ASTRA FARMS

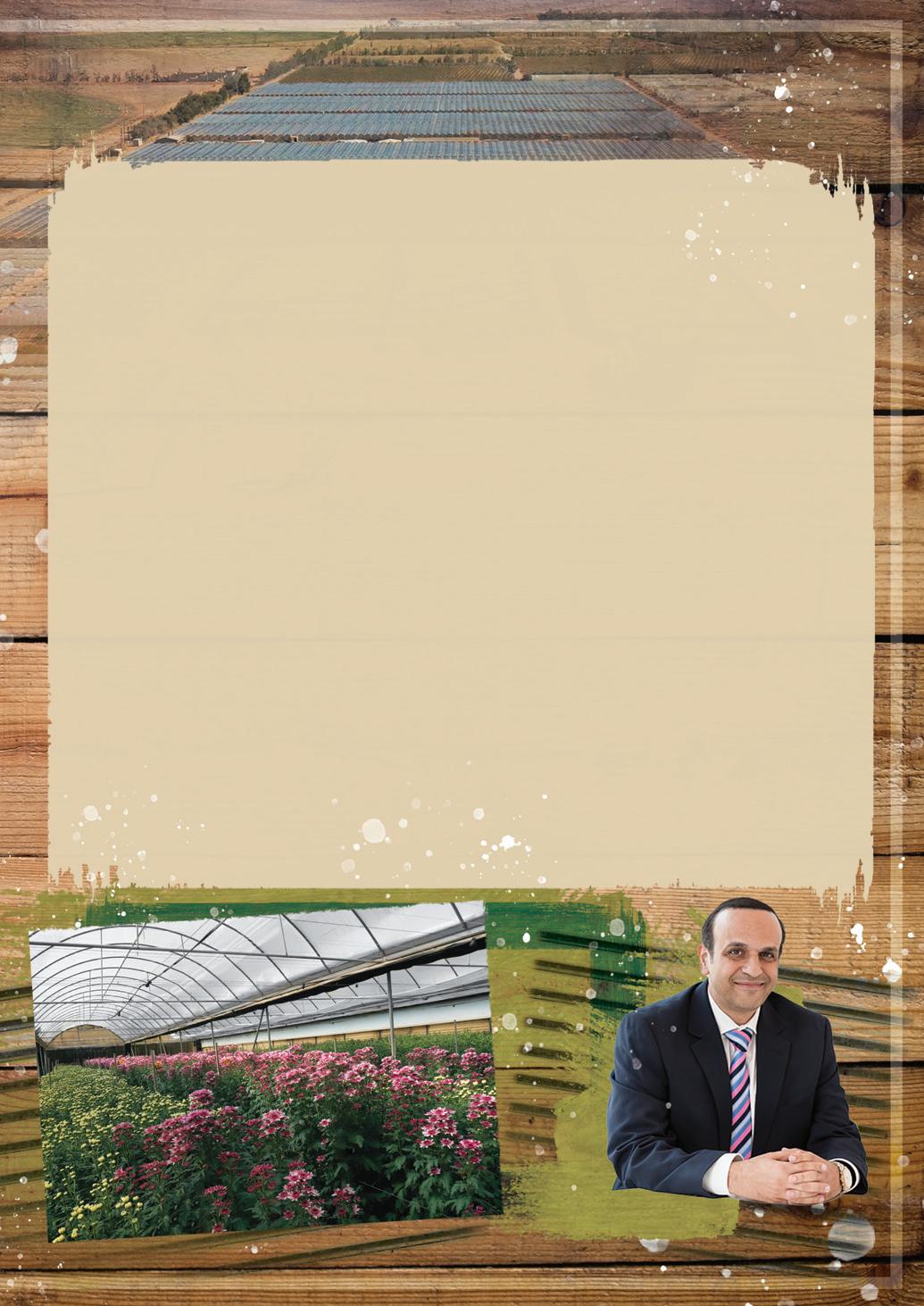

Astra Farms, based in the Kingdom of Saudi Arabia, is one of the world’s largest breeders and providers of quail, catering to an insatiable demand across the Gulf region and tapping into consumer trends for nutritious and healthy products. Deputy CEO and Chief Operating Officer Hasan Rimawi told Andy Probert how this unassuming bird is now at the heart of an aggressive strategy to grow internationally.

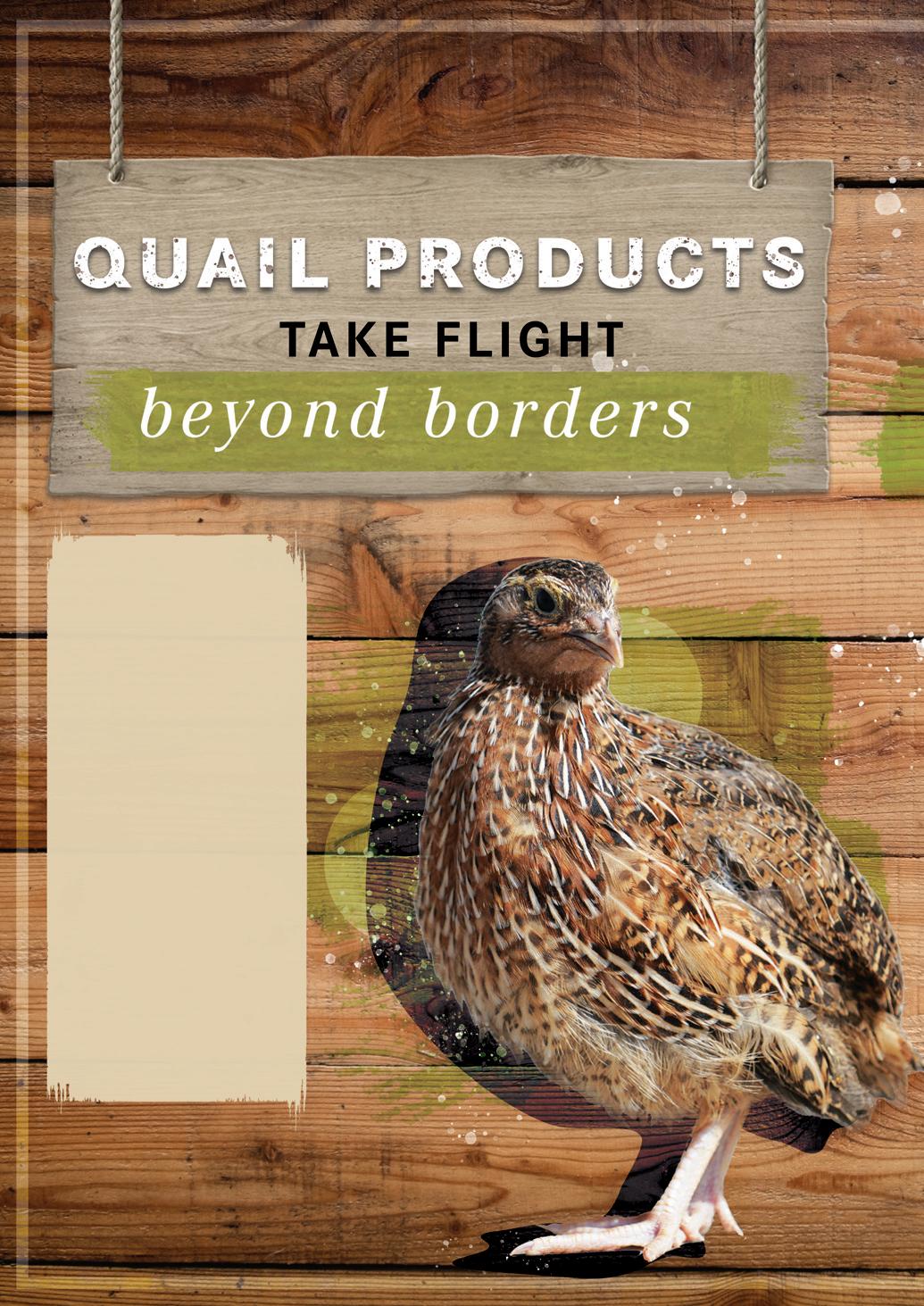

Widely regarded as one of the jewels in the crown of food production in the Gulf region, Astra Farms has exciting and ambitious plans to take its great tasting and grain fed range of quail products to Europe and the US.

Farm founder Mr Sabih Al Masri saw enormous potential in quail meat in the 1980s and created a farm for 1.5 million birds. That grew to a capacity of 30 million birds per annum by 2015, making it one of the largest vertically integrated quail operations globally.

But Astra Farms goes well beyond mere animal husbandry. It hosts a complex, circular business with 10 farms (with 10 rooms each) and processing facilities equipped with the latest technologies for quail farming, egg incubating and hatching, slaughterhouse, and packing to assure uncompromised highquality products that consumers can trust.

“Our quails are pure, low in cholesterol, and loaded with vita mins and minerals. They are naturally grown and grain-fed, free from antibiotics, growth hormones and preservatives,” asserted Mr Hasan Rimawi, Deputy CEO and Chief Operating Officer.

“That’s why Astra’s quail are renowned for being the best quality and our quail eggs for their great taste and loved by con sumers, especially children, as they offer superior health bene fits compared to poultry eggs.”

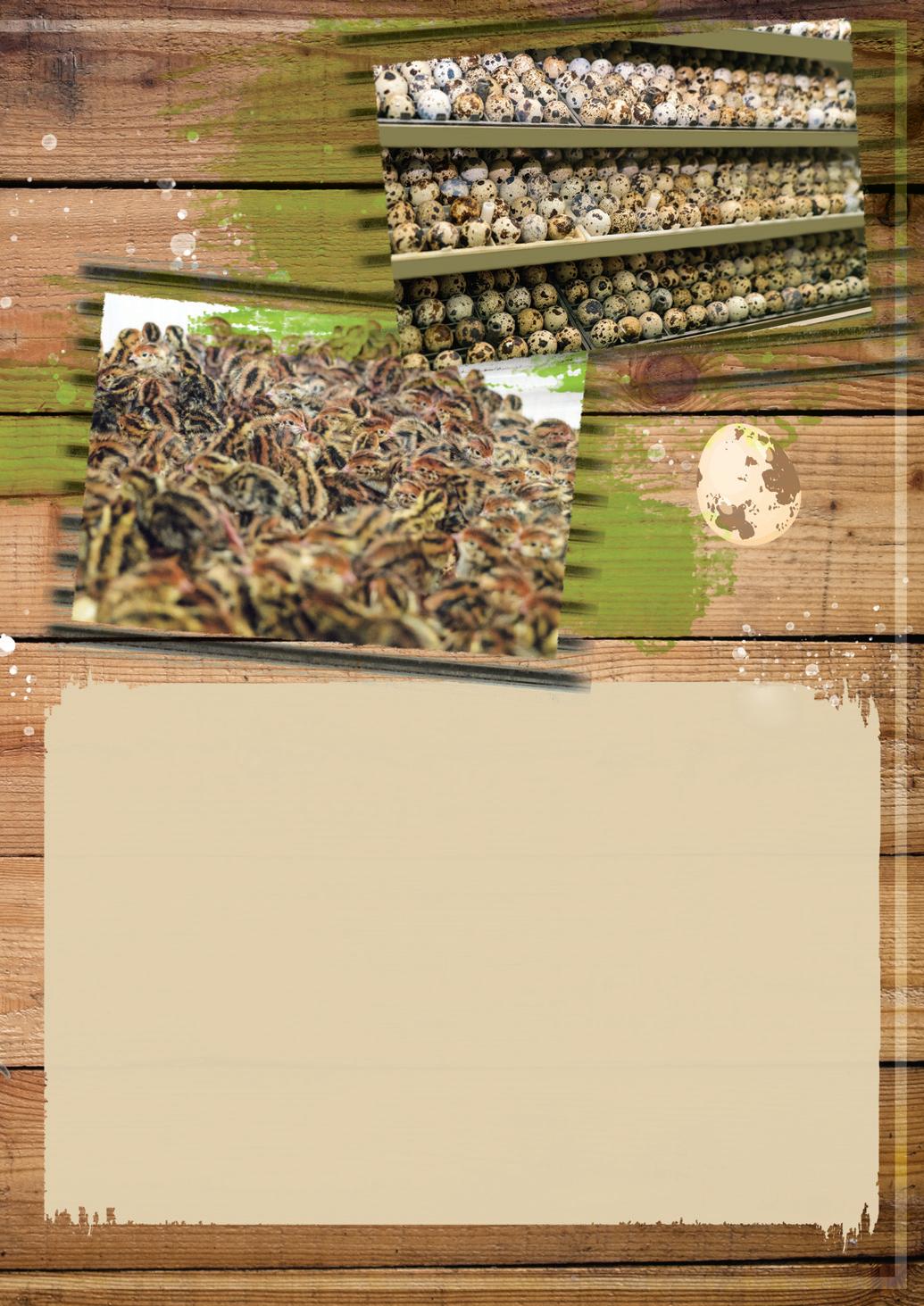

The company’s farms and slaughterhouse, in Tabuk, in northwest KSA, are managed and operated by a skilled team and advanced moni toring systems to ensure the highest health standards are maintained at all breeding stages, in addition to production, packaging, and storage.

While the slaughterhouse is BRC-certified, quail is processed according to Halal principles and monitored through an ISO 22000-

approved food safety management system to ensure the highest quality and healthiest products.

“Traceability is exceptionally important, so it is controlled and tracked,” Mr Rimawi added. Products are distributed through Astra Farms’ distribution networks, mainly across the Gulf region, with the aid of its modern transportation fleet.

As part of its food innovations, Astra Farms has introduced mari nated quail products that are ready to cook for consumers to use for barbequing and quick meals. The company also plans to intro duce new and exciting products be in 2023 and 2024. These will include value-added quail eggs and meat, and new packing for chilled products.

Having recruited a new export executive and team, Astra Farms plans to showcase products and capabilities at international exhibi tions and forge new partnerships with key players.

“We are very interested in partnering with interested parties to make these quail products available to their local consumers and Horeca clients in different countries. We have successfully done this already in the Gulf countries,” said Mr Rimawi.

Astra Farms is set to pilot different exciting initiatives in mid-2023 in KSA and then expand.

Mr Rimawi explained: “We will be working with health experts and nutritionists to create a mechanism to communicate the products’ benefits. We want to expand our quail offerings globally where we have all the key enablers to make it a success. By implementing new strategies, we can grow at speed and with focus.”

The passion for natural, healthy and great-tasting food has been part of Astra Farms’ DNA since it was established in 1978. Initially based on 25 hectares, the company now has 3,300 hectares, pro viding a wide array of quality fruits, livestock, quails, poultry, plants, fresh cut flowers, processed food, as well as trading in a variety of food products.

Operations are supported by 20 glasshouses and 56 greenhouses over 26 hectares, around 1,000 hectares of fruit orchards, two slaughterhouses for chicken and quails, a dairy processing plant, two animal feed mills, a wastewater treatment plant, food pro cessing facility, packaging and polystyrene factory, and a fruits and flower packing hub.

Its orchards and groves produce peaches, apricot, nectarines, plums, pears, grapes, pomegranate, oranges, mandarins, tanger ines, lemon, grapefruit, dates and figs. With the first R&D centre in the area, and nurseries for seedlings, experimental plots and stringent quality control systems, Astra can maintain the highest product quality.

The company’s capacities include 10 million poultry birds annually, 10,000 tons of fruit per annum, 1,500 tons of food processing, 2,100 cows/calves that produce 6 million litres of milk annually, and a 30 million flower stem capacity.

Employing 1,500 people, Astra reaches its customers via a wholly owned state-of-the-art logistics system that includes packaging facili ties, warehousing, and a distribution fleet, which includes modern refrigerated trucks.

Astra Farms has amassed a 28% market share in selling poultry products in Tabuk and has a national presence and majority market share in quail. As the region’s largest flower producer, it sells an estimated one in five stems across KSA.

Astra Farms has built an extensive database of suppliers in opera tion, domestically and internationally. Its unique advantage was being part of a larger group of companies, some of which are leaders in their domains and provide services or produce some of the raw materials.

Becoming one of the first agricultural projects in Tabuk, Astra Farms has seen many companies established to serve its needs, then growing in stature as the farms’ operations increased.

“They continue to serve us and based on our mutual history and cooperation, we receive their best services, competitive prices, and excellent payment terms,” said Mr Rimawi. “We always look to partner with leaders in every category. Hence, we have established long-term contracts and strategic relationships with top packaging manufacturers in the Kingdom.”

In recent years, Astra has tapped the growing market of pro cessed food.

“We began trials of importing some private label products to test the market, and those products that showed signs of success were signed on long-term contracts,” said Mr Rimawi. “We have plans of a joint venture to establish those products in the market further and explore export opportunities to neighbouring countries.”

There are also plans in place to initiate a manufacturing capability to produce ready-to-serve products with one of its suppliers in Tabuk by 2024.

All these various actions and strategies have enabled Astra Farms’ natural product range to be widely respected for quality and superior taste. All dairy products are 100% made from cow milk without preservatives or artificial colouring; chicken is the freshest and tastiest on the market, and grape leaves have the best taste and quality on the market.

The strategy for the next three years is to adapt and innovate to reduce operational carbon emissions and waste. Astra Farms has already implemented a central treatment plant project to treat all types of liquid waste produced in industrial and residential processes.

It utilizes water output onto watering trees as windbreaks on the farms and reuses liquid fertilizers resulting from the irrigation of roses through reuse by adding quantities according to the percent ages found in the excess water from irrigation operations.

Mr Rimawi said: “We also extensively recycle all cardboard and plastic waste through third party recycling plants, and are exploring several strategic projects to manage any negative impact.”

Our strategy includes installing solar energy to reduce the dependence on diesel; recycling and converting waste from slaughterhouses into protein; converting waste from quail birds and agricultural waste to fertilizer; and composting that results in organic fertilizers for its trees.

Flourishing, at pace Global uncertainty has been a major challenge whether fuelled by the Ukraine conflict, drought in South America, new Covid outbreak in China, or constraints on the supply chain.

“Prices of animal feed have gone out of control, increasing by 30-140% in the last 12 months,” commented Mr Rimawi. “Shipping, logistics and fuel costs have all risen, impacting most operational expenses and transportation and distribution costs.”

He added: “Despite these pressures, we have not taken any shortcuts to reduce our quality or compromise our brands. With the growth of KSA and its population, we are now looking at aggressive distribution plans and executing a new sales struc ture to help us achieve that.

“New products are essential. We recently launched a new line of ready-to-eat products and consumer packs (23 SKUs), and consumer feedback has been great. We also plan to offer new products in quail and dairy, while strengthening our presence in channels we haven’t served aggressively before, such as Horeca and wholesale.”

Mr Rimawi concluded: “Growth opportunities that we can seize on really excites us. We are on a mission to be at every breakfast, lunch or dinner table across KSA and beyond. We believe that what you put into your body matters, which is why we strictly produce the most nutritious and best-tasting foods that nature offers.” n