Maustaja'snewproduction line provides a handy solution for fluid or squeezable food supplies. The production process enables products fr.ee from preservatives and additives -healthy and deHcious!

Maustaja has a 50 years' experience of designing and producing sauces and condiments for private labels and brands. Maustaja provides an overal! service concept from an idea to finished products.

Currently available product categories are:

• Snacks

•Baby food

•Porridges

•Smoothies

• Functional beverages

•And plenty more

Are you looking for a comprehensive manufacturer for your product?

Made to be planet-positive and full of flavour, Avallen Calvados is a crisp and floral apple drink presented in a beautiful paper bottle that has 1/6 of the carbon footprint of a regular glass bottle. Enjoy this detailed look at the carefully engineered cardboard neck of the Calvados bottle.

Managing Director

John White

Finance Director

Filomena Nardi-Smith

Editor

Phil Nicholls

Editorial Assistants

Imogen Ward

Hannah Barnett

Feature Writers

Andy Probert

Romana Moares

Richard Hagan

Colin Chinery

Business Development Manager

Darren Foiret

Research Editors

Jeff Johnson

Mark Simmonds

Judi Wheaton-Mars

Ginelle Lorenzo

Natalie Martin

Dane Coady

Becky Scrivens

Sam Ransome

Matthew Spalding

Sales Director

Richard Brightmore

Sales Manager

Helen Leisi

Project Managers

Alexander Paterson

Tony Ingrouille

Kym Hamilton

Chris Renicar

David Earl

Lisa Smith

Will Tottie

Bobby Godfrey

Loretta Smith

Julien Carew

Art Director

Ian Spencer

Art Editor

Philip White

Webmaster

Michael Stamp

Designers

Sarah Jones

Georgina Harris

Events Manager

Jasmine Lodge

Marketing Executive

Adam White

Administration & IT

Summer Clover

Gavin Bellward

T: +44 (0)1493 445121 +44 (0)1502 566216

E: media@insidepublication.com

W: www.insidefoodanddrink.com

John White Managing Director

Managing Director John White shares a mince pie with Charles Dickens.

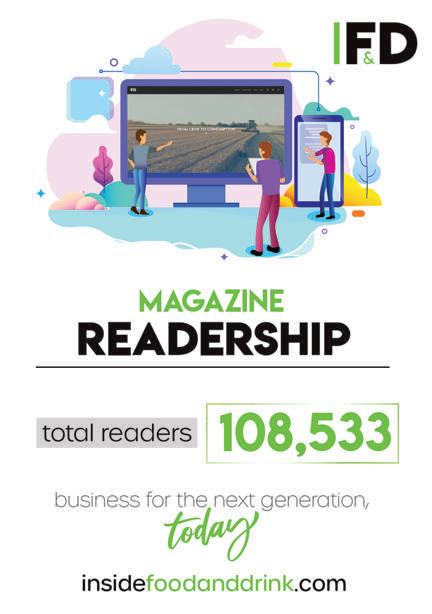

Welcome, Dear Reader, to your Christmas edition of Inside Food & Drink. What better magazine, amongst all our business titles at least, could we use to discuss the festive season?

This magazine is ever popular, due in part to all the tantalising imagery used to help portray the products and services of our customers to our readers. This edition, therefore, with its focus on ‘Taste of the Season’ and a piece on the nostalgia of seasonal food and drink, should, I hope, be a festive treat for one and all.

Personally, my nostalgic view of Christmas food and drink is based on ‘A Christmas Carol’ by Charles Dickens: cheeky young scallywags running around a snow-covered Victorian England, having snowball fights, singing carols outside the doors of jolly looking homes, cosy log fires burning and the smell of a turkey and trimmings fresh out of the oven.

Clearly, though, this was far from the truth for the poor in those days. The past was not without its poverty. Thankfully for many, but sadly not all, the present day

sees an indulgence in a wealth of seasonal food and drink choices that our ancestors from 180 years ago could only dream about.

Whilst romanticising about that table full of delights, we bring you, within the following pages, some ideas about modern tastes of the season. My editorial team have been busy reviewing and sampling many seasonal treats and are pleased to present their findings to you.

Before tucking in, though, I would encourage those of us with plenty, to take heed from Dickens’ Ebenezer Scrooge. Share the good cheer with those who have less, or none. Better that, than get indigestion whilst awaiting a visit from those troublesome Christmas Spirits! n

Latest developments from the UK’s industry

In November, the Marine Conservation Society, the UK’s leading ocean charity, launched its pioneering chef training programme, School of Fish. The short and easy to use course aims to educate catering professionals about sustainable seafood sourcing in the UK.

Working closely with the food service industry and catering colleges, the Marine Conservation Society has designed a comprehensive and entirely free training programme to empower chefs with the knowledge and skills needed to make responsible seafood choices. With the user-friendly and easy to use online course taking less than an hour to complete, and accessible via mobile devices, it offers a convenient and flexible learning opportunity for chefs, seafood buyers and catering students.

The launch of School of Fish is driven by the urgent need to promote responsible fishing, better fisheries management and protect the delicate ecosystems of UK seas. The course covers a range of essential topics, such as identifying sustainably sourced seafood, recognising unsustainable choices, and the importance of supporting marine conservation efforts.

This initiative is a significant step towards fostering sustainability within

the food service industry, encouraging informed, responsible choices that will benefit the UK’s environment and seafood industry. By educating chefs and food sourcing professionals on sustainable seafood buying, the Marine Conservation Society hopes to reduce the impact of overfishing, bycatch and other unsustainable practices that threaten the ocean’s health. The charity already works closely with seafood suppliers, with its Good Fish Guide used to check the sustainability of around 20% of the seafood meals served in the UK every year. n

To have your company’s latest news included online or in our Inside Food & Drink magazine, contact us today media@insidepublication.com

To give more students the resources they need for the fun they deserve,

FRITO-LAY® Variety Packs and CHEETOS® Mac ‘N Cheese have donated more than $300,000 to GENYOUth to provide access to 10 million meals through Grab-and-Go school breakfast and after-school programmes.

Through the support of GENYOUth, a national non-profit that creates healthier school communities, this donation will also supply 120 NFL FLAG-InSchool kits to keep 66,000 kids active in youth sports.

In celebration of this partnership, husband-and-wife duo and former professional athletes JJ and Kealia Watt, are teaming up with Frito-Lay Variety Packs and CHEETOS Mac ‘N Cheese to spread awareness about the importance of increasing access to school meals and youth sports programming.

“As athletes and parents, we know it’s essential for our youth to have access to school meals and the value of accessible youth sports to develop teambuilding skills and teach the importance of hard work and perseverance,” JJ Watt said.

Watt, who spent 10 years of his professional American football career playing in

Houston, has long supported youth sports initiatives within the community.

“Schools play a crucial role in ensuring proper nutrition and providing safe places to play and learn for 55 million students,” said Ann Marie Krautheim, CEO, GENYOUth.

“With one in eight US children living in food insecurity and only one in four getting the recommended 60 minutes of daily physical activity, we ensure schools have the resources to help children thrive. We are grateful for Frito-Lay Variety Packs and CHEETOS Mac ‘N Cheese’s support to help end student hunger and encourage play through school sports programmes.”

The collaboration between Frito-Lay and GENYOUth builds upon their longstanding relationship and shared commitment to combating food insecurity. Frito-Lay, Quaker and the PepsiCo Foundation have collectively provided over $6 million to GENYOUth since 2009. n

Latest developments from the Japanese industry

Romanian-based beverage company, Alexandrion Group is planning to open a new distribution centre in Japan, following the successful soft launch of its products earlier this year.

Celebrated for its unique blend of tradition and innovation, the Alexandrion Group introduced its flagship portfolio to Japan, through a business reception in Tokyo. The event was the first step in the Group’s expansion plans in Japan. With a broad global network, coordinated through business hubs opened in the USA, Brazil, Dubai –UAE and the UK, Alexandrion Group has ambitious plans for Japan.

“Alexandrion Group has grown so much in the past few years,” Dr Nawaf Salameh, Founding Chairman Alexandrion Group, stated. “We sell our products on almost every continent and because we have already sold some of our products in Japan and the customers’ feedback was very positive, it made perfect sense for us to take the next step forward. We will open a distribution company in Japan in the first semester of 2024, a country where consumers appreciate well-made, premium spirits and wines like ours.”

Alexandrion Group has grown so much in the past few years “ “

Alexandrion Group’s sales strategy for Japan will be built around the premium and ultra-premium spirits and wine portfolios. In terms of spirits, the Group aims to sell over 50 types of single malt and blended malt whisky, the premium ranges Brâncoveanu Vinars, Alexandrion flavoured brandy and Saber Elyzia fruit liqueurs, as well as premium and ultra-premium gin and vodka brands. Japanese consumers will have the opportunity to purchase and consume premium wines from the Hyperion and Rhein Extra ranges, as well as premium vermouth. In the second semester of 2024, Alexandrion Group also plans to launch premium and ultra-premium ranges of rum in Romania and in Japan. n

Latest developments from the French industry

XPO, a leading provider of innovative and sustainable end-to-end logistics solutions across Europe, has announced a partnership with METRO Markets.

METRO Marketplace, which has already been launched in Italy, Spain, Portugal, the Netherlands, and Germany, is METRO's online marketplace. Unique in Europe, it offers a wide range of non-food products for hotels and restaurants. Building on the success of these initial launches, METRO inaugurated an 18,300sqm warehouse in Roye, France, on 12 September, to accelerate the roll-out across Europe.

The new warehouse brings together 3,300 direct non-food references (furniture, small and large appliances, tableware, food preparation, disposable solutions, hygiene and maintenance, office supplies and equipment, etc.) for a total of 100,000 references available for order.

To ensure the delivery of the heavy and bulky products on offer, METRO Markets selected XPO Logistics as its partner because of its expertise in palletised distribution and its last-mile delivery service.

One of XPO Logistics' largest distribution centres in France is located in the same industrial estate as METRO France's Roye warehouse, with a 7,500sqm cross-dock. With a workforce of 175 employees, including 93 drivers and a fleet of 127 semitrailers, an average of 600 deliveries are made daily for all XPO Logistics customers. The geographical proximity of the two sites is one of the key advantages of the collaboration, with deliveries possible throughout France within 24 hours.

By handling these deliveries for METRO Markets, XPO is reinforcing its position as a key partner for companies wishing to transform and accelerate their business by relying on a dependable and innovative expert. XPO Logistics' territorial coverage, its 10 years of expertise in last-mile delivery and its tracking system, which enables customers to follow the various stages of their shipments in real time, are among the main reasons why METRO Markets has placed its trust in XPO Logistics. n

Interesting and unusual facts from around the food and drink world

T he modern traditional UK Christmas dinner comes from the Victorians, and Charles Dickens in particular, who spread the idea of a Christmas dinner, with a roast bird, all the trimmings and a pudding on the table.

Traditional Swahili food for the Christmas holiday includes chapati and spicy rice and meat known as pilao.

Many Australians prefer eating cold ham and turkey instead of a warm formal dinner due to the hot climate. Some celebrate in their backyard with BBQ prawns and beer. The traditional Australian desserts, such as pavlova and the Christmas trifle, are also a huge part of Australian Christmas food.

In Japan, Christmas means KFC. On December 25th every year, millions of Japanese people sit down to a hearty meal of Kentucky Fried Chicken, with orders placed with the restaurant months in advance. The campaign started in the ‘70s to tempt tourists and expats with chicken on Christmas Day when they couldn't find turkey to eat, and was the brainchild of Takeshi Okawara, the manager of the first KFC in the country.

– Anthony Robbins –“ “

Every problem is a gift, we would not grow without problems

Picana, the main Christmas meal in Bolivia, is usually eaten after midnight mass and is a stew/soup made from chicken, beef and pork, served with potatoes and corn.

The oldest surviving fruitcake was baked in Tecumseh, Michigan by the loving matriarch of the Ford family, Fidelia, back in 1878. Unfortunately, Fidelia died before she was able to cut into the 1878 fruitcake. Her son then became its keeper, taking great care to ensure the cake was preserved to honour her legacy.

Christmas pudding began as something called plum porridge a dish made from beef shin, spices, sugar and fruit, boiled in a broth and reduced until gelatinous.

Most historians agree that mulled wine was invented by the Greeks sometime around the second century. Known as hippocras, it was intended to be a health tonic during the cold winter months. As the Roman Empire expanded across Europe, so too did the popularity of this hot, spiced wine.

Food futurologist Dr Morgaine Gaye reports on Christmas traditions.

Food is a complex topic, involving society, geo-politics, culture and much more.

As a food futurologist, Dr Morgaine Gaye explores all facets of food, including trends, why we eat what we eat and what the future of food looks like. In the article for Inside Food & Drink, Dr Gaye examines Christmas foods.

INthe style of Charles Dickens, any review of Christmas should be broken into three parts.

Food of Christmas past It already seems like the Dark Ages when the much desired ‘selection box’ was a Christmas highlight for every child in Britain, because six individually wrapped whole chocolate bars was more than most children had seen all year. This was the same era that blancmange was a popular dessert.

Christmas also ushered in the yearly exoticism of the prawn cocktail. Turkey was

reence of Christmas can be divided into two very distinct phases; pre-pandemic in 2019 and post-pandemic up until the new year of 2023.

Three key shifts have happened during these past three years. Firstly, we became acutely aware of how much people meant to us and how sharing food was one of the anchors in our daily routine. We began cooking at home more mindfully and sharing food prep and creativity in the kitchen together.

always de rigueur on Christmas day and the table centre piece was the Christmas cake, often painstakingly topped with a winter scene that was lodged into the hardest substance known to man; royal icing. In the ‘90s, celebrity chefs began to encourage recipe and menu rebellion. Around the turn of the new millennium, the way in which food was presented started to become more of a styling focus and previously whole deserts were offered by brands in mini-individual portions.

Secondly, nature became our lifeline; we relished our daily walk and heard the words ‘forest bathing’ for the first time. Finally, our lives began to revolve around the table. It became a schooling hub, an office workstation, a family gathering space as well as a Zoom location which could be modified for meetings and social gatherings.

Given this trifecta of change within our lives, Christmas has been affected irreversibly. The key component of the Christmas meal became a dialled-up sharing concept. It is no longer about individual desserts and dishes but more about large sharing plates.

According to the data analysts Kantar, one million more Christmas puddings were

Food futurologist Dr Morgaine Gaye reports on Christmas traditions.

Food futurologist Dr Morgaine Gaye

sold in 2022 than the year before, giving a nod not just to sharing but also to tradition and heritage - both things we crave during periods of uncertainty and instability.

Christmas 2023 is really building on these themes of nostalgia and nature, with Christmas colours of plain green and red a distant memory. We can expect plenty of floral inspired desserts that pay homage to nature will also sit alongside retro puddings which have been given a modern twist –from baked Alaska and Battenburg to Black Forest Gateau.

Nostalgia from the ‘80s will also influence this Christmas as food is ‘blinged up’ with gold leaf and hyper-coloured packaging. Expect to see a revival of beautiful, decorative and embossed tins of chocolates and biscuits – Christmas keepsakes which the Victorians originally created to appeal to children. There will also be a rise in delicious non-alcoholic tipples for the growing teetotal market.

is that it has given rise to what matters most to us. This has changed the future trajectory for many things including the way we will celebrate Christmas in future. Looking into the future, let us look at what will disappear by Christmas 2033. Firstly, goodbye Christmas cards. Several European countries do not send Christmas cards, and over the years, that trend is spreading. The rise of social media and concerns around the environment will contribute to the decline in this tradition.

The eight hottest Christmases on record have occurred in the past 10 years. Therefore, a white Christmas with snow scenes, songs and motifs will decline. We also see less and less of carolling and door knocking already, so we can expect it to be absent from our lives by 2030.

The over-buying and over-consumption at Christmas results in more food waste than usual (on average around 10% of all of Christmas food ends up in the bin). The issue of food waste is coming into sharper focus, and by 2030 our diners will be less tolerant of wasteful behaviour.

In turn, here is a look at what we can expect to become the norm by Christmas 2030. Firstly, gifting will be more eco-friendly.

More and more, we will be gifting experiences, our time or something we’ve made – plus we will re-use decorative materials to wrap our gifts.

Christmas will also become healthier. Even at the Christmas table we will expect food with added goodness, multi-functional ingredients, lower processed sugar and much less stodge. With warmer winters, we will be looking for lighter lunches and less calories. Desserts and treats will be less sweet, as our overall pallet has already begun to accept less sugar in most processed foods.

The rise of food allergies, specific food preferences and more bio-hacking information will have a big impact – one meal type will not fit all, so Christmas dinner will be more personalised, with of a buffet of options. We will be sharing a smorgasbord of dishes, plant-based options and interesting new combinations.

Food tech appliances will enable our home cooking to be easier and more integrated. We will have more in-house growing systems and in just a few years the AI tech will far exceed anything we can currently imagine, so cooking at home will be a much more efficient process.

itself with more augmented realities, haptic sweaters and even holograms to give the ability to share the day with absent loved ones – both far away and deceased.

In short, we can expect Christmas 2030 to be more about personalised nutrition with high tech components, paired with very eco-friendly attitudes in the way we think about waste. The celebration will focus more on the core moments of togetherness and joy, whilst avoiding excess and extravagance. n

To learn more about Dr Gaye’s work, please visit: www.morgainegaye.com

Exciting ways to celebrate Christmas

With Christmas calling, festive foods and tantalising tipples are very much on the minds of households across the world. Whether you celebrate the season with a bottle of bubbly or a stocking full of chocolate, we have gathered the perfect range of enticing options to get your taste buds tingling and your tummy rumbling – each one sampled by a member of the Inside Food & Drink team.

Holding the title as the UK’s number one Vegan & Free From chocolate brand, NOMO prides itself in creating delicious and chocolate alternatives that taste just as good as the real thing. Heralded as a chocolate revelation, the company seeks to remove FOMO from the agenda and replace it with NOMO – No Missing Out.

For those looking to treat their friends and family this Christmas, NOMO also offers a Christmas Selection Box, filled with the nation’s favourite choices.

This year, in celebration of the festive season NOMO has released several on-brand options. Whether you’re in the mood for the rich indulgence of a Choc Fudge Reindeer or the moreish decadence of the Hollow Reindeer, NOMO has made sure its Christmas range packs a punch. Here at Inside Food & Drink, we were lucky enough to give them a try.

“ The NOMO Hollow Reindeer was delicious! The cute packaging makes it the perfect gift for any Christmas fan – young or old – and the inclusion of rainforest alliance certified cocoa beans makes it the perfect feel-good treat. I can’t wait to try the rest of NOMO’s Christmas range!.” – Imogen Ward, Editorial Assistant.

Have FOMO NO MO-re. You can find the full Christmas range here: https://nomochoc.com/

Limoncello Di Capri

Originating from the Island of Capri, Italy, Lemoncello Di Capri evolved from Vincenza Canale, the landlady of the renowned Mariantonia Hotel, and her desire to offer homemade limoncello to her guests. Now a fully-fledged business, Limoncello Di Capri took form in 1988 and became the first establishment to patent and use the name Limoncello. Ever since, the company’s drinks have become renowned for their distinct flavour and bright, lemon- yellow bottles.

Now, just in time for Christmas, the company has developed another way for fans to enjoy the flavours of Capri. Dressed in a beautiful deep blue bottle, Limoncello Di Capri Crema is a zesty indulgence that pairs perfectly with starters, mains and desserts.

Not just for Christmas, this delicately smooth cream liqueur can be enjoyed all year long in the form of cocktails and delicious desserts.

“ Limoncello Di Capri Crema has a gorgeous silky-smooth texture that works wonderfully with the sharpness of its Sorrento lemons. It was the perfect addition to my lemon tiramisu and has quickly become a firm favourite of mine ” – Editor, Phil Nicholls. i F D &

You can find out more about how the company turns lemons into limoncello here: https://www.limoncello.com/en/

Made to be planet-positive and full of flavour, Avallen Calvados is a crisp and floral offering presented in a beautiful paper bottle that has 1/6 of the carbon footprint of a regular glass bottle. Brimming with delicious apples that have been pollinated by the company’s own bees, this brandy is sure to have a lasting impact on your pallet.

Determined to become the world’s most sustainable spirit, Avallen works in harmony with nature to create the perfect apple brandy using only apples, water and time.

Whether mixed with the perfect concoction of Christmassy spices or as a standalone refreshment, Avallen Calvados is the ideal option for any brandy fan.

“Avallen Calvados is the perfect combination of fruity and floral. It is refreshingly light, yet full-bodied and had me going back for more. With a sweet taste and a hearty fragrance, this is the perfect feel-good drink, with an import climate-conscious message that really made me think about the origins of my usual drink choices. The paper bottle was the cherry on top, making the entire product a piece of art.” – Jasmine Lodge, Events Manager.

To experience the refreshing taste of Avallen for yourself, head to: https://avallenspirits.com/

Christmas comes but once a year and the Cornish Scone Company has devised an ingenious way to enjoy the famous flavours of Cornwall, usually associated with summer, by adding a festive twist.

The company began when founder Karen Gilchrist’s father moved away from Cornwall, and she started sending cream teas to him in the post. The traditional Gilchrist family scone recipes have been handed down through generations and remain a closely guarded secret. All ingredients are, of course, locally sourced.

This festive season, the company has more Cornwall-related Christmas offerings in their hampers than you can shake a yule log at. These include, but are not limited to, Christmas cake slices, festive Christmas scones baked with extra spice, (as always, finished off with Rodda’s cream and delicious Boddingtons strawberry jam) and Christmas tiffin made with fairtrade dark chocolate, ginger snaps, Christmas spices, cranberries, raisins and sultanas.

There are also savoury options, including cheese and cranberry scones, or a tasty Christmas Cornish pasty made by the company’s favourite local specialist baker. The pasty contains turkey, sausage meat, stuffing, cranberry sauce, potato, swede and onion.

“ I adored the variety of this hamper.

I am a big fan of the Christmas scone, what a great idea! And the Christmas tiffin was exceptional. I could really taste the ginger nuts which gave it a truly delicious seasonal twist. ” – Hannah Barnett, Editorial Assistant. i F D &

To see the full range, and organise a hamper to be sent to your loved ones in time for Christmas, check out: https://www.cornishsconecompany.co.uk/

latest news from around the food and drink industry

The UK’s number one pulses and grains brand, Merchant Gourmet, has extended its pulses and grains offering with the launch of its new, readyto-eat Black Dhal.

The launch comes as Merchant Gourmet seeks to provide delicious, quick and better-for-you meal options, as research shows that 20% of Britons are eating Indian cuisine at least once a week at home in the UK.

Made with coconut cream, rich black lentils and a careful balance of over 20 warming herbs and spices to provide full flavour, Merchant Gourmet’s Black Dhal is vegan-friendly, a source of protein, high in fibre and contains 33% less salt than leading competitors.

Ready in just 45 seconds, the delicious dhal pairs perfectly with rice or naan, making it a great addition to speedy plantpowered lunches or dinners.

“With more and more people choosing to eat at home, we wanted to give shoppers an option for a high-quality, convenient ‘fake-away’ that doesn’t compromise on taste or health,” said Richard Peake, Managing Director at Merchant Gourmet. “Our creamy Black Dhal is perfect for foodies

with busy lives, looking for quick, easy and exciting meals that deliver on flavour.”

Merchant Gourmet’s new Black Dhal is available now in Sainsbury’s and Ocado.

The UK’s number one pulses and grains brand, Merchant Gourmet, was founded back in 1994 by brothers Mark and Oliver Leatham, who were inspired by the nation’s growing appetite for exciting and innovative cooking ingredients.

Today, the brand continues its mission to inspire more people to eat more plants, with 20% growth YOY and a market share of 47%.

Best-known for its colourful pouches of pulses, grains and top-selling chestnuts, Merchant Gourmet continues to pioneer new and exciting plant-based products that are simple to prepare and made using delicious, natural ingredients. n

Ocean Spray®, the UK’s leading cranberry juice brand, has brought innovation to the juice category and the goodness of the cranberry to more consumers with the launch of a different, sweeter type of cranberry juice drink, Ocean Spray Pink Cranberry, with vitamin C and no added sugar, artificial colours or flavourings.

New Pink Cranberry is also filled with purpose as Ocean Spray has pledged to donate five pence from every carton sold to breast cancer trust The Pink Ribbon Foundation.

Launched into the ambient aisle in Morrisons, Sainsbury’s and independent stores from the end of October, Ocean Spray Pink Cranberry is different because it contains a unique blend of pink, red and white cranberries, giving it a smooth, sweet and refreshing taste compared to the crisp tangy flavour of red cranberry juice.

Not only does the sweeter taste appeal to a wider audience, but it also makes it a more versatile, healthier alternative drink outside the traditional breakfast occasion, such as at lunchtime, early evening or as an afternoon pick-me-up.

“We wanted to create a different type of cranberry juice filled with passion and

purpose that appeals to the younger, non-cranberry drinker who is often put off by the tartness of traditional cranberry juice,” explained Jo Dickinson, Senior UK Marketing Manager Ocean Spray. “It also needed to have wider appeal outside of the breakfast occasion.”

Ocean Spray has been a farmer owned cooperative since day one and its unique harvest produces inherently healthy fruit which has a distinctive taste and contains naturally occurring antioxidant vitamin C.

Ocean Spray is launching both ambient and chilled varieties of its new Pink Cranberry, with the ambient juice drink launching first into retailers in October, and the chilled variant, containing higher levels of vitamin C, launching in spring 2024. n

latest news from around the food and drink industry

Cavendish, the full-service investment bank for growth and investment companies, announced that it had advised on the merger of Goedhuis & Co and Waddesdon Wine, a subsidiary of the Rothschild Foundation, which completed on 3 November 2023.

Both companies will initially continue to trade under their existing names while the two businesses are fully integrated, to ensure no disruption to clients or suppliers.

The new entity, Goedhuis Waddesdon Limited, is poised to become a formidable presence in the wine industry, uniting exceptional wine expertise, prestigious portfolios and first-class levels of service to create an unparalleled destination for wine collectors, retailers and hospitality businesses seeking to elevate their standards of wine excellence.

Goedhuis & Co is a distinguished, multiaward-winning fine wine merchant with over four decades of experience, celebrated for its expertise in all the great wine regions, with a particular focus on Burgundy and Bordeaux. Waddesdon Wine represents wines from Domaines Barons de Rothschild

Lafite and Edmond de Rothschild Heritage exclusively within the UK. Waddesdon Wine also represents Hundred Acre and collaborates closely with esteemed wineries including Henri Bourgeois and Penfolds.

Chateau Lafite Rothschild will retain a shareholding in the newly merged Goedhuis Waddesdon Limited. Goedhuis Waddesdon’s headquarters will be in London Bridge and at the Rothschild estate, Waddesdon Manor which has recently opened its newly renovated cellars which house the largest collections of Chateau Lafite Rothschild and Chateau Mouton Rothschild outside of Bordeaux.

The lead advisers on the transaction were Senior Partner Lord Leigh of Hurley, Director Rebecca McCredie and Associate Tom Holland-Hibbert. n

Stroodles, the British edible tableware retailer that has made headlines worldwide for its food-based, biodegradable dining products, has partnered with ‘sell first, pay suppliers later’ fintech Treyd to capitalise on Stroodles’ already explosive growth.

Stroodles began revolutionising the notoriously unsustainable drinking straws sector in 2019 with its pasta-based straws; its range has since grown to encompass edible (wheat-based) cutlery, crockery, and most recently even play, activity kits. To fuel the growing demand for its products internationally, Stroodles has entered a partnership with Stockholmbased Treyd, which helps retail SMEs to grow by providing upfront financing for

paying suppliers in advance. The partnership will enable Stroodles to continue to expand its production as well as freeing up capital to invest in R&D.

Cashflow is a recurrent issue for food and beverage SMEs due to typically long payment terms – meaning SMEs can be out of pocket for many months on end. Treyd provides growth opportunities to long-shelf-life F&B retailers that are cheaper than investment and more flexible and attainable than bank loans.

Last year, Treyd grew its global customer base of small and medium enterprises by 500% and revenue by 1,000%. It now works with over 600 retail SMEs across Northern Europe, 150 of which are British. n

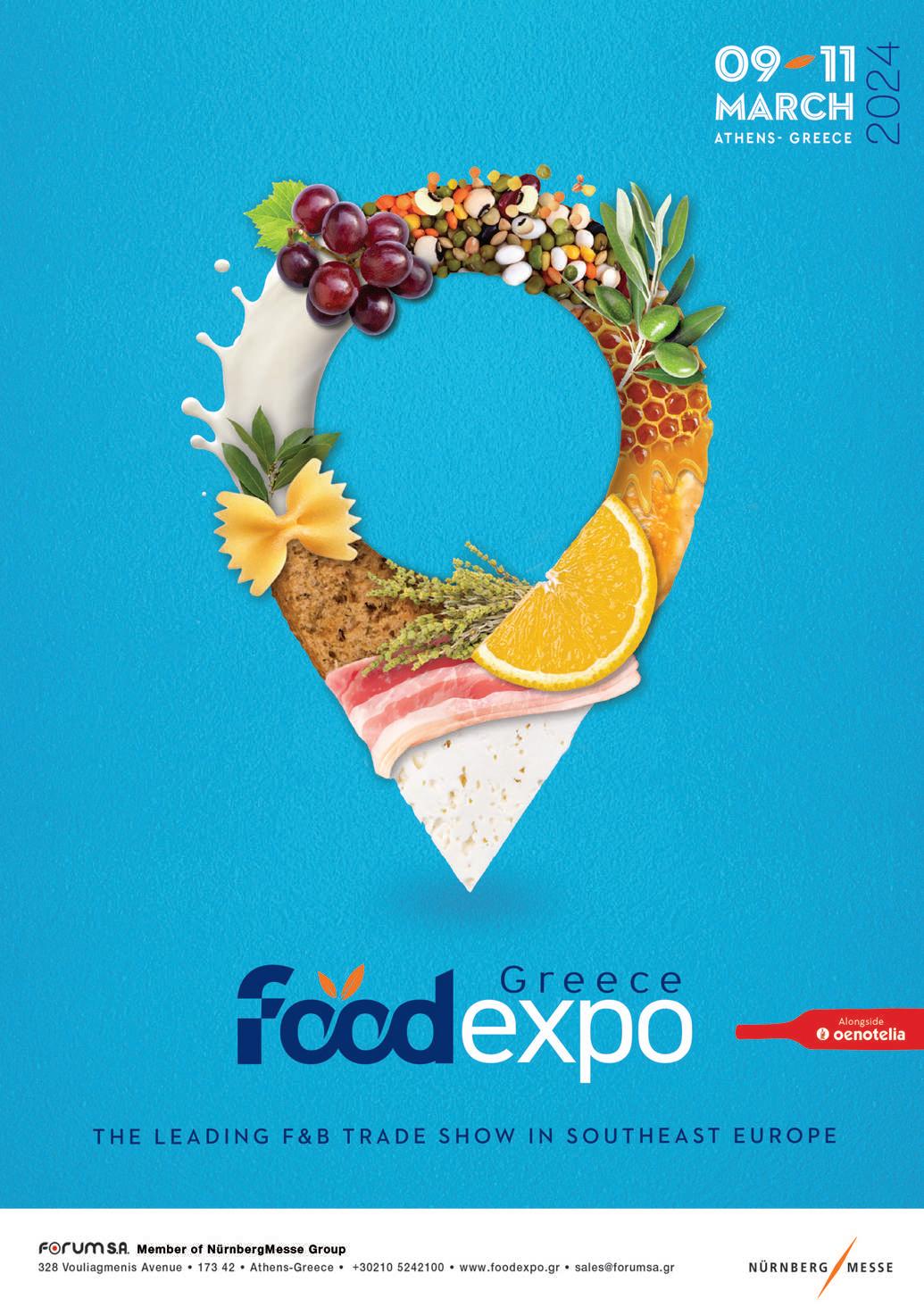

A selection of upcoming events, followed by an overview of Gulfood 2024 and a preview of FOOD EXPO Greece 2024.

09-11 March 2024

FOOD EXPO Greece

FOOD EXPO 2024 represents the dynamic food and beverage industry at an international level in the best possible way, presenting all the trends and innovations shaping the future of the F&B industry. 1,300 leaders of the Greek and global industry will showcase products at this event.

[click here] for weblink

19-23 February 2024

Gulfood

Attend Gulfood to establish close connections with leaders from the F&B industry, government associations and world-leading brands. Source new opportunities and prospects from more than 5,500 exhibitors from over 125 countries - the ideal place to meet and expand your global F&B network.

[click here] for weblink

IFE 2024

IFE, ba tive will have a to uncover industry wil

[click h

20-24 January

SIGEP: The Dolce World Expo

SIGEP is the world’s leading B2B dessert-and-coffee foodservice to discover the latest news, inno dessert-and-coffee sector: raw materials and equipment, furnishings, packaging a

[click here] for weblink

27 March 2024

, International Food & Drink Event, is ck to deliver high-quality and effece business connections. The event range of new features and exhibitors what the exciting food and drink l look like in 2024 and beyond.

here] for weblink

12-13 April 2024

The only event in the UK to connect with a large selection of franchise brands. Each year, thousands of entrepreneurs and business owners flock to the ExCeL London for unmissable seminars, panel debates, insights and information from big brands, over 250 exhibitors, networking and more.

[click here] for weblink

y 2024

B show dedicated to the e industry. This is the event ovations and trends in the s and ingredients, machinery and services.

Why not give your event exclusive coverage to thousands of readers and connections globally? Contact us: events@insidepublication.com

CEO & President of BOD FORUM SA Thanasis Panagoulias shares his insights.

FOOD EXPO 2024 represents the dynamic food and beverage industry at an international level in the best possible way, presenting all the trends and innovations shaping the future of the F&B industry. Thanasis Panagoulias

CEO & President of BOD FORUM SA, a Member of NürnbergMesse Group, previewed the event for Inside Food & Drink’s Jasmine Lodge.

Inside Food & Drink last spoke with you about the 2022 event. How has FOOD EXPO Greece evolved since then?

Since our last talk, FOOD EXPO has cultivated the credibility, loyalty, recognition and support of the global food and beverage sector by being the biggest one-stop shop for the industry in Southeast Europe. FOOD EXPO 2024, which will be held March 9 to 11, will stay true to the trade show’s goal and mis -

sion, and will present all the trends and innovations shaping the future of the Food & Beverage industry.

How many visitors and exhibitors are you expecting to attend?

The 2024 event will welcome a global lineup of 1,300 Greek and International exhibitors, all of whom will once again place their trust in the FOOD EXPO brand and will benefit from the valuable deals that the trade show offers to its participants. At this point, I would like to mention the fact that this year more than 280 exhibitors from 40 countries are expected to participate. Lastly, FOOD EXPO 2024 is expected to welcome more than 35,000 F&B professionals from all over the world.

What would you highlight about the show for visitors to this edition of FOOD EXPO Greece?

The trade show will provide buyers from all over the world with the perfect opportunity to discover what is new in the global food and beverage market, source around 50,000 products, build com mercial

CEO & President of BOD FORUM SA Thanasis Panagoulias shares his insights.

relationships with 1,300 Greek and international exhibitors – all market leaders – and learn how to stay ahead of competition. Industry experts and visionary leaders will meet buyers at the exhibitor’s booths to inform them about new ideas and products transforming the F&B industry.

In terms of your many exhibitors, what would you say are the advantages of attending the show?

FOOD EXPO is the place to raise brand awareness and showcase innovations, products and concepts to more than

9th – 11th March 2024, Metrop

35,000 global F&B professionals from the organised retail, the wholesale sector, the hospitality and catering industry and the food service sector.

The trade show will once again enable the exhibiting companies to establish new contacts, deepen existing partnerships with the Greek market, as well as expand into Europe and other markets around the globe. Over 4,000 food traders from 80 countries have already put the 2024 event on their agenda. At the same time, 900 key buyers will visit via the Hosted Buyers Programme and the event will facilitate 13,500 B2B meetings with exhibitors.

politan Expo, Greece www.foodexpo.gr

FOOD EXPO Greece runs alongside OENOTELIA 2024, the leading trade show for wine and spirits in Greece. What are the benefits to your visitors and exhibitors of running these two shows in parallel?

As part of FOOD EXPO, OENOTELIA offers a variety of important synergies, allowing exhibitors to present their products and get in touch with thousands of representatives from organised retail, wholesale and catering, as well as important international buyers. Nearly 190 of the industry’s best suppliers, wineries and distilleries will showcase their latest products and services to a stellar crowd of quality professionals from the food & beverage industry.

At the same time, visitors will obtain a complete, global picture of both the gastronomic and the wine wealth of Greece. Thus, in a single visit, they will have the opportunity to look for all the products in which they are interested in investing and to lay the foundations of new trade agreements with the exhibitors.

In conclusion, what is most exciting for you about FOOD EXPO Greece, on a personal level?

I am really proud of the fact that we have built over the past 10 years a trade show that is a significant meeting point for the global F&B community. This is an international event that inspires conversations and collaborations, with an impact on the industry’s growth. n

One of the main factors that have led to the success of FOOD EXPO, and to its truly international appeal, is the trade show’s Hosted Buyer Programme. Our team will select 900 key buyers, importers and distributors from strategic countries from five continents so that they can attend the show. With all, or part, of their travel and accommodation expenses paid for, qualified Hosted Buyers will enjoy exclusive benefits and will also have the chance to participate at prescheduled B2B meetings with exhibitors. If you want to join the Hosted Buyer Programme, fill in the form on the website.

https://foodexpo.gr/en/hosted-buyerprogram-2023/

Companies attend Gulfood to establish close connections with leaders from the F&B industry, government associations and world-leading brands. Here is the chance to source new opportunities and prospects from more than 5,500 exhibitors from over 125 countries – the ideal place to meet and expand a global F&B network.

Gulfood is the gold standard for the global F&B community, and the most trusted name as a source of lucrative deals, knowledge and networking. The event is the ultimate opportunity for retailers, food suppliers, distributors, wholesalers, chefs and thought leaders to discover the latest products, connect with industry players and explore the latest innovations shaping the future.

The 29th edition of Gulfood, taking place at the Dubai World Trade Centre from 19th to 23rd February 2024, will host over 5,500 exhibitors from more than 125 countries. The show will unveil new business opportunities and provide solutions to new and evolving global challenges.

Visitors will experience the global diversity within the F&B industry thanks to 127 country pavilions. 2024 represents the event’s biggest lineup of participating countries. These pavilions are part of the astounding one million square feet of show floor space across 24 massive halls filled with exhibitors, country pavilions and culinary experiences.

Within these 24 halls, visitors will have the chance to explore more than 100,000 new products and innovations from Gulfood’s vast exhibitor showcase across seven distinct sectors. Almost half of the exhibitors are attending the show for the first time, meaning that visitors will be offered a first look at these fresh and innovative products.

- 19th-23rd, February 2024 www.gulfood.com

The Gulfood show floor is segmented across seven food and beverage sectors. This organisation allows visitors to easily and quickly find the right products and suppliers.

• Beverage: Soft drinks, hot drinks, water and fresh beverages.

• Dairy: Milk, yogurts, butters and cheeses.

• Fats & oils: Nut and plant-based edible oils, animal fats, and ghee.

• Meat & poultry: Halal, grass and corn-fed, free-range, poultry, and organic meat.

• Power brands: One-stop shop for multiple product categories.

• Pulses & Grains: Grains, beans, rice, cereals, flour, oats, dry peas, pigeon peas and lentils.

• World Food: Country pavilions, niche and speciality products.

Supporting events at Gulfood include a programme of free summits, giving visitors the chance to engage in thoughtprovoking conversations with over 100 industry leaders, gaining valuable knowledge and perspectives.

Gulfood also offers masterclasses and chef talks. Visitors will be able to participate in interactive sessions, learning new techniques and culinary secrets from the best in the industry. This programme promises to be a spectacular culinary experience featuring the world’s largest line-up of renowned Michelin-starred chefs.

Throughout the event, visitors will also have extensive opportunities to network and attend meetings. Gulfood is an ideal opportunity to establish close connections with F&B industry leaders through prescheduled meetings arranged via the official event app and meetings programme. n

from crop to consumption

delice de france c.h. guenther & son soreen the bread factory cavan bakery diatosta & rialto milish bakery brook bakery

Delice de France has continued to thrive as the UK’s largest independent distributor of bakery goods. With a booming order book, the company is planning a significant investment in its facilities: increasing its vehicle fleet and nudging its way to becoming a producer of fantastic-tasting food. Andy Probert sat down with CEO Thierry Cacaly to discover more about the company, which is on the cusp of 40 years of trading and a £100 million turnover.

The UK public’s appetite for affordable luxuries supplied by Delice de France shows no signs of abating as the UK’s largest independent bakery distributor continues to grow.

“We have been in the right spot at the right time,” CEO Thierry Cacaly reflected. “Our business plans continue to revolve around thinking creatively, from increasing the product range to stocking our trucks better. All these activities have converged to result in a very positive business performance.”

One milestone of recent times has been the adoption of a new ERP system that has quickly become the company’s backbone. “We also launched a new e-shop, which helped us attract more orders and made it easier to connect with clients,”

Mr Cacaly added.

This shift to ordering online compared to traditional telesales amounted to a £60 difference per spend. “This opened our eyes,” Mr Cacaly said. “We intend to make it more engaging for clients, who are mostly

corporate and from the tech-savvy, younger generation. The digital revolution is on: more people are ordering online, and we intend to take full advantage. ”

£100 million milestone

Delice de France has also switched focus to four specific channels – retail convenience, hospitality, contract catering and wholesale/innovations - where its teams have a deeper understanding of each and can provide greater added-value services to the clients.

“While we are primarily a B2B business in the foodservice-convenience sector, we have never been into the larger retail sector,” Mr Cacaly said. “However, we are testing a range of self-branded Delice de France bake-at-home morning goods with Tesco Ireland, and it is evolving well. It is all about projecting the brand for the long term.

“That said, Delice de France celebrates its 40th anniversary in 2024. While 202 3 will see us top £80 million in turnover, we are intent on climbing that £100 million milestone in the next 5 years.

“Covid has exacerbated the entrepreneurial spirit and we have quickly grasped that opportunity. We did the right things at the right time, and quickly re-positioned the business and continued building momentum.

“We are now contemplating going into production of bakery products as evidenced by our project in Ireland. It will be a change, but will help cement our position as a market leader in the UK industry.”

Comes with added bite

Launched in a small coffee shop in West London by forward-looking French chef Phillippe Signolet, Delice de France became a national distributor of frozen bakery products.

By 1999, it was owned by global bakery player ARYZTA and swallowed up in the organisation’s corporate structure. However, in 2019 Delice De France became independent again following a management buyout led by Mr Cacaly.

By 2021, the bakery specialist, in adopting ARYZTA’s UK assets and customer base, had nearly 1,000 product

lines which it supplied to more than 9,000 clients in the UK. These included food service and retail convenience channels, such as coffee shops, restaurants, hotels, food courts, contract caterers and leisure.

Delice de France employs 300 people and has distribution hubs in London and the West Midlands for frozen food products. It also has five satellite units across the UK, enabling 10 million palletised units to be distributed annually.

The move to independence has enabled the company to embrace true innovation and quality across all product types, which

the UK market demands. All its products are bought from huge bakeries, and it is renowned for genuine products.

The company’s chef and marketing teams launched Baked by Delice, a brand enabling Delice to deliver freshly baked delicious products daily, wrapped or unwrapped and distributed within the M25 or as a frozen thaw and serve option for national distribution.

Other branded developments included Delice to Go, the company’s modular retail proposition covering all-day parts with classic viennoiserie, hot food-to-go, sweet and savoury snacks, and a range of deli sandwiches – prepacked and freshly made onsite.

It also provides beverage partners Seattle’s Best Coffee for a rich and smooth comprehensive coffee and hot beverage solution in convenience retail and petrol forecourts.

With Projuice, the company offers customers healthy shakes, smoothies and

frozen gelato. It also works with high-end partner Coup de Pates, providing an extensive range of semi-prepared, mouth-watering reception delights.

On the vegan front, alongside its vegan cakes and sweet treats, its award-winning vegan sausage roll remains top of the menu within both convenience retail and foodservice sectors. Delice de France has also launched a new chilled range of sandwich fillers, including cheese, ham and bacon.

“Another milestone has been shifting our vehicles from providing completely frozen products to a frozen and chilled products’ operation,” Mr Cacaly added. “This has been quite a revolution for us and helped to bring lovely creations to the trade.

“We have developed new technology with a route metrics system to offer the most efficient way to deliver to our customers and improve our carbon footprint.”

The company has been highly active in trade conferences in London and Birmingham, plus in focused shows on retail convenience and at universities. “It is essential to put the brand out there and continue the momentum by showing our innovation potential,” Mr Cacaly said. “We produced our first catalogue for summer, offering 50 new products, such as bread ranges, pastries and desserts.

“We are also launching a winter TOP UP with 40 new products. We essentially act as the gateway for our suppliers to thousands of clients nationwide.”

A well-known Korean concept called Paris Baguette, a French-style bakery, has opened in London and has developed a high-end patisserie line in partnership with Delice.

“It is pushing the quality up all the time, with the products being the best of the best and tasting beautiful,” Mr Cacaly said. “We see catering contractors going from strength to

strength, and we provide more business to hotels across the UK. We also support innovative artisan coffee shops.”

The primary challenge is keeping pace with business growth through product innovation and infrastructure investment. Delice will spend £4 million to make its London warehouse more efficient and sustainable, while £250,000 will be invested in upgrading its West Midlands facility.

According to Mr Cacaly, the company’s transport fleet could be expanded by another 30 vehicles when it achieves its £100 million target. It is also tackling its Scope one and two carbon emissions and engaging with its supply chain on Scope three.

“All these activities have been achieved by our amazing team,” he concluded. “I would like to say a massive ‘thank you’ for their wholehearted support.” n

C.H. Guenther & Son is a leading food manufacturer that has delivered highquality products and ‘just baked from scratch’ flavours for over 170 years. With manufacturing locations worldwide – including Europe’s most advanced bakery – it is making significant strides in sustainability through energy and waste reduction, and progressive farming practices. Andy Probert discovered more in discussion with Rosalinda Sanquiche, Global Senior Manager, Sustainability & Communications, and Jean-Charles Philippon, Managing Director, Europe.

IN1851, C.H. Guenther & Son (CHG) began life as a humble flour mill near Fredericksburg, Texas. Its entrepreneurial visionary of the same name switched operations to neighbouring San Antonio, and CHG has been a powerhouse of production ever since.

Now employing 4,100 people across 29 manufacturing facilities in the U.S., Canada, and Western Europe, the company is a leading supplier of value-added grain-based and frozen food products for food service clients and select consumer markets.

CHG’s current portfolio focuses on ten areas ranging from artisan bread, buns, and English muffins to baking, griddle, batter, and breading mixes, biscuits, doughs, gravies, and dips. Its much- loved

retail brands, such as Pioneer, White Wings, Sunbird, and Cuisine Adventures, have been present at family meals for generations.

While CHG which is owned by Pritzker Private Capital is deeply committed to advancing food quality across its diverse operations, its dedication to sustainability is deeply embedded within its DNA.

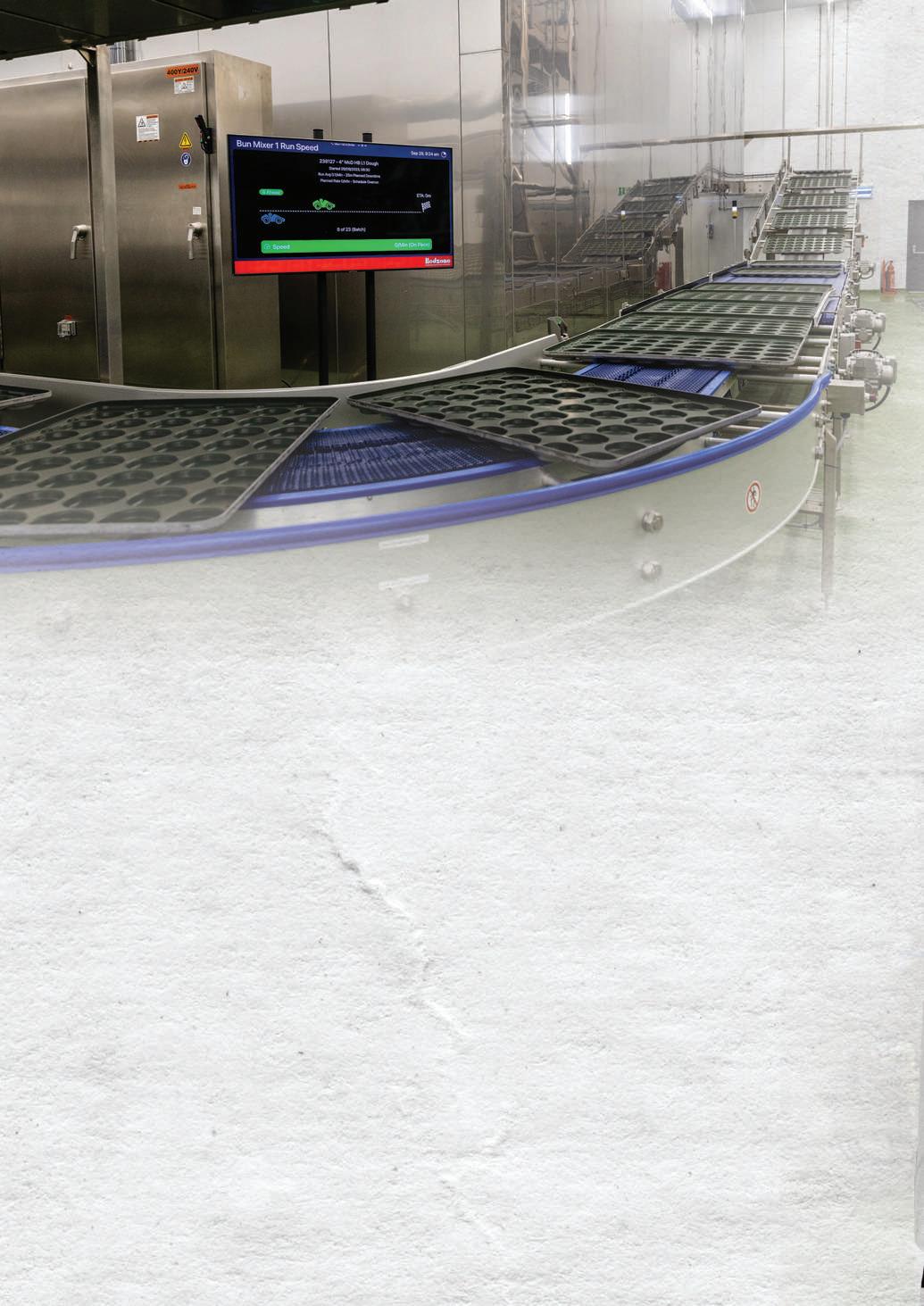

These principles are best demonstrated at its latest high-tech operation at Coventry, in the UK. The £38M facility, which employs 90 people, can create 72,000 buns an hour or 1.1 million buns a day - one of the fastest bun production lines in Europe. The 106,000 sqft plant, designed and

built from scratch, is C. H. Guenther Bakeries in Europe’s third UK site.. Significantly, the facility is fully supported by McDonald’s as it will create fresh, quality buns exclu sively for the fastfood giant’s restaurants.

Jean-Charles Philippon, CHG’s Managing Director, Europe, said the facility underscored the company’s longstanding commitment to McDonald’s, which it has been supplying with fresh, quality buns since 2005.

Sited ideally in the West Midlands between major UK cities, the facility has been praised by senior McDonald’s management to help better serve their customers and is an excellent example of the work it is achieving with CHG.

The site is designed to BREEAM ‘Excellent’ specification and is targeting an EPC ‘A’ rating. Supporting CHG’s environmental commitments to reduce electricity, natural gas, and water intensity, and a zero waste

to landfill target, the building has installed solar PV, electric vehicle charging infrastructure, and a water recycling system.

“CHG is committed to high quality products, while sustainability and flexibility are key considerations with this latest facility,” said Mr Philippon. “We believe the development will become a key asset in C.H. Guenther Bakeries’ European growth plan.

“One of our core values is to offer bespoke production that exceeds customers’ expectations. Our customers are considered valued partners as we often collaborate with them to ensure we’re fully invested in their specific operations. Ensuring we never compromise on quality means their end users get the best products.”

Rosalinda Sanquiche, Global Senior Manager, Sustainability & Communications said CHG, backed by its parent company, is continuing to make significant strides in

sustainability activities on all its sites. This is through energy and waste reduction, advanced farming practices, and increased use of sustainable and recyclable sources for its product ingredients and packaging.

The company produced its first environmental, social, and governance report in 2022 and highlighted the many initiatives it is achieving, which are being shared with stakeholders, suppliers, and customers.

“Sustainability has become a firm focus for us. We are one of the few bakers in the industry to tackle Scope 1 and 2 carbon emissions, and we are now looking at Scope 3,” said Ms Sanquiche. “We began this initiative with our German plant, and it is now being rolled out across the company’s footprint.”

The report highlights a variety of sustainability measures undertaken. For

e ach metric tonne of product CHG creates, it is working to reduce the usage of electricity and natural gas, and waste generated to help lower its carbon footprint.

CHG supports farming practices and water efficient technologies that protect watersheds in communities at drought risk. Its facilities also meet all environmental compliance requirements, ensuring water released into community systems is contaminant free.

Most of the organic waste CHG plants produce is diverted from landfill and converted to animal feed. CHG also diverts waste through upcycling, turning organic materials into new product. Working towards zero waste to landfill has already been achieved at eight facilities.

A greater focus has also been placed on products made from sustainable ingredients, according to Ms Sanquiche:

“CHG requires all vendors to adhere to a Supplier Code of Conduct that tracks where ingredients are grown and harvested.”

CHG is also working closely with partners to develop packaging that is 100% reusable, recyclable, or industrially compostable by 2025 for retail markets.

“Our effort remains to reduce electricity, natural gas, and water intensity from

a 2022 baseline with SBTi-aligned goals and to target zero waste to landfill,” she explained. The corporate headquarters in San Antonio, Texas, is a LEED Silver building, using solar panels and an innovative HVAC system.

CHG’s R&D and culinary team is innovating with clients to provide options for healthy offerings: high protein, low sodium, whole grains, clean label, and more. It is also seeking out sustainably sourced or harvested ingredients, including RSPO certified palm oil.

“Having customers that share our beliefs and values, and backed by a parent company that is prepared to invest heavily, demonstrates how serious we

are in driving our sustainability goals further,” Mr Philippon agreed.

The company is also fully aligned with helping farmers look at new ways of innovating in growing wheat, maximizing yield while being mindful of best agricultural practices.

Both interviewees paid tribute to CHG’s global workforce in their commitment to maintaining best practices in performance, many geared towards the company’s sustainable goals.

The company is bestowed with many experienced workers who have served more than five, ten, and 20 years. “They are at the heart of what we do; they bring forward ideas for change and how we can evolve into a better company,” said Ms Sanquiche. “We ensure that the performance of the company and our sustainable goals are always interrelated.”

Additionally, CHG’s efforts to increase diversity and educate its workforce about diversity, equity, and inclusion (DEI) culminated in the company being named by Newsweek as one of America’s Greatest Workplaces for Diversity for 2023. CHG began its DEI journey in 2021 with a threeyear strategy to align diversity goals with its corporate business plan. The organization has spent the last two years implementing various programs and initiatives to help create a more diverse and inclusive corporate culture.

In conclusion, Mr Philippon said: “We never lose sight of what drives the consumer and how we work collaboratively with our partners to deliver on those trends and perceptions. CHG will never compromise on quality and will always strive for excellence. Those principles will always underpin our approach and growth.” n

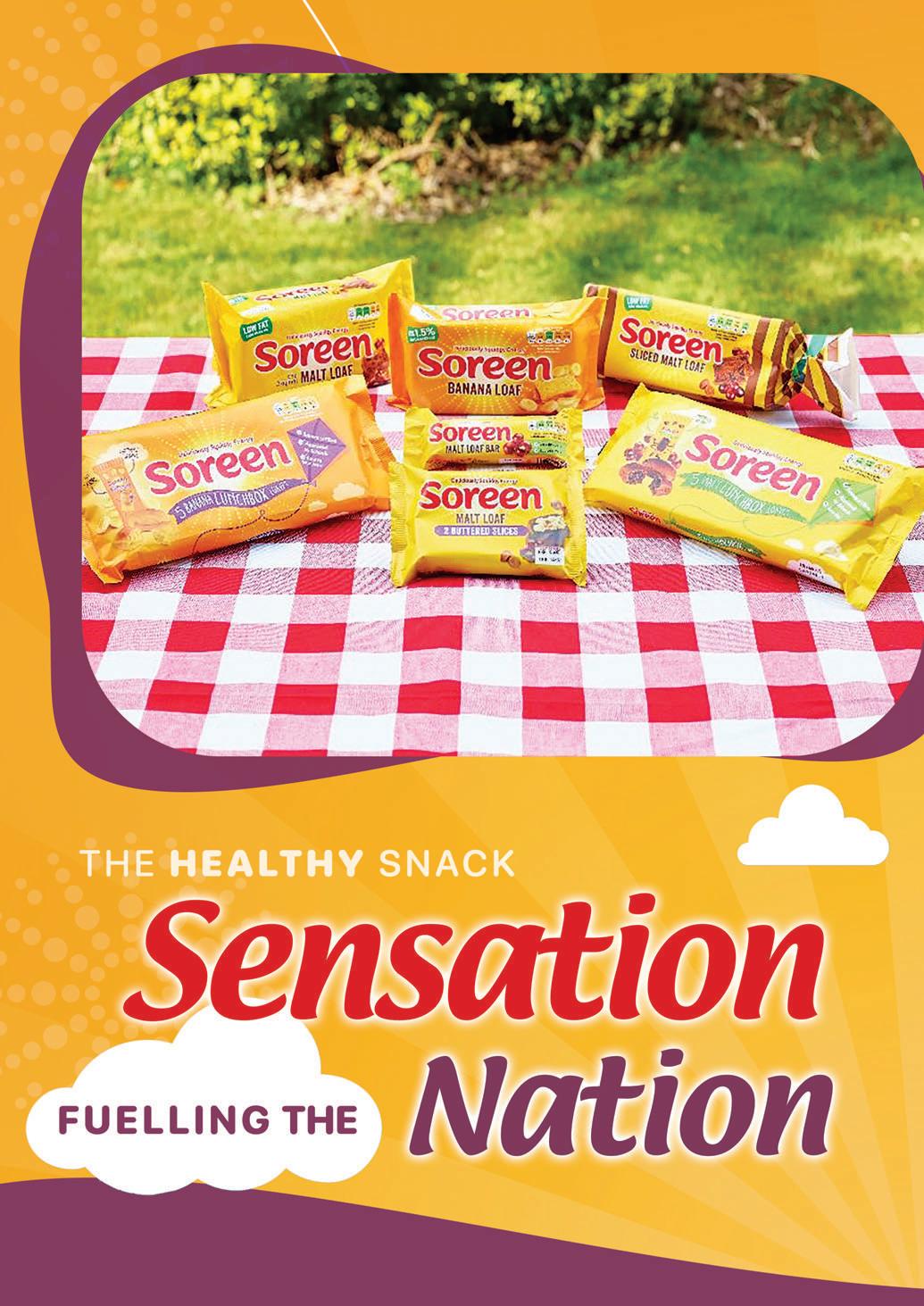

Originally developed as a sweet treat, Soreen’s loaves have been a pinnacle part of Mancunian diets since the company was first established back in 1938. Now, off the back of the nationwide success of its Lunchbox Loaves, the company is launching another brand-new product. Managing Director Mark Simester explained more to Imogen Ward.

Th e heart-warmingly scrumptious taste of Soreen is well-known across the UK.

From its famous malt flavouring to its Lunchbox Loaves, Soreen is adept at making snacking solutions that satisfy

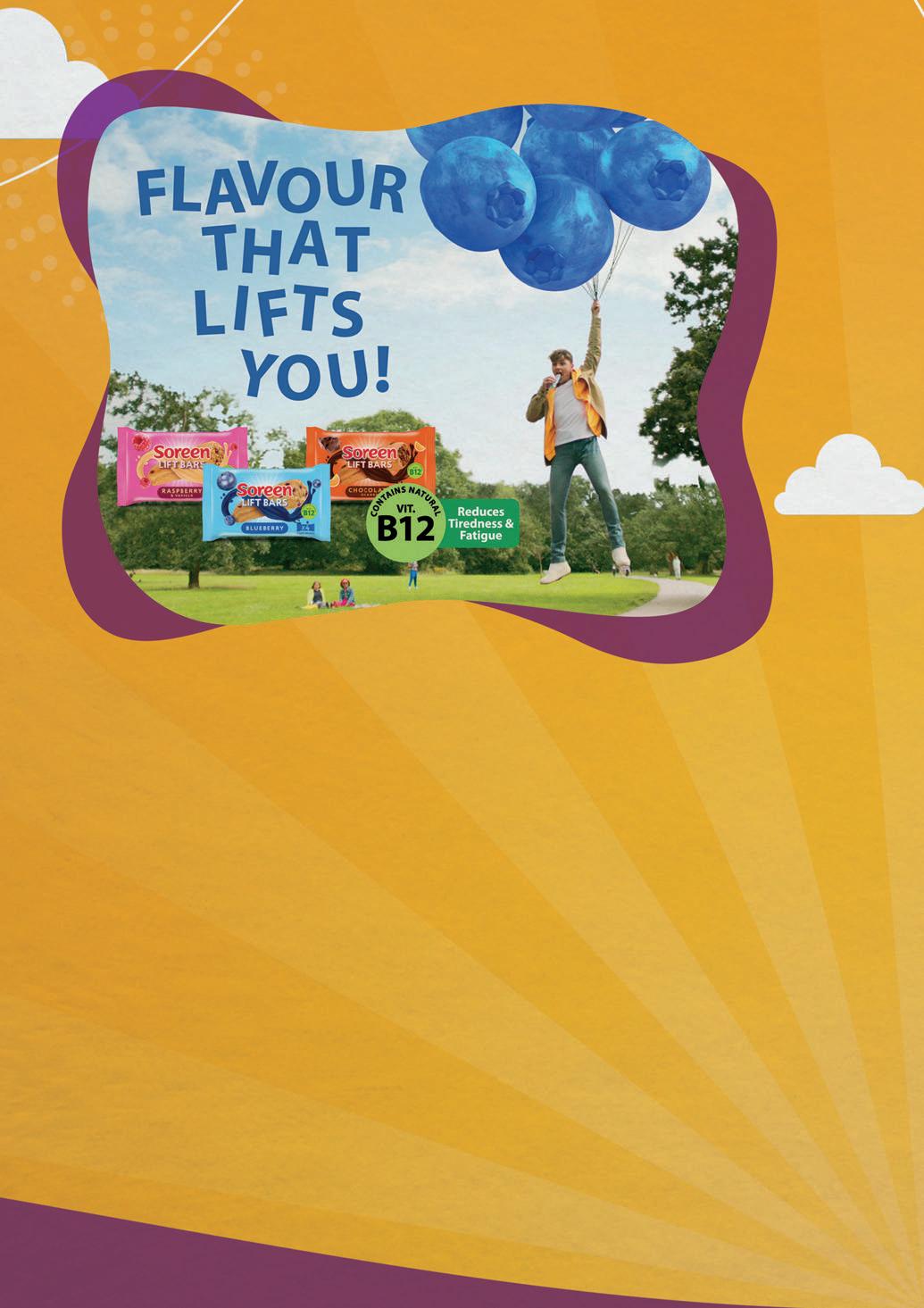

“Soreen is really strong with families with primary school-aged kids,” said Managing Director Mark Simester. “but, as those kids grow into teens and then young adults, it’s natural for them to progress on from the snacks they ate growing up – especially when they feel these snacks are targeted towards a younger audience. That’s why we designed the new Soreen Lift bars.”

Soreen was a staple for many growing up, with the iconic malt flavour still its best-seller.

According to Mr Simester, the reason for this is all in the ingredients: “Malt has so much power. It’s almost a superfood because it contains a whole host of health-boosting B vitamins. Not only do you get this wonderful malty-sweet flavour, but you get the health benefits as well.”

Yet, as coffee shop openings peaked around 2010 and eating out became more prevalent, Soreen realised that in-home sweet treats were becoming less popular. In 2012, the company released a product that would completely change its presence in the market.

From the get-go, Soreen’s Lunchbox Loaves were a hit. Designed to meet the nutritional needs of its infant or primary schoolchild target audience, whilst being the perfect portion for a lunchbox-sized snack, this product was enjoyed by both children and adults alike.

“ The Lunchbox Loaves were a huge success,” Mr Simester said. “In its early years, sales grew by 50 per cent every year, and its distribution grew significantly. It quickly became apparent that they were more than just a lunchbox item for young kids. Everybody was eating

them, even households without children. We’d launched the products at a convenient size for lunchboxes, but we didn’t realise how convenient this health snack would be for all ages.”

Initially introduced to the market with a malt and banana flavour, the Lunchbox Loaves range quickly grew with the addition of apple in 2017 and strawberry in 2018. Soreen also entered the seasonal market in 2015 with its first Halloween offerings, Toffee Apple and Chocolate and Orange Lunchbox Loaves.

“Entering the seasonal market was a successful growth strategy,” Mr Simester explained. “With our initial target audience being school children, we know that they get very excited over the key seasons, so we started with Halloween

and released a number of Lunchbox flavours for that occasion, including Toffee Apple and, more recently, a Scary Cherry Jelly flavour. We then released gingerbread along with raspberry and white chocolate flavours for Christmas. Our number one best-selling seasonal product, however, has been our Easter limited edition lemon drizzle.

“Our presence in the seasonal market really highlights our versatility, but also shows that Soreen is a brand people can have fun with. And our consumers really look forward to finding out what new flavours we have planned.”

Each malt Lunchbox Loaf is individually wrapped, ready to eat and boasts a nutritional value with less than 100 calories, 0.5 g of fat and 5.7g of sugar. For consumers, these Lunchbox Loaves were ticking all the right nutrition boxes and

l ed to a complete overhaul of Soreen’s marketing strategies, welcoming in the new era of Soreen snacking success.

In 2016, following the huge success of Lunchbox Loaves, Soreen made the strategic decision to focus its marketing message solely on the nutritional benefits of the products, whilst also entering the snacking sector.

“At the time, our marketing messaging was really split,” Mr Simester said. “We were marketing Soreen as both a nutritional snack and a treat food. Although Soreen has the benefit of being a healthy snack that is sweet and tasty, we realised that we needed to focus on one market

position. Our products are low in fat, and Lunchbox Loaves have 50 per cent less sugar than alternative cake bars on the market. Thanks to our nutritional values, all Soreen products are also HFSS compliant (not high in fat, salt, or sugar).

“Being HFSS complaint was a pivotal moment for our business, it highlighted that we have been using the right recipe for 85 years: one that is healthy before anyone really knew about it.”

Over the years, Soreen has worked hard to promote healthy eating and encourages its consumers to have more active lifestyles. Thanks to its commitment to nutrition, the company has actively removed 78 tonnes of sugar from the nation’s diet between 2020 and 2023.

“To promote Soreen’s positive nutrition values, we have sponsored a lot of sporting events,” Mr Simester said. “We were the official snack of the Tour de Yorkshire and Tour of Britain. We even sponsored Olympic gold medal cyclist Laura Kenny.”

Alongside its sporting sponsorships, Soreen also has a strategy to support community-based initiatives.

“We want to have a wider and more positive impact on the country, the nation and the planet,” Mr Simester said. “We have partnered with a foodbank called the Bread and Butter Thing, where we donate a lot of our products. Our staff regularly volunteer at these food banks as well. To help ensure kids get access to the right nutrition in school holidays, we

also provide hundreds of thousands of free snacks for kids’ summer sports and activity clubs across the UK.”

Raising sales with Lift

Keen to become a part of everyone’s snacking routine, Soreen has just launched a new product range, targeted towards teenagers and young adults.

“Soreen Lift comes in three flavours and is high in vitamin B12 – providing essential anti-fatigue benefits perfect for a target audience who are very active,”

Mr Simester explained. “These bars are available now from Asda, Morrisons, Sainsbury’s and Co-op, along with Tesco from September 2023.”

With the launch of this new product range comes new opportunities for

Soreen. For the first time, the company has produced a marketing campaign for TikTok and created promotional events for Freshers’ Week. As part of the company’s largest marketing spend to-date, this campaign is set break records.

Like all of its products, Soreen Lift comes in sustainable packaging. The company has steadily removed unnecessary packaging from its products and continues to work in collaboration with suppliers to remain at the forefront of the latest innovations.

Playing its part in the UK Plastics Pact, Soreen has pledged to use 100% recycled packaging by 2025. The company is also monitoring its energy usage and carbon emissions output to be more environmentally conscious.

Over the years, Soreen has been on an impressive journey, one that is filled with progression, excitement and success. Since 2014, the company has more than doubled its sales and now makes a whopping four million products every week. Going forward, it would love to continue on this path, and further its presence to really make a difference to making the UK diet healthier.

“ Soreen would love to be recognised for playing a really positive role in helping the UK snack healthier,” Mr Simester concluded. “We’re going to continue help educate about good nutrition, and we hope t hat in doing so, we can raise awareness with consumers, retailers and the media.

Despite our success, we are a small-sized business run by 160 amazing colleagues, and we are proud of everything we have achieved so far.” n

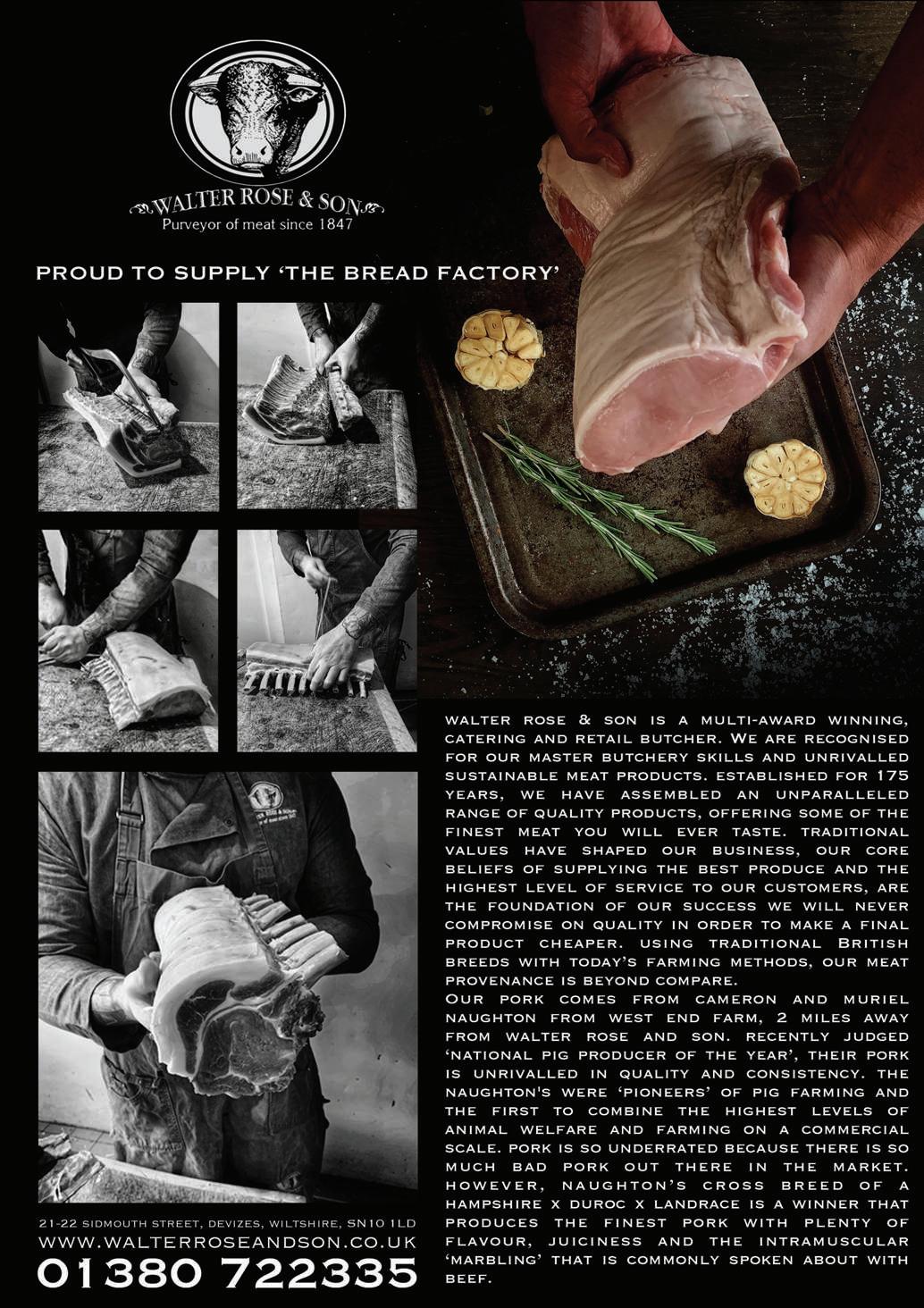

Nestled in the heart of London, The Bread Factory has been setting the standard for artisanal baking for three decades. And now, as the company celebrates its 30th anniversary, Tara Griffin, the Bread Factory’s dynamic Head of Food Service, took Richard Hagan behind the oven doors to share the secrets of the Bread Factory’s success, explaining how traditional breadmaking methods – preservative- and additive-free - never go out of fashion.

Established 30 years ago as an artisanal bakery, The Bread Factory has become synonymous with artisanal breadmaking. “Right up until today, our focus remains on using traditional breadmaking methods and ensuring that our products are completely natural,” Tara Griffin, Head of Food Service, explained.

A diverse customer base: Originally servicing 5-star hotels and Michelin restaurants, The Bread Factory has since broadened its reach, catering t o national wholesalers, independent cafes, delis, restaurants, casual dining chains, contract caterers and more. This expansive

customer base, demanding about 1,000 direct deliveries from The Bread Factory facilities every single day, showcases the scale of the company’s operations.

“The needs of those customers vary significantly,” said Ms Griffin. “Being able to cater to these different segments makes us fairly unique in the market. Our clients have come to understand the quality that we can offer, and we’re committed to continuing all of those relationships by

The most exciting part of working at The Bread Factory is working with, talking about and being involved with food all the time

ensuring that we maintain our quality and flexibility, even as we grow bigger.”

The other significant arm of The Bread Factory’s business is the grocery sector. The company recognised the growing demand for natural products in supermarkets, where preservatives are often used to extend shelf life.

“We're continuing to strengthen our presence in the grocery market,” Ms Griffin said. “We’re quite unique in the grocery bread market because our products are natural, which is more unusual for that

sector. It’s also a great opportunity for us because we want our products to be available to everyone, not just on the tables of fancy restaurants.”

To keep the nation’s tables stocked with delicious artisanal bread, The Bread Factory owns five production sites around the UK. Its largest production site, occupying 100,000 sqft, is located in Hendon, London, and is responsible for producing sourdoughs, pastries and

cakes. Next is its semi-automated bakery in St Albans: that produces mainly burger buns and bread rolls, with some being produced fresh and some frozen.

Two more sites - in Manchester and Bath - operate regional wholesale offerings. And finally, The Bread Factory’s newest facility is located in Milton Keynes. This new, highly automated facility spans 60,000 sqft and has additional room for future expansion. Its primary role at present is making burger buns.

“This site has a huge amount of potential for us,” Ms Griffin said, “and adds more than 50 per cent capacity to our overall capabilities.”

Across all five sites, The Bread Factory employs approximately 1,000 staff members ranging from skilled bakers to sales staff, new product development and operations teams.

Traditional baking at scale

Despite its vast growth in the last three decades, The Bread Factory has not wavered from its core values, as Ms Griffin explained: “We don’t do temporary trends, and whilst we’re unlikely to be offering the next rainbow bagel or the next cruffin, we do forward-thinking tradition very well, and that never goes out of fashion. That’s especially true now, with consumers being more knowledgeable than ever before, valuing the quality and provenance of ingredients, and the story behind the food that they buy.”

The company’s sales figures confirm this. Following some challenges during Covid, The Bread Factory’s food service business in particular has grown 20% year-on-year. On the whole, its most popular products continue to be burger

buns, pastries and sourdough: “the classics,” as Ms Griffin noted.

Each day, The Bread Factory’s substantial scale is brought to bear as its facilities produce 200,000 units per day across hundreds of SKUs for its customers all over Britain. This scale – plus the company’s flexibility - is a big part of what sets the company apart from competitors.

“Our ability to produce artisanal recipes at scale is what makes us special,” said Ms Griffin: “we have huge agility as a business across our sites, both in size and ability. We happily occupy the middle ground between very large but inflexible producers making millions of products, and small producers who are doing amazing things, but sometimes lack the infrastructure that we can offer.”

Sustainability and the planet’s wellbeing are both key concerns at The Bread Factory. This has led to the installation of solar panels on its larger facilitie, as well as various other interventions, such as its fleet of electric delivery vehicles and trials for using reusable crates instead of cardboard. Notably, the Bread Factory has also embarked on an exciting sustainability project with Wildfarmed, a regenerative flour co-operative carrying out sustainable farming in the UK.

“With growth and size comes a responsibility that we must take seriously,” Ms Griffin said. “We are in a position now where we are big enough to make a real impact to farming methods, and this is

really important to us. By using grain that’s grown in the right way, we hope to make a significant difference to the way in which our farmland is treated as well as how our crops are grown, and the soil rotated.

“Making a difference is so important to us, so our work with Wildfarmed is really exciting for The Bread Factory. And though we’ve already scored a lot of good wins with our sustainability programmes, we firmly believe that we

should never rest on our laurels. You’ve got to always try to innovate and move forward.”

Concluding, Ms Griffin highlighted both her own and her colleagues’ passion for the business: “The most exciting part of working at The Bread Factory is working with, talking about and being involved with food all the time. We’ve got a team of people who are trying to do something really transformational, and that’s especially exciting to be a part of.” n

Cavan Bakery has been making authentic handmade bakery goods since it was first established in 1929. From perfectly flaky pastries to wonderfully crusty loaves, Cavan Bakery is a doyen of dough. CEO Jeff Greenall laid out the bakery’s journey, in an exclusive interview with Hannah Barnett and Imogen Ward.

Family-built and organically grown, Cavan Bakery has maintained a history of success over nearly a century.

According to CEO Jeff Greenall, this can be attributed to a very important set of principles: “From the very beginning, Founder David Cavan embraced innovation, craftsmanship and quality. Those principles remain a crucial part of the business today, and they have been incredibly successful for us. Last year, we managed to surpass £5 million in turnover.”

Established in 1929, Cavan Bakery was brought to life by the Cavan family whose passion for pastries res onated throughout every element of the business. From its first expansion in the 1950s to its leap into wholesale at the turn of the century, the bakery has always strived to create an enjoyable and memorable experience for everyone involved.

“In 2012, we moved the bakery to a new location,” Mr Greenall said. “At the time, we had six shops, and 30 per cent of the business was dedicated to wholesale. When the pandemic hit, we were really beginning to focus more on retail and that led to the introduction of our sourdoughs and more up-market products.

“We had to reassess our business strategy: most of our wholesale customers were in the hospitality sector, and with the whole industry shutting down overnight, we lost a big chunk of our business. That’s when we really refocused our efforts on expanding our retail portfolio.”

The company has invested in further shops, taking its total to 13. After coming to the conclusion that its site was too small to accommodate this expansion, the company made the courageous decision to relocate to a new facility in 2022.

“We moved into a 16,000 square foot purpose-built facility last November,” said Mr Greenall, “and that has really opened the door for future growth. But it wouldn’t have been possible without significant investment from Lloyds Bank.”

When the company decided it was ready to relocate, there were many factors to take into account, number one being the cost.

“The move cost us somewhere in the region of £750,000,” Mr Greenall said. “On top of that there were a lot of other smaller things to consider, including the acquisition of new machinery. Our relationship with Lloyds was purely transactional until 2021 when I approached them about a loan for the factory move. They allowed us to modernise our facilities, take our wholesale sector into new markets and were incredibly supportive throughout our expansion. All that was really thanks to the bank’s Relationship Manager, Victoria Vawdrey, who has been really helpful.”

The move has also enabled Cavan Bakery to take a more hands-on approach when it comes to sustainability. The company now uses an electric delivery van and intends to purchase more in the near future. The bakery also features an eco-oven that is designed to retain heat and reduce the

need for firing up. Waste management is an important factor, and the company has been using recycled and recyclable paper and cardboard packaging where possible for many years.

Despite expanding the retail side of the business, wholesale remained a vital component. Once hospitality reopened its doors, the bakery set its sights on rebuilding its presence within the sector.

“Our wholesale trading took a huge hit from Covid, and once we were on the other side, we decided we wanted to reinvigorate that side of the business. However; we really wanted to go in with a different approach and change the way we interacted with that market,” Mr Greenall said. “Before the pandemic, we would go after anybody that

wanted bread; now, we feel our relationship with the client is much more important.

“If a client’s only priority is price, then that isn’t the kind of partnership we want to go into. They have got to value quality as much as we do. They need to understand our process and the time and effort that goes into that. Not just that though: we want to ensure that our clients feel they can come to us when they want a new product. We can work together to create something great.”

Keen to stick by its roots, Cavan Bakery incorporates many traditional methods into its production process. With a commitment to authentic, great-tasting goods,

The creations behind Cavan:

Currently making 15 different types of cakes each week, and around 6,000 cakes, 5,000 pastries and 10,000 loaves per day, Cavan Bakery expects these numbers to double in the future thanks to the capacity of its new state-of-the-art facility.

the business has developed a process that mixes passion, skill and time to make the perfect products.

“Much of what we do is handmade,”

Mr Greenall explained. “Making sourdough bread for instance: that is a four-step process which occurs over the space of 48 hours – sometimes even longer. All the pastry for our morning goods is also laminated, rolled out and cut by hand.

“Of course, we incorporate technology into that as well. We have mixing machines

and ovens and also utilise new technology that ensures the accurate measurement of ingredients, but those technologies still remain a smaller element of the business. If we were to automate everything, we would lose the essence of what we have and who we are. That’s why we are determined to remain an artisanal bakery.”