ATLANTIS OF KILMORE QUAY: Ireland’s favourite fishmonger

CAVE DIRECT: The UK’s leading craft beer wholesaler

WE SEAL: Reusable and eco-friendly bag seals

FROM CROP TO CONSUMPTION

inside (

F O O

NK & D i F

(

D & D R I

FD28 n MAR/APR 2024

Eat, drink and be healthy

From crop to consumption

Here at Inside Food & Drink, we are starting the year with a focus on healthy foods. Follow the journey of fresh food from a small seed to a delicious meal that tastes good and helps you feel great.

Managing Director

John White

Finance Director

Filomena Nardi-Smith

Editor

Phil Nicholls

Editorial Assistants

Imogen Ward

Hannah Barnett

Feature Writers

Andy Probert

Romana Moares

Richard Hagan

Colin Chinery

Business Development Manager

Darren Foiret

Research Editors

Jeff Johnson

Mark Simmonds

Judi Wheaton-Mars

Ginelle Lorenzo

Natalie Martin

Dane Coady

Becky Scrivens

Sam Ransome

Sales Director

Richard Brightmore

Sales Manager

Helen Leisi

Project Managers

Alexander Paterson

Tony Ingrouille

Kym Hamilton

Chris Renicar

David Earl

Lisa Smith

Will Tottie

Bobby Godfrey

Loretta Smith

Julien Carew

Art Editor

Philip White

Webmaster

Michael Stamp

Designers

Sarah Jones

Georgina Harris

Events Manager

Jasmine Lodge

Marketing Manager

Adam White

Administration & IT

Summer Clover

Gavin Bellward

T: +44 (0)1493 445121 +44 (0)1502 566216 E: media@insidepublication.com W: www.insidefoodanddrink.com © Inside Food & Drink 2024 No part of this publication in any form for any purpose, other than short sections for the purpose of review may be reproduced without prior consent of the publisher. Company Reg No: 06783092 • Company VAT No: 167 6757 57 4 Inside food & drink

Healthy living… and the occasional relapse

Welcome, Dear Reader, to the first edition of Inside Food & Drink of 2024. Since our Christmas edition, my team have worked hard to create this pre-Easter healthy living focus.

Humorously, at time of writing, it is Shrove Tuesday. Thus, we have a staff kitchen full of naughty-but-nice chocolate crêpes and pancakes, plus accompanying syrup, chocolate spreads and other, not quite so healthy treats. To follow that, I have also bought each of our team little chocolate treats ready for Valentine’s Day tomorrow!

Traditionally here, we start the year off with a weight loss club. Volunteers weigh-in early in January, then see who can lose the greatest amount of weight to win a small prize. I’m pleased to say that almost all competitors managed to lose some weight, and yours truly came fifth (no, not out of five, before you ask).

Such challenges make me think about what I eat and drink. My healthy living over these last six weeks has involved an improved diet with a little more exercise

than usual. The true challenge, of course, is to maintain this. I will be reading this edition to pick up some top tips!

So, what do we have in store for you? Well, the usually popular plating of advertisements, articles, news and views, along with upcoming events that we are proud to be official media partners with.

I hope that when some of you bump into our events team throughout the year, they will be slimline, toned and ready to get their step count in with ease, whilst visiting customers old and new at the exhibitor stands. That is, so long as they can resist the tasty enticements many of you use to lure in the passing visitor!

n

Inside food & drink 5

John White Managing Director

Managing Director John White dips a celery stick in chocolate, proving life is all about balance.

have your company’s latest product, technology or concept included in Inside Food & Drink, contact us today media@insidepublication.com GE T INVOLVED

To

6 Inside food & drink intro Fazer 50 Cave Direct 05 Director’s comment 08 Country focus 12 Special report 16 Taste of the season 22 Latest news 24 Innovations PRODUCERS 64 Petrou Bros EVENT PARTNERSHIPS 28 Upcoming events 30 IFE 2024 40 Atlantis of Kilmore Quay 58

Inside food & drink 7 Contents 94 Ugo Foods Group Porokylän Leipomo Oy We Seal i F D & 70 Prima Bakeries 104 118 112 C.H. Guenther & Son MANUFACTURing & Equipment 78 Redpack Packaging Machinery 86 Tummers Food Processing Solutions BAKERY

KINGDOM

All Things Butter partners with farming charity RABI

Organic dairy up-and-comer All Things Butter has partnered with RABI to support farming families across England, Wales and Northern Ireland.

British brand All Things Butter is excited to partner with farming charity RABI (Royal Agricultural Benevolent Institution). As part of its commitment to supporting the farming community, All Things Butter will be donating 1% of all its revenues to support RABI’s mission of aiding farming families across England, Wales and Northern Ireland in times of need.

The farming industry is increasingly put under strain due to factors beyond its control – EU funding, the cost-of-living crisis and climate change. Farmers face challenging, isolated conditions characterised by long working hours, and the sector has a rate of accidents 20 times higher than the all-industry rate. At the core of RABI’s mission is the commitment to address the unique needs of farming people. It offers one-to-one, expert support, advice and guidance, tailored to the individual circumstances of the farming person.

“All Things Butter relies upon the farming community to create its

products and is proud to have developed a range that is made from a British farm, using organic British cream,” said Toby Hopkinson, Co-Founder of All Things Butter. “We believe in giving back to the communities that sustain us, and are proud to partner with RABI, contributing to its mission to support farming families.”

All Things Butter, launched in November 2023 by Toby Hopkinson and chef Thomas Straker, is manufactured by Brue Valley Farm in Somerset. The farm has unwavering dedication to a production process that still uses traditional batching and hand-salting methods, including twice churning the butter to achieve the perfect texture and creaminess. More than just purchasing its produce, All Things Butter wants to form deeper relationships with the community and support the incredible industry at a time when they truly need it through the partnership with RABI. n

COUNTRY FOCUS Latest developments from the UK’s industry

8 Inside food & drink UNITED

USA

Can recycling programme expands to the United States

The new US chapter joins 20 Every Can Counts chapters across Europe, the United Arab Emirates and Brazil.

Every Can Counts, the leading awareness programme for drink can recycling, has announced the launch of its United States chapter, a significant addition that follows closely after its expansion into the United Arab Emirates during COP28 in Dubai.

This new chapter enhances Every Can Counts' position as the leading global initiative dedicated to raising awareness about the recycling of aluminium drink cans. With 21 chapters worldwide, the programme's shared mission is to inspire and empower people to recycle aluminium drink cans, especially when they are on the go and away from home.

Every Can Counts US is a partnership between aluminium drink can manufacturers (Ardagh Metal Packaging, CANPACK, Crown Holdings and Envases) and aluminium suppliers (Constellium, Kaiser Aluminum, Novelis and Tri-Arrows Aluminum). These partners are passionate about encouraging people to do the right thing with their empty drink cans by recycling them.

The new chapter’s vision is to significantly increase the amount of aluminium drink cans collected and recycled in the United States with a focus on away-from-home drink can collection. These efforts are part of a multi-pronged strategy to make progress toward the ambitious US aluminium drink can recycling rate targets set by Can Manufacturers Institute (CMI) aluminium drink can members. These targets include going from the current 45% US aluminium drink can recycling rate to a 70% recycling rate by 2030.

To kick-start its away-from-home recycling efforts, Every Can Counts US is joining the City of New Orleans and many local organisations in the Recycle Dat initiative to make the 2024 Mardi Gras parades more sustainable. This year’s initiative hopes to surpass the 1,475 pounds of drink cans (nearly 150,000 individual cans) recycled during the 2023 parade season from those collected along the parade route and those sold to a local metal recycling facility. n

COUNTRY FOCUS Latest developments from the American industry Inside food & drink 9

JAPAN

Forsea unveils first cultured eel

Cell-cultured seafood start-up Forsea Foods, Ltd. sails on its mission to save wild eel populations from near extinction by unveiling its first prototype of cell-cultivated freshwater eel. Forsea successfully replicated the traditional Japanese unagi eel (Anguilla japonica) featuring the same tender, succulent texture and rich savoury flavour as real eel.

The visionary start-up has been working together with the celebrated executive chef Katsumi Kusumoto to create two popular traditional Japanese dishes –unagi kabayaki (marinated grilled eel over rice) and unagi nigiri. Kusumoto runs the vegan restaurant SAIDO in Tokyo, which was voted the world’s best vegan restaurant in 2019 by the online vegan and vegetarian restaurant guide Happy Cow.

The company has achieved a working proof-of-concept that embodies the sensory attributes of real eel meat and is now prepped for scale-up. In the collaboration, Forsea contributes its

novel technology for cell-cultivating eel cuts, while Kusumoto contributes his culinary mastery to refine the product to perfection in texture and flavour. Forsea was the winner of the Startup Pitch Hour Prize at the AsiaPacific Agri-Food Innovation Summit last October in Singapore.

Forsea was founded in 2021 with a mission to turn the tide on the downward spiral of the ocean’s seafood populations by developing a cell-cultivated alternatives. Overfishing of eels has turned this aquatic delicacy into an endangered species. The immense popularity of eel meat in Asia, Europe, and the US poses significant challenges for suppliers who struggle to keep up with the surging demand. This leads to supply bottlenecks, illegal trade and high prices.

Forsea projects that its inaugural product will be ready for commercial launch in 2025 as it seeks strategic partners in Japan (the largest consumer of freshwater eel) and across Asia. n

10 Inside food & drink

COUNTRY FOCUS Latest developments from the Japanese industry

FoodTech start-up collaborates with SAIDO restaurant to craft prized Japanese dishes based on cultivated eel.

NETHERLANDS

Plant-based food cheaper than meat and dairy

Dutch shoppers can save up to 20% when buying plant-based foods.

Plant-based meat and dairy products are now cheaper overall than conventional meat and dairy products in nearly all Dutch supermarkets, according to a study conducted by research body Questionmark on behalf of food awareness organisation, ProVeg Netherlands.

Questionmark compared the prices of shopping baskets filled with the 12 most common product types, including vegetarian meatballs, plant-based cheese and plant-based yogurt. The cheapest plant-based version was always compared with the cheapest animal-based counterparts of the same products from seven supermarket chains: Albert Heijn, Aldi, Dirk, Jumbo, Lidl, Plus and Ekoplaza.

The price advantage for plant-based foods can be up to €9.66 at Ekoplaza, a saving of no less than 20%. At Jumbo and Lidl, the price-conscious consumer also benefits from a cheaper plant-based shopping basket (€3.89 and €3.11 respectively). Only at Dirk does the consumer pay €0.18 more for a basket filled with plant-based products.

Similar studies commissioned by ProVeg in Belgium and Germany in 2023 have shown that prices of plant-based and animal-based foods are converging there as well, with more and more plantbased products reaching or crossing the point of ‘price parity’ with their animalbased counterparts.

Although consumers pay less overall for plant-based groceries, there are still large price differences between product categories. In the meat substitute category, the plant-based alternative is often cheaper, while plant-based cottage cheese and yogurt are always more expensive than their animal counterpart.

Jumbo is the first retailer in the Netherlands to implement a ‘price parity’ policy, coupling the prices of meat substitutes to their animal counterparts.

The Dutch supermarkets have also set goals to change the ratio of animal and plant-based proteins on the shelves. Aldi, Dirk and Ekoplaza are aiming for a 50/50 ratio by 2030. Albert Heijn, Jumbo, Lidl and Plus are raising the bar and aiming for 60% plant-based and 40% animal-based. n

Inside food & drink 11

COUNTRY FOCUS Latest developments from the Dutch industry

Business resilience in

food and drink

David Plowman, Head of Property Risk Engineering at PIB, explores the subject of business resilience within food and drink manufacturers. In this article for Inside Food & Drink, he examines the risks that can interrupt a business and the challenges of implementing a business continuity plan.

Statistically, around 90% of companies that suffer a catastrophic loss are likely to go out of business within two years. This is a sobering thought, especially given the many challenges we currently face as a result of the ongoing economic uncertainty, increase in severe weather events and global geopolitical instability.

While business resilience is a growing concern within the food and drink insurance industry, with few currently moving beyond

SPECIAL REPORT

David Plowman from PIB discusses risk engineering.

12 Inside food & drink

reactive crisis management. Although constraints on resources can impact the ability to implement a business resilience plan, especially on known issues, there is still a very good case for the sector to consider how to deal with a significant interruption.

Specific challenges

The food and drink manufacturing sector faces a number of specific challenges when it comes to business resilience or business continuity planning in the event of a significant interruption. Many of these challenges are exacerbated by the very nature of the food and drink industry, where a few key

customers often account for significant elements of a company’s turnover.

Additionally, many food and drink products are perishable, leading to lower maximum tolerable periods of disruption. Seasonal factors apply here too, including harvest periods, increased demand periods and seasonal products.

The food and drink sector has a limited ability to outsource due to required customer and other standards (such as BRC, Red Tractor, etc). The market is generally competitive with low margins and there may be seasonal capacity issues. Finally, complex supply chains

k Inside food & drink 13

have limited margins for error and there are challenges around sourcing premises, installing hygiene measures and gaining accreditations.

Internal and external risks

Food and drink manufacturers face many, wide-reaching risks that could cause significant interruption in their ability to supply products. Traditional business continuity

14 Inside food & drink

SPECIAL REPORT

David Plowman from PIB discusses risk engineering.

David Plowman, Head of Property Risk Engineering at PIB

plans take into account issues that may occur at the premises, such as fire, flood or breakdowns. However, a number of other factors also exist that could produce a significant challenge, should they occur. Business resilience planning needs to consider both internal and external risks that may impact the organisation and its ability to supply.

There is an extensive list of significant factors that businesses should consider. This includes geopolitical risks, such as sanctions or the inability to source supplies from particular countries of origin. Then there are transportation risks, which range from shipping issues to foul weather conditions, all of which can cause a failure to deliver.

Additional significant factors would be major workplace accidents, disruptions to IT systems or product-specific issues, such as recalls and the associated reputational risk. Finally, with the food drink sector, there is the risk of a harvest failure.

Risk engineering support

Working with corporate clients in the food and drink manufacturing sector, PIB helps to build an understanding of the risks to business resilience that can face an organisation.

PIB goes beyond simply finding risk transfer solutions. Its experienced team has the capability and know-how to provide guidance and support to businesses on all aspects of enterprise risk management and business resilience. PIB will work with a client’s own risk management processes to integrate resilience into standard business planning.

The practical support available from PIB includes help in identifying risks and maximum foreseeable losses to ensure the correct (and not excessive) levels of risk transfer are put in place. PIB will also help clients to identify additional off-site risks and ensure they are appropriately considered. Finally, there is assistance in understanding the potential mitigating measures - both to prevent risks from materialising and also how the business might respond in the event of an incident. n

To find out how PIB can help your food and drink manufacturing organisation to achieve greater business resilience, please contact David Plowman and his team at: www.pib-insurance.com

Inside food & drink 15

for the new year Feel good fixes

As many often do, Inside Food & Drink is kickstarting the year with a focus on healthy living. Having survived the January blues, we have set to work, scouring the world of food and drink, determined to locate delicious examples that taste good and make you feel great. Below you will find just a few such examples that are guaranteed to leave you wanting more.

NOJO is a proudly female-owned, B-Corp certified company that is working hard to create delicious cooking sauces with sustainability in mind. Made with plant-based ingredients, NOJO has a delicious range of awardwinning sauces that are sure to satisfy. Consumers can choose from a selection of six awe-inspiring options, including White Miso Cooking Sauce and Teriyaki Stir-Fry Sauce. Keen to inspire, NOJO has also created its own recipes that are sure to make its flavours pop.

“The White Miso Cooking Sauce was deliciously creamy. I gave one of NOJO’s recipes a try – pairing it with aubergine, spring onion and a sprinkling of chilli – it was the perfect pairing, with the two flavours complementing one another. I can’t wait to give the rest of the NOJO range a try.” – Phil White, Art Editor.

TASTE OF THE SEASON Exciting ways to stay healthy

Head on over to NOJO’s website to find out more about the company’s drive for sustainable sustenance: https://nojolondon.co.uk/ i F D & 16 Inside food & drink

NOJO

Cheesies

On a mission to combine cheese and crisps without the addition of junk, Cheesies was established in 2019, as a healthier twist on a snacking favourite, providing the next flavourful fixation without revolutionising people’s snacking occasions.

Cheesies are the perfect choice for those looking for a feel-good snack that is low in sugar and carbs. Made from just one ingredient, these zingy bites are formed from blocks of cheese that are baked until crunchy.

Available in five tongue-tingling flavours – Cheddar, Red Leicester, Chilli, Gouda and Goat’s Cheese

– Cheesies are the feelgood snack than can be enjoyed on-the-go and without the need for refrigeration. Ever responsible, all of Cheesies’ cheese comes from off-cuts to reduce industry-wide waste, with the cheese for its Cheddar, Chilli and Red Leicester samplings sourced from a single family-owned farm.

i F

“I really enjoyed the punchy taste of the Cheesies range. Packaged for snacking, each one has its own distinctive taste and strength. They’re not just limited to snacking too, I added some Cheddar Cheesies to the top of my pasta bake to give it an extra cheesy, crunchy topping.” – Phil Nicholls, Editor.

You can get your Cheesies fix by heading to: https://www.cheesies.co.uk/

D &

Inside food & drink 17

TASTE OF THE SEASON

Exciting ways to stay healthy

SHREDDY

Initially established during Lockdown, SHREDDY entered the market with a female fitness transformation app aimed to get people moving. Since then, SHREDDY has gone on to create three hugely popular SHREDDER protein bars (Gooey Salted Caramel, Chocolate Brownie Crunch and Peanut Butter Cup). Now, the company is targeting the supplements market, helping those who are embarking on their personal fitness journey.

SHREDDY SUPERGREENS contains over 30 daily greens, including kale, broccoli, spinach and brussels sprouts, combined with the sweet flavouring of mango and pineapple, it’s hard to believe something so healthy could taste so good! Developed to combat the unaffordability of supplements, SHREDDY SUPERGREENS is jam-packed with 62 ingredients and extracts, to provide an immunity-building, energy-restoring, probiotic superfood that also helps maintain healthy hair, skin and nails.

i F D &

“As someone who is always on my feet, I often forget to take the time to make sure I’m looking after me. SHREDDY SUPERGREENS is a great solution that is hassle-free and quick to mix. It has been a welcome addition to my hectic day, and its fruity flavour is the perfect palate pleaser. ” – Hannah Barnett, Editorial Assistant.

To learn more about SHREDDY’S dedication to providing the best guilt-free, gut-friendly supplements, head on over to: https://shreddy.com/

18 Inside food & drink

Known for producing cheeses that are deliciously different and full of British taste and character, Applewood is a connoisseur of hearty rustic cheese. With almost 60 years’ experience behind it, the company has melted its way into the hearts of the nation, creating Britain’s favourite smoky cheddar. For those looking to cut down on dairy, Applewood has the perfect solution. After launching Applewood Vegan in 2019, the smoky cheese expert has done it again with its new Vegan Bites. Having just won its 15th award, this bite-sized offering is perfect for grab and go snacking or grated on a hearty dish. However you enjoy your “cheeze”, Applewood is here to help your snacking dreams come true.

“Applewood Vegan Bites are ideal for any cheese lover. Smoked cheese is my go-to when I am making a sandwich, and having it packaged in a convenient size made quickfire lunch decisions that much easier.” – Imogen Ward, Editorial Assistant.

To find out more about Applewood’s enticing range, travel on over to the website: https://applewoodcheese.co.uk/

D &

i F

Inside food & drink 19

Applewood

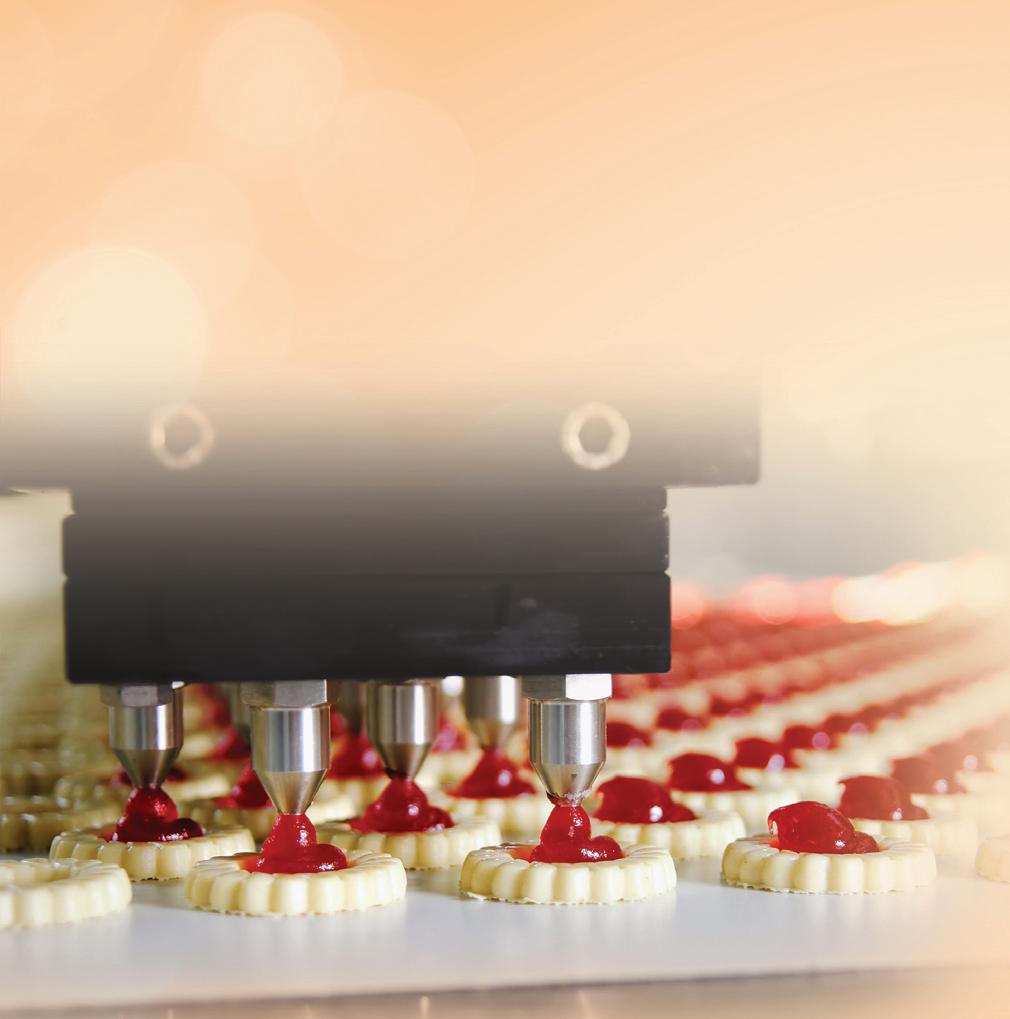

We are BSA Schneider Anlagentechnik GmbH. We design, develop and produce machines and plants for the confectionery and food industry.

In addition, we offer comprehensive services: Line planning, restoration of rollers and conches, roller grinding, accessories, spare parts, and much more.

Realisation of ideas, construction and manufacturing –everything from one source!

+49 241 1580-66info@bsa-schneider.de

www.bsa-schneider.de

Inside food & drink 21

Solar powered soft drinks

ASof February 2024, 75% of the electricity used to make Britvic soft drinks in Great Britain is generated by a 160-acre solar farm in Northamptonshire.

Providing clean energy to factories in Rugby, London and Leeds, the ten-year solar power agreement covers three quarters of Britvic’s electricity needs in this country – with the aim of reaching 100% solar powered operations in the near future.

The solar site, commissioned in January 2024, will generate 3.3GWh of power, enough to power the equivalent 11,500 homes. This could cut as much as 1,113 tonnes of carbon dioxide from the drink manufacturer’s supply chain each year – the equivalent of planting 260,000 trees.

Working with renewables provider Atrato Onsite Energy, the 650,000sqm solar installation, will scale up to produce 27GWh. This initiative is part of Britvic’s long-term commitment to achieve net zero carbon emissions by 2050.

The project makes use of a former quarry site that is unsuitable for farming, with

double-sided solar panels that use tracking devices to follow the sun, increasing efficiency by 10%. The site will provide opportunities for allowing nature to flourish – a rewilding approach that will increase biodiversity.

The announcement is the latest milestone in Britvic’s Healthier People, Healthier Planet sustainability strategy. Last year Britvic signed an agreement to produce Ballygowan Mineral Water using 100% renewable electricity from wind energy. The company also launched an £8 million project to improve energy efficiency and cut carbon emissions by 50% at its Beckton site. n

22 Inside food & drink LATEST NEWS latest news from around the food and drink industry

To have your company’s latest news included online or in our Inside Food & Drink magazine, contact us today Please send to: media@insidepublication.com GE T INVOLVED

Stuart and Deliverect supercharge food delivery

Last-mile delivery solutions specialist

Stuart has announced a new partnership with operations and order management platform Deliverect. This partnership will help restaurants increase and improve their delivery offering through an integrated platform by connecting Stuart’s leading last-mile delivery platform with Deliverect’s seamless order and operational management technology.

Both organisations have technology at the centre of their business and have worked to make their platforms as user-friendly as possible for restaurant partners. Now, large or small restaurant businesses can access this combined platform to tap into the delivery market.

This new capability will enable businesses to expand their customer base through a robust delivery offering, increasing their overall revenue and helping them navigate slower economic periods. Especially for small restaurant businesses, delivery can significantly grow their business and enable them to weather difficult economic periods.

“Businesses now operate in an increasingly digital-first economy where consumers demand a frictionless order experience,” said Cornelia Raportaru, CEO of Stuart. “This partnership marks a new chapter for both Stuart and Deliverect, uniting the best of Stuart’s expertise in urban logistics and Deliverect’s integrated tech capabilities to improve the digital food ordering experience for both business owners and consumers.”

“As Deliverect continues to revolutionise the restaurant industry, our partnership with Stuart marks a significant stride forward in expanding our ecosystem,” added Joe Heather, Regional GM Northern Europe at Deliverect. “With Deliverect’s Dispatch solution and innovative delivery capabilities from a multitude of partners like Stuart, we are empowering restaurants to manage their own last-mile delivery experience, seamlessly connect with their customers, redefine their delivery experience and unlock new dimensions of operational efficiency.” n

Inside food & drink 23

Lir Chocolates launches Baileys Chocolate and Guinness Easter eggs

Popular Irish chocolatier Lir Chocolates is expanding its offering in preparation for Easter.

TOhelp retailers capitalise on Easter confectionary sales, leading Irish chocolatier Lir Chocolates is expanding its range introducing three new Easter eggs, while also bringing back a seasonal favourite.

Baileys Chocolate is launching two new Easter eggs, a Baileys Salted Caramel Easter Egg and Baileys Strawberries and Cream Easter Egg. To cater for consumers seeking to trade up to indulgent, adult Easter treats.

The Baileys Salted Caramel Easter Egg has a milk chocolate shell with crunchy caramel pieces and includes Baileys Salted Caramel Chocolate Truffles, while the Strawberries and Cream Easter Egg is a white chocolate shell with strawberry pieces, accompanied with Strawberries and Cream Truffles.

Baileys Chocolate is also bringing back its much-loved Baileys Chocolate Original Easter Egg for 2024. The Baileys Chocolate Easter Egg includes a milk chocolate shell egg with a hint of the iconic flavour of Baileys Irish cream liqueur, accompanied by Original Baileys Chocolate Truffles.

Lir Chocolates is also launching a brandnew Guinness-flavoured Rugby Ball Easter Egg. The new treat comes with a robust dark chocolate shell, alongside Guinness chocolate truffles.

With striking designs for maximum shelf impact, each egg is in a carton with no plastic fitments as Lir Chocolates continues its journey towards reducing plastic from its packaging and providing more sustainable products for consumers to buy. n

24 Inside food & drink INNOVATIONS Latest innovations from the food and drink industry

Warrior announces Protein Water

Leading sports nutrition brand, Warrior®, owned by KBF Enterprises, is launching a new product line to celebrate a successful start to 2024.

Following the huge success of its renowned range of high protein bars, flapjacks and supplements, leading sports nutrition brand Warrior has expanded its portfolio to include the new Warrior Protein Water.

This latest addition is a fruit-flavoured, easy-to-consume high protein, low calorie drink, packed with essential vitamins and electrolytes to maintain hydration levels. With the added benefit of 10g of Collagen Peptides, this healthy drink boosts protein intake, whilst also helping to nourish skin, hair and nails.

Offering a convenient alternative to on-the-go protein powders, Warrior Protein Water is sugar-free with less than 50 calories per bottle. Available in two refreshing flavours, Tropical and Berry, which are suitable for vegetarians and vegans, these drinks are produced without any genetically modified ingredients. Each 500ml bottle is ideal for those looking for a tasty way to hydrate whilst on-the-go, or to enjoy during, or after, a workout.

The Warrior Protein Water launch is yet another achievement for KBF Enterprises

which has secured retail listings with Asda and Tesco in the past 12 months.

“Last year was a phenomenal year for product innovation and we are thrilled to be starting 2024 by introducing Warrior Protein Water to the market,” said Kieran Fisher, Founder of Warrior and KBF Enterprises. “This provides an easy and convenient solution for people to boost their protein intake whilst on-the-go, and we are confident this new addition will excite new and existing customers.” n

Inside food & drink 25

from crop to consumption

EVENT PARTNERSHIPS

A selection of upcoming events, followed by a preview of IFE 2024.

i F D &

29April - 01 May 2024

Food & Drink Expo

Food & Drink Expo provides the number one route to the UK food and drink market, helping hundreds of companies showcase exceptional products. Buyers and decision-makers across the whole industry are invited to uncover the hottest trends and latest product launches.

[click here] for weblink

23-25 April 2024

Seafood Expo Global

Seafood Expo Global/Seafood Processing Global is the worldwide seafood marketplace, serving industry professionals and buyers from all corners of the supply chain. If you purchase seafood for your business, then you simply cannot afford to miss this event.

[click here] for weblink

21-2

The Saud

The an tion communities brands, and all on one gr

[click h

25-27 March 20

IFE 2024

IFE, International Food & Drink high-quality and effective bus event will have a range of ne to uncover what the exciting food and like in 2024 and beyond.

[click here] for weblink

28 Inside food & drink

23 May 2024

di Food

Show

e Saudi Food Show brings together unmatched global line-up of internanal exhibitors, thought leaders, F&B s, strategic partners, never-seen-before d top regional and international chefs, round-breaking stage.

here] for weblink

28-29 May 2024

World of Private Label International Trade Show

For over 35 years, PLMA’s annual World of Private Label International Trade Show has brought retailers together with manufacturers to help them find new products, make new contacts, and discover new ideas that help private label programmes succeed and grow.

[click here] for weblink

024

Event, is back to deliver

siness connections. The

w features and exhibitors

d drink industry will look

Why not give your event exclusive coverage to thousands of readers and connections globally? Contact us: events@insidepublication.com

Inside food & drink 29

IFE 2024

IFE, International Food & Drink Event, the UK’s ultimate business event for food and drink product discovery, returns to ExCeL London on 25th to 27th March 2024. The event showcases the latest innovations in the sector and empowers buyers to elevate their offerings, according to Federico Dellafiore, Event Manager for IFE.

Inside Food & Drink last spoke with IFE in 2022, so how has the show evolved since then?

What is new for this year?

It is hard to believe how much the show has evolved over the past two years! Since 2022, we have introduced an exciting feature

called the New Products Tasting Theatre. Visitors will have the opportunity to hear pitches from startup brands and sample ranges from a number of key distributors, this year including Bidfood and Sysco.

EVENT PREVIEW

Federico Dellafiore, Event Manager for IFE, updates Inside Food & Drink.

32 Inside food & drink

Federico Dellafiore, Event Manager for IFE

Can you please share your anticipated numbers of visitors and exhibitors?

This year, we are expecting over 27,000 buyers to attend the show and meet with more than 1,500 exhibitors representing thousands of amazing products.

Please summarise for us what a visitor might expect from a trip to IFE.

A visit to IFE is an immersion into the world of food and drink, with exciting (and delicious) new products around every corner and

a packed content programme unveiling the most important trends and topics in the sector.

It is a true journey of discovery for buyers, who rely on IFE to sample the latest new products and meet face-to-face with the people behind the brands. With over 30 countries represented at the show, IFE is a unique chance to sample not just the very best of British, but also quality food and drink products from around the world.

The show is also an unrivalled networking opportunity for the industry, with visitors from across the UK and around the world

Inside food & drink 33

meeting friends old and new to collaborate, learn and do business.

One of our speakers this year, DesignHawk Founder Brett Goldhawk, said: “IFE never fails

to deliver on inspiration, insight and innovation. It’s one of my favourite events every year, as I get to discover everything food and drink, network with amazing people, try great products and unearth future trends emerging within the industry.”

As the largest event for food and drink buyers in the UK, what are the benefits of attending IFE as an exhibitor?

IFE’s size makes it an incredible opportunity for food and drink brands to meet directly with thousands of potential buyers across

PREVIEW

EVENT

25 – 27 March 2 34 Inside food & drink

Federico Dellafiore, Event Manager for IFE, updates Inside Food & Drink.

2024, ExCeL London

www.ife.co.uk

retail, wholesale, hospitality, travel and much more. We find a lot of the suppliers that take part in the show speak with not only the buyers they want to meet, but also potential partners from completely unexpected sources which takes their business in an amazing new direction!

With IFE taking place alongside sister events IFE Manufacturing, HRC, The Pub Show and chef competition International Salon Culinaire, the event is packed with professionals from the full food, drink and hospitality sector. IFE is a hive of collaboration and new opportunities.

In addition to exhibiting at the show, suppliers can take advantage of a number of opportunities including live product pitching, meet the buyer events hosted by Aramark and the Federation of Wholesale Distributors and entering the World Food Innovation Awards.

The floor at IFE is divided into multiple sections. How does this structure impact the experience of attending the show?

We have 14 unique sections at the show which include Vegan & Plant-Based, Drinks, Chilled & Frozen, and a newly introduced Fresh Produce Section in partnership with the Fresh Produce Consortium. This layout is great for navigating the show as we have a lot of category-specific buyers in attendance, as well as visitors interested in exploring the diversity within different categories.

We also have a section called The Startup Market, where companies trading for less

Inside food & drink 35

Federico Dellafiore, Event

than two years can showcase their products and buyers can discover completely new brands and meet face-to-face with ambitious and innovative entrepreneurs.

Several of the themed sections at IFE reflect modern food trends, such as Vegan & Plant-based, Free from, organic, etc. How important is it to highlight these trends within the show?

One of our key mission statements is to showcase innovation and new products at IFE, not to mention highlighting the most important industry trends and the product types growing in popularity with consumers.

25 – 27 March 2

In addition to reflecting trends, the show is often a starting point and a launchpad for the brands of tomorrow – a glimpse of the future of food and drink.

IFE also runs a range of business support features as part of the show. How popular are these sessions?

We have a Business Services section of the show where visitors can meet experts on distribution, export, marketing, ESG, logistics, supply chain services and more. In our Certification Clinic organisations including RSPCA Assured, BRCGS, Halal Certification Europe, SALSA and The Vegan

EVENT PREVIEW

Manager for IFE, updates Inside Food & Drink.

36 Inside food & drink

www.ife.co.uk

Society will be on hand to shed a light on industry accreditation. In our Exporters Hub visitors can hear about the latest trends and challenges in international trade, plus our sister show IFE Manufacturing is home to a range of suppliers providing services including design, labelling and compliance.

Which aspect of IFE are you personally most excited about?

This will be my first time at the show since taking over as Event Manager, so I think I am most excited about just seeing all our plans come to life and meeting face-to-face with our exhibitors, visitors and partners over the three days!

To conclude, is there anything further that you would like to share with our readers?

IFE, part of Food, Drink & Hospitality Week, takes place on 25-27 March 2024 at ExCeL London. Register for your complimentary trade ticket at ife.co.uk and do not miss your chance to be part of the UK’s biggest celebration of industry innovation. n

Inside food & drink 37

2024, ExCeL London

from crop to consumption

PRODUCERS

atlantis of kilmore quay cave direct fazer petrou bros ugo foods group

i F D &

40 Inside food & drink ATLANTIS OF KILMORE QUAY I PROFILE

Atlantis of Kilmore Quay has been Ireland’s favourite fishmonger for several years, sustainably supplying the best fresh seafood and in-house smoked fish to discerning chefs, retailers and the public. With exceptional product quality and range, the company remains focused on protecting the ocean environment while keeping a weather eye on consumer trends. Managing Director John Kenny spoke to Andy Probert.

Established 30 years ago, Atlantis of Kilmore Quay is a family-owned and operated fishmonger based in Wexford, on Ireland’s southeast coast. It has built a formidable reputation for sourcing the best fish, delivering quality products and defining Ireland’s fish industry with a hands-on approach.

“From trawler to table, Atlantis of Kilmore Quay is driven by a desire to showcase the best product range that allows food lovers to experience restaurant standard seafood

dishes at home,” said Managing Director John Kenny.

Becoming a permanent fixture for discerning chefs, retailers and consumers has enabled John and his business partner, Mark O’Connor, to evolve the business.

John’s family initially operated several fishing vessels from Wexford, landing the freshest seafood and exporting most of the catch. Soon, Atlantis of Kilmore Quay spotted an opportunity to supply restaurants and hotels on its doorstep.

Today, the business is Ireland’s leading fishmonger whilst retaining close ties with the Wexford fishing community. Atlantis of Kilmore Quay has 20 fishing trawlers from Rosslare to Castletownbere under contract to deliver fish and shellfish to its processing facility. Exotic species, like sea bass, red snapper and marlin, are sourced from trusted international suppliers.

Partners in sustainability

Atlantis of Kilmore Quay is a verified member of Origin Green – Ireland’s pioneering food and drink sustainability programme designed to achieve sustainability targets that respect the environment.

Recently, the company has made significant reductions in water consumption, cutting energy use by over 10%, investing

Inside food & drink 41

42 Inside food & drink

in new delivery vans with improved fuel efficiency and committing to a further reduction in general waste by 24%.

Following an overhaul, the company utilises 40% less packaging, eliminating over three tonnes of waste annually for its Haddock Goujons alone. Atlantis of Kilmore Quay has also launched a nutritional pet food brand derived from fish parts that cannot be used for human consumption

“Our location at Wexford makes sourcing locally for most fish very easy,” John said. The waters off the coast of Kilmore Quay are known as the Celtic Sea;

part of the Atlantic Ocean, and home to a great variety of fish from cod to prawns. The company works with a few select partners to guarantee quality produce. This includes Saltees Fish, a family fishing business founded by the O’Flaherty brothers in 1996 and now operating one of Ireland’s largest fishing fleets.

Kingfisher Fresh is another trusted partner, which was set up in 2007 by Michelle O’Neill and Brian Everard. It is a fellow member of Origin Green and partner in the White Fish Fishery Improvement Project, programmes working towards sustainability. The company works with Bord Iascaigh Mhara, Ireland’s Seafood Development Agency, to improve fishing methods, focus on conservation measures to secure the future of the fishing industry, and protect the environment.

Goatsbridge Trout is a sustainable trout farm near Thomastown, County Kilkenny. Each catch is delivered daily from the crystal-clear waters of the Little Arrigle

ATLANTIS OF KILMORE QUAY I PROFILE

44 Inside food & drink

Atlantis of Killmore Quay Directors, Mark O'Connor (Left), John Kenny (Right)

River that runs through the family’s estate, giving the produce a unique taste and texture.

“Atlantis has enjoyed a successful working relationship with Peter and the team at Gastrome Professional Ingredients for several years,” explained John. “Here at Atlantis, we find the Dutch Spices superior range fully meets our needs. The range of products are versatile in their application and consistently high quality. The range offers a wide variety of allergen-safe, (including glutenfree products), in which we have full confidence, ensuring that Atlantis can offer a competitive product to the retail market.”

Atlantis of Kilmore Quay’s oysters, clams and mussels are supplied by Kelly Oysters in Galway. A family business since 1963, their shellfish is reared in a small inlet in Kilcolgan, where they are nourished by the nutrient-rich Atlantic waters.

Brothers James and Willy Walsh run Rosslare Crab and work their trusty fishing

boat off the coast of Rosslare. They have lobster and crab pots in the sea from Tuskar Rock to Carnsore Point. The impact on the lobster and crab fishery is minimal and sustainable, given their traditional approach and use of vessels under 25ft. They typically land brown crabs, spider crabs and lobster.

“We are proud of our long associations with local suppliers and partners,” said John. “they have been an important part of our business since the start.”

Dishes of innovation

In becoming the leading purveyor of fish to hotels, top-class restaurants, national supermarkets and even home delivery, the company has stayed on top through its commitment to innovation in creating added-value recipes and investment in its people and premises.

Inside food & drink 45

46 Inside food & drink

Its Sea Fishers Protection Authorityapproved facility houses a 5,000 sqft state-of-the-art temperature-controlled filleting hall, a 500-pallet capacity cold store and a purpose-built smoking kiln. It also features the latest processing equipment, technology and machinery to ensure the best in food safety.

In 2020, despite economic uncertainty and Covid-19, Atlantis of Kilmore Quay upgraded its machinery and packing lines enabling continued growth, better use of

Irish-landed fish, and reducing its environmental footprint. Improvements were partly funded by the Irish Government and the European Maritime and Fisheries Fund under the Seafood Capital Investment Scheme.

The company’s in-house smoking kiln produces high-quality smoked salmon, haddock, mackerel and more innovative fish like cod, bass and hake, using oak shavings to create an exciting and delicious offering.

Atlantis of Kilmore Quay’s master smoker loves experimenting with different flavours like beetroot, gin or barbecue. From its famous Kilmore Quay Seafood Sausages to Master Chef Meal Kits, the company’s innovation team brings new and nutritious seafood dishes using local artisan ingredients.

Products from essentials like Dublin Bay Prawns to value-added specialities

PROFILE 48 Inside food & drink

ATLANTIS OF KILMORE QUAY I

like scampi and breaded fillets are stored in optimum conditions and available for delivery when needed. For quick, convenient options for the family, Atlantis of Kilmore Quay has a selection of oven-ready meals like salmon-en-croute. Gluten-free breadcrumbs are used on breaded products, while its haddock goujons were developed to use the smaller Wild Irish Haddock.

Fishing for opportunities

Clients can track products from trawler to table with the company’s comprehensive tracing system, giving complete confidence in traceability.

“The main issue for Ireland’s fishing industry is that it has the biggest fishing waters in Europe, but the smallest fish quotas,” John reflected. “It is an ongoing battle to get a fair share.

“Atlantis of Kilmore Quay must focus on doing more with less raw materials. While Covid rocked us, we pulled through and are now trading ahead of where we were before the pandemic.”

With 60% of its business dedicated to food service and the remainder to national retailers, Atlantis of Kilmore Quay retains ambitions to enlarge its retail footprint, expand its export trade and grow its Harley and Marley brand.

“Our goal is to make it easy and enjoyable to choose seafood meals that are healthy, high quality, sustainable and delicious,” John concluded. “It’s not only about the taste, freshness, texture and colour, but showing respect to the fish throughout its natural, healthy life, protecting our oceans and rivers, and ensuring species will continue to flourish for generations.” n

Inside food & drink 49

50 Inside food & drink

DIRECT I PROFILE

CAVE

With more than 40 years’ experience, Cave Direct is the UK’s leading craft beer wholesaler. Having built up a solid portfolio, the company is determined to keep on growing. Newly appointed Managing Director Neil Kitching sat in on an exclusive interview with Inside Food & Drink, to explain more. Report by Imogen Ward.

With several new brewery partners added to the Cave Direct lineup, plus new and exciting flavours on the way, the company is set to experience an action-packed year.

“So far, 2024 has kept us busy, and we are expecting that to continue throughout the rest of the year,” said Managing Director Neil Kitching. “The industry is still experiencing the after-effects of Covid. It has been a turbulent ride, but we are back up at our pre-Covid turnover rates, and that is set to continue rising.”

Cave Direct was established in 1979 by Colin and Louise’s father, Brian Gilhespy, with both of them joining soon afterwards.

Since then, Cave Direct has developed a striking portfolio which features craft beers from a large array of breweries.

The big buyout

In September last year, with retirement on the mind, the owners of Cave Direct agreed to a management buyout.

“Louise and Colin decided on the MBO route as a way of ensuring that Cave Direct continues as an independent owner-operated business,” Mr Kitching explained. “Louise will remain a Director and Colin will be Chairman of the Board with myself as MD, plus Laurence Smale and Michael Rochester taking up Director roles.”

Inside food & drink 51

52 Inside food & drink

With the desire to secure the company’s future, holding the best interests of the business and its people in mind, the owners decided that a management buyout was the way to go. This not only secured the future of the business, but also allowed for the familial ethos of the company to continue, with Laurence Smale, (Ms Smale’s son), a prominent part of the team.

“They really wanted the business to stay the way it is for the next generation,”

Mr Kitching continued. “The structure of the business was also an important factor to consider, and this development was set to improve that going forward.”

Crafted collaborations

Cave Direct’s extensive portfolio is only possible thanks to the hard work and innovative nature of its brewery partners. Each one has worked hard to produce first class beers that prioritise quality ingredients and taste.

German-based brewery Paulaner – one of Cave Direct’s main partners – offers a wide selection through the wholesaler, including one non-alcoholic Weiss.

“The alcohol-free sector is quite big in Germany, accounting for about 7%-8% of the country’s overall turnover from the beer

54 Inside food & drink CAVE DIRECT I PROFILE

industry,” Mr Kitching explained. “In comparison, it’s quite a new sector for us; but we work with a great selection of brewers who are experts in non-alcoholic brewing.”

Also on offer, for those looking for a 0% option, are several other top-quality options from the likes of DONZOKO, Tiny Rebel and LERVIG.

When looking for new products to add to its collection, Cave Direct first looks to its chain of valuable suppliers.

“The suppliers are the unique selling point of Cave Direct,” Mr Kitching commented. “We bring in beers that are unparalleled, from creative minds all over the world. This would not be possible without our suppliers. When looking for new additions, we turn to them first, because we know and trust the premium quality of their products.

“We are actually in the process of introducing some new products from LERVIG we have a good development programme with them, which is currently focused on

3.4% beers. This is a new category that has evolved from the UK tax regulations, with beers with an alcohol volume of 3.4 or less being taxed at half the rate of higher percentage beers.”

Cave Direct intends to further develop its ongoing supplier relationships as well. These people are an incredibly important element of the business, and their expertise is pivotal to providing Cave Direct’s customers with the very best selection of craft beers.

Inside food & drink 55

The perfect portfolio Cave Direct has developed an extensive portfolio of top-quality craft beer, which is divided into two ranges: exports and domestic. Within these categories, the company also offers several options that are sold exclusively through Cave Direct.

Just last year, the company added two new breweries to its exclusive range. Flötzinger, a 120-year-old, family-run brewery in Germany was of particular interest, thanks to the premium quality of its 5.5% lager.

The wholesaler has also seen an increasing demand for dry stout. In response to this, Cave Direct recently added Slow Life – a 4.5% nitro stout produced by award-winning Irish brewer Whiplash.

“There’s been a lot of interest for dry stout, and Whiplash are the perfect partner to meet that demand,” Mr Kitching explained. “The brewery has been operating for around six years now, and it produces a fantastic liquid.”

Whiplash launched with Cave Direct in October last year; two months after Flötzinger joined the wholesaler’s exclusives range. Both breweries have received positive praise from Cave Direct’s customers, and the company is looking forward to exploring future opportunities with both.

“The launch of Flötzinger and Whiplash has been very successful, and in February we made the decision to integrate them both into our core range,” said Mr Kitching. “The remainder of this year will be spent establishing support from our customers, before we look to introduce more products.”

What next?

Just like every other business, Cave Direct has felt the impact of inflation and increasing energy prices, with its cost of operations increasing by around 20% over the last few years. In an attempt to overcome these rising costs, the company

CAVE DIRECT I PROFILE 56 Inside food & drink

has been searching for ways to improve its efficiencies.

“We are trying to bring as much of our operation in-house as possible,” said Mr Kitching. “We now have our own fleet, that delivers to 90% of the UK, and we intend to pursue other improvements in the future.”

As it continues to grow, future development remains a large goal for Cave Direct. The buyout brings with it a new structure that will support future growth plans –including a desire to develop a portfolio of American breweries.

“We are really trying to develop the presence of American breweries in the UK,” Mr Kitching added, in conclusion. “We’ve been going out to talk to companies there: we even plan to attend a craft beer conference in Las Vegas.

“I think expanding into the American market will be a really exciting development for a lot of people. The key for us

is bringing over to America the freshest, most innovative beers by developing a good trade route that keeps the beer fresh, while minimising as much of the carbon footprint as possible.

“No matter what the future brings, we have an amazing group of people who will see us through and support our every success.” n

Inside food & drink 57

With a permanent presence in eight countries and a 133-year history of excellence in the food industry, Fazer is deservedly a household name across the Nordics. Starting out as a confectionery company, Fazer has diversified into multiple food sectors, with its latest success being in the oat product market. Yelena Piskun, Operations Director, and Taija Felt, Commercial Director, spoke with Richard Hagan about Fazer’s new, exciting range of oat-based products.

58 Inside food & drink

FAZER I PROFILE

Fazer’s story began 133 years ago when Karl Fazer returned to Finland carrying the secrets of Swiss chocolate making after studying in Switzerland Karl Fazer started the company with a small cafeteria in Kluuvikatu, Helsinki, offering home-made chocolate made using fresh, locally produced milk. The café is in exactly the same place today, and Fazer's most popular chocolate, Fazer Blue, is still

made with fresh milk. As the company gradually grew, it diversified into the baking sector.

To support these baking operations, Fazer opened its first mill in Finland in 1971, which it still owns and operates to this day. In 2013, Fazer began oat milling and the almost overnight success of its oat-based products would lead Fazer to buy a second mill in Sweden, only three years later, bringing both mills under the Fazer Mills umbrella.

A powerhouse of oats Oats has since become a major growth sector for Fazer and it is an opportunity that the company has substantially leaned into, according to Commercial Director Taija Felt: “Oatbased products are one

Inside food & drink 59

of our key strategic focus areas. Fazer has made substantial investments in oat product development, innovation and production capabilities. Recent investments include building up two new oat mills in Finland and Sweden, thus doubling the capacity. We now confidently say that Fazer is a powerhouse of oats.

“Added to that, we have world-class oat expertise and highly skilled professionals. Some of our employees have spent almost their whole lives working with oats, giving us the versatility to produce a variety of oat products.”

Fazer’s oat product portfolio bears this out, already boasting over 200 oat products delivered to B2B and B2C customers in 40 different countries. Its oat catalogue includes flours, flakes, bran, porridges, oat drinks, gurts, oat-based cooking products and others. The raw materials for all of these oat products are locally sourced from nearby farms in Finland

60 Inside food & drink FAZER I PROFILE

and Sweden, further adding to the portfolio’s sustainability and credibility.

An indulgence for every palate

Fazer’s complete product portfolio includes a catalogue of ingredients for its B2B clients - such as bakeries - and a delicious range of Fazer-branded consumer products such as confectionary, biscuits, smoothies, bread and sweet bread, the aforementioned oat products and even an innovative oat rice.

Notably, in 2022 Fazer also began producing and selling xylitol made from oats. Sold under its ‘Xylimax’ branda comprehensive range of 100% xylitol products - Fazer’s new oat-based xylitol is manufactured in-house using Fazer’s brand new, patented upcycling technology that produces xylitol from oat hulls, those

being another side stream product. This innovation makes Fazer the first food production company in the world to produce xylitol from oats, and the first to use oat hulls as a raw material for another value-added product.

The waste product generated by the xylitol production process - a side stream known as oat cake - is then sent to a nearby energy plant, which is able to generate power using the cake, the energy produced by this is then supplied back to Fazer and used at its mill.

Reducing and reusing waste

Food waste is one of sustainability challenges that Fazer has tackled. “We have put a lot of focus and emphasis on food waste reduction,” said Taija Felt. “In one effort to address this problem, we developed innovative new bread improvers

Inside food & drink 61

for our baking industry customers. These improvers allow the industry to prolong the shelf life of their products, so that their bread can stay fresher and softer for a longer period of time.

“This reduces food waste across the whole food chain, and it’s all powered by the latest technologies and knowhow that we are developing at the Fazer lab team in Finland.”

Food waste in its own milling is also being addressed by another of Fazer’s innovations. At the end of 2023, Fazer launched the new generation Oat Protein SGen – short for ‘Sustainable Generation’. This new superfood protein is manufactured from Nordic oats using oat bran that is produced

as a side stream - a byproduct – of the oat drinks manufacturing process.

“It’s a very versatile ingredient and suitable for many different applications, including dairy alternatives, healthy snacks and meat analogues,” Taija Felt explained “We expect to see even more sustainable and wellness-promoting products from side streams emerge from our Fazer lab team.”

Synergising across borders

Yelena Piskun joined Fazer Mills in late 2023 and was tasked with synergising the operations of Fazer’s two mills, developing a mutual culture across the border with both teams and harmonising the

FAZER I PROFILE 62 Inside food & drink

management of the two operations, amongst other responsibilities.

“It’s a big project combining several sites into one business, but it’s boosting the business in general and improving our customer service,” said Yelena Piskun. “We now have one voice, harmonised ways of working and synergised practices That all makes us stronger.”

Sustainable milling

Fazer has joined the Science-Based Target Initiative (SBTI), a global programme that seeks to ensure that corporate emissions reduction goals align with the objectives in the Paris Agreement in particular, and with climate science in general.

“Our commitment to the SBTI is firm; it requires lots of work and investments as well as working with and reviewing our company culture,” Yelena Piskun said.

In addition to upcycling its side streams, Fazer has switched to using 100% renewable electricity at both of its mills. “We also have a sustainable farming programme, called Grain Vision, in which we work closely with our local farmers, advising them on how to cultivate grain with the most sustainable methods,” Yelena Piskun explained.

Concluding, Yelena Piskun celebrated her new work with Fazer: “I chose to join Fazer because I was inspired by its values : Northern Liberty, True Relationships, Fearless Creativity. We’re brave and strong.

“None of our products contain anything we’re unsure about; they’re good, healthy and loved by so many people. I always have our products in my home, in my kitchen. When you’re personally consuming the products you create, then that’s the best quality guarantee!” n

Inside food & drink 63

64 Inside food & drink

BROS I PROFILE

PETROU

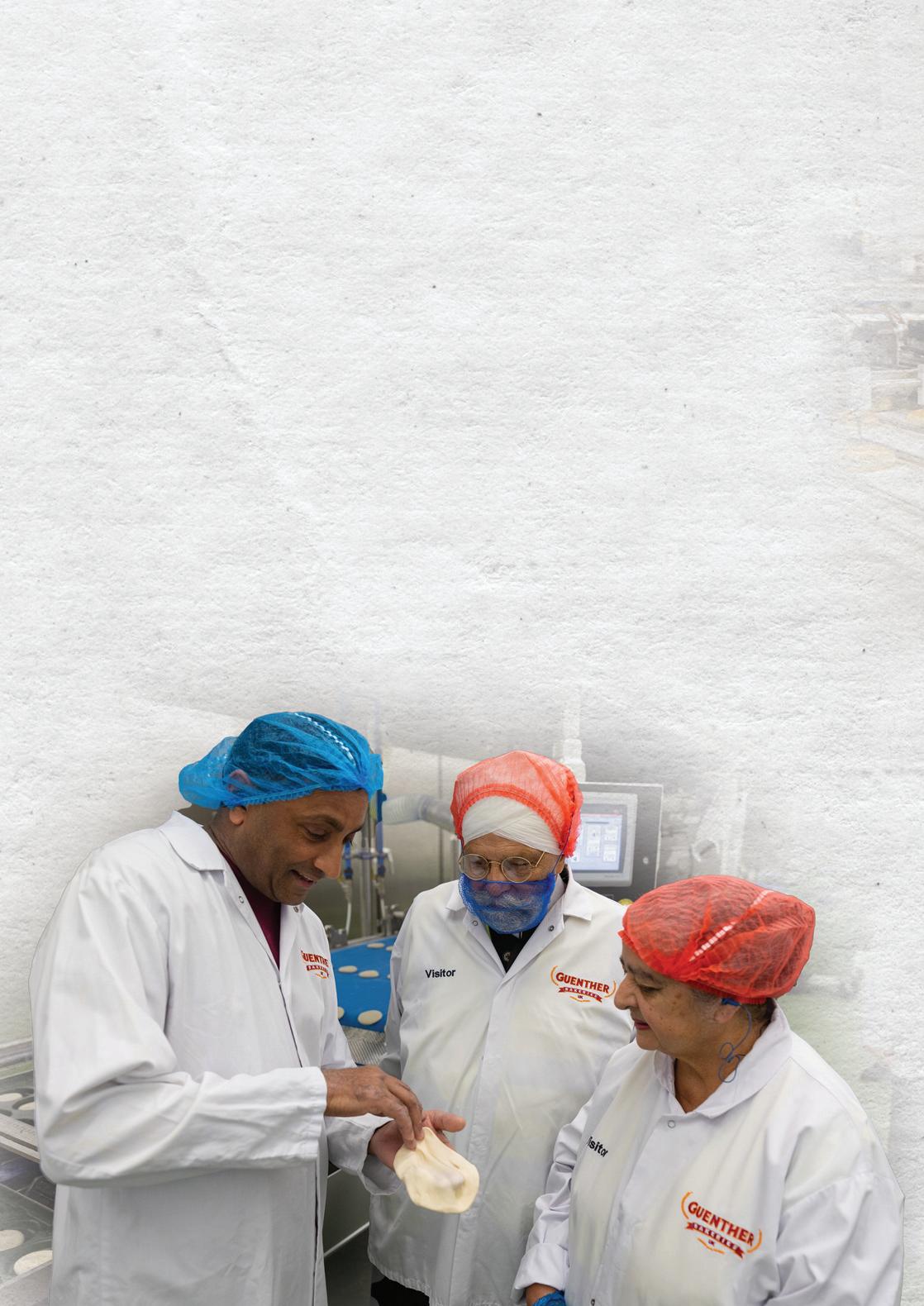

Petrou Bros Dairy Products is a renowned and successful producer of Cypriot dairy products, founded in 1982. Since then, the company has operated with the stated mission of providing high-quality products that exceed a customer’s expectations and ensure a safe and healthy environment for employees. Hannah Barnett spoke to Commercial Manager Michalis Petrou to find out more.

The last five years have been busy at Petrou Bros. The company has opened two new production lines as well as ramping up its investment into green energy.

The first of these developments involves a new 6,000 square metre production, packaging and logistics area for halloumi cheese. “We have doubled the size of the factory; we now have 15,000 square meters just for the production of our

signature halloumi,” Commercial Manager Michalis Petrou said.

The second expansion pertains to the new filling lines, pasteurisation line and automation for fresh milk and fresh juice. This is a €10 million investment into a stateof-the-art factory and is fitted out to a high standard of EU-approved technology.

Petrou Bros continues to dominate the market, with a 35% share in authentic halloumi cheese production, which is

Inside food & drink 65

exported to 40 countries. The company now produces more than 80 million litres of milk and more than 10,000 tonnes of halloumi. This success is supported by 270 employees and a turnover that exceeds €100 million.

New ventures

In March 2023, the organisation opened a new production line for fresh milk, under its Alambra brand. With 40 years of tradition, experience, and know-how behind it – as well as a leading position in the field of processing fresh milk for cheese making – the company is able to guarantee the quality and freshness of the milk. It now offers goat’s and cow’s milk at a range of fat percentages, alongside natural juices, plant-based milks and other beverages.

“This fresh milk production line is especially for the local Cypriot market,” said Mr Petrou. “We offer fresh milk on a daily

basis. We have been producing different dairy products like cheeses and yoghurts for the past 40 years and the only thing we didn’t produce was fresh milk. So, we have the opportunity now. Alambra is a unique brand that can offer a whole range of dairy products.”

Petrou Bros is also channelling investment into green energy and has recently installed solar panels onto its facilities, as well as purchasing an innovative biogas plant.

“Based on current estimations, we are covering about 50 per cent of the total demand of energy from our solar panels, because Cyprus is an extremely sunny island,” Mr Petrou explained.

“The biogas plant allows us to process waste and create biogas for the energy of the factory. And we have also been investing in a central cooling system, using ammonia, which will have a zeropollution effect.”

66 Inside food & drink

PETROU BROS I PROFILE

Global success, local spirit

Despite its worldwide presence and success, Petrou Bros Dairy Products is a proud local company. “As we are an island, we cannot import any milk,” said Mr Petrou. “The milk we process and sell is 100 per cent Cypriot. Each litre of this milk is collected from Cypriot producers, and we use it in our cheese-making process too.”

The halloumi made by Petrou Bros is a protected designation of origin product, as set out by the EU. This means it must be produced in a certain way, in a specific area, using traditional methods.

“We have to follow the procedures and standards that the government gets from the EU,” Mr Petrou explained. “Our halloumi cheese must be made with 100 per cent local milk, and there is a minimum

Inside food & drink 67

percentage of sheep’s and goats’ milk that you have to use in a cheese to call it halloumi. There are also various other production procedures and parameters that must be met, and we do so proudly.”

Like any successful company, it is vital that Petrou Bros maintains a strong relationship with its supply chain. The company has 400 milk suppliers spread across Cyprus and uses its own fleet of trucks to collect milk daily.

“Then we do a quality check for each batch of milk that we receive at the factory,” said Mr Petrou. “So, it’s very important to have transparent and direct communication with our suppliers. We are a family-owned business; therefore, it is vital that we maintain the personal touch with our supply chain. The key to our success is that we are transparent and fair, and we expect the same back.”

The company remains active in the community in many other ways also, by running multiple Corporate Social Responsibility initiatives. For example, Petrou Bros recently partnered with the charity Goal in Life, helping to fund the renovation of the paediatric ward of Archbishop Makarios III Hospital in Cyprus.

“We also work with supermarkets, and we agree that for each litre of milk we sell, a percentage of the income will be donated to a charity,” Mr Petrou explained. “It is not a fixed figure: each period we agree to run the campaign with a different supermarket chain, with a percentage of the income to be donated to a different charity.”

Continuing the legacy

Going forward, Petrou Bros looks set to maintain its leading position for halloumi cheese production and to continue

68 Inside food & drink

PETROU BROS I

PROFILE

Michalis Petrou Commercial Manager

promoting the delicious, traditional, Cypriot cheese worldwide. This is alongside the backdrop of an unstable global market, in which all companies are to some extent impacted by various wars and rising costs.

For Mr Petrou, however, the challenges are to be expected when inheriting the reins of a well-loved family business. Petrou Bros is a company he has grown up with and one he knows inside-out.

“I am second generation,” he said “and I started getting involved in the family business from 10 years old. So, all of us in the family know the business really well and we know how to produce efficiently and how to promote what we do successfully It is our company.

“I love what I do. Therefore, it’s very important to maintain and improve the level of success for the next generation by continued investment. The key to success for me at the Alambra organisation is to keep the passion for the business by always focusing on the next thing.” n

Inside food & drink 69

70 Inside food & drink UGO FOODS GROUP I PROFILE

Ugo Foods Group is a fourth-generation family business which prides itself on innovation and never compromising on quality. Hannah Barnett spoke to Charlie Ugo, Group Operations Director, and his brother Freddie, Head of Corporate Social Responsibility, to learn what makes this forward-thinking family firm tick.

There are businesses run by families and then there are family businesses. Ugo Foods Group is the latter. A large measure of its enduring success is down to the company’s strong commitment to moral values and innovation, as passed down from its original founder.

“It’s not just about producing highquality food, we want to make a better impact on the planet,” said Head of Corporate Social Responsibility, Freddie Ugo. “That’s our philosophy. A lot of that comes from being a family business. It started with our great-grandad. He passed it down to our grandad, Leo, who passed it down to our father, Paul, who still works here as Chairman. And then there’s me and Charlie.”

Innovators from the start

Ugo Foods Group is infused with the values and vision of its founder, Luigi Ugo He emigrated to the UK from Italy in the

early 1920’s and began selling paper bags of homemade pasta, not a wellknown product in the country at the time.

In 1929, Luigi opened his first delicatessen on Gerrard Street, Soho, and began making fresh pasta in the window of his shop. Another man, who was trying – and failing –to source noodles for a Chinese restaurant, spotted this activity.

“Nobody was making noodles in the UK at the time,” Group Operations Director Charlie Ugo explained. “This man eventually ended up teaching my great grandfather how to make noodles and opened his Chinese restaurant next door. Gerrard Street is now the centre of Chinatown. So, we’re quite proud of our part in that history.”

As a result, Ugo Foods Group spent much o f the interwar period producing Chinese cuisine. There was a fundamental shift in focus following the Second World War, and the company began manufacturing dried and fresh pasta once more, supplying

Inside food & drink 71

high-quality shops like Selfridges, John Lewis and Harrods. Innovation and new cuisines fit for the UK palate followed in abundance.

“We brought gnocchi to the UK and developed the first gnocchi machine using fresh potatoes rather than dried,” said Charlie Ugo. “We also produced organic and wholewheat pasta for the first time in the UK in the ‘60s. We even created a gluten free solution in the early ‘90s. A lot of the period from the ‘60s onwards was about innovation and how we could create a bespoke, unique product offering for the UK. We started experimenting with lots of different fillings and flavour profiles.”

Ugo Foods Group now produces 500 million parcels of pasta a year from its HQ in Hertfordshire, accumulating a turnover of £25 million.

The company continues to innovate and its Cromer Crab and Crayfish raviolo

72 Inside food & drink

I PROFILE

UGO FOODS GROUP

As seen on TV

Ugo Foods Group recently appeared on BBC TWO’s Inside the Factory. In the episode, Charlie Ugo showed Gregg Wallace an innovative machinery process that makes the company’s popular Cromer Crab and Crayfish raviolo so delicious, while Cherry Healey took a trip to Norfolk to meet the ingredients suppliers.

recently won a Gold Q Award; the ultimate accolade, bestowed on products which are truly outstanding.

Ugo Foods Group remains committed to using the highest quality ingredients in innovative ways, like a semolina-blend flour base for pasta dough.

“The semolina has a large grain size, is very yellow and high in protein, which allows us to create quite a unique dough,” explained Charlie Ugo. “This means we can reduce our egg content versus competitors, lowering our carbon footprint, while still having the texture and flavour expected.”

Socially aware sustainability

As a conscientious company run on family values, it is no surprise that Ugo Foods Group is keen to minimise both its environmental and social impact.

“Something that sets us apart is that we have a lot of charitable commitments that actually make a direct impact,” said Freddie Ugo. “We don’t just give a pot of money and say: ‘go ahead and use it,’ we like to be involved.”

This includes a partnership with the European Nature Trust, helping to preserve wildlife and ecosystems in Italy. A local hospice, Keech, for terminally ill

Inside food & drink 73

children, is supported with fundraising initiatives and by inviting residents to the factory to learn pasta making.

On the environmental side, Ugo Foods Group has almost eliminated scope 1 and 2 emissions by moving to renewable energy sources and replacing refrigerants. The company has also developed a semi-bespoke system for its triple-layered boiler to significantly increase efficiency and reuse waste heat as part of a reclamation system.

“We’re directly involved in the sustainable measures we go for,” Freddie Ugo explained. “We’re doing our due diligence, but we actually care about it. And that also comes across in the ingredients that we buy. There’s been multiple occasions where we’ve changed supplier because we realised there was either an ethical or an environmental issue with them .”

The company works closely with suppliers; sourcing ingredients as locally as possible and prioritising partners that are focused on carbon

reduction. In particular, Ugo Foods Group highlighted ethical flour millers, Wildfarmed.

A pint of pasta

Both Ugo brothers are particularly passionate about the eradication of waste where possible. As a result, company wastage has significantly reduced in recent years; but it cannot be entirely avoided due to vital quality control processes. Of course, Ugo Foods Group has multiple innovative solutions to mitigate this.

One partnership with a notable celebritychef-turned-farmer, involves feeding pigs uncontaminated scraps, thereby reducing food waste and the emissions usually derived from animal feed. Though successful it is not a consistently reliable solution to excess waste, due to variation in demand.

The next step involved even more innovation, when the novel idea of brewing beer from pasta was raised.

“We didn’t know whether it was even possible,” said Charlie Ugo. “We did

UGO FOODS GROUP I PROFILE 74 Inside food & drink

some early-stage trials with pots and pans in the kitchen to see if we could create fermentable sugars. This took maybe a year and a half to advance to a point where we had a good quality product. We have since patented that process throughout Europe and the UK, and we’ve launched applications globally.”

And with that, Beyond Belief Brewing Co. was born. The process involves using surplus fresh pasta as a base malt replacement, saving 2/3 of a litre of water and over 110 grams of CO 2 for every pint.

After nearly a century of innovation, Ugo Foods Group is not the kind of business to rest on its laurels. The company recently introduced fully recyclable packaging, investing hundreds of thousands into

converting its machines as a response to feedback from customers.

And there is plenty more to be done, according to Freddie Ugo: “We’re in the process of getting B Corp status. We’re signing up to the Science Based Targets Initiative to set a verifiable carbon emission reduction goal. We’re working with various consultancies to do lifecycle assessments of different products. Carbon accounting is a very collaborative thing, and we are trying to make it more accessible to smaller producers.”

This scope of innovation, as always, extends to the products themselves too.

“We are trying to do what we have always done: bring new things to the UK, just like our great-grandfather did,” Charlie Ugo concluded. “So, of course there is plenty coming up in the new product development pipeline.” n

Inside food & drink 75

from crop to consumption

MANUFACTURING & PACKAGING

redpack packaging machinery tummers food processing solutions we seal

i F D &

RedpackPackagingMachineryhasexpertlymanufactured flow-wrapsystemsforthepast50years.Now,celebrating itsanniversary,thecompanyisbusierthaneverinvesting innewmachineryandexpandingitscustomerbase.General ManagerGaryHowardexplainedmore,inanexclusive interview.ReportbyImogenWard.

78 Inside food & drink

REDPACK PACKAGING MACHINERY I PROFILE

With a combined expertise of 756 years, the team at Redpack Packaging Machinery is renowned for designing and manufacturing reliable equipment with the help of its three pillars of strength:

“Our three pillars – quality, service and innovation – aid our strategic goals,” General Manager Gary Howard explained. “If a project doesn’t have all three elements, then we don’t do it. We dedicate a lot of time to our customers; not only listening to their needs but the needs of their customers as well. They are the ones that use the machines, so we have to pay attention to what they do and where improvements can be made.”

Founder Michael Briston established his precision engineering company in 1973, providing machined parts for companies in and around Norfolk, UK, one of which