Aritex has over 60 years’ experience serving the automotive industry as a provider of assembly lines and automation. Following its success in the market, the company diversified into the aerospace sector in 2001 and has continued to expand its capabilities ever since. Chief Sales Officer Carlos Mendez has more than 20 years’ experience working for the company and spoke in detail about the company’s vision and plans for the future. Reporting on this topic is Imogen Ward.

Aritex made several advancements over the past few years, solidifying its position as a market leader in the automotive, aerospace and robotics sectors respectively.

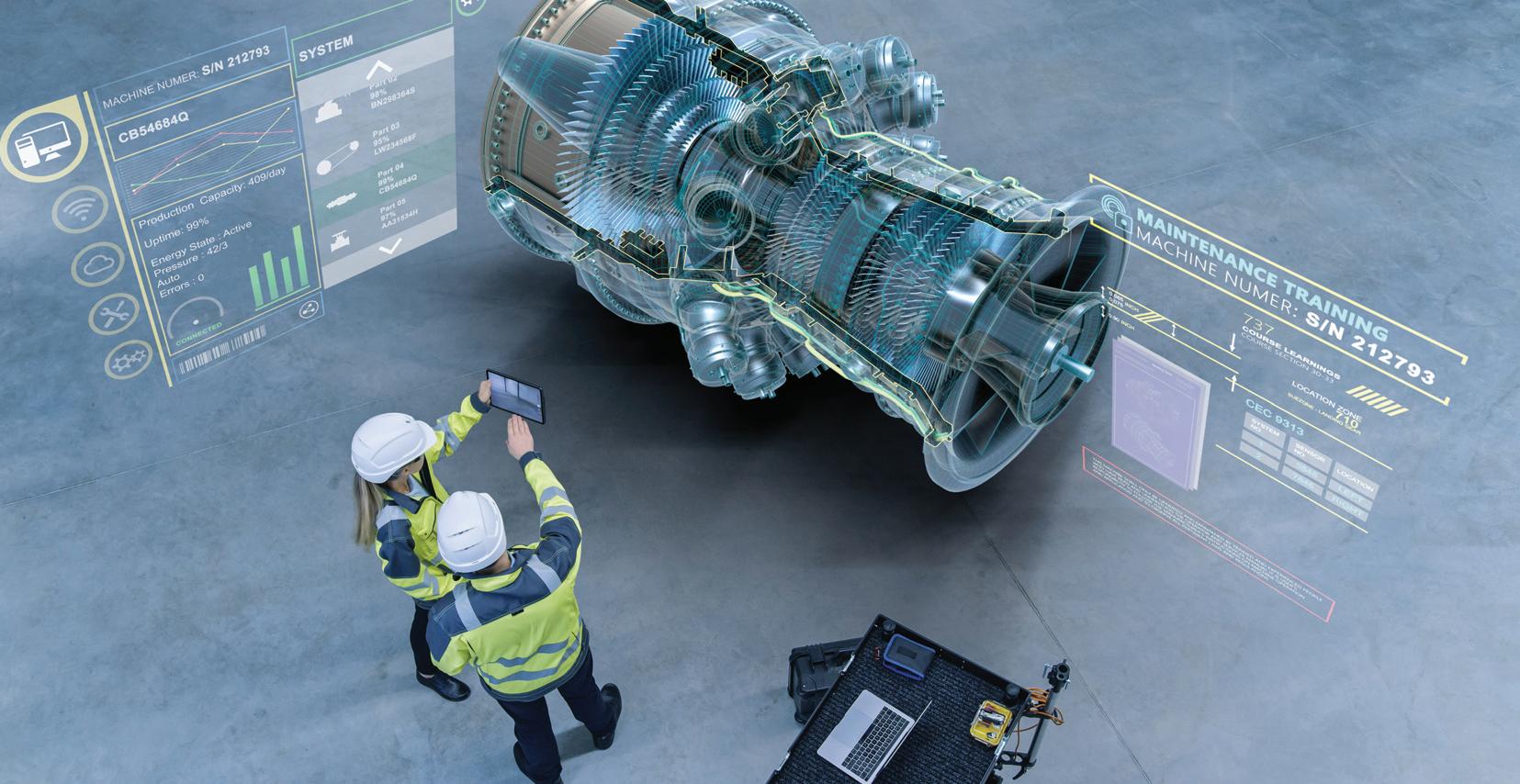

“We want to have a hugely diverse and impressive portfolio,” Chief Sales Officer Carlos Mendez said. “Originally, our company focused on large-scale turnkey projects. Now, more so, we are also developing technology that not only aids these engineering projects, but also can be adapted to work for any industry. We are working hard to keep our roots whilst continuing to evolve and grow – for instance, we are digitalising, with the development of IIoT and Augmented Reality.”

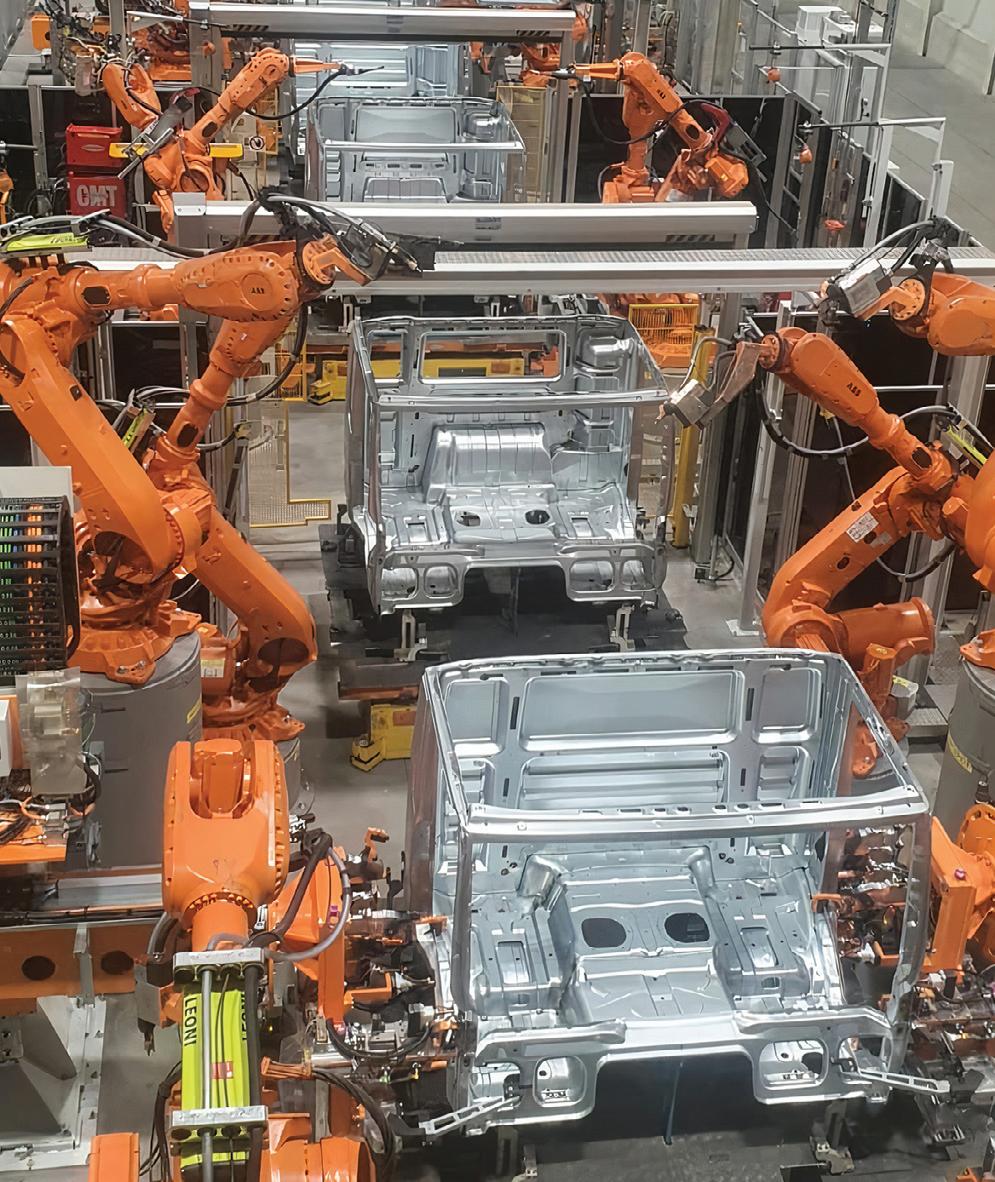

In 1961, Aritex entered the automotive scene and has offered its clients creatively tailored solutions ever since. With pride in its work, Aritex engineers solutions for a diverse range of sectors, and is always on the lookout for new markets to infiltrate.

The company is currently breaking into the renewable energy sector, offering turnkey packages and high-specification tools and equipment using a highly precise manufacturing process.

Airbus, Boeing, Nissan and Volkswagen are just a few of the companies that Aritex has worked hard to supply with innovative and cost-effective turnkey packages. With the help of its evolving supply chain, Aritex has successfully created production lines that simplify the process and make manufacturing more efficient.

Launching into Industry 4.0

After the company’s success with more traditional engineering projects, it decided to focus on Industry 4.0. Following a boost in demand for the product, Aritex realised that digitalisation and robotics were an increasingly lucrative prospect to focus on.

“We have started several new businesses,” Mr Mendez said, “allowing us

to diversify our turnkey products. In some cases, we produce complete world data distribution. In other words, we are launching into Industry 4.0. We are achieving this with the development of our robotics solutions, and the more recently launched Aritex Code.”

With an impressive range of knowledge and experience, Aritex decided to sell high-specification solutions under the name Aritex Code. The company exploited its extensive industry knowledge through consulting and implementation services, to enable customers to minimise costs and increase productivity. Merging the digital with the real, the client can access the digital twin as a tool to obtain vital information, including running times and machine restrictions.

Augmented Reality as an accelerator for the learning of operators and machinery maintenance, is consolidated day after day. Augmented Reality-guided assembly instructions ensure frontline workers are

equipped with the information they need to complete even the most complex tasks with precision and efficiency, improving ontime delivery and customer satisfaction.

From the #AritexCode unit, Aritex guides companies on their path towards the digitalisation and automation of industrial processes, through complete solutions based on the latest technology, starting from project consulting, to development, implementation and after-sales services.

Revolutionary robotics

After becoming a major shareholder in Loxin in 2012, the company has produced several highly successful patents, including its work in parallel kinematics. Aritex then began offering conventional robotics systems as well as new ones: mobile and col laborative robots.

The advancement of robotics at Aritex is a spectacular feat. Removing the need for isolation provides opportunity for smaller companies to incorporate

collaborative or mobile robotics into their production lines. This, therefore, offers more efficient services to smaller companies that previously did not have the space for more conventional robotics systems.

This type of robotics also encourages cooperation between man and machine –ensuring both can work side-by-side, increasing efficiency (in comparison to more conventional robotics that would take up a greater portion of the production line). Another advantage of this robotics range is that it reduces injuries and accidents within the work environment. On top of this, collaborative robots are lightweight and easy to install, making them highly efficient and as stress-free as possible for the customer.

Thanks to Aritex’s advances in Industry 4.0, it is not just customers that have benefitted: due to the increase in efficiency, the reduction in waste materials and the minimisation of rejection rates, Aritex’s turnkey products help the environment too.

Furthering its mission to aid the planet, Aritex also entered the renewable energy sector. During Covid, the company worked on a large wind farm project: “we have been working on manufacturing production lines for wind turbine blades,” Mr Mendez said. “We have recently completed a project with General Electric. After the successful development of this project, we plan to offer our turnkey production line out to other wellknown companies working within the wind energy sector – creating long-term relationships with them.

“Although we are quite new to this sector, it has similarities to aerospace – they are different markets, but we can apply similar solutions to both.”

Ready… steady… GROW!

Aritex’s future is as bright as an aeroplane landing strip. The company is focused on continuing growth, with the aim of expanding its product portfolio. This goal will see Aritex further its work within the

automotive industry. Specifically, the company is hoping to meet customer demand for electric cars.

After working on small-scale projects, and a massive new electric vehicle production line, the company hopes to take on even more of these contracts going forward. With extensive automotive experience spanning back over half a century, the company is confident entering this division of the market.

As Aritex increases its production capabilities, it is determined to retain its reputation for excellence. Aritex holds a range of certifications, including the ISO 14001 (which is an international standard of requirements for an environmental management system) and the ISO 27001 (this is the best standard for information security management systems). These accreditations not only ensure quality, but also guarantee customer confi-

dentiality – offering customers that extra peace of mind.

“I have been in the company for 21 years. So, they must be doing something right for me to stay here that long,” Mr Mendez joked. “The company is always working on lots of huge projects and each one brings new challenges. I think those hurdles inspire us; there is no repetition in our work as no two days are the same.

“Aritex achieves a lot of impressive feats that other companies struggle to compete with. The continuous development and business model evolution completed by Aritex ensures the very best for our customers. Going forward, expect to see us continue down the path of digitalisation and robotics; we aim to evolve and grow in this area –opening doors to new markets and allowing us to reach a wider range of customers who need our help.”