A fresh batch

HOBBS HOUSE BAKERY

Pioneering bread baking since 1920

WYE VALLEY BREWERY

UK's leading advocates of sustainable brewing

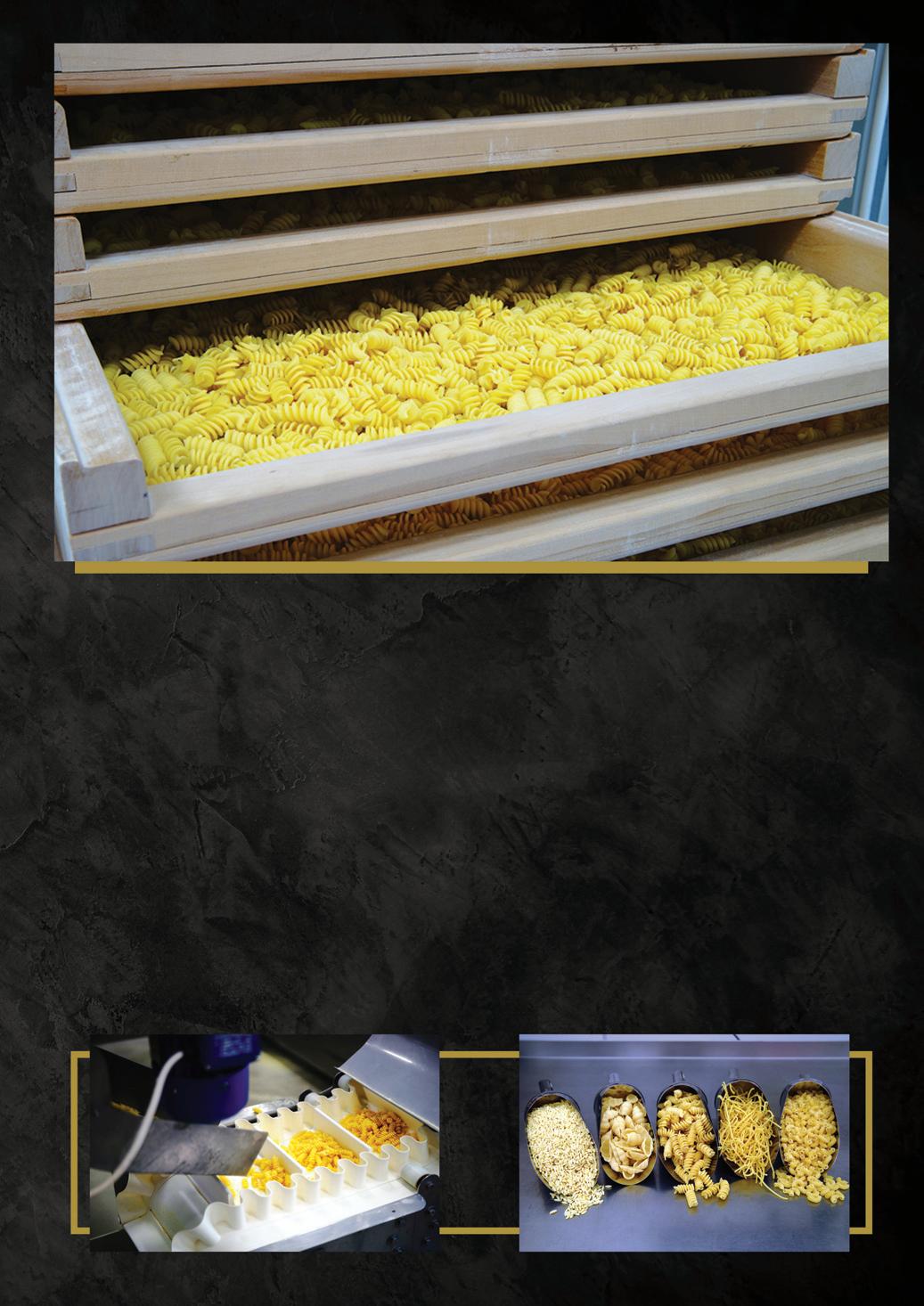

PRÉ PAIN

Supplying Europe with bake-off lines

White Managing Director

White Managing Director

A fresh batch

HOBBS HOUSE BAKERY

Pioneering bread baking since 1920

WYE VALLEY BREWERY

UK's leading advocates of sustainable brewing

PRÉ PAIN

Supplying Europe with bake-off lines

White Managing Director

White Managing Director

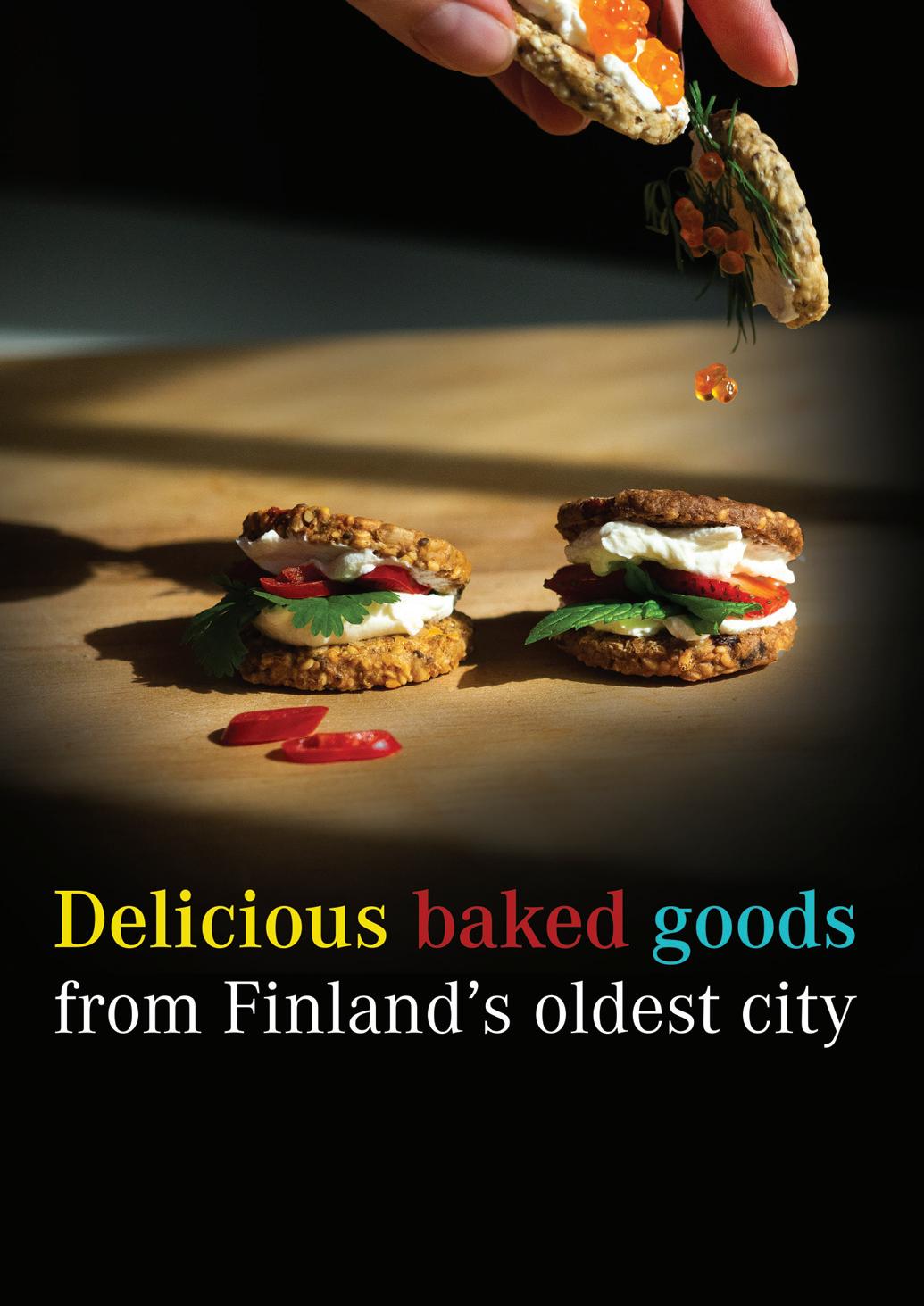

with any meal and with a wide variety of toppings, fillings and dips to accompany it.

Sadly, painfully, I had to cut down on all these treats to help lose a few stubborn kilos! Therefore, reading some of the superb and delicious – looking bakery articles in this edition has been a challenge. After having to turn down pancakes, cakes, pastries, doughnuts and the like for two months, even the photographs started to look appetising.

You will be pleased to hear that I have not, as yet, resorted to feasting daily on these mouth-watering images. I am, for the moment, happy to merely read about them within this tantalisingly tasty treat of a publication.

Welcome, dear reader, to your latest edition of Inside Food and Drink. This is easily our most popular publication in the office, not because it is a better read than the others, or working on it is more enjoyable than our other titles: the real reason is that we enjoy the treats some of you send in for us to review.

From tasty nibbles to the latest alcoholic beverage releases, there is always lip-smacking expectation amongst our employees when clamouring for a look into the latest box to arrive. Indeed, it is such a common occurrence, that I am half tempted to make a big deal about the delivery of printer paper, just to see the look of disappointment on their excited little faces when the box is opened!

However, tasty treats have been off the menu for many of us in the office. Annually, after overindulging during Christmas, we

have a weight-loss competition at work with a prize (no, not chocolate cake) for the person losing the highest percentage of body weight over an agreed period.

This contest has been tough, especially as many staff have birthdays in January or February, and it is traditional here to bring in cakes, doughnuts or other similar treats on your birthday. Adding to the temptation, we also celebrate Shrove Tuesday in the office with hot pancakes at break, sup plemented with deliciously sweet and calorific fillings!

Having been a runner up in previous years, I am proud to announce that I won this year’s contest (takes a bow). In order to win, I not only had to spend more time up the gym but had to limit my diet as I enjoy my food and a good glass of red wine. Another guilty pleasure, and a key focus within this edition, is bread. I love all types of bread

I have a small confession to make, before you inundate me with the rapturous applause and praise which I clearly deserve. On the weigh-in day last week, when I was crowned the weight loss champion, I celebrated with wine and bread and cheese and some more wine and maybe some chocolate…I can’t be sure as it was all an exciting sugary haze.

So, whatever your guilty gastronomic pleasures or dietary preferences, I am sure you can still appreciate the skills, advancements, research, developments, innovations, products and services found within this edition. I loosen my belt to you all and your companies.

I have enjoyed reading all the wonderful articles, news, advertisements, events and more that this edition contains. It has been a tough journey and a difficult read whilst I diet, but a no less enjoyable experience. Your good health. n

Upcoming events in the industry

Industry professionals from viticulture, production, trade and gastronomy, and the spirits segment meet for three days of concentrated business and a highly educational ancillary programme. Join international market leaders, importers and exporters, commercial agen cies, select vintners and the growing regions from the big wine nations. www.prowein.com

For more than 40 years, IFE, International Food & Drink Event, has sat at the heart of the food and drink community, welcoming 25,000 retailers, wholesalers and foodservice professionals to taste, test and source products from a global list of suppliers. www.ife.co.uk

SAGALEXPO

SAGALEXPO - Flavours of Portugal is a key event for Portuguese companies to strengthen the export side of their brands and products. SAGALEXPO has over 300 national companies and 1,000 international buyers from more than 80 countries. Visitors will see the best Portuguese products. www.sagalexpo.pt

The LCF was born out of love for the UK coffee scene. This year 30,000 creative urbanites and industry professionals are expected to attend the festival at the Truman Brewery, in Brick Lane, London. So, what should you expect from the event? All the tastings your heart could desire? Demonstrations from world-class baristas and interactive workshops? Live music, DJs, art exhibitions and coffee-based cocktails? All of this can be found at the London Coffee Festival. https://www.londoncoffeefestival.com/

interpack is a global trendsetter for the future themes of the food industry. From sustainability to digitalisation: what will be reality in the future is presented at interpack. Hosted at the Messe Düsseldorf, the focus of the show is on packaging materials, packaging machines and related process technology for the food, beverage, confectionery, bakery, pharmaceutical, cosmetics, non-food and industrial goods sectors.

www.interpack.com

Food ingredients North America is the largest ingredient event in the US focused on food, beverage and supplement innovation. Join 16,000 professionals from the health and nutrition industry. Learn about new trends from over 1,000 exhibitors and well-curated educational con tent and conference programming. www.figlobal.com/northamerica/en/home.html

Reporting on the latest developments from the South African food and drink sector

Mission Produce has partnered with ZZ2, Criterion Africa Partners, and Core Fruit with plans to develop over 1,000 hectares of avocados in South Africa for global distribution.

Mission Produce, a world leader in sourcing, producing, and distributing fresh Hass avocados (with additional offerings in mangos and blueberries), has announced a joint venture with ZZ2 Boerdery (one of South Africa’s largest farming companies) and Criterion Africa Partners (CAP), a private equity firm developing assets within the forestry value chain in Sub-Saharan Africa. The joint venture company, Selokwe Agri, is expected to expand to over 1,000 hectares of avocado orchards in the premium growing region of Limpopo, South Africa.

“As global demand for avocados continues to grow, establishing additional sources of owned production through vertical integration is a key element of our sourcing strategy to promote increased supply reliability,” said Steve Barnard, Founder and Chief Executive Officer, Mission Produce. “South Africa is the second largest exporter of avocados to the EU and the UK during the summer season. So, our new investment in the region is expected to support our expansion into export markets, especially in conjunction with the anticipated March opening of our newest forward distribution centre in the UK.”

Partnering with ZZ2 and CAP to vertically integrate the company's operations in South Africa leverages the expertise of each shareholder to maximise the production and distribution potential of the region.

CAP established Selokwe as part of its higher and better use (HBU) investment strategy, which creates value through

the improved utilisation of land, water and labour resources in South Africa and increases employment opportunities in its regional communities. In addition, ZZ2 brings its expertise in avocado cultivation and environmentally conscious farming to maintain compliance with CAP’s environmental, social and governance (ESG) standards, including the maintenance of the Global G.A.P. and Sustainability Initiative of South Africa (SIZA) certifications.

“We look forward to deepening our relationships with some of the most wellestablished, reputable partners in South Africa, the world’s eighth largest exporter of avocados,” said Keith Barnard, Senior Vice President of Sourcing, Mission Produce. “The avocado seasonality of South Africa extends our supply availability by approximately two-to-three months before Peru’s peak season, and it is expected to bring a long-term benefit in our ability to offer a year-round supply of ripe Hass avocados.”

ZZ2 has developed more than 250 hectares of avocados at Selokwe, which are expected to be harvested for the first time in the 2023 season. Mission has engaged Core Fruit to manage its logistics and transportation to the European market, where the majority of volume from South Africa is planned for distribution.

“The opportunity to grow the avocado market in Europe is significant: in 2022, the EU’s per capita consumption was 3.3 pounds, compared to the US at 8.5 pounds,” added Steve Barnard. “The addition of a high-quality source to our existing network strengthens Mission Produce’s position as a global market leader and enhances our ability to drive avocado market growth in the EU.”

Mission Produce is vertically integrated in Peru, Colombia, Guatemala, and South Africa, and manages over 5,500 hectares of avocados. n

Reporting on the latest developments from the Austrian food and drink sector

ACI Group, a leading distributor working with some of the largest global food, pharma, industrial and road construction brands, has entered into a new partnership with international market leader Soy Austria to distribute its soy-based solutions in the UK and Ireland.

Founded in Austria in 1752 as a mill, Soy Austria has been producing soy-based ingredients since 1989 (when its production facility was inaugurated). In 2003, the company closed production on grain processing to fully focus on soy for both feed and food production.

Operating from its headquarters in Prinzersdorf, Soy Austria turned its business efforts to solely manufacturing food ingredients in 2016, having perfected the processing of soy by using every part of the bean to create a multifunctional portfolio. The company also has an office in Vienna. Its minimal processing facility enables the soybean to be treated via a mechanical and thermal process avoiding the use of any chemical solvents or auxiliaries, to retain a clean-label and high nutritional profile.

In 2021, the company had a brand relaunch, changing its name from Soja Austria to Soy Austria sharpen its international company profile as a globally-acting food ingredient house. This shift of focus is reflected in the ACI deal.

The new, exclusive contract will enable the distributor to meet the growing demands of the food industry with sustainable, non-GMO and natural soy-based ingredients to drive product innovation.

“Consumers are increasingly seeking transparency and minimally processed products,” said René Skarnager, Managing Director at Soy Austria. “This rising demand

for simple and recognisable ingredients means that more companies are removing or replacing artificial ingredients with more natural options in the purchasing decision ladder.

“With sustainability one of our core values, Soy Austria is excited to partner with a distributor that puts environmental, social and governance goals at the forefront of its strategy. We look forward to working closely with ACI Group to meet the needs of food ingredients manufacturers across the UK and Ireland.”

“The popularity of soy-based solutions will continue to soar well beyond 2023,” commented Karsten Smet, CEO at ACI Group. “Currently, the global soy protein market is estimated to reach $15.3 million (£12.5m) by 2023 at a 4.4% CAGR. Health and environmentally conscious consumers that are looking for alternative protein sources are driving this market to a whole new level, pushing food ingredients manufacturers to step up to the plate and innovate.

“At ACI Group, we want to help our customers meet the demand for plant-based, high value protein and are delighted to partner with Soy Austria to deliver high quality, sustainable ingredients to the UK and Irish markets.”

The company’s extensive product portfolio includes full-fat soy flours, enzyme-active and enzyme-inactive, roasted soy grit, highquality debittered soy bran and premium

At ACI Group, we want to help our customers meet the demand for plant-based, high value protein and are delighted to partner with Soy Austria to deliver high quality, sustainable ingredients to the UK and Irish markets

full-fat soy flakes for the bakery and confectionery markets. In its second production plant, its 100% natural textured soy protein range is produced from semi- defatted soy flour to meet the demands of the plantbased meat market.

Soy Austria has committed itself to the strictest quality regime in the soy business, aiming for long-term relationships with its customers. Production is under constant and strict quality control in order to guarantee the highest possible product safety.

Supported by a computer-assisted control system and state-of-the-art food safety equipment like metal detection and X-ray technology, Soy Austria provides safe food ingredients for the global market. Emergency plans, spare capacity at plants and a dedicated team of mechanics, available 24/7, ensure uninterrupted production.

The partnership with Soy Austria follows last year’s news, which saw ACI Group secure exclusive UK distribution agreements with two leading nutraceutical ingredients suppliers, Caltron Clays and GR Herbals. n

Reporting on the latest developments from the UK’s food and drink sector

Food and Fuel supports the financial and physical wellbeing of young pupils and their families and will offer workshops, lessons, web-based assemblies and online cook-alongs. The scheme also gives ingredients to families and an innovative opportunity to borrow slow cookers and air fryers from school libraries.

The project supports the wider environmental and community mission of UKHarvest, to help people out of food insecurity and end food waste across the UK. The charity also offers education across the country and hosts an award-winning community food hub in London.

UKHarvest is already on a mission to eliminate hunger and food waste through the redistribution of quality surplus food. The company collects perishable food from places like supermarkets, hotels, whole salers, farmers, stadiums, catering companies, shopping centres, delis, cafes, restaurants, film and TV shoots, and boardrooms. UKHarvest take it, directly and free of charge, to charities who are helping vulnerable men, women and children in the UK.

The charity already offers money-saving, waste-preventing cookery courses and tips with engaging sessions that are designed to improve cookery skills, educate about healthy choices, and fight food waste in the home. The intention is to eat well for less, whilst also reducing an individual’s environmental impact.

“It’s heart-breaking to see so many people affected by the cost-of-living crisis,”

said Yvonne Thomson, CEO of UKHarvest. “We meet families every day who are forced to choose between paying for heating or feeding themselves. We’ve launched this project to immediately ease some of the pressures faced by those most in need, to enable everyone to prepare healthy food at an affordable price. This adds value to the support we already provide directly to charities and individuals through our food rescue and redistribution service, community hubs and by helping people cook well for less and make the most of their food.”

Recent figures from The Food Foundation show one-in-four households with children cannot afford the healthy meals they need for their family. With high inflation on the costs of food and energy, households are looking for ways to reduce expenditure. Even if a food bank or pantry can provide free or low-cost food parcels, it still costs money to prepare the meals.

“We are committed to supporting families that are living in fuel poverty,” said Phil Burrows, Head of Customer Vulnerability Social Programme Delivery at UK gas distribution company Cadent. “Each week, many families are making a difficult decision between heating their homes and feeding their families. This project will support many families across our networks to alleviate some of the challenges they currently face by giving help and guidance on cooking nutritious, healthy and cost-effective meals that will feed their family.”

“Our customers are facing unprecedented challenges,” added Ian Cameron, Director of Customer Service and Innovation at UK Power Networks. “So, we have expanded our fuel poverty support over the last year, working with more partners than ever before to deliver practical support to more customers. We are delighted to team up with UKHarvest and Cadent to help support more of those families who are struggling the most.” n

A partnership between Cadent, UK Power Networks and UKHarvest aims to reach up to 20,000 pupils and their families in 70 schools across the East of England. This project will help people to eat well for less and cut the cost of cooking by exploring fuel efficient methods, introducing new technologies and revisiting some traditional essentials.

Reporting on the latest developments from the USA’s food and drink sector

Sysco has partnered with two leading universities to accelerate climate innovation and prepare the next generation of sustainability and supply chain leaders.

Sysco Corporation, the leading global foodservice distribution company, has launched its new ‘Recipe for Sustainability’ programme. Through this programme, Sysco will collaborate with top universities to explore innovations that will accelerate climate action and lead the industry towards a more sustainable future.

Students at Arizona State University and Pennsylvania State University will have the opportunity to solve real-world challenges and propose innovative, costeffective solutions to reduce packaging, food waste and the use of plastic in takeaway containers.

“Sysco is proud to partner with leading universities to help develop the next generation of sustainability leaders,” said Neil Russell, Sysco’s SVP Corporate Affairs and Interim Chief Financial Officer. “We’re eager to see the bright ideas generated through these partnerships that will help address sustainability challenges faced by our industry, and ultimately reduce our impact on the planet.”

In 2021, Sysco set an industry-leading science-based climate goal to reduce 27.5% of its direct emissions (Scope 1 & 2) by 2030. Sysco also committed to engaging supplier partners (representing 67% of Scope 3 emissions) to set their own sciencebased targets by 2026.

“The climate crisis is too big for any one company to tackle alone,” explained Mr Russell. “By collaborating with our customers, our supplier partners and other innovators such as Arizona State University and Pennsylvania State University, we can drive real change across our industry.”

In addition to partnering with Pennsylvania State University on sustainability innovations, Marie Robinson, Sysco’s EVP and Supply Chain Officer, was recently appointed to the university’s Centre for Supply Chain Research (CSCR®) Board of Advisors. The CSCR Advisory Board members commit to a two-year appointment where they are active in CSCR-sponsored programmes and events and provide input and guidance for the centre’s strategic plan and forward-thinking initiatives, as well as approving faculty research affiliates and fellowships.

In-line with its target of 2030, Sysco aims to add 2,500 electric trucks to its US fleet and utilise 100% renewable energy across all its facilities.

The company also hopes to reduce its annual greenhouse gas emissions by more than 445,000 tonnes, which equates to 7.3 million tree seedlings grown for ten years, or 1.1 billion miles driven by an average passenger vehicle.

In recognition of its efforts, the company has ranked in the top 20 Texas businesses committed to conservation and sustainability by TxN20 and was ranked by JUST Capital 2022 as the number one food and drug company to commit to serving the environment.

Sysco is the global leader in selling, marketing and distributing food products to restaurants, healthcare and educational facilities, lodging establishments and other customers who prepare meals away from home. Its family of products also includes equipment and supplies for the foodservice and hospitality industries.

With more than 71,000 colleagues, the company operates 333 distribution facilities worldwide and serves approximately 700,000 customer locations. For the fiscal year 2022, ending July 2, 2022, the company generated sales of more than $68 billion. Information about the company’s Sustainability programme, including Sysco’s 2022 Sustainability Report and 2022 Diversity, Equity & Inclusion Report, can be found on its website.

For important news and information regarding Sysco, visit the Investor Relations section of the company’s Internet home page, which Sysco plans to use as a primary channel for publishing key information to its investors, some of which may contain material and previously non-public information. In addition, investors should continue to review its news releases and filings with the SEC. n

By collaborating with our customers, our supplier partners and other innovators such as Arizona State University and Pennsylvania State University, we can drive real change across our industry

“ “

SAGALEXPO 2023

SAGALEXPO runs from 27th to the 29th of March, held at the FIL - Feira Internacional de Lisboa atividades - in Lisbon. The show is the largest national fair aimed at the export of Portuguese products. CEO José Frazão reviewed the show and what visitors can expect. Questions by Phil Nicholls.

What do you see are the benefits to businesses of attending the show?

SAGALEXPO – Portuguese Flavours is the only food fair held in Portugal that directly promotes the meeting of Portuguese food and beverage companies with international buyers from all five continents.

SAGALEXPO actively seeks out the biggest players in foreign markets and invites them to attend the fair as our international guests. By participating as potential buyers, they represent endless business opportunities for our exhibitors, building their exports.

At its first event, SAGALEXPO had more than 250 Portuguese companies exhibiting and over 700 international buyers attending. During the three days of the event, the exhibitors had several meetings with the buyers, giving them the opportunity to present their

products, and this resulted in new partnerships – which, in turn, allowed them to increase turnover and expand their exports.

Please summarise what Portuguese food and drink companies can offer the global market?

The Portuguese agri-food sector can answer market needs and create high-quality products and services to address them. Portuguese companies in the food and beverage sector are highly specialised and are known for their first-rate products.

Portuguese olive oil producers, milk and dairy producers, and preserves and meat companies are all famous internationally. Tourists are usually fascinated about our gastronomy, and frequently want these foods available in their own countries. This brings two opportunities: an increase of tourism inflow, boosted by recommendations

from friends and relatives who have already been to Portugal; and an increase in demand for our products from international buyers wishing to import them.

How has SAGALEXPO 2023 evolved since the last show? What is new for this year?

This year, we present a more sophisticated version of the fair by simplifying the way the exhibiting companies and international buyers interact. All companies who register beforehand benefit from privileged publicity and promotion in our digital channels, as well as in our magazine Veja Portugal.

We have considered all the feedback from the first event and improved several operational aspects. As in 2022, we offer all international buyers accommodation for the three nights of the fair, entrance tickets to the event, and the opportunity to have lunch with the exhibitors every day. The latter is an additional networking opportunity that allows buyers to sample our national products and brands.

SAGALEXPO 2023

What visitor and exhibitor numbers are you targeting for this year?

Our goal was to exceed last year’s numbers, and we achieved that during 2022. We expect to surpass 350 exhibiting companies, and to welcome over 1,000 international buyers at SAGALEXPO 2023.

What can visitors expect from their trip to SAGALEXPO 2023?

We have a very complete and diversified range of exhibitors and, therefore, brands and products. The importing company can not only find a specific product that one of the companies exhibiting is already selling, but also request a variation of an existing product to be created by that same company. The possibility to create an exclusive brand for a market is something that our international guests really liked in 2022 and continues this year. Additionally, the exhibitors also present seasonal products. The international visitor will have a lot to see, taste and learn about.

What benefits can Portuguese companies expect to gain from exhibiting at SAGALEXPO 2023?

We represent a wide range of Portuguese food and drink products. Attending SAGALEXPO means travelling abroad without having to leave the country. By bringing to our event key importing companies from all over the world, we facilitate more business contracts and partnerships.

Your specialised commercial team helps international visitors attend the show: how much do you feel this additional service helps boost attendance?

SAGALEXPO has a specialised commercial team with over 30 years of work experience organising events, having gathered a network of reputable contacts from different markets. By spending the time to get to know our guests and their needs, as well as to hear what they have to say about our performance, we try to ensure that they attend the fair and will want to return for years to come.

After all, SAGALEXPO is not only about the internationalisation of Portuguese brands and products, but also about helping our international guests expand their portfolios according to their market’s demands.

Looking at the companies already booked for SAGALEXPO 2023, can you share any previews about the Portuguese food trends and developments on display this year?

We are very pleased that we have not only kept 90 percent of the exhibiting companies from the first event, but also that new ones have joined us this year. It was a risk to start this project, because there were still a lot of concerns from our guests about travelling abroad due to the pandemic. However, we are thankful that we decided to push through.

Both Portuguese companies and international players believed in us, and that proved beneficial, due to all the subsequent new businesses. This year, everyone expects even better results. We know that our exhibitors are excited to surprise our international guests with new products, but we need to keep them as that: a surprise.

Are there any special aspects of SAGALEXPO 2023 that you would like to include in this feature?

We have a special event prepared for all the buyers that want to know about Portuguese wines. Our partner, ViniPortugal, the promoter of Portuguese wines abroad, will organise a wine tasting, giving the buyers the opportunity to taste the different grape varieties produced in our beautiful vineyards.

On a personal level, what aspect of SAGALEXPO 2023 are you most excited about?

SAGALEXPO is a very ambitious project, with a different dynamic from other fairs that we organise during the year, and that is a challenging task. It is very fulfilling to design and plan a project, then see it steadily come together.

Logistically, SAGALEXPO requires careful planning, demanding a lot of the team’s time and attention. Much can happen during the

event itself and not everything will go exactly according to plan, but we see it as an opportunity to do better. E-commerce and its development and growth could be harmful to companies such as ours that organise in-person events, but we realise that buyers do not dismiss the importance of face-to-face contacts or the chance to taste the products before making a commitment; we promote a dynamic event so buyers can interact with several different suppliers in a single space. We are studying the feasibility of a digital project that we want to disclose soon, and that will improve the digital side of things.

Is there anything not covered by the above questions that you would like to share with our readers?

To keep posted on our social media accounts and to our digital magazine Veja Portugal. Here we disclose new exhibiting companies and share everything happening in the country. We want to show the world the best that Portugal has to offer. n

F4F – Expo FoodTech

F4F – Expo FoodTech, the global technology event for the food industry will host a new edition of the FoodTech Startup Forum 2023. Once again, the FoodTech Startup Forum will bring together more than 2,000 new startups to present their projects, solutions and business models that will revolutionise the food and beverage industry.

For three days, and in a space of more than 4,000 square metres, startups from around the world will showcase technological innovations to face the challenges of safety, traceability, sustainability and efficiency of the value chain within the food industry. A committee of experts will select the 200 most innovative startups, and the 60 most disruptive ones will be able to present their projects to investment funds and leading companies in the sector. Agrotech, Industry 4.0, Automation, Refrigeration and Climate, Food Processing, Food Packaging, and Food Science categories will divide the presentations at FoodTech Startup Forum 2023. In addition, the selected startups will be direct candidates for the FoodTech Innovation Awards 2023.

The FoodTech Startup Forum offers the entrepreneurial ecosystem a knowledge platform to promote entrepreneurship and the most dis ruptive innovation projects based on technologies such as IoT, Artificial Intelligence, Data Analytics, or new ingredients and foods developed through biotechnology.

Foodtech startups will be able to meet with corporate ventures, international technology clusters and the food industry as a whole. Also, they will have contact with government agencies, clusters and associations, universities, and technology and innovation centres, incubators and accelerators so that they can establish synergies.

The world's largest event for startups in the foodtech sector is now open for applications so foodtech startups from all over the world can present their projects and solutions. Interested companies can register to the FoodTech Startup Forum until the 7th of April 2023.

Among the participating startups who attended in previous years were DAT Technologies, which developed a blockchain platform to guarantee the traceability of the food value chain, and Factic, which uses AI and Machine Learning to forecast demand in food and beverage companies.

Alacarte and its automated device that reduces the alcohol content and calories of any bottle of wine or liquor while preserving its original essence, and Insekt Label Biotech and its vegetable protein alternative (developed from crickets and beetle larvae), have also showcased solutions at the Foodtech Startup Forum. n

Biffa is a leading sustainable waste management company that annually recycles

151kt of plastic into material which is used to make new products. Report written by Waste Strategy & Packaging Manager of Biffa Roger Wright.

The unpalatable fact is that the UK still produces too much waste and does not recycle enough of it. Currently the UK is falling short of its 2050 target to prepare 65% of municipal waste for re-use and recycling, and plastic packaging is an important part of this story. As of 2021, the UK has a recovery/recycling rate of 44% for plastic packaging, while materials such as aluminium (75%) and paper and cardboard (70%) are much higher.

It is easy to point at plastic packaging to say the material is a problem, to get caught up in the good-bad debate that polarises public opinion and media commentary. However, when items are made from reusable and recyclable plastics and managed correctly, they provide sustainable, cost-efficient, and durable packaging solutions.

The five best ways to create a more positive future with plastics involve utilising recyclable plastics, increasing capacity and infrastructure, reducing contamination, replacing single-use plastic, and simplifying packaging.

WRAP’s 2022 update to its annual recycling tracker shows that 90% of UK citizens regularly recycle when asked about all types of materials. However, the recovery rate of plastic packaging is 44% because much of it (flexible plastics or pouches) is not recyclable or reusable. While recycling is part of the nation’s day-to-day activities – and the motivation and behaviour are clear – the packaging used for many products does not support recycling.

What can be done about this? People and businesses need information to guide and support their choices. From businesses’ product design and packaging decisions to consumers’ purchase choices, understanding is needed at every stage of the process. If people know more about the different types of plastic and the environmental and economic impact of their choices, then a change in behaviour would be more likely, all the while increasing the quality of recyclable material by creating separate waste streams.

When recyclable plastic packaging leaves the UK, the carbon cost of transportation leads to more emissions compared to onshore recycling. There is a clear argument for more plastic to be recy cled in the UK; to support green investment, infrastructure, eco nomic growth and jobs.

An end to the export of plastic packaging would mean the UK must recycle the 0.7mtpa of plastic packaging waste a year currently exported. This would take at least 12 polymer plants with a minimum 55,000-tonne processing capacity. Biffa’s 57,000-tonne capacity recycling plant in Seaham brought 100 full-time jobs to the local region: investment in infrastructure benefits both the economy and local communities in addition to the environment.

The Deposit Return Scheme in Scotland, launching 16th August 2023, is an example of how bold legislation can drive investment in and improvements to recycling infrastructure. As the logistics provider for the Scottish scheme, Biffa is developing new facilities to handle increased volumes of materials. The consultation for England, Northern Ireland and Wales is now complete, with the launch date set for 1st October 2025.

Last year, Biffa highlighted that nearly a fifth of all recycling is lost due to contamination. Food contamination on or inside packaging is one of the major issues hindering our recycling efforts, but it doesn’t

https://www.biffa.co.uk/sustainability

From bamboo cutlery to plant-based plastic alternatives, any mate rial in a single-use and on-the-go context presents a unique challenge. For example, it doesn’t matter if something is compostable if it ends up in general waste or if non-recyclable materials are put in the recycling bin. Both result in resources being lost and emissions being created.

The ban on single-use plastics will help increase the use of readily recyclable packaging solutions; it is, however, just one piece of the puzzle that will help the UK circular economy.

Brands are operating in highly competitive markets, working with tight margins. Packaging needs to be easy to fill, protect the contents and catch the eye of consumers in a split second in saturated environments. Often this leads to choices in colour and materials that render the container unrecyclable. It does not have to be one or the other; it is possible to create sustainable plastic packaging that speaks to the consumer.

have to be this way. Increased awareness around the recycling pro cess and the impact of contamination will help change behaviour for consumers and businesses.

There are plans for legislation to make the current voluntary, on-package labelling system mandatory. This needs to be realised for both consumer and business packaging, with the clearest messaging possible, to drive awareness of what the recycling symbols mean and the condition a container needs to be in to be recycled. This will reduce the amount of unrecyclable material in the UK collection and processing systems, improve the quality of our recycled materials and lower the carbon emissions output.

Our industry, regulatory bodies and government need a greater understanding of the packaging materials in circulation. Extended Producer Responsibility begins this year, obligating businesses to report greater detail on the packaging they produce and in what quantity. This will provide valuable insight to support customer choice and promote better packaging design for recycling.

The UK government recently announced its intention to ban certain single-use plastics, including plates and cutlery. While this is a welcome step in the right direction, the plastics themselves are not the problem; it is that they are single use. As single-use plastics are phased out, they need to be replaced by more multi-use or reusable options.

Commonality and consistency are key to creating simple, sustainable packaging. If materials or different types of plastic are mixed, then it becomes harder to separate these materials and recycle them. Packaging such as laminated material, plastic wrapping and big sleeves need to be separated or recycled at specialist facilities; this is often impractical and unsustainable at scale.

This is also true of packaging that contains more than one colour of plastic. No food-grade coloured plastic can be recycled back into natural-coloured food-grade packaging as the pigment remains in the polymer. When mixed pigments are recycled together, the material becomes grey. Adopting clear plastic wherever possible will help move towards more sustainable packaging. Improvements can also be made by shrink-wrapping labels rather than gluing and tethering bottle tops to bottles (ideally the same colour).

Plastic packaging is unlikely to lose its edge if it is clear, homogenous and consistent. Eye-catching designs can still be used, provided the components are easily removed and recyclable. Increasing public awareness will support positive changes in consumer behaviour. People want to do the right thing, and those brands which explore sustainable options first will catch the eco-conscious eye and achieve cut-through – the time to start is right now.

Biffa supports some of the UK’s leading brands through this process. Its Blueprint for Waste Net Zero outlines the role of recyclable plastic packaging within the future carbon hierarchy and what further changes are needed to deliver a truly circular economy.

You can learn more about Biffa and its efforts towards sustainability here:

The latest news from across the global food and drink sector

Nao Spirits and Beverages (India’s first Craft Gin Distillers) announced the Jay Dhawan Scholarship in association with the Gin Guild. The distillery will sponsor one student every year from India, to pursue an MSc in Brewing and Distilling from Heriot Watt University in the UK (one of the most prestigious and respected institutes in the world of brewing and distilling).

This scholarship was created to celebrate the memory of Nao Spirit’s late distiller, Jay Dhawan. Much loved by all, Jay had started his career behind the bar at one of Mumbai’s most celebrated establishments – Bombay Canteen. Wanting to pursue a different path

though, he jumped at the opportunity to join Nao Spirits and be trained to be a distiller under Dr Anne Brock.

He trained in 2017 alongside Anand Virmani, the Co-Founder and Master Distiller at Nao Spirits, and went on to produce India’s first craft Gins – Greater Than and Hapusa. The team at Nao Spirits and the Gin Guild would like to thank Jay’s parents and family for allowing them to create a way to remember him.

This scholarship will be open to all applicants from India, with a preference given to those from the Indian F&B sector. Applications are currently being accepted for September 2023.

Since the start of February, eggs laid and sold through the British egg industry Lion Code label can no longer be labelled as free-range or free-range organic. This means consumers will only see ‘barn’ or ‘caged eggs’ on their supermarket shelves.

The changes to the labelling of eggs is due to the compulsory nationwide housing order which was put in place for all birds in the UK at the end of last year, to help contain one of the worst cases of Avian Influenza (AI), also known as ‘bird flu’, ever seen.

There is an EU derogation for free-range laying hens which states they can be kept inside for up to 16 weeks, if they are required to be housed in an event such as a bird flu outbreak their eggs can still be labelled free-range during this time. Since this time period has now ended for the whole of the UK, all eggs from free-range birds that are being housed must now be labelled as ‘barn.’

“We want to reassure the public that it is still possible to buy eggs from hens that have been well cared for,” said Kate Norman, the RSPCA’s laying hen welfare expert. “RSPCA Assured eggs are always from farms inspected to the RSPCA’s higher welfare standards. This means they are 100% cage-free, and the hens are provided with raised perches and plenty of enrichment inside the barn to peck at, forage and express their natural behaviour.”

The Kroger Co recently announced the opening of a new spoke facility in South Florida. Joined by the local community, Kroger celebrated the expansion of the delivery service and welcomed 90 new associates.

The 60,000-square-foot spoke facility will work in conjunction with the Groveland, Florida fulfilment centre. All orders are picked at the products' peak freshness within the Groveland facility. The expansion to South Florida, including Miami represents an extension of a collaboration between Kroger and Ocado Group, a world leader in technology for grocery e-commerce.

At the hub sites, more than 1,000 bots move around giant 3D grids, orchestrated by proprietary control systems. The grid, known as The Hive, contains totes filled with products and ready-to-deliver customer orders. As customers' orders near delivery times, bots retrieve products from The Hive and present them at pick stations for items to be sorted for delivery, a process governed by algorithms that ensure items are intelligently packed. Bags are evenly weighted, and each order is optimised to fit into the lowest number of bags, reducing plastic use.

Kroger's end-to-end cold solutions keep groceries fresh once loaded into a customised refrigerated delivery van, which can store up to 20 orders. Vans may travel up to 90 minutes with orders from the hub and spoke facilities to make deliveries.

Europe Snacks, a leading European producer of savoury snacks for third party brands, has announced acquisition of 100% of crisp manufacturer, Burts Snacks. This operation enables Europe Snacks to accelerate its growth in the UK, which is Europe’s largest snacking market.

Supported by Apax Partners, Europe Snacks entered the UK market with the acquisition of Kolak Snack Foods in 2016. The acquisition of Burts represents a further step in expanding the group’s presence in the UK, with the product portfolio being highly complementary.

Morning routines have just been made simpler with the launch of Rokit Health’s wellness coffee pods.

Compatible with Nespresso machines, these 100% recyclable aluminium pods, bursting with goodness are now available in Tesco in three varieties: Mind Boost, Immunity Boost and Mighty Matcha, RRP £4 for 10 pods.

Mind Boost is 100% Arabica coffee enriched with vitamins B2, B3, B5, B6 and B12, to support the nervous system and contribute to mental performance. The drink promises aromas of cereal and malt, and a spicy, fruity aftertaste. Immunity boost is a coffee promising benefits for the immune system. Mighty Matcha continues the matcha revolution with a hot drink from Japan, high in antioxidants.

Rokit Health drinks are all made from the highest quality natural ingredients, sourced from sustainable and ethical farms all over the world and only ever use raw ingredients that are minimally processed and free from chemicals, preservatives, and flavourings.

The unification of the two companies in the UK will enable the group to better serve existing clients and unlock growth through a wider offer of snacking products and a market leading innovation pipeline. The combined manufacturing and supply chains of Europe Snacks and Burts will facilitate the group’s further investment in additional capacity and service excellence.

Burts will continue to operate from its two manufacturing facilities in Plymouth and Leicester, led by current Managing Director Dave McNulty.

Taste of the season

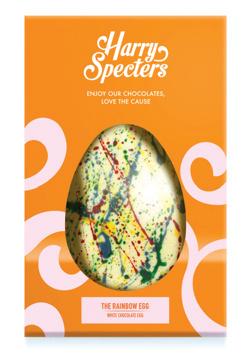

Easter chocolate delights

Its never too early to start thinking about Easter chocolate. These days, there are more choices than ever, from some of the most sophisticated and delicious chocolate makers on the globe. Inside Food & Drink sampled some of the best. It was a hard job, but someone had to do it.

Inspired to create a positive change for people with Autism, Harry Specters was the vision of founder Mona and her family. The award-winning company creates taste sensations that directly improve the lives of autistic people. The Rainbow Egg is a white chocolate egg consisting of 29% cocoa solids. With natural ingredients and a breath-taking design, this Easter treat is a delight for the eyes and the tastebuds. The chocolate is also gluten-free and is always made with the freshest of ingredients. The company also offers Chocopops: these fun lollipops feature exciting Easter-themed edible designs and come in packs of five –the perfect element for any Easter egg hunt. On average, for every £1 spent at Harry Specters, 69p is dedicated to providing paid employment, work experiences and training opportunities for people with autism. Since 2012, the company has helped more than 300 autistic people and supported 155 carers.

Our thoughts : “This egg was unlike anything I’d ever tasted. The flavour was as powerful as the exciting visuals, and the strong creamy flavour was unforgettable and enticing. It’s definitely one that everyone should try.” – Daniel O’Malley, Marketing Manager.

i F D &These products are available now at:

www.harryschocs.co.uk

These products are available now at: www.bettys.co.uk

The Betty’s ‘Easter Eggs for Grown Ups’ range includes some of the most impressive offerings you are likely to see this year. The limited-edition Spring Bloom egg is handcrafted in the company’s Yorkshire bakery, made with exquisite eau de nil-coloured white chocolate and hand-decorated with royal icing flowers and a silver shimmer. At 19cm high and 310g there is also a good height and weight to them. And that is before you have tried the quality of the chocolate itself. The company offers a wider Easter selection, including mini eggs, milk choco late orange button eggs, and the post-friendly ‘flat egg.’ There is a vegan alternative, a strikingly elegant egg containing 65% Venezuelan cocoa. Betty’s is a truly luxury option.

i F D &Our thoughts: “The first thing I noticed was that this egg was a feast for my eyes. It is truly spectacular, with great attention to detail. The taste did not disappoint either, with a divine sweetness that was both substantial and comforting. This is not only the best white chocolate I have ever tasted, but some of the best chocolate altogether.” – Hannah Barnett, Editorial Assistant.

The Chocolate Tree is an award-winning chocolatier who has mastered craft chocolate that tastes exceptional and protects biodiversity. The Milk Chocolate Easter Egg is the epitome of luxury. With a 45% cocoa content and an eye-popping design, this egg is sure to keep people coming back for more. The addition of a surprise compartment in the vibrant box filled with hearty salted caramel popcorn is a treat for all the senses and really magnifies the enchantment of Easter. This egg is perfect for all ages as a feel-good indulgent treat. Also on offer are a variety of bars perfect for any occasion, the bean to bar chocolates utilise single estate sustainable cacao from South and Central America and have a rich and succulent taste perfect for any chocolate enthusiast. With 100g bars of craft chocolate available as well, this company knows how to combine the perfect ingredients to take its customers on a spectacular taste journey.

Our thoughts: “The egg had a rich chocolate taste, which was light and moreish. The design was so beautiful and really envisioned the magical essence of the theme, plus its ethical nature made me feel great eating it. The salted caramel popcorn was also melt-in-your-mouth good.” – Imogen Ward, Editorial Assistant.

These products are available now at: www.choctree.co.uk

Easter chocolate delights

Our thoughts : “The egg had a surprisingly subtle crunch with every bite and maintained a perfectly balanced nutty and bitter taste with exceptional smoky undertones. We loved the playful characterisation of Frizzle and the creative shape really brought her to life.” -The Studio Team.

Montezuma’s is a fun and enthusiastic innovator of the chocolate world and a huge advocate for sustainability. Creating a one-of-a-kind experience with every offering, the brand has knocked it out of the park with its Easter range. Furthering its eco-friendly initiative, whilst providing delectable flavours, Montezuma’s Organic Chocolate Eco Eggs are a sight to behold. With 100% recyclable packaging and no plastic in sight, these eggs – filled with organic goodness – are the perfect choice for those looking for ethical chocolate that tastes amazing. Alternatively, the company’s Easter Hens come in three flavours and a unique shape that is fun for all the family. The packaging pops and the excellent value for money makes Silkie, Frizzle and Orloff the perfect addition to your egg basket this Easter. Another wonderful offering is the Chocolate Peanut Butter Mini Eggs; the perfect balance of earthy peanut butter, mixed with tantalisingly sweet chocolate is enough to wish everyday was Easter.

These products are available now at Waitrose stores and online: www.montezumas.co.uk

The Läderach FrischSchoggi is a Läderach classic, and a perfect gift. FrischSchoggi is a marriage of fresh Läderach chocolate with carefully sourced ingredients, presented in its iconic slab form. It is handmade without additives or preservatives by artisan chocolate makers in Switzerland, using a combination of traditional and innovative methods. The name FrischSchoggi comes from a Swiss-German expression for fresh chocolate It is synonymous with creativity and a unique taste experience. The creaminess of the chocolate is ensured by the milk which comes from Alpine cows that have been out in the fields and enjoyed the Swiss sun and grass. From fruity and fresh with white chocolate and rasp berry pieces, or classic with milk chocolate and caramelised Piedmontese hazelnuts, to pure rich indulgent enjoyment with dark chocolate, there is something for everyone here.

i F D &

These products are available now at: www.laderach.com

Our thoughts: “The dark chocolate with raspberry had the bitterness one associates with high-quality dark chocolate. It really brought out the sweetness of the raspberry. In general, the variety of textures was superb and the flavours divine. You could tell this was a handmade, artisan product. Truly exceptional.” – Phil Nicholls, Editorial Manager.

Valrhona’s limited edition collection for Easter 2023 is all about ushering in the lightness and lushness of spring. The charming packaging suggests all the joys of the season of renewal: flowery meadows, woodland creatures and starry-eyed chicks. The contents are even more exciting. An assortment of eggs made with delicate milk chocolate praline, shortbread pieces coated in gianduja milk chocolate, a dark chocolate ganache, and dark and milk chocolate caramel hearts. There is something to suit the whole family in this distinctive Easter collection. Pioneering chocolate artisans since 1922, Valrhona is constantly pushing the limits of creativity to expand ethical chocolate’s aromatic palette and spark the next taste revolution. This innovative approach was what brought about Guanaja, Valrhona’s iconic dark chocolate, known as the most bitter in the world when it was launched in 1986, and Dulcey blond chocolate ‘chocolate’s fourth colour.’

Our thoughts: “There was a subtle yet distinctively delicious flavour in the dark caramel heart. I really enjoyed the dark ganache for its creamy, smooth, chocolate filling. It contrasted perfectly with its rich shell. The blond Dulcey fishshaped chocolate treat was amazing. Biting into this confectionary left me with a velvety, caramel aftertaste.” – Adam White, Marketing Executive.

These products are available now at: www.valrhona.com

Interesting and unusual food and drink facts from around the world

Diospyros Digyna is a species of persimmon. It is also known as the chocolate pudding fruit due to it tasting like the sweet dessert when ripe.

In 1759 Arthur Guinness boldly signed a 9,000-year lease on the St. James’s Gate Brewery to establish the iconic Guinness factory in Dublin.

Macaron Day was first founded in 2010 by Chef François Payard to celebrate the sweet treat. On the day, participating New York bakeries offered customers free macarons.

In celebration of its 50th anniversary, Schreiber Foods Inc cooked the world’s largest batch of macaroni and cheese. Weighing in at 2,151 kg, the super-sized meal was distributed to more than 2,000 people.

Jellyfish have no brain, heart or bones and consist of 95% water.

The world record for the most Cadbury Creme Eggs consumed in one minute was awarded to Peter Czerwinski in 2014. He successfully consumed six.

The world record for the heaviest carrot was awarded to Christopher Qualley in 2017 for his carrot weighing 10.17 kg.

The Ivory Coast is the largest producer of cocoa in the world, producing an estimated 2.2 million tons during the 2021-2022 crop year.

Marshmallows originated from the use of sap from the marshmallow plant in ancient Egypt. The recipe called for the sap to be mixed with honey and nuts.

The earliest record of the Easter egg in the UK was in 1873, produced by Fry’s of Bristol.

Betty Crocker is a fictional character, created by Washburn Crosby Co. Originally designed to add a personalised touch for responses to customer queries, the name was later turned into a brand.

Breadfruits are rich in starch, so when cooked they are said to taste like freshly baked bread.

There is no sincerer love than the love of food

– George Bernard Shaw –

Inside Food & Drink meets Ecolab’s Senior Marketing Manager UK & Ireland Christian Southall and Regional Marketing Manager

UKIE-Nordics Mark Wright

A trusted partner at nearly three million customer locations, Ecolab (ECL) is the global leader in water, hygiene and infection prevention solutions and services. Senior Marketing Manager UK & Ireland Christian Southall and Regional Marketing Manager UKIE-Nordics Mark Wright outlined the latest developments at Ecolab. Questions by Phil Nicholls.

To begin, could you please briefly introduce Ecolab to our readers?

With annual sales of $12 billion and more than 44,000 associates, Ecolab delivers comprehensive solutions, data-driven insights and a personalised service to advance food safety, maintain clean and safe environments, optimise water and energy use, and improve operational efficiencies and sustainability for customers in the food, healthcare, hospitality and industrial markets in more than 170 countries around the world.

Focusing on the food & drink sector, can you please outline Ecolab’s programmes and solutions for a healthier world?

Ecolab’s programmes and services improve upon the environmental performance of the customer’s plant or building, by reducing the amount of natural resources consumed (water and energy), emissions

(both wastewater and gases) or waste. Our approach helps customers meet environmental standards and control environmental costs.

A safe food supply is essential for feeding the world’s growing population. Ecolab has unrivalled expertise in GMP food safety to help prevent food-borne illness throughout the supply chain, including the farm and animal health, food and beverage manufacturing, plus foodservice and food retail industries.

Food security is an important issue today. How does Ecolab contribute to food security across the global food chain?

During the pandemic, but also now during the current times of uncertainty, food availability cannot be taken for granted. Food prices for the consumer, but also raw material cost for the processor went up significantly.

This incentivises the reduction of food waste

Through improvements in hygiene management, Ecolab can help customers reduce quality-attributed food losses and maintain longer shelf life. For instance, the Ecolab digital solutions help customers to be more efficient in controlling deviations from defined cleaning procedures. This ensures a more consistent hygiene outcome which reduces quality induced losses and re-works, plus offers insight for continuous improvement towards food safety and quality.

Through expert consultancy in combination with our hygiene products we help customers to break cross-contamination pathways and make cleaning processes more efficient. Current utility cost of energy and the availability of water are major triggers that push processors to reach a next level of efficiency. Ecolab’s scope of expertise in water and energy management can significantly move the indicators without compromising on food safety.

The food & drink sector was hit hard by the global pandemic. How much do you feel this has altered public perceptions about food safety and global health?

Food safety has always been a prerequisite for customers. The general expectation is that food is safe to eat. People do not generally care about how the food gets to the store. They expect the food manufacturing company and the supply chain to provide safety measures for the people in the facility. During the pandemic, many of them had staffing issues mostly related to workers safety not food safety. Today, the public generally has increased awareness, due to the ability to detect and recover food safety hazards. Availability of rapid testing, much improved tracking of pathogens to the origin of a contamination and more stringent publication of recalls play-

essential roles in this. Increased awareness eventually impacts buying behaviour: trusted sources will be preferred, not only by the consumer, but also by all participants in the supply chain.

In most cases, viruses are not on the food safety list - even though they should be. Norovirus for example causes many infections and it is generally found on fruits and uncooked items. The corona virus has been reported to survive on packaging. Longer term this will impact the buying behaviour of consumers, but more imminently it has impact on the procedures, storage and selection processes of food processors, because they can take informed decisions.

Ecolab provides solutions to clients to minimise and eliminate contamination risks. This helps to prevent the spread of contaminations along the supply chain. Validated efficacy of hygiene products in line with worker safety and environmental requirements, plus expert guidance in how to apply them safely and effectively are essential elements to achieve this.

Inside Food & Drink meets Ecolab’s Senior Marketing Manager UK & Ireland Christian Southall and Regional Marketing Manager

UKIE-Nordics Mark Wright

In February, Ecolab launched the Innovation that Leads to Impact project. How would you summarise this project?

Our customers have come to expect Ecolab to develop innovations that improve their operations, reduce business risk, and lead the industry. With this in mind, we brought together the food and beverage industry to present our newest innovations.

Over the years, Ecolab programmes and services have helped clients:

•Ensure food safety

•Achieve operational efficiency

•Address public health concerns

•Reduce labour

•Lower environmental impact

•Save water and energy

•Extend the life of assets

•Reduce packaging waste

•Improve safety for employees and their customers

During the event we discussed several new innovations targeted towards applications for surface disinfection, drain disinfection, digital monitoring and versatile CIP (Cleaning in Place) disinfection, plus fryer and oven hygiene .

Could you please highlight the innovations you launched as part of this project?

Manual Cleaning Insights:

Track critical open plant cleaning parameters such as chemistry concentration and water temperature in an easy-to-read dashboard and receive exception notifications for quick action.

ExelerateTM Tufsoil

Ready-to-use heavy duty gel cleaner and degreaser designed to remove tough burnt-on soils that can withstand hot surfaces without drying for up to 90 minutes.

Drainspexx

Easy and reliable method for food producers to significantly reduce pathogenic microorganisms in drains, prevent cross-contamination on food contact surfaces, and support food safety.

Nodsan EAS®

Effective non-oxidising clean-in-place (CIP) disinfectant that can be used alone or in combination with alkaline or acid detergents.

3D TrasarTM Technology for CIP

3D Trasar is a diagnostic tool to verify every clean-in-place (CIP). 3DT identifies opportunities to improve CIP efficiency and provides the customer peace of mind that someone is monitoring their food safety risk 24/7.

Non-Rinse Disinfection

Surface disinfection range for food and beverage operations that does not need to be rinsed off from the surface saving time and water.

Sustainability is such a global buzzword. How does the Innovation that Leads to Impact project support customers’ sustainable operations?

Our impact is greatest in the work we do for our customers. By helping businesses enhance their performance while reducing reliance on finite natural resources, we reduce their costs and support their growth. Through digital technology, connected chemistry and other innovative solutions, we deliver economic and environmental benefits that make businesses more efficient, productive and sustainable.

Does Ecolab have any plans or objectives for the future that you would like to share?

By 2030, we aim to help our customers conserve 300 billion gallons of water per year by reducing consumption in our own and our customers’ operations. This equals the annual drinking water needs of more than one billion people.

Ecolab will also help to provide enough high quality and safe food to feed two billion people for an entire year, preventing 11 million food-borne illnesses. We aim to clean 90 billion hands and provide safe medical care for 116 million people each year, reducing more than 1.7 million infections.

Finally, we will help customers become carbon neutral by reducing greenhouse gas emissions by 6 million metric tonnes, preventing almost 10 million pollution-related illnesses.

What aspect of your job excites you personally?

Mark: I have a mission to create and develop engagement, connecting people to conversations that result in a collaborative effort to make a difference.

It is important to me that my impact goes further than words, and everyday my job allows me to do this; from being involved in sustainability circles, building cross functional networks, creating advocation through online platforms and social media, connecting customers to innovation and digital technology that drive change in both sustainability and new standards of food safety

This all makes for a rewarding environment.

Is there anything not covered by the above questions that you would like to share with our readers?

Technology plays a critical part in our delivery of service to customers, and we have incorporated new digital technology into both our associates’ service delivery, but also at the fingertips of our customers.

Our Bluetooth enabled monitoring system allows Ecolab to monitor rodent activity on a 24/7 basis on a customer’s site. Empowering our teams to quantify the rodent pressure at critical points across the site and respond accordingly. Never has this level of quantification and understanding been available and it is forever changing the pest landscape.

For an F&B production facility, to have the peace of mind their site is being monitored 24/7, can reduce the risk of product contamination, as Ecolab, through the power of data and insight, can act faster and smarter, to rid any rodent activity. All the data captured is also

available to our customers, via our online portal: MyEcolab. With both parties working in partnership, armed with up to date data, we work together to better understand the onsite factors, including the data insight, and together act more effectively and efficiently.

Ecolab’s service has always been delivered with an Integrated Pest Management (IPM) approach, but now through leveraging digital technology, a new layer of intelligence can be applied to IPM. Changing the pest landscape forever. n

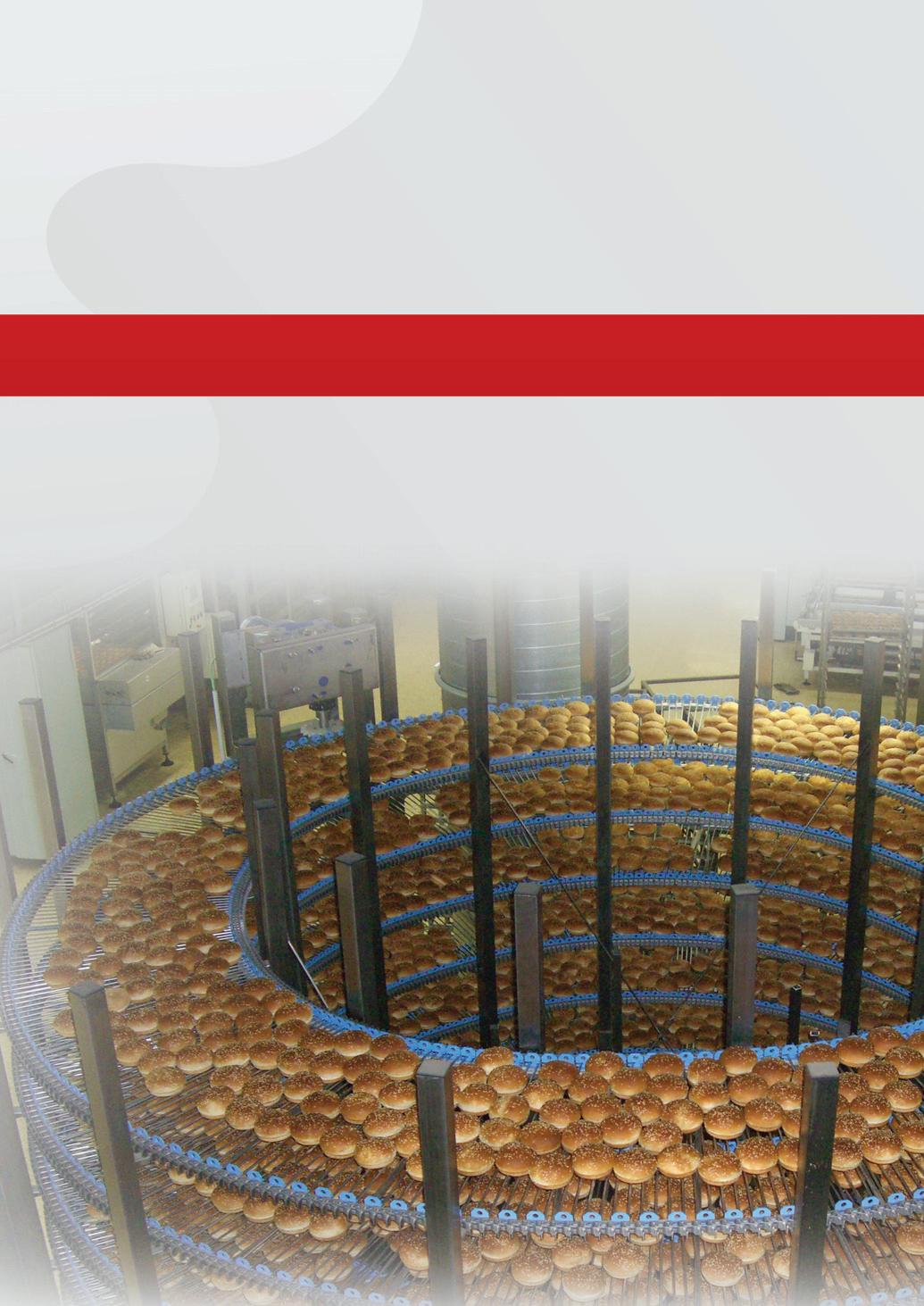

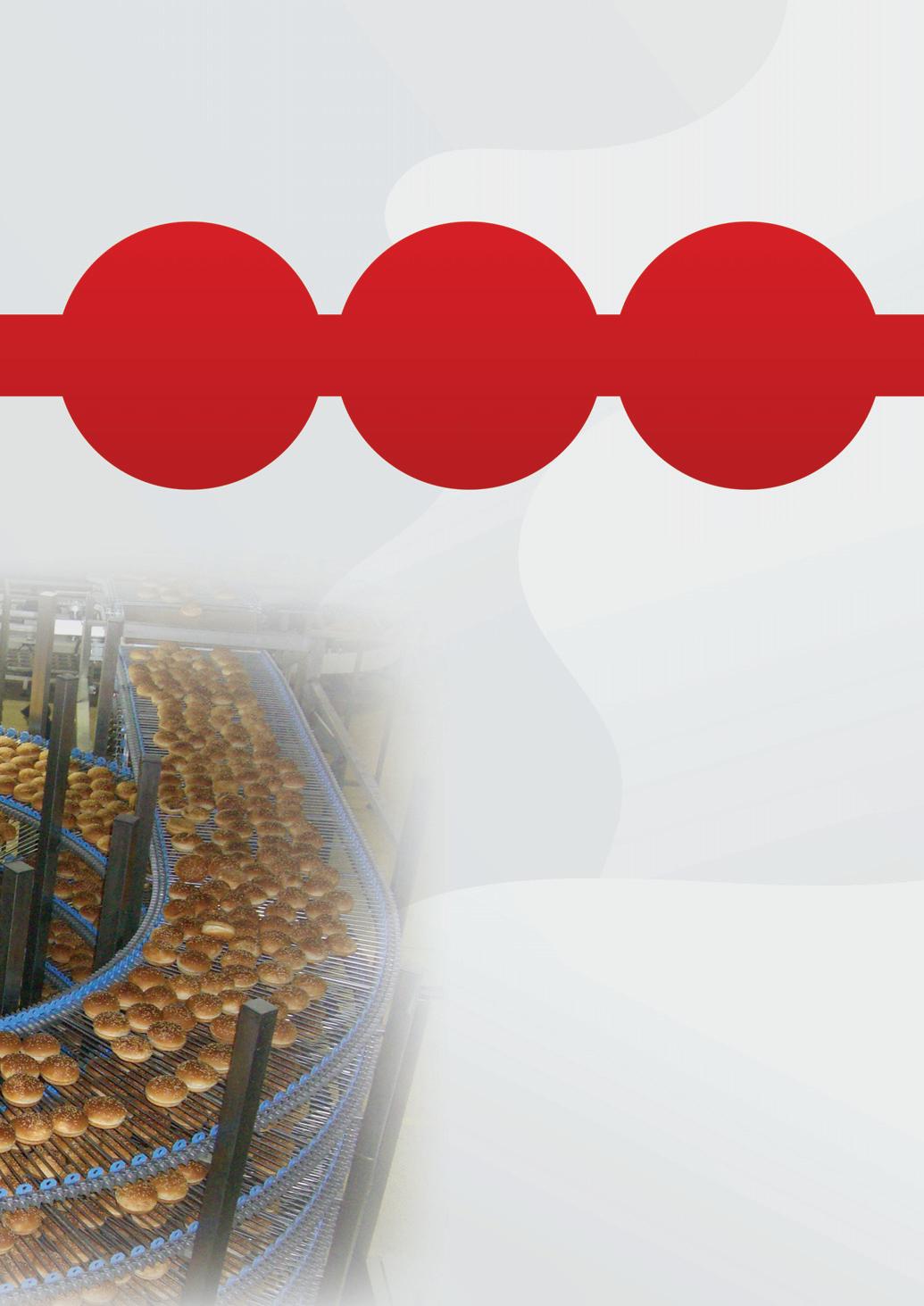

pré pain hobbs house bakery leipomo rosten oy wenzel’s the bakers

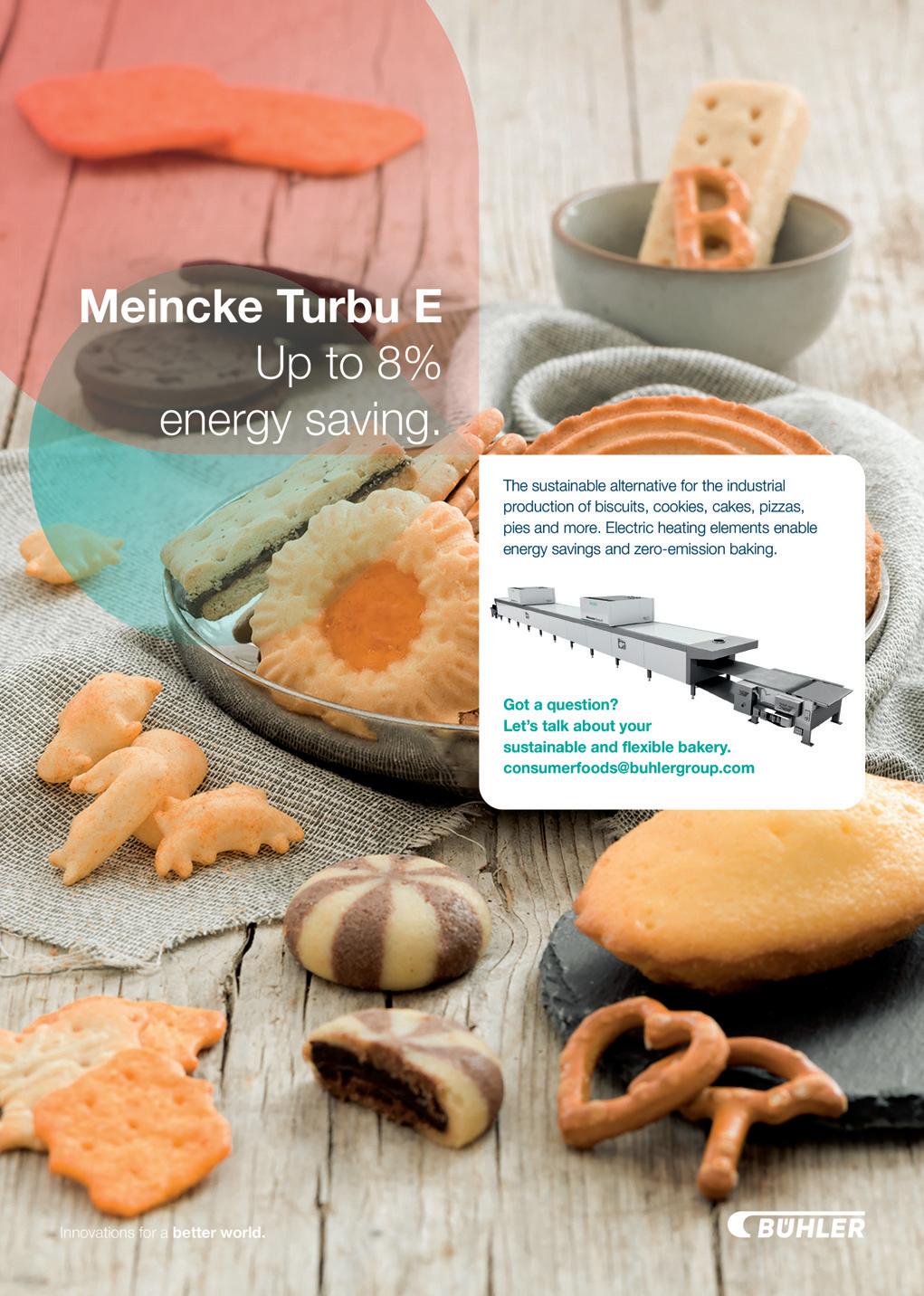

Dutch baker Pré Pain has 30 years’ experience supplying Europe with a delicious range of bake-off lines, including best-in-class french baguettes and petit pains. Commercial Director Gerben Vollenbroek outlined the company’s history and the ongoing series of innovations to enhance the product line, in conversation with Phil Nicholls.

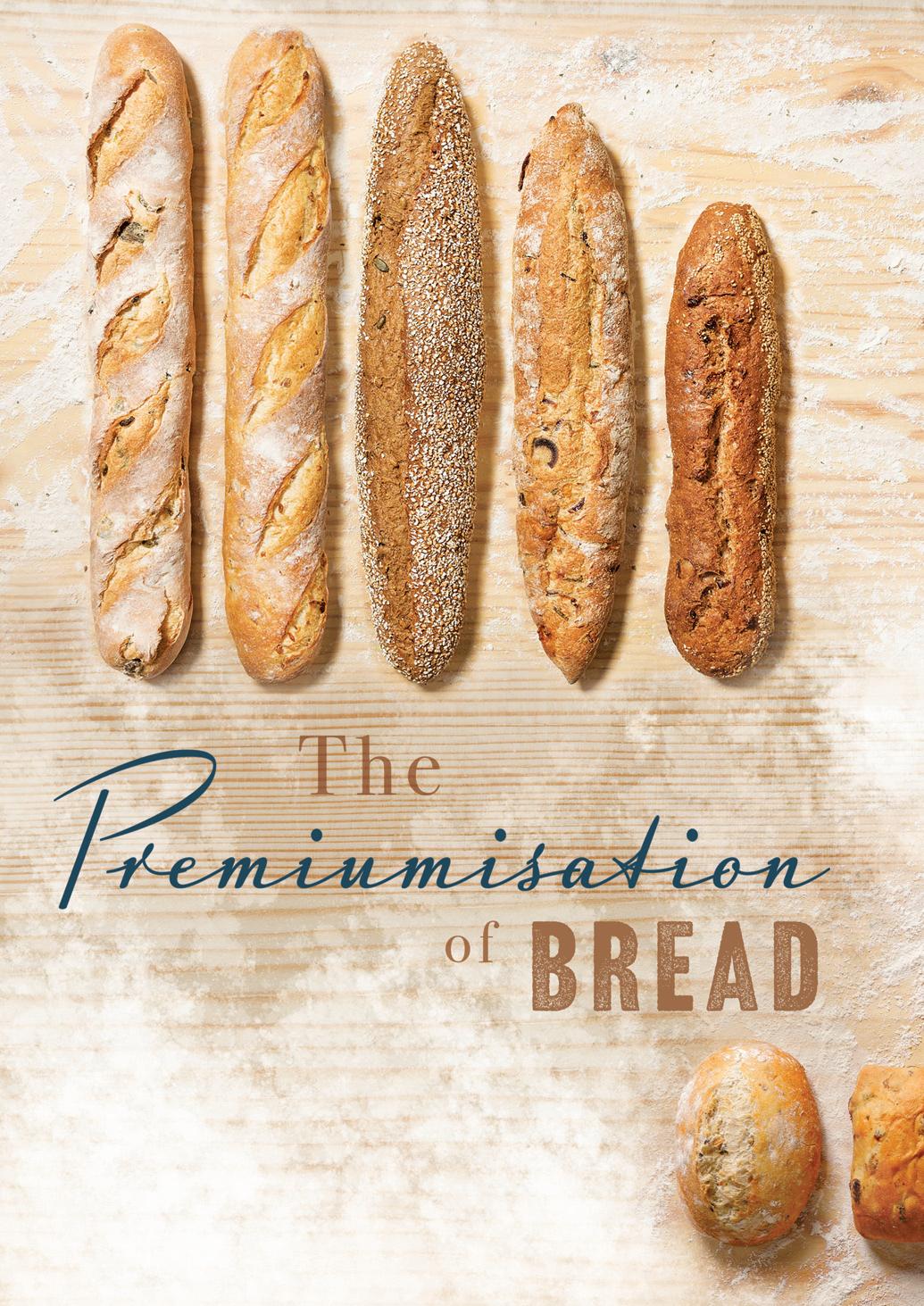

Pré Pain is working through a programme of premiumisation as part of its vision for the future. The company has state-ofthe-art bakery technology and years of experience, but this does not mean that Pré Pain is standing still.

“Our short to mid-term strategic aim,” explained Commercial Director Gerben Vollenbroek, “is to change our portfolio to a more balanced combination of top-quality commodity products on the one hand, and added-value artisan and premium products on the other. This combination allows us and our customers to accelerate growth whilst giving a superior consumer experience.”

Pré Pain’s founding company, Smithuis, started in 1889 as an artisan bakery in Oldenzaal. Smithuis created Pré Pain in 1992 as the first company in The Netherlands to produce ISB bread.

In 2014, Pré Pain established a stone oven line; one of the longest in Europe. In the following year, Pré Pain became a part of ARYZTA, the international bakery company. Further expansion followed in 2017 with the installation of a dedicated sourdough kitchen, then 2022 brought heavy investment in its french bread line with a stress-free dough preparation. The result of this investment programme is that Pré Pain now produces best-in-class french baguettes and petit pains.

T he company remains based at Oldenzaal in the east of The Netherlands, with eight production lines at the facility, five of them being mega lines. The factory has 220 employees, operates around the clock and enjoys BRC and IFS certification. Pré Pain supplies

customers in The Netherlands, Belgium, Germany, the United Kingdom, Ireland and around Europe.

“We have an annual capacity to produce 90,000 tonnes of product,” said Mr Vollenbroek. “Through 2022, Pré Pain created 650 million rolls, baguettes and loaves.

“Our list of biggest selling items includes french and artisan baguettes, kaiser rolls, artisan and italian rolls, plus a premium stone oven loaf that we produce for the UK market. In 2023, we expect our next generation french baguettes and petit pains to be among the biggest selling products.”

The extensive Pré Pain range of bake-off products are primarily delivered frozen however they still produce some ambient product for key customers. This portfolio is steadily being upgraded through the premiumisation programme.

“Our premium portfolio has three pillars,” Mr Vollenbroek continued. “Stone oven sourdough products baked with a living starter culture, next generation french baguettes and petit pains made with a stress-free dough preparation, and finally artisan bread, baguettes and rolls made with roasted and cooked seeds and kernels.

“In the future, we still want to serve our key customers topquality commodity bread, but our anticipated growth will come from this premium portfolio, as we wish to lead the market in innovative and speciality bread products.”

As a market-leading bakery, Pré Pain maintains an ongoing investment strategy to consolidate its position and ensure quality products for customers. “We recently invested in machinery to allow us to roast and cook seeds and kernels, which are then entered directly into the dough, to ensure the best possible taste for our breads and rolls,” Mr Vollenbroek explained. “Later this year, we will take delivery of a new machine that will allow us to produce a new range of rolls in many different shapes and sizes, to accommodate the wide range of requirements from our customers. These ongoing investments all support the growth of our premium product portfolio.”

Across the broad Pré Pain portfolio, there are many features which help the company stand out from the competition. Pré Pain is one of the very few industrial bakers to make sourdough bread with a living starter culture, giving its bread a unique taste. Also, the roasted seeds concept gives a delicious nutty flavour to Pré Pain’s bread.

Alongside these unique concepts, Pré Pain also operates in a highly efficient manner, enabling it to make very affordable high-quality products.

“We are alone in this part of Europe in our ability to make the quality of the next generation french baguettes and petit pains that we are now able to bake,” Mr Vollenbroek said. “The features that set these items apart from our competitor products are the light airy crumb, a very thin crispy crust and the fact that the bread stays fresh for longer.”

Pré Pain works in close cooperation with suppliers and partners, collaborating with key customers to co-develop new concepts and lines. This process involves a shared vision to initiate new product development and achieve category growth.

“Our partners are crucial to our success,” explained Mr Vollenbroek. “We have our own innovation team and an

industrial“PréPainisoneoftheveryfewbakerstomakesourdoughgivingbreadwithalivingstarterculture, itsbreadauniquetaste”

in-house test bakery that cooperates closely with customer teams. We also rely on our supply partners to share new and best practices, helping us to continue to improve what we do.”

Continual improvement is also a feature of Pré Pain’s sustainability programme. The company builds environmental efficiencies into its everyday operations and supply chains. This involves a particular focus on reducing its carbon footprint and all types of waste, notably food and packaging, plus a drive to improve the company’s water usage.

“At Pré Pain, we have installed a rework machine on our biggest line,” Mr Vollenbroek said. “With this machine, we reuse finished breads that have been disapproved due to size or shape, then

recycle them to make new breads, significantly reducing waste. In conjunction, we are making our cooling and freezing equipment more sustainable by increasing energy efficiency.”

While the bakery industry was negatively affected by the recent global crises, bread will always remain an important product for customers. Pré Pain’s strategy of growing with premium products is expected to unlock opportunities to gain further market share in the coming years. The challenge remains to find the right skilled workforce for this premiumisation journey –people such as bakers and technicians.

“We are already executing our strategy to premiumise our portfolio,” explained Mr Vollenbroek. “For the future,

“What excites me is when I see Pré Pain introduce new and successful products into a supermarket or a restaurant; fresh items that help our customers achieve their business goals”

we are looking at investing in new lines that support this growth. We want to further roll out our unique concepts of next generation french bread and stone oven sourdough bread, plus our lines featuring roasted and cooked seeds and kernels.

“Our mission is to serve inspiration,” he concluded. “We work very hard every day to help our customers grow their ISB sales line and, in turn, provide their consumers with tasty and nutritious bakery products. What excites me is when I see Pré Pain introduce new and successful products into a supermarket or a restaurant; fresh items that help our customers achieve their business goals.”

Hobbs House Bakery has been quietly flourishing, pioneering its way through bread baking across a history stretching back to 1920. A name that still conjures quality, innovation and satisfying taste, the fiercely independent business continues to thrive through the talents of brothers Tom and Henry Herbert. Andy Probert sat down with Henry to discuss the company’s desire to 'green-up' its expansion plans, and the true meaning of sourdough.

Henry Herbert is passionate, as he hammers home the truths of shouldering a five-generation hub of innovation with his brother George, the desire to de-mystify what ‘sourdough’ is – and a commitment to bring sustainability to the table.

From their Hobbs House Bakery HQ, located in the Cotswolds in Chipping Sodbury, the brothers enjoy the views of quintessential English countryside. But look closer, and the brothers’ environment is one of industriousness, urgency and no lack of forward planning.

“We remain a fully independent family business, with a pipeline of family members coming through,” said Mr Herbert. “What sets the bakery apart is having very clear strong core values indelibly stamped at its heart.”

The bakery employs 160 people and operates five shops, one in Bristol and four in the surrounding market towns of Chipping Sodbury, Nailsworth, Malmesbury and Tetbury. The business has taken on more wholesale customers, a mix of hospitality and resellers, such as country shops, delis and retailers. “We have seen massive growth on this front in the last decade,” explained Mr Herbert. “We are good at making bread to a high standard. Wholesale now represents 85% of our business.”

The company operates two business models: with fresh products delivered within 25 miles of its production hub, and a frozen range

for customers nationwide. “We offer a consistent 24/6 baking operation, and bake between 130,000 and 150,000 units a week,” he added.

“We see ourselves as custodians of a business, building a legacy with a long-term view. Our team is an extended family, the customers our backbone. We are a growing bakery, but with strong family values driving its soul. We are not dazzled by the bright lights of fast profit and rapid growth.”

With the production hub spread over nine facilities on one site, the bakery is looking to expand and maintain its 10% year-on-year growth of recent times. It has signed a 20-year lease for the site and taken on an additional 10,000sqft, taking its total footprint to 30,000sqft.

“We are rebuilding the bakery,” Mr Herbert explained, “which is about three-quarters done. It will cost about £2 million, but once complete, it will set us up for the next 20 years.”

Hobbs House Bakery began life when a blacksmith hit hard times. He was persuaded by his wife to hang up his leather apron, swap it for a linen one, and learn to bake bread. He began to make bread with less yeast and started using the 'overnight' method, which the family uses to this day.

The business thrived, and in 1970, baked Bristol’s first known organic loaf. The family continued to move with the times, culminating with their Olive Loaf winning two stars at the illustrious Great Taste Awards in 2020. It has perfected baking one of its most loved loaves, the mighty Organic Wild White Sourdough. With a flavour-filled crust, a moist and chewy centre, and an irresistible sourdough taste, the loaf is slowly risen for 14 hours and made with their nearly 70-year-old Sourdough recipe. For the past two decades, the Herbert brothers have continued pushing the frontiers of baking, as well as finding fame on the Channel 4 television series The Fabulous Baker Brothers, showing how anyone can bake.

In 2019, the bakery became the first in the UK to become a Certified B Corporation. This accreditation proves it meets the highest social and environmental standards for people and the planet.

“Community and sustainability have been at the heart of our business since we baked our first loaf of bread over 100 years ago,” Mr Herbert said. “Now, through the B Corp accreditation, we have the stamp to prove it, and this validates what we stand for.”

Hobbs House Bakery’s charitable efforts range from donating 250 loaves a week to the local community to a ‘buy one, give one’ initiative in, which one loaf is donated to children in Tanzania for every gluten-free loaf sold. The bakery has removed all plastic packaging for its online orders and works hard to eliminate waste, such as using leftover croissant dough to make cinnamon buns.

The company’s most important ingredient, flour, is sourced from Shipton Mill, 15 miles away from the bakery. “We have worked with the mill’s owners for over four decades,” added Mr Herbert, “and we mirror their sustainability, provenance and quality values.”