Astilleros y Servicios Navales (ASENAV) continues to set the standard as a leading shipyard in South America for its world-class quality approach and adoption of new technologies for ‘greener’ shipping. With several projects on the go or planned, the future looks immensely bright, confirmed Business Development & Marketing Manager Germán Schacht in discussion with Andy Probert.

ASENAV, the famous Chilean shipyard, is experiencing an immensely productive period, having navigated through Covid and being close to its 50th anniversary. It has confirmed new shipbuilding projects, approved or planned, through 2026.

The family-owned shipyard, located on the Calle-Calle River in the city of Valdivia, 15 km from the Pacific coast, continues to be a model of world-class production quality and at the forefront of technological development in meeting modern challenges for ’greener’ ships. Business Development and Marketing Manager Germán Schacht is the third generation to enter the business, founded by his grandfather, Eberhard Kossmann.

“Our shipyard offers a global showcase for Chilean engineering and is recognised as one of the most important on the Pacific Coast,” Mr Schacht said. “The shipyard continuously scales the highest quality standards required and is a renowned shipyard in South America, which comfortably maintains itself competing shoulder to shoulder with global players.”

Powering ahead

ASENAV followed up on the completion of two vessels for the Chilean aquaculture industry: Patagon X, a 69.5m live fish transport vessel and the tenth construction for Patagonia Wellboat, a leader in the live fish transport vessels segment of Chile, and the Owurkan, a first, unique deworming ship of its kind developed to treat different diseases that affect salmon.

Today, ASENAV nears the delivery of the Patagon XI, a live fish carrier with a fish tank capacity of 3,000cbm. The 80m vessel built for Patagonia Wellboat is diesel-electric powered and will be one of the largest vessels built in the Americas for the salmon farming industry, with Chile second only to Norway.

“The ship is equipped to reduce its gas emissions” said Mr Schacht. “Her size reflects the growth of the industry. With a large cargo volume in two holds, she can transport up to 400 tonnes of fish from the farm site to the processing centre. That means improved efficiency, better loading and unloading times, and fewer hauling trips.

“The ship has an oxygenation system based on low pressure and high water flow. This allows greater efficiency in

achieving oxygen concentration levels and treats the water discharged into the sea so that it does not contaminate the water in the area where the ship operates or affect local biodiversity.”

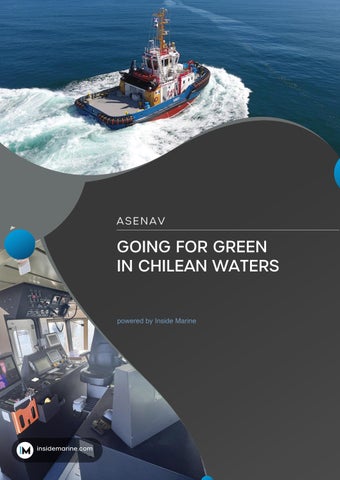

Another recent milestone was the construction and sale of a powerful speculative 25m ASD tug with 75 tonnes of bollard pull to the customer Ultratug. The ASD-type tug, designed and built by ASENAV, named Grey, is equipped with a firefighting system, MAN engines, a carbon fibre shaft and Kongsberg propellers. It is already operating in the port of Arica.

“The speculative nature of this project testifies to the strong financial position of the shipyard to finance the construction itself, its precision in cost control, discipline in execution time and trust in the technical abilities of our staff and suppliers,” said Mr Schacht. He also anticipated the growth and needs of the tugboat industry.

Ultratug and ASENAV enjoy an invaluable long-term relationship dating back

30 years. ASENAV has built 32 ships for this company, with the first still operating in Pisco, Peru.

National pride

One of the main objectives of ASENAV is to deliver a 31m fishing and oceanographic research vessel for the Instituto de Fomento Pesquero of Chile.

This will be the first oceanographic research vessel designed and built in the company’s 50-year history. Scheduled for the end of 2023, it will be used for maritime exploration for scientific purposes, operating along the Chilean coast and navigating the fjords of southern Chile. She has been named in honour of the Chilean oceanographer María Ángela Barbieri.

The vessel will capture fish, crustaceans and other species for research and will have scientific equipment that makes it an optimal vessel for meteorological data. Its main features include a 3m draft and low emission and vibration systems, which allow it to work in shallow areas while being less invasive to the maritime ecosystem.

“This demonstrates the great confidence that national institutions have in the worldrenowned capabilities of our shipyard,” Mr Schacht said. ”A ship built in Chile for the country’s maritime navigation, and in honour of a world-renowned biologist, is a source of great national pride.”

ASENAV plans to build another speculative tug, the RAstar 3200-W Escort Tugboat. The 32m vessel, with 80+ tonnes of Bollard Pull, has been designed with precision by the Canadian engineering office Robert Allan and represents the first alliance between both companies.

“This project provides the shipyard with a great opportunity to expand its presence in other international markets,” said Mr Schacht. “Given the success in selling its first speculative tug, Grey, the shipyard’s strategy is to build even bigger.

“We chose this larger and more powerful design, where its manoeuvrability, speed and strength stand out, as we see that the market needs these boats to operate in different formats globally.”

The vessel will be easily navigable by towing the vessels laterally, maintaining adequate stability during entry and exit to and from terminals, as well as navigation through demanding areas. It will be equipped with a firefighting system,

a misting system to allow the tug to tackle fires more safely, and will be equipped to meet Tier III emission reduction requirements.

Building for the future

In 2024 ASENAV will celebrate its 50th anniversary. And while it is on its way to celebrating half a century of existence, it is already working on plans to continue positioning itself as a leader in maritime solutions on the Pacific Coast. One such development was recently confirmed: project number 200 will be a ferry that will contribute to the connectivity of the

Chilean continental zone with the large island of Chiloé.

Designed with a maximum load capacity on deck of 350 tonnes, this ship will measure 70.9m in length, 17.3m in width, while its height will be 2.8m. With these dimensions, the ship will operate to transport people, vehicles and other types of cargo.

The German Chamber of Commerce recently recognised the shipyard with an environmental award for its work on the Magellan Explorer, given the low impact on the environment that this work has.

Other exciting plans include building a second cruise ship with more sustainable

technology on board and a hybrid propulsion system, further reducing emissions. It is speculated that the sister ship will also be able to operate in the Antarctic and Arctic regions.

But that is not all: “There are hopes for another live treatment vessel similar to the Owurkan, and there are other projects currently under negotiation,” Mr Schacht said. “If these projects come to fruition, we will have a significant workload until 2026.”

As a pioneer in the construction of ferries, ASENAV has helped connect hundreds of islands in southern Chile. It introduced a simple, safe and durable technique with a double ended ferry solution and continues to manufacture vessels for that market today. This is enhanced by the recent signing of project 200.

The company recently invested in adopting a line of microwelded panels for

hull structures, with the goal of reducing welding time by 30%. It has also installed LED lighting in the shipyard, reducing energy consumption by 60%.

ASENAV’s engineering department is always innovating. “Our current focus is on propulsion systems that use green fuels that will significantly reduce emissions,” said Mr Schacht. “When the time comes, we will be ready to adapt the new technology to our ships. We are proud to play an active role in contributing to the change in the energy matrix of maritime transport.

“ASENAV is always looking to enter new and interesting markets because our Chilean engineering is world-class, and it receives more and more recognition with each project it carries out,” he concluded. “Our goal is to remain at the forefront of the industry.” n