Technological advances in the research of geological cores have presented UK-based Geotek with significant opportunities to become the partner of choice in the science and industrial fields. Using its suite of geophysical and geochemical sensors primed for non-destructive analysis, the company is at the heart of a transitional digitisation effort to unlock and understand more with fewer core materials, according to Sales Director James Shreeve. Profile by Andy Probert.

Extraction of accurate data about the makeup of a geological core is of exceptional importance. These core data are essential for the science, research, oil and gas, mining or renewables sectors, and that is where Geotek comes to the fore. Geotek specialises in the highresolution, non-destructive analysis of geological cores. For more than 25 years, it has designed, built and supplied a range of Multi-Sensor Core Logger (MSCL) sys tems that utilise a suite of geophysical and geochemical sensors.

Geotek, established in 1994, developed its first MSCL system to measure deepsea soil or sediments whilst offshore on a vessel. “The concept was to extract the density and P-wave velocity nondestructively from samples in near-real time while drilling, or shortly after,” said Sales Director James Shreeve.

The development culminated in the first MSCL system sale to the United States Geological Survey (USGS). From that point on, the company provided equipment sales and services to science and industry worldwide. Geotek further developed its systems to allow for hard rock core scanning, in addition to soft sediments which enabled it to serve more commercial

clients. Its systems and services are provided on a sales, rental, or consultancy basis for either onshore or offshore projects.

Now, applications vary from academic users examining the sedimentary record in oceans and lakes for climate research, to industrial applications in the mineral exploration, mining, hydrocarbon and offshore geotechnical sectors.

Geotek has also adapted its core analysis technology to work with specialist pressure cores containing gas hydrates where the pressure can be retained at in situ conditions of up to 350 bar during the analysis.

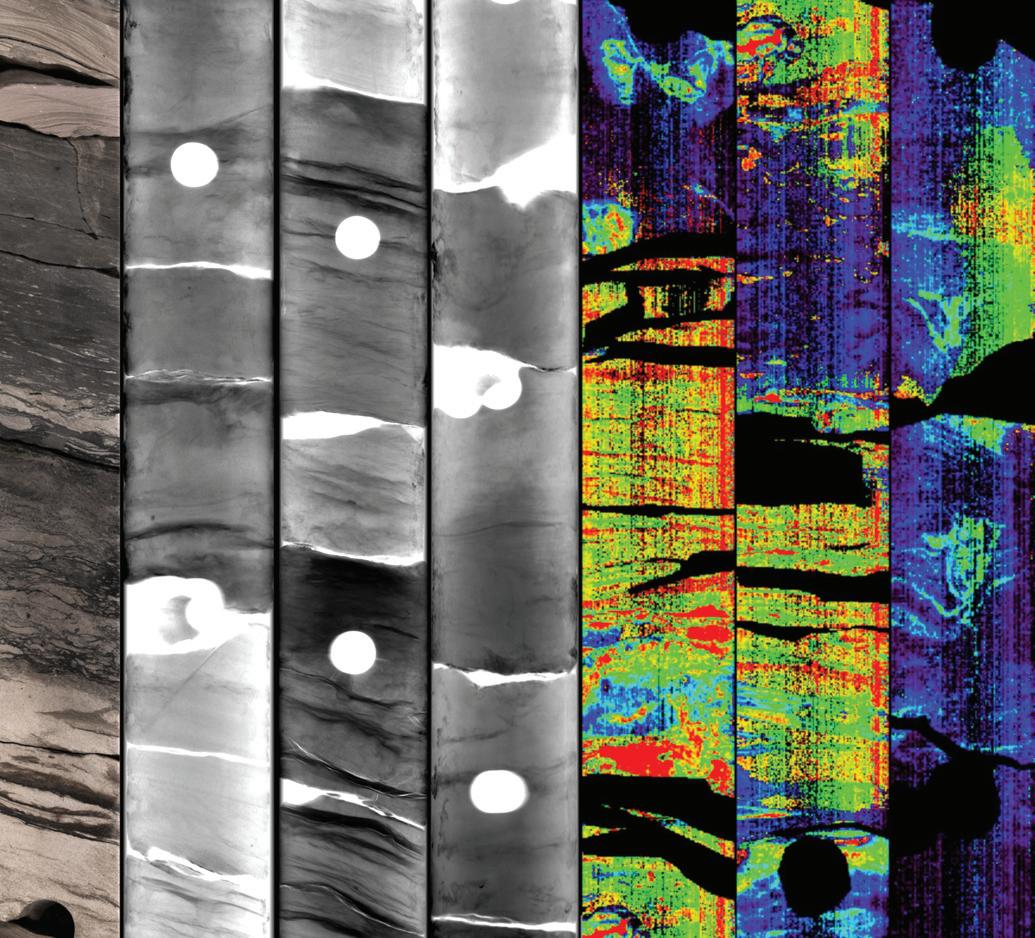

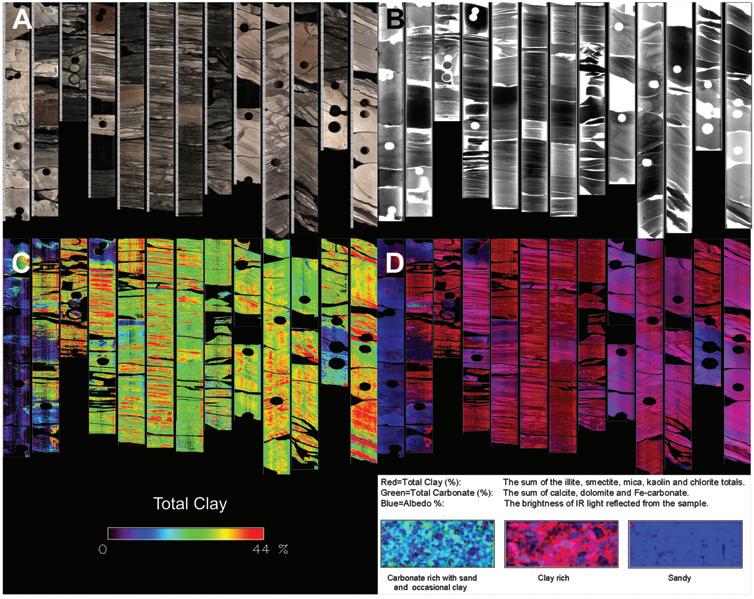

Continued development of the MSCL has resulted in the acquisition of a wide range of multi-parameter data from sediment and rock cores with unparalleled

resolution, accuracy and efficiency. The modular and flexible design means the core scanner can work multiple core types, from hard unlined rock cores to soft unconsolidated sediment cores in plastic or metal liners.

In the late 2010s, Geotek launched its X-Ray CT technology, building a comprehensive equipment portfolio of core analysis equipment. Mr Shreeve explained: “X-ray CT helped drive our presence in the oil and gas industry, where we offered the service to major players and their service labs.

“More recently, digitisation of archived core samples is becoming a central theme as our data acquisition processes have

evolved into a comprehensive workflow. The workflow combines the petrophysics, mineralogy, chemistry and imaging datasets enabling clients to achieve the maximum yield of data from their core to create a valuable digital archival record.

“Interestingly, oil and gas companies are wondering where their next business component is coming from. As regards carbon capture storage, they don’t want to look at their reservoirs, but at the seal, so a different aspect of their geology and digitisation is playing a major role there.”

Geotek’s multi-sensor core logger and imaging technology creates value for oil and gas operators with core repositories by providing geological context, increased data density and improved consistency that is AI/ML-ready. “That creativity of developing innovative technology and creating services is driving our future, with system portability at the root of the business,” Mr Shreeve continued. “Geotek can provide and build equipment in container labs or build in the field and go to where the core is; we take the laboratory to the repository.”

The growth of the UK company, which has offices in Brazil, Malaysia and the USA, remains primarily focused on digitisation. “COVID has sharpened people’s minds when it comes to digital datasets,” he said. “They are more focused on how to put data in front of others and collaborate online or remotely. Which means digitising physical objects, such as a core.

“The future of digitisation will be a crucial focus and feed into our product development. We’ll look at automation, different types of sensors and how to visualise the data.”

Innovation in the digitisation component will be around software, data processing and storage, but also integration of new sensor technologies onto Geotek’s instruments, such as infrared hyperspectral imaging and laser-induced breakdown spectroscopy (LIBS).

“All will feed into the grander picture of developing a complete package of services that help turn a physical object into a digital one and extract new understandings of geological samples,” Mr Shreeve explained. “Core scanning technology

creates an objective multi-parameter dataset that challenges how geologists describe core by providing new insights to help them draw conclusions of what they might have previously missed.

“What differentiates Geotek is the number and diversity of sensor tech nologies it can integrate and deploy. There is no form of geoscience we have not been in. Innovation, adaption and openness are what drive our long-term relationships with clients. Geotek has been fortunate to have grown a fabulous wealth of information and experience, and that is solely down to its people.

A core repository is a physical record of a country's or commercial organisation’s subsurface wealth. Some of the largest core repositories hold thousands of kilometres of core material, and it is a challenge to turn this physical archive

into an accessible digital resource for all. A vast wealth of information remains locked within every metre of core stored in a repository, where only a fraction of data has been collected.

Geotek is involved with a global energy group extracting data from 33 kilometres of core in their repository, Mr Shreeve related : “All our services were deployed to create a digital record and helped the client get a thorough understanding of a particular basin and the materials involved.”

www.earthdoc.org/content/papers/ 10.3997/2214-4609.202270107

The work with repositories culminated in a paper by Mr Shreeve published by the Geological Society of London www.lyellcollection.org/doi/epdf/10.1144/SP527-202265) . It focused on how non-destructive multi-sensor core logger, hyperspectral and X-ray imaging techniques can offer a unique chance to rescue valuable data trapped within core samples held in repositories.

Often, research cruises, onshore drilling programmes or industry projects go to great expense to acquire new core material when in some cases the same questions could be answered from previously acquired core.

“The reality of the situation, and potentially the biggest problem, is that a lot of money is spent on storing and collecting rock,” Mr Shreeve said. “We need to ask ourselves: can we do more with less? What more can we do with the rock we already have? As custodians of geological samples, can we improve how a core repository delivers data to academic or industrial end users and do that in a way that fits global change?

“A vital component of Geotek’s future growth is to keep challenging itself with innovation and how it can better drive

that digitisation concept,” Mr Shreeve concluded. “We want to upscale technologies and help extract trapped data from repositories that may have millions of metres of core.”