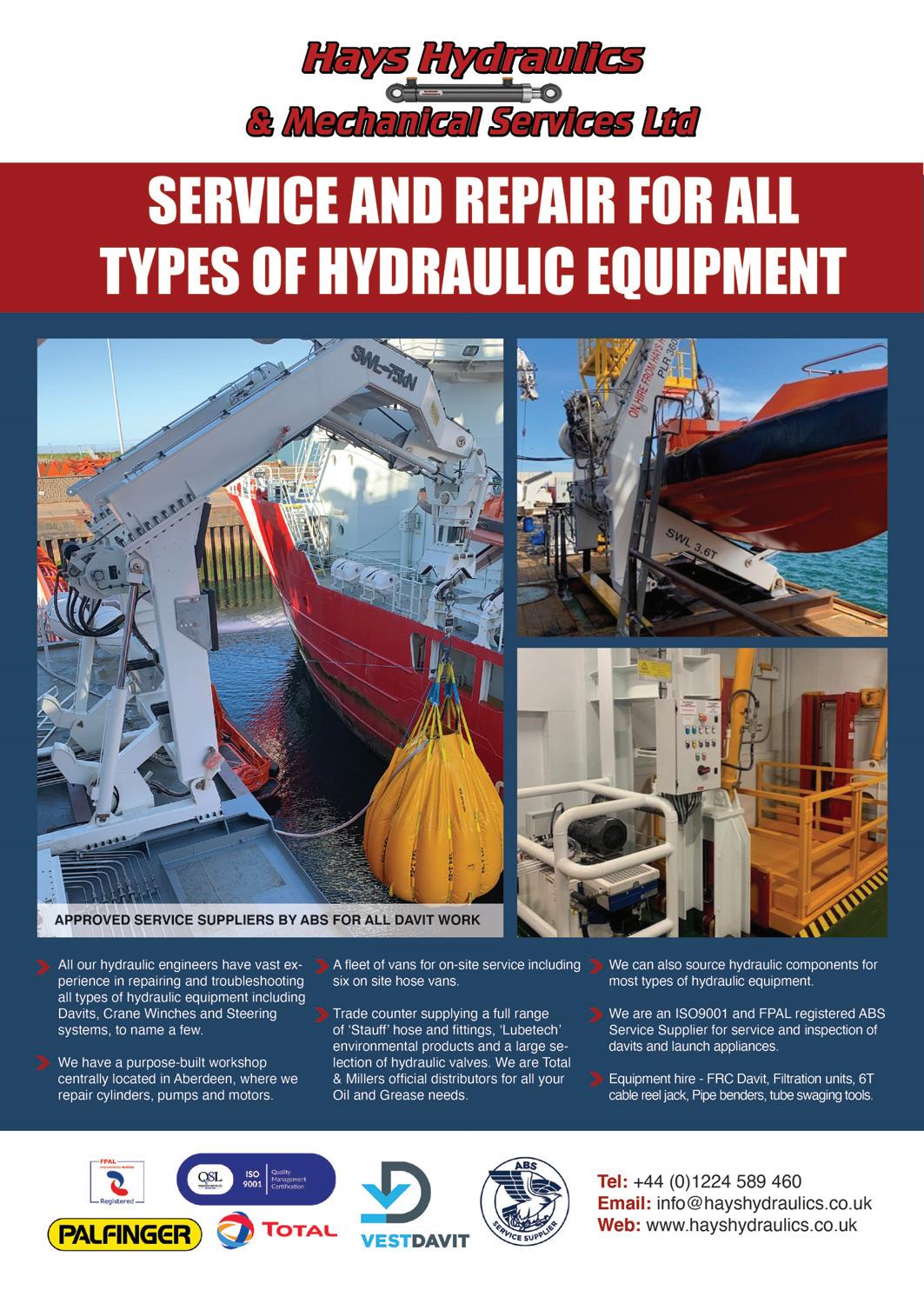

Positioned two minutes from the Aberdeen Harbour, Hays operates from a purpose-built facility, supplying a diverse range of hydraulic components and lubricants to both the marine and the oil and gas sectors. More recently, the company has been making a name for itself within renewables.

A path to renewables

Determined to make waves in the renewables market, Hays recently entered a significant contract with North Star Renewables. Having worked with North

Star previously on several successful oil and gas projects, Hays was confident that this partnership would continue to bloom in new waters.

“The contract with North Star Renewables has just been extended,” Mr Steel explained. “Originally, the company contracted us to design two cargo lifts for its new vessels; we are now under contract to manufacture six. This has been an incredibly successful project, and we now have several other clients enquiring about the same equipment for various applications.

“We are really enjoying growing this side of the business, having previously focused on repairs. It has taken us out of our comfort zone and been a huge learning curve, but we are incredibly proud of what we have achieved.

“Having worked with North Star since the inception of Hays, it has been great to con-

tinue our relationship with that company in a way that has enabled us both to flourish and grow.”

The new cargo lifts will help to speed up North Star’s operations considerably, whilst also working to improve safety at port and save the company money.

Opportunities for expansion

Renewables is a sector that has witnessed rapid expansion over the last decade, and now with the world transitioning to greener energy, it is an area within which both companies are hoping to branch out further.

“In our line of business, everything is much the same,” said Mr Steel. “That’s why, for us, the transition from traditional energy to renewables was fairly straightforward. Of course, the equipment is a bit more advanced, but we are confident we can keep up.

“We have even had several companies requesting our skills to help them break into the renewables market here in

Aberdeen. More than anything, breaking into the market is the biggest challenge. So far, we have experienced quite a simple transition.”

Hays also works closely with Dales Marine, which is a dry dock specialist with multiple facilities located across Scotland.

“We travel to the Dales Marine dry docks frequently,” Mr Steel added. “This is where we complete all the hydraulics works for the vessels that come into dock. We carry out inspections and repairs to various types of cranes and davits.”

Hays and CA also share a davit system, which is available for hire throughout the year. This is great for launching lifeboats and fast-recovery craft.

Shared success

Teamwork is a crucial element of both Hays and CA. The two companies regularly work together when opportunity arises.

“If one company is significantly busier than the other, then we are able to share the workload to ensure the job gets com -

pleted on time,” said Mr Steel.

“This collaboration also helps when location comes into play. If Hays is working on a job and CA needs to respond to a breakdown in the same area, we can pool our workforce and remove unnecessary traveling by sending our Hays engineers to both sites.”

This teamwork really helps to provide the best customer service, whilst also keeping their combined carbon footprint to a minimum. This is reinforced by the locality of the two companies, with them both situated within a mere 15 miles of one another.

Staff are also an important element of this collaboration, with both companies utilising a solid team of hardworking individuals. Included in this are several apprentices. With CA housing two and Hays supporting another, the sister com-panies really value the importance of bringing fresh faces into the industry, whilst providing them the knowledge and support needed to succeed.

This sentiment is also extended to the wider workforce with regular training sessions provided from an in-house training room. Most recently, employees were recertified for ABS accreditation, allowing them to carry out annual and five-yearly inspections on life saving equipment.

The two businesses also rely on a chain of reliable suppliers to complete each project to a high standard.

“We couldn’t do it without our suppliers,” Mr Steel explained. “In our line of business, everyone wants everything yesterday. When it comes to boat repair especially, there is only a short period of time where repair work can be carried out, so we rely on our suppliers to be able to source parts quickly and at a reasonable cost.”

Onwards and upwards

With more than 30 years’ experience combined, Hays Hydraulics and CA Engineering have built a solid base of reliability, quality and ingenuity. As far as the future is concerned, the two companies intend to continue this journey of success with new growth opportunities.

“We really want to concentrate our efforts t owards growth,” Mr Steel said, in conclusion. “However, we also want to take the opportunity to streamline our businesses to make them better for our customers.

“When we set up CA Engineering 12 years ago, we never visualised that it would take off in the way that it has,and we can’t wait to see what the future brings for both CA Engineering and Hays Hydraulics.” n