Drilling in the jungles of sub-Saharan Africa is no small feat. With temperatures that routinely can reach 40 degrees Celsius and humidity of 90-95%, it requires specialised people, dedicated machinery and particular expertise - precisely the formula that Caroil has spent two decades perfecting. Richard Hagan spoke to CEO & General Manager Steve Lamet and Business Development & Contracts Manager Bernardo Pettenatti to find out what it takes to be successful in the jungles of Africa.

Caroil, headquartered in France, is a specialist contractor providing drilling rigs and associated services for oil and gas operators in Sub-Saharan Africa. Thanks to a highly qualified workforce of technical personnel and a diverse fleet of four drilling rigs, with capacities varying from 1,200 to 1,500hp, Caroil is capable of addressing the most challenging drilling and reservoir conditions faced by its customers.

With nearly 700 wells drilled to date, Caroil continues to maximise its competitiveness in the drilling services

industry through its technical expertise and mobilisation of new, state-of-theart equipment.

Company history

Caroil was created as the drilling subs idiary of Maurel & Prom Group, and officially launched its operations in the M’Boundi Field in the Republic of Congo in 2003.

Initially, the group’s strategy was to have Caroil perform all of the group’s drilling projects worldwide. However, amidst a global oil boom in the early

‘00s with accompanying high demand for rigs, Caroil substan tially expanded its fleet, providing drilling services to several other oil and gas operators in the region.

At its peak, Caroil had a comprehensive fleet of 15 drilling rigs operating in seven countries and two continents. After the major industry downturn between 2014 and 2015, the company decided to refocus its strategy and resources, consolidating its activities exclusively in sub-Saharan African markets.

The decision soon bore fruit, and by 2018, Caroil had established itself as a specialist contractor in Sub-Saharan Africa, with a new executive and management team. Caroil was present in Gabon and Congo, while active in other challenging oilfield environments including Cameroon, Tanzania and Uganda.

Training tomorrow’s professionals

Today, Caroil has a workforce of approximately 230 highly skilled employees spread across two major facilities, consisting of headquarters and training centre in Pau (France), as well as an operational

base and a modern training centre located in Port-Gentil (Gabon).

At its operational base in Gabon, Caroil s upports its rig operations in the region with maintenance, repairs and rig-up preparations. The training centre, accredited by IWCF and IADC (industry-recognised bodies), delivers technical drilling and well control programmes to several organisations in the region. This training centre is a highlight for Caroil, according to CEO & General Manager Steve Lamet: “Students enjoy all of the necessary amenities, plus a state-of-the-art well control and drilling simulator, allowing students to immerse themselves in drilling operations, all from the comfort of our training centre.”

The right tool for the job

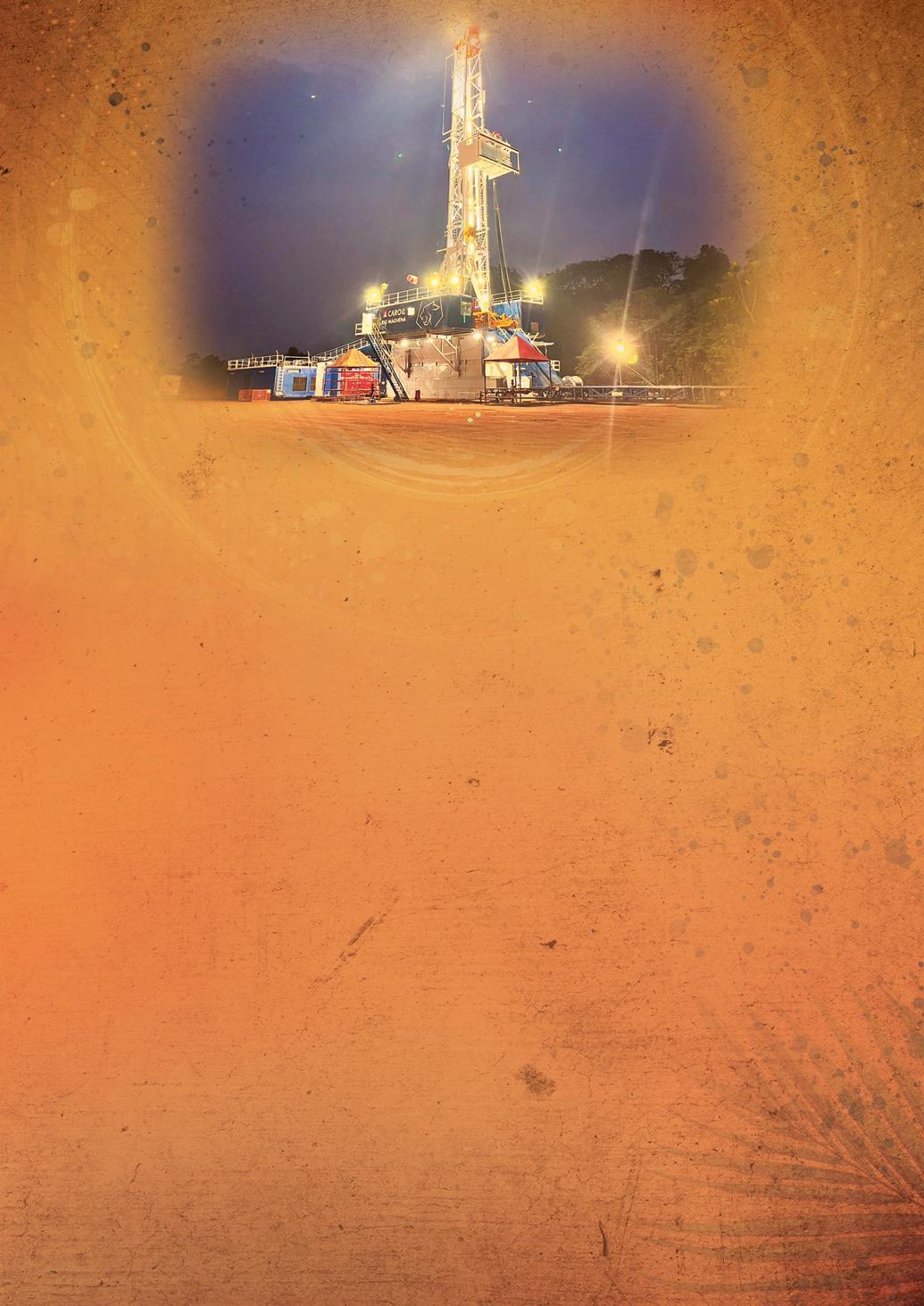

Caroil recently welcomed an exciting and very impressive new addition to its fleet: Rig Maghèna is a 1,200hp AC Electric

drilling rig specifically modified to conquer the challenges of sub-tropical drilling oper ations. The rig has state-of-the-art technology, featuring equipment from top manufacturers in the industry. With cyber chair controls, alongside other advanced tools, Caroil expects to deliver higher drilling and rig moving performance for its customers, thus supporting them in optimising their projects and costs in a highly competitive environment. Many other equally impressive specifications confirm that Rig Maghèna is a drilling tour de force.

But getting it to its present site was not easy. “Sourcing and purchasing Rig Maghèna was a very challenging and demanding project,” said Business Development & Contracts Manager, Bernardo Pettenatti.

The rig was sourced and then re-designed and fully recertified in

ELECTRIC HORSEPOWER INC.

Electric Horsepower Inc. designed and manufactured Rig Maghena through a collaborative approach, producing a high-specification AC double that we are confident will be a high performing rig for years to come.

As an industry leader in drilling rig refurbishments and AC upgrades, EHP is excited with the deployment of Rig Maghena for Caroil.

Edmonton, Canada, a project lasting eight months.

“The mobilisation of the rig from Edmonton to Port-Gentil, Gabon, was very complex,” continued Mr Pettenatti. “We moved the rig in convoys of trucks for approximately 3800km from Edmonton to Houston, where it was placed on a vessel for shipping to Gabon That, in itself, was a milestone for us as it involved coordination with multiple service providers and customs authorities in three different countries.

“ The rig was then moved on river barges and trucks to the drilling site of a major operator in Gabon and fully rigged-up fo r the commencement of operations. We’re confident that Rig Maghèna will be a game-changer not only for Caroil and Maurel & Prom Group, but also for our other customers in the region.”

Rig Maghèna now deservedly takes its place as a centrepiece in Caroil’s fleet, allowing the company to decisively deliver modern, high-tech drilling technology to clients in Gabon and other markets. “It’s

a clear example of Caroil’s constant investments in the modernisation of its fleet,” said Mr Pettenatti. “It features a state-of-the-art design and rig technology and will allow us to substantially enhance the drilling and rig moving performance we can offer our customers.”

Solving challenges

Caroil has a strong reputation for delivering specialised drilling services in subtropical Africa, one that has been hard-earned because operating in that environment is challenging. “The specifications of our rigs are very important to our success,” Mr Lamet noted. “The rigs must be tropicalised to operate in these regions, as the temperatures frequently reach 40 degrees Celsius, with air humidity at between 90 and 95%. Therefore, the rig must be designed and rated to operate in these conditions.”

Caroil’s operations must resolve additional challenges relating to remoteness and environmental sensitivity. “This requires us to carefully plan

and organise things ahead of time,” said Mr Lamet, “Especially given the difficulties in obtaining parts and services in these areas, as well as ensuring that we are complying with the environmental and safety regulations of the countries in which we provide our services.”

Throughout its history of operating in various African countries, Caroil has developed a track record of being a flexible and creative contractor, focused on finding solutions to its customers’ drilling challenges. A project that Caroil carried out between 2019 and 2020 in Gabon is a particular highlight of its capabilities in that regard.:

The project involved drilling an exploratory well located within a logistically challenging and extremely environmentally sensitive area. It consisted of placing Caroil’s C07 (a 1500hp Electric Rig) onto a combifloat which then moved approximately 5km up a man-made river channel to the wellsite area. The well was located in a swampy, flooded environment, making it

extra-challenging. Some features of the rig had to be redesigned simply in order to get the rig onto the barge.

Despite these substantial challenges, the project was a success, and executed as planned, without any incidents or accidents.

In conclusion, Mr Lamet touched on the company’s vision for its future: “Given the success with Rig Maghèna, we hope to develop further opportunities to replicate that approach for other clients. In a time when the fleets across the region are ageing, it’s all about understanding the customer’s needs and then sourcing and redesigning a rig to fit those needs, followed by efficiently mobilising, commissioning and then safely operating the rig for that specific customer.

“Ultimately, we hope to continue driving our reputation as a contractor with technical knowledge and proven-track record in delivering fit-for-purpose rigs and solutions, with the ability to address the specific needs of our customers.”