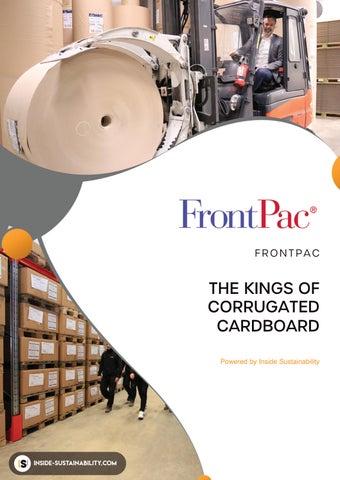

With over 40 years’ experience, FrontPac is Scandinavia’s leading manufacturer of offset-printed corrugated cardboard. Over the years, the company has continued to create high-quality products whilst respecting the planet. Managing Director Martin Enocson spoke exclusively to Inside Sustainability, providing insights into the company’s dedication to going green. Report by Imogen Ward.

Ever since its establishment in 1982, FrontPac has regarded sustainability as a huge element of its DNA.

“Although today, sustainability has become somewhat of a buzzword, it has always been a natural part of FrontPac’s operations,” said Managing Director

Martin Enocson. “We have been working with green electricity for 15 years now –not because the demand was there, but because we felt that it was the right thing to do.

“It is so frustrating seeing big companies shouting about their latest deals in greener

electricity when it has been available for so many years. It makes you wonder why they have waited so long to get involved.”

Over the past 40 years, FrontPac has worked hard to build a reputation for excellence, one that has afforded it a longstanding and loyal customer base, as well as an annual turnover of over €40 million.

“We are proud that we still have some customers who have been with us since the beginning,” said Mr Enocson. “Even as FrontPac has evolved, these companies have stuck by us. We have gone from being

a huge supplier to the mobile phone industry to packaging toys. Where we are today is very focused on supplying corrugated boxes for the wine sector.”

Sustaining the planet

The environment has always been an important factor when it comes to FrontPac’s decision making process.

“15 years ago, we replaced all our lighting with LEDs and have been using electric company cars since they were first introduced to the market,” Mr Enocson explained. “Sustainability is part of our DNA.

We even produced a sustainability report in 2019, which we weren’t obligated to do; but we felt it was important. Our carbon emissions are something that we work on day-to-day, and it really helps us when it comes to asking the right questions of our suppliers as well.”

These principles are reflected in every aspect of FrontPac’s operations. From design to investments, every element is carefully thought out to ensure it aligns with the company’s ethos.

“Manufacturing corrugated and cardboard packaging is what we do,”

said Mr Enocson. “Of course, we have the facilities here in-house to do that, but whenever we need to make investments or find new suppliers to help us, we always prioritise our vision of making appealing packaging that is low in carbon emissions.”

Over the years, these investments have come in various forms, with the most recent revolving around the company’s choice of handles. Originally working with plastic for most of its packaging handles, FrontPac

has invested in new ways to remove this plastic element.

“We have found some paper handles that are very strong, and have been introducing those to our customers’ packaging for some time now,” Mr Enocson continued. “All these small things add up, which is why it is so important to tackle them one by one to find better solutions. After all, Rome wasn’t built in a day.”

Working with one of its clients, FrontPac has also begun incorporating

fully recyclable tear tape made from paper. When it comes to new developments, FrontPac values the opinions of its customers and partners.

Investing for the future

To ensure the continued efficiency of its operations (and to minimise risk of downtime), FrontPac has recently invested in a second printing press. The addition of this new machine means the company now has dual machinery for every aspect of its production process. This has also resulted in an increase in capacity.

“Dual machines allow us to secure contingency,” Mr Enocson explained. “If something were to happen to a machine, we always have a backup one that can run at the same time. Being able to offer

that reliability is very important for our customers. Of course, a new machine adds capacity as well, which will give us the opportunity to take new market shares.”

In a world where evolution is continual and the needs of many are changeable, FrontPac understands the importance of adaption. To further improve its production efficiency, the company is turning to technological advancements.

Since the Summer of 2023, FrontPac has relied on AI-based software to collate all its data on chemical safety regulations. The company has found this to be the most quick and efficient way to group important information. Additionally, this system can accurately locate and highlight the most relevant segments so that FrontPac’s engineers are always working safely.

“All the safety declarations need to be read and understood, so our AI system reads all of these documents and flags the most important parts so that management can inform staff in production,” Mr Enocson explained. “If accidents happen, then we need to make sure the right information is in place to help.”

A year for growth

Another exciting development planned for 2024 is a new Digital Buddy system that is designed to help newcomers with queries. The software will also ensure accuracy in work, eliminating any potential minor mistakes that occur as employees learn.

“We have been doing a lot of investigation on a Digital Buddy system,” Mr Enocson continued. “It’s a really interesting project,

because I think it will help make us better as a company. One of the main challenges involved in the integration of technology, though, is getting people to embrace it and see the possibilities. Nowadays, people are scared of AI, because they think they’ll lose their jobs: I don’t think that is the case at all. What we are doing is utilising AI to help the company improve.”

It is not just 2024 that is looking prosperous; FrontPac maintains a positive

outlook when it comes to the future in general.

“With the trend of transitioning from plastic to paper set to continue, we foresee a future of positive growth in our segment,” Mr Enocson concluded. “It’s a very exciting time, and I can’t wait to see where the future takes us. We are on a journey with an amazing team of people who are incredibly enthusiastic; their passion is a prominent part of our success.” n