CETCO is the construction technologies unit of Minerals Technologies Incorporated and consists of an international team of clay mineralogists, chemists and polymer scientists. John Fletcher, Business Development Director, Eastern Hemisphere, explained to Hannah Barnett how the company transforms ordinary minerals into extraordinary technology.

When it comes to the treatment and filtration of produced water (a byproduct of oil extraction), CETCO are the go-to business serving the oil and gas industry.

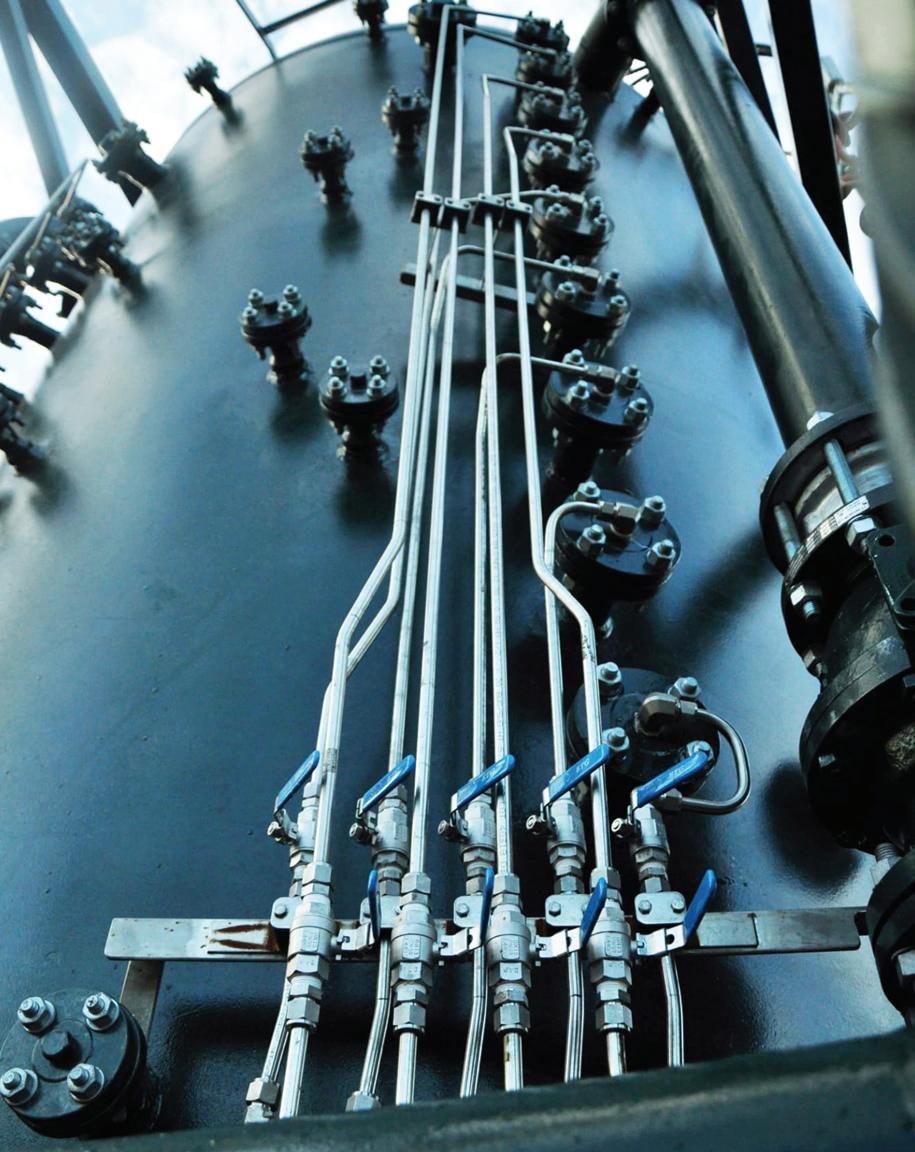

“We are specialists in removing hydrocarbons and solids from produced water,” said Business Development Director, Eastern Hemisphere, John Fletcher. “We deliver a unique service offering, as well as manufacturing and selling permanent process equipment. We offer troubleshooting across a client’s production systems because we understand the fluids, the particle distribution for solids and how oil characteristics might change with each bit of equipment.

“We look at what’s upstream, what’s downstream and what’s happening across valves – basically, anything that affects the ability to remove oil from the water. This is driven towards reducing the

amount of oil that is discharged to the sea or to new injection wells. It’s all about that environmental compliance.”

The full package

CETCO is a global enterprise. From Aberdeen, the company runs a gateway to Europe, Africa and the Middle East. This includes an entity in Nigeria, and support across most of sub-Saharan Africa. There is also an ongoing joint venture in the Middle East, as well as entities in the Far East, Australia, Brazil and the US.

With a fairly unique service offering, CETCO has extensive experience treating FPSOs; vessels which traditionally struggle with accumulated water and separating fluids to specification.

“Assets are generally designed and built based on the characterisation of fluids at the start of production,” said Mr Fletcher. “What will happen is that the profile of the

fluids produced over the lifetime of the asset will change; and so, we tend to focus on brownfield applications.”

The company operates witing the ‘Five Ds’ method: Define, De-risk, Design, Develop and Deploy.

Define involves understanding the fluid. CETCO will visit an asset and use analysis equipment and a variety of tools to conduct a study and site survey. This allows the company to create a report alongside the customer.

“Then, we offer the client the ability to pilot that technology if they want,” Mr Fletcher explained. “We call it de-risking, so we can prove that a solution will work before a client spends millions of dollars buying and installing a permanent piece of equipment.

After that we can design, develop and deploy the product.”

Commonly referred to as the ‘mineral of a thousand uses’, bentonite is at the centre of much of what CETCO does. From innovative lining systems and remediation technologies to cutting-edge waterproofing membranes and drilling products, CETCO continues to find new ways to utilise bentonite and help customers worldwide.

One such product is CrudeSorb®, which is extremely efficient at removing oil, grease and soluble organics from water systems.

“CrudeSorb is a modified bentonite clay-based product which goes through a manufacturing process and has excep -

tional oil adsorption properties,” Mr Fletcher explained. “We use it in a wide array of temporary solutions and applications including pipeline decommissioning. It’s non-regenerable, but it holds on to the impurities, so it’s exceptionally effective.”

The company also has the capability to manufacture derivations of the product focused on a specific impurity, such as mercury. This can be used in areas of the world where mercury is particularly prevalent, such as parts of Asia and the Northwest shelf of Australia.

Alongside impurities like mercury, CETCO is also focused on tackling the ‘forever chemical’ PFAS through its FLUORO-SORB® adsorbent. The

proprietary, NSF-certified product is designed to support remediation efforts surrounding PFAS globally. Vetted by leading research universities, the FLUORO-SORB adsorbent is proven to be both effective and economical.

“PFAS doesn’t biodegrade, and it’s been used in a variety of chemical products for decades,” said Mr Fletcher. “Theres’s bio-accumulation of PFAS in firefighting foams, Teflon and much more. So, there’s a big push to address the problem and to capture and destroy it based on our bentonite clay, because of the adsorption properties. We developed FLURO-SORB specifically and it is very flexible in the way it can be deployed.”

Then there is Hi-Flow®, “the workhorse of our product line” according to Mr Fletcher. The simple and robust system treats high rates of free oil in water, allowing the operator to discharge fluid back into the environment while maintaining the compliance requirement. Working in the reverse way to CrudeSorb, fibrous media is compressed into a canister and fluid is passed through the media from the inside out, forcing oil droplets together.

“What goes in as small tight oil droplets comes out as very big ones: it almost looks like a lava lamp,” Mr Fletcher explained. “They float up and gather on the outside of the media and then you’ll get big bits floating off. We use this in most of our filtration applications – it’s an amazing technology and hugely versatile.

“We use Hi-Flow in a lot of our decommissioning scopes, and we deploy it all over the world as one of our very reliable core technologies. The benefit of Hi-Flow is that it doesn’t consume. So, the oil will gather at the top and we take that out, but the type of media will last for several years, if it’s restricted correctly. It gives a really good performance and a low operating cost.”

Both CrudeSorb and Hi-Flow are manufactured in-house, and CETCO is a largely vertically integrated business, with its own designers and ownership over much proprietary media. When it comes to process equipment, though, the company works closely with regular partners and maintains strong relationships with customers on an international scope too.

Due to the size of sector, and the type of company that CETCO is, employees can have a direct influence on the direction of the business and the delivery of products, according to Mr Fletcher.

“As a result, we have close relationships with our clients on a global basis,” he concluded. “Whether that’s international oil and gas operators, or our particular focus on FPSO providers.

SBM is one of the big FPSO providers, based in Monaco. It has an engineering centre in the Netherlands and an office in Portugal. We do a lot of work with SBM in Malaysia and most of its building yards are in Singapore.

“The end product for many of these FPSOs is going to Brazil and Guyana. So, within our

everyday operations, we can be talking with Brazil about the operation of an FPSO or we can be having discussions with the client engineers in the Netherlands, and then liaising about a build in Asia. That’s a really interesting, international dynamic that we have: yes, it’s challenging, but it’s exciting too.” n