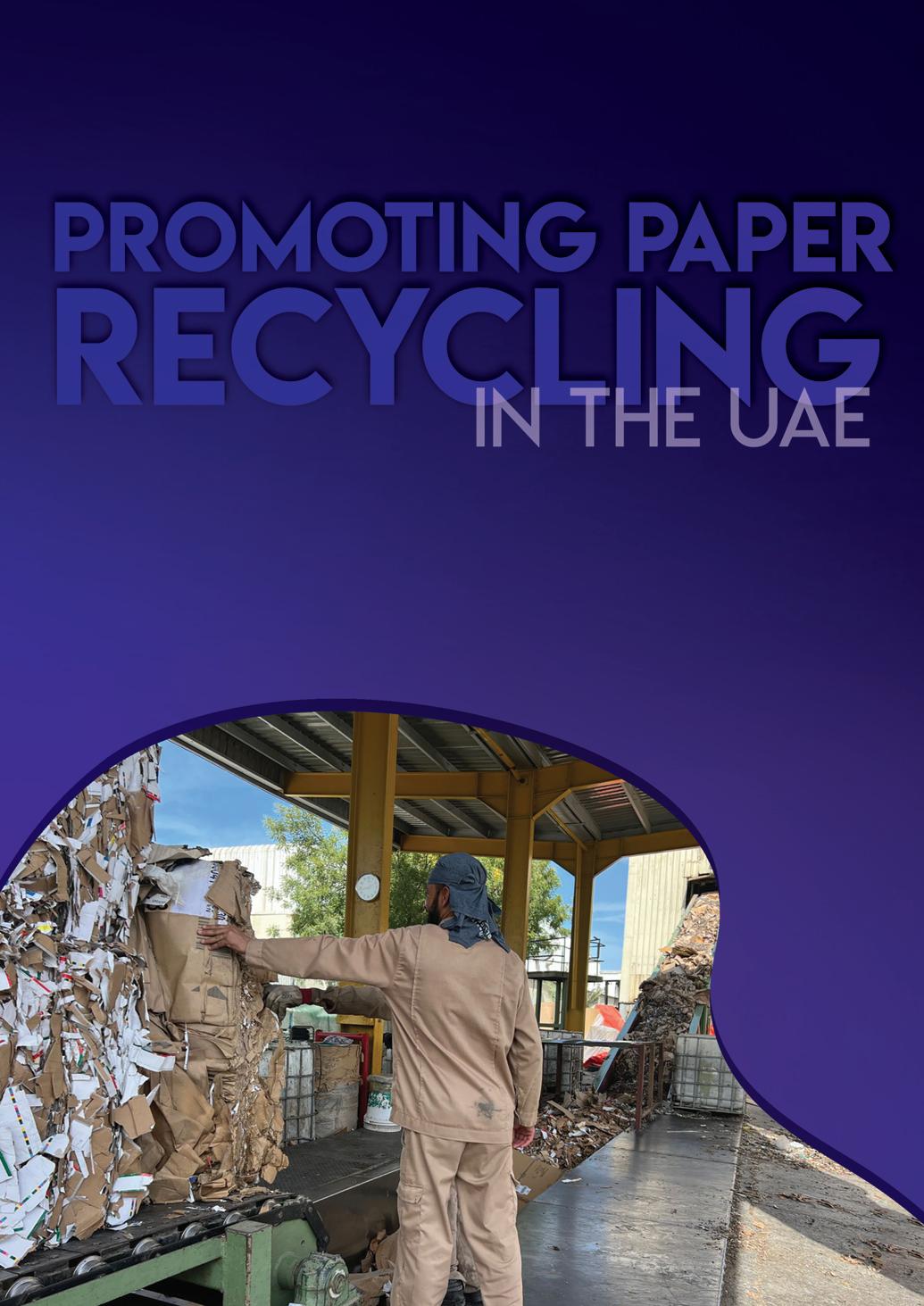

PROMOTING PAPER

GULF PAPER MANUFACTURING

by Inside Sustainability inside-SUSTAINABILITY.com

RECYCLING IN THE UAE powered

Established in 2005, Gulf Paper Manufacturing FZCO is a paper mill based in the Jebel Ali Free Zone, Dubai. It produces paper that is the perfect packaging solution, using recycled corrugated carton paper. General Manager Qaim Shah discussed the company’s capabilities and its sustain able processes, in a report by Imogen Ward.

106 Inside sustainability

GULF PAPER MANUFACTURING I PROFILE

With almost 17 years’ experience giving carton paper a new lease of life, Gulf Paper Manufacturing FZCO works hard to meet all customers’ requirements and maintains a reputation for reliability.

“We have a very good relationship with all our customers,” General Manager Qaim Shah said. “We can provide them with topquality paper whenever they need it, and because of this, they are very happy with the service.”

Reliable roots

Gulf Paper Manufacturing was set up in 2005 after its parent, Gulf Paper Manufacturing Company, Kuwait, decided to diversify its production capabilities.

Located in the Jebel Ali Free Zone was a factory that was set up for paper production. Due to its readiness for operation, the company decided to invest in the facility.

After the company successfully obtained the paper mill, it set about upgrading and rebuilding the machinery to ensure all

Inside sustainability 107

GULF PAPER MANUFACTURING I PROFILE

equipment ran at optimum capacity, was modernised and safe to use. The paper mill currently produces fluting paper and brown top liner in rolls. The fluting paper is offered in sizes of 112, 120, 125, 127, 140, 175 and 200 GSM. The brown top liner rolls are produced in 120, 125, 140, 150 and 175 GSM.

The company boasts extremely efficient delivery times, with local orders delivered in just 24 hours and an export estimate of one week. Gulf Paper Manufacturing also consistently sells an average of 5,500 tonnes of paper each month: this success is partly due to the country’s thriving economy.

Mr Shah had a very positive outlook on the market: “There is a lot of demand for packaging grade paper in the market, which shows the thriving economy of Dubai.”

Green, clean, paper machine

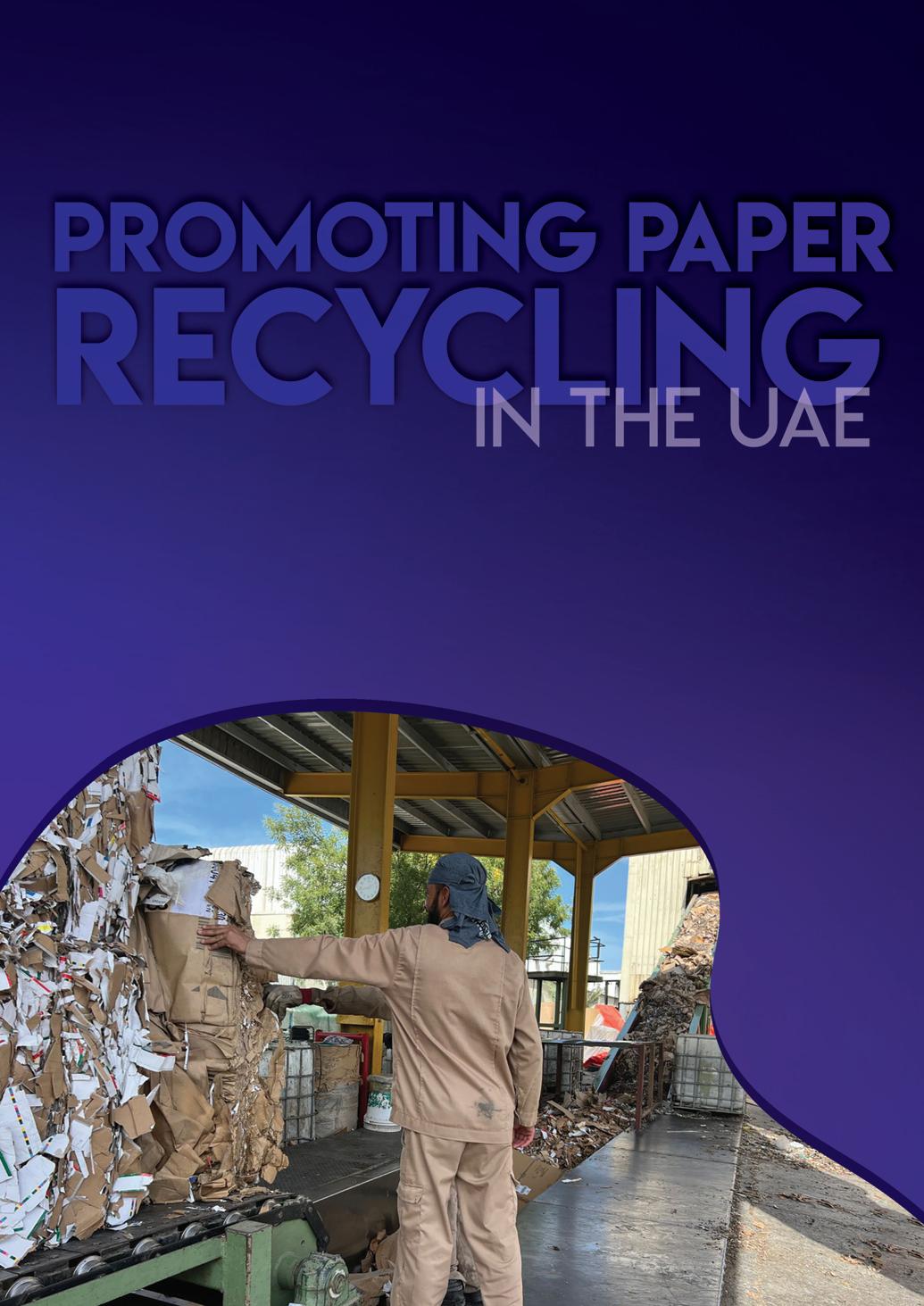

The company maintains an impressively sustainable practice; recycled cartons are used as the main source of raw material, creating a circular economy.

108 Inside sustainability

“Our paper is made almost entirely from used cartons,” Mr Shah said. “We do also take cuttings from the carton factories; new corrugated cuttings are off-cuts from the carton production process – this accounts for about 5% of our raw material.”

Zero reject waste is a vital element of Gulf Paper Manufacturing’s production process. “A lot of companies really struggle with reject waste, which has led to a landfill crisis,” Mr Shah explained. “More businesses should aim to reduce this waste to better sustain the planet.

“We produce high-quality paper to continuously meet customer demand, and our commitment to the environment is never compromised,” Mr Shah continued. “As a recycler, sustainability is always going to be a crucial element of the business. We rely on cleaner fuel sources and have implemented monitoring equipment on our boiler, which observes the system 24 hours a day, to monitor our flue’s carbon emissions.”

Inside sustainability 109

GULF PAPER MANUFACTURING I PROFILE 110 Inside sustainability

The mill’s boiler is powered by LPG – which has a low carbon impact – compared to other companies in the region that rely on diesel. It is used for the production of steam and is one of the first LPG boilers to be utilised by a paper mill in the UAE.

Pressing production plans

Competition in the paper milling industry has increased, more notably in India and other countries. “These companies are entering the market offering extremely competitive pricing,” Mr Shah clarified. “However, these prices often reflect the product quality as well.”

In line with its exceptional quality standards, Gulf Paper Manufacturing’s machine is entirely comprised of European parts. This enables the company to maintain international quality standards. Mr Shah said: “Whenever we refurbish or upgrade our machine, we always use European equipment”.

To improve further production and quality of paper, Gulf Paper Manufacturing has recently installed a Turbo-Jetter headbox, supplied by Bellmer, Germany. This head-box is designed to deliver a speed of 400m/minute.

“By replacing and refurbishing our old equipment we have successfully increased our production capacity from 110 tonnes to 200 tonnes per day,” said Mr Shah. “Our production line is now fully automated, from the initial input of raw material to the final product.” The automation has improved cost efficiency and has had a positive impact on the company’s objectives for the future.

Having successfully exceeded its production goal of 70,000 tonnes per year, Gulf Paper Manufacturing now hopes to stretch this target even further. “Our main plans for the future involve further improvements to our production capacity and quality control,” Mr Shah said. “With management support, I believe over the next five years we will be able to double our production capacity.

“I’ve been with the company for 42 years: they’re a great company to work for and our employee’s satisfaction reflects that,” he concluded. “I have worked at both the Kuwait mill and here in Dubai; I love the interactions that come with my current role. I get to work alongside great people, in a positive environment.” n

Inside sustainability 111