CONIDIA BIOSCIENCE

insidemarine.com

powered by Inside Marine

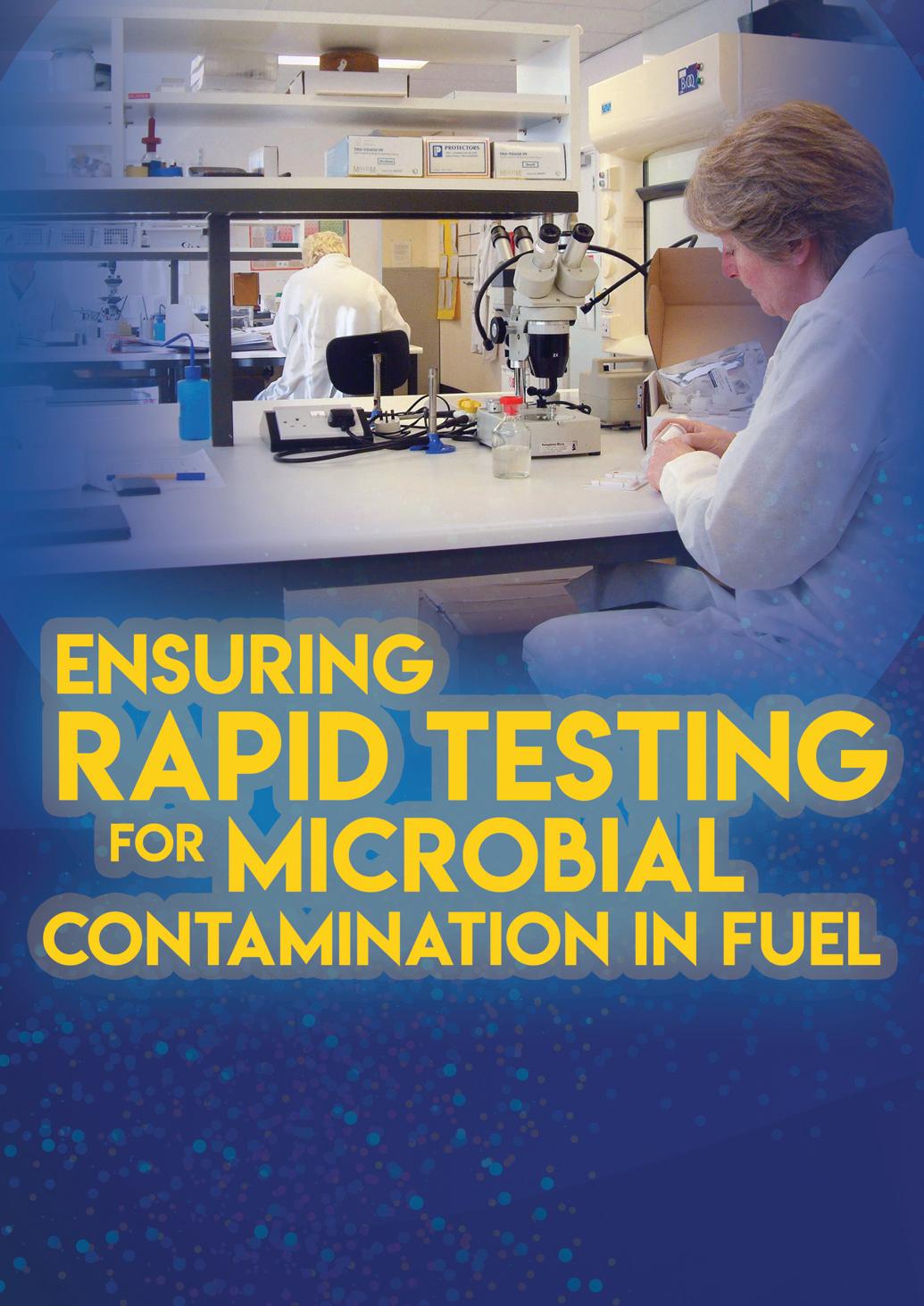

ENSURING RAPID TESTING FOR MICROBIAL CONTAMINATION IN FUEL

Conidia Bioscience is a leading UK-based biotechnology company specialising in developing rapid microbial detection technologies for the maritime and oil & gas sectors. Having passed the milestone of selling its six-millionth microbial contamination test, the company is well-positioned to respond to the ongoing fuel transition process across industry. Technical Consultant Pierre Poitras and Commercial Account Executive Paul Hicks discussed the, company in conversation with Andy Probert.

204 Inside marine

CONIDIA BIOSCIENCE I PROFILE

Conidia Bioscience might be small, but it is a global giant on the frontline of microbial detection technologies. From global heavyweights of the oil and gas sector to maritime vessel owners and one-person startups, Conidia’s testing kits are critical to the efficient working of industry.

In 2008, the company launched FUELSTAT®, a rapid microbial contamination test for diesel fuel. It is an immunoassay antibody test kit for microbe detection and can be used wherever fuel is manufactured, stored, sold or used. Unlike traditional tests, FUELSTAT can run different tests for bacteria, fungus and H-res (known as the ‘diesel bug’) and only finds micro-organisms that damage fuel systems and tank structures. Tests take as little as 15 minutes, onsite, at the tank, compared to others taking at least 48 hours.

Fuel testing kits can be used for many purposes: traditional marine fuel testing

methods have depended on fuel samples being sent onshore for analysis and waiting days or weeks for the result. Microbiological contamination often creates operational issues that can disrupt the use of an asset, such as an aircraft or generator, which leads to the question of whether sending samples onshore for lab analysis is worthwhile or economical.

If left unchecked, it can lead to microbial growth, corrosion and decreased fuel efficiency. A large tank could develop a leak causing fuel to escape into the ground, or, in the case of commercial aircraft, a blockage could cause engine failure and put human life at risk.

Rapid testing

This is where the FUELSTAT kit comes into its own, particularly in the commercial marine industry. In a white paper, Pierre Poitras, Technical Consultant at Conidia Bioscience, highlighted how the increased

Inside marine 205

CONIDIA BIOSCIENCE I PROFILE

percentage of biofuels could raise the cost of fuel and leave it susceptible to microbes.

To help meet environmental regulations and reduce shipping's environmental impact, increasing percentages of bio-components are being added to marine fuels, including additional Distillate Fatty Acid Methyl Esters (FAME) grades, another potential facilitator of increased water content and microbial contamination. These are complemented with new biofuels created using innovative refining processes.

“The heightened threat comes from an increased potential for microbial contamination,” said Mr Poitras. “Dormant spores

of microbes, including yeast, filamentous fungi and bacteria are present in the fuel and, when water and air are in the system, create an ideal breeding ground for them to multiply.”

Utilising a fuel testing kit to identify microbiological contamination at the earliest possible stage is faster, cheaper and less risky. “While sampling can be sent to a laboratory,” continued Mr Poitras, “microbes are living, dynamic organisms. This means the microbial population can change while the sample is in transit and results may not be representative of the tank environment.”

208 Inside marine

However: the FUELSTAT testing kit can be used to test fuel in situ, whether in port or at sea. As a quick, easy and cost-effective alternative, the kit is proven for identifying microbes that can degrade fuel and accurately indicate contamination levels.

These low-cost, single-use test kits are simple, require minimal training and no special handling, and can readily be integrated into day-to-day operations. They provide rapid results, which can be scanned into a mobile app for logging and sharing results immediately from ship to shore.

“They offer an economical and quick way to determine levels of microbial contamination in fuel and enable fuel tank testing while at sea, and any required remediation work to be scheduled for when the ship returns to port,” said Mr Poitras.

The paper acknowledged that increasing the percentage of FAME in marine fuels to

reduce greenhouse gas emissions is a clear winner in the short term. He concluded: “Contamination can occur throughout the fuel supply chain, and simple, onboard testing provides instant results, facilitates optimisation of maintenance procedures, and may save thousands in repairs or lost operating time.”

Milestones and growth

Such has been the effectiveness of FUELSTAT, Conidia Bioscience has sold more than six million testing kits to more than 400 operators and ten major oil companies in over 130 countries, according to Paul Hicks, Commercial Account Executive.

The company, founded as a spin-off from the UK's Defence Science and Technology Laboratory, has achieved critical milestones to become a leading provider of microbial detection technologies and services.

Inside marine 209

These include the development of multiple product lines, establishing partnerships with major industry players and receiving industry-standard accreditations.

In 2016 Conidia Bioscience launched a smartphone app, allowing users to analyse test results, track testing results by asset around the world in real time and receive guidance on how to manage fuel contamination issues.

The company expanded its range with the FUELSTAT Resinae PLUS test kit, which detects fungal contamination in aviation fuel and other fuel types. Conidia Bioscience then received ISO 9001 accreditation for its laboratory services' technical competence and quality management.

Conidia Bioscience expanded into the USA in 2020, with a new sales and service

team focused on the growth of various aviation and diesel sectors. Mr Hicks said FUELSTAT provides the lowest cost to the result of any test on the market and is considered the only actual on-site test that gives dependable results – even in the dirtiest of conditions.

It is also ASTM D6469 compliant, the Standard Guide for Microbial Contamination in Fuels and Fuel Systems, which states in Section 8.3: ‘Ideally, all testing should be accomplished at the sampling site, within a few minutes after a sample is drawn.’ Testing immediately most accurately represents actual fuel system conditions and allows for faster maintenance decisions to be made.

He also described how using rapid microbial detection technologies can help reduce environmental impacts, promote more sustainable fuel usage, minimise the need for re-testing and allow for faster remediation of contamination issues.

Conidia Bioscience intends to expand its range; increasing its FUELSTAT line to include tests for different fuel types, expanding its microbial detection services to various industries and enhancing its digital offerings.

“The company continues developing new technologies by investing in research and development,” said Mr Hicks. “It also

210 Inside marine

CONIDIA BIOSCIENCE I PROFILE

focuses on expanding its global reach by establishing new partnerships and increasing distribution channels.”

Conidia Bioscience is also committed to developing products and services that address sustainability concerns in the industries it serves, potentially including waste reduction and emissions reduction measures. “The change in fuel types and fuel transition for engine types susceptible to contaminants shows that the company is well-positioned to take advantage of that trend.”

The company recently announced a new partnership between Conidia Bioscience and DieselCare AS, which sees Conidia acquire the global distribution of Aquafighter® water removal filters for Diesel and middle distillate fuels. “Water is one of the biggest enemies of fuel systems,” said Mr Hicks. “When present in fuel, water can cause a range of issues, including microbial growth, corrosion, and decreased fuel efficiency.”

Aquafighter captures and eliminates water directly in the tank. By using Aquafighter, individuals and businesses enjoy a range of benefits. These include increased fuel efficiency, improved engine performance, reduced maintenance costs and longer fuel system life. Plus, with its environmentally friendly formulation, Aquafighter is a responsible choice for those looking to reduce their carbon footprint.

Increasing competition, regulatory changes and global economic conditions made the industry landscape challenging, as Mr Hicks clarified: “Through transparency,

open communication, being responsive and dedicated to innovation and collaboration with our partners, Conidia Bioscience continues to thrive in an ever-changing world.

“Our long-term relations with suppliers and clients are a testament to our success. Conidia Bioscience is well-positioned to meet the evolving needs of its clients and the industry. The potential for our technology is limitless.” n

Inside marine 211