Published by:

379 Docklands Drive

Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO Christine Clancy

E: christine.clancy@primecreative.com.au

Editor William Arnott

E: william.arnott@primecreative.com.au

Assistant Editor: Adam Daunt

E: adam.daunt@primecreative.com.au

Journalist:

Daniel Williamson

E: daniel.williamson@primecreative.com.au

Business Development Manager

Rob O’Bryan

E: rob.obryan@primecreative.com.au

Client Success Manager

Janine Clements

E: janine.clements@primecreative.com.au

Head of Design

Blake Storey

Design

Laura Drinkwater

Subscriptions

T: 03 9690 8766

E: subscriptions@primecreative.com.au

www.bulkhandlingreview.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

Everything with moving parts will, at some point, break down and stop working. It doesn’t matter if it’s the car you drive to work, or the kilometrelong conveyor system, eventually it will need to be serviced and repaired.

Conveyors, in particular, are under a lot of stress. Often, they are exposed to the elements, baking under the harsh Australian sun or adjacent to corrosive salt water. Vibrations from daily use put strain on the equipment, not to mention the conveyed material could be wearing down the belt.

If proper maintenance and servicing isn’t done in scheduled periods, bulk handling businesses face the threat of unplanned downtime.

All it takes is one small component failing to start a cascade that could halt production entirely, or worse, put lives at risk.

For example, a roller could break and start to shred the belt like a pizza cutter, forcing operations to stop. Emergency repairs are an expensive thing. Every minute a belt is not moving counts, and the lost production costs can be staggering.

That’s why in this edition of Australian Bulk Handling Review (ABHR) we highlight the organisations and technologies that are helping bulk handling sites stay on top of their maintenance needs.

Most businesses offer after sales support, to ensure their customers can rely on the equipment even if something goes wrong. Some have embraced the Internet of Things, incorporating sensors into their equipment to help monitor the performance of a system in real time.

Access to this data allows sites to make more informed decisions and can highlight when something has gone wrong. In many cases, the digital monitoring can spot potential problems well in advance of manual maintenance, giving the operators more time to respond in scheduled downtime.

Some companies, like Kinder Australia, help customers learn more about their conveyors by providing a fresh pair of eyes. Their team will “walk the belt” on a site, gathering information and ways to improve.

The next edition of ABHR will shine the spotlight on packaging and flow aids. If your business is involved in this vital part of the industry, please get in touch.

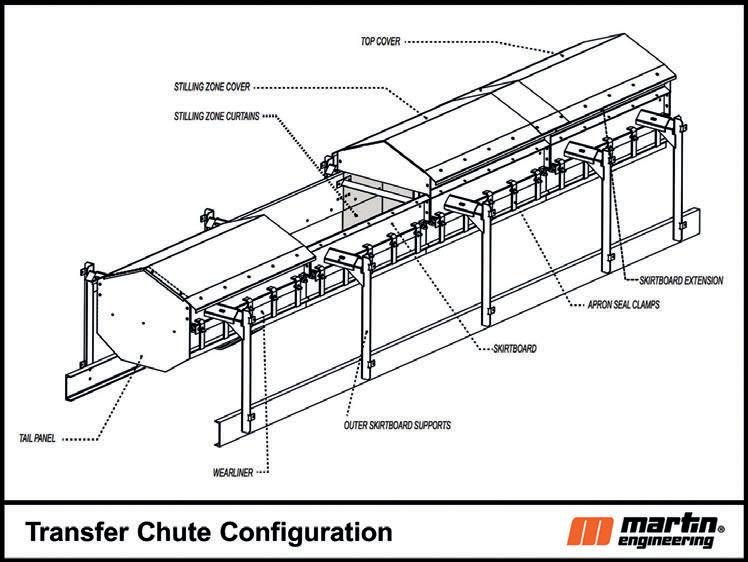

ugitive dust and spillage escaping from conveyor transfer points create costly production challenges. Martin’s ApronSeal,™ Impact Cradle, and Dust Curtain system helps protect the belt and seal the conveyor enclosure. Our steel-reinforced urethane Skirtboard Liners protect the enclosure from wear damage caused by abrasive material. These field-proven components control material loss, reduce dust emissions, and improve the operating environment, resulting in enhanced safety and optimized efficiency.

There is a lot that can go wrong when working with conveyors, which is why a Michigan-based business is providing Australian companies with the tools they need to protect employees and equipment.

CONVEYORS, LIKE MOST HEAVY machinery, pose serious dangers to anyone working alongside them. If a person falls onto, or is pulled into, a conveyor system, the results can be deadly.

Belts that drift or become damaged also create serious hazards, posing opportunities for people or their clothing to get caught in the fast-moving machinery. Misalignment also risks damaging one of the most expensive components on the conveyor – the belt itself.

This is where tools like emergency stop systems can help stop a bad situation from becoming worse. Now, one company is encouraging bulk materials handling operators to think holistically when investing in safety equipment and devices.

Conveyor Components Company sales manager John Carlson said one of the challenges facing sites that want to become more safety-focused is a lack of understanding about the devices that can help.

“People know there are emergency stop systems, because they are required

by law,” he told ABHR. “But they don’t know that there are devices that can detect damage to a belt or monitor for belt slippage.”

The Michigan-based business unveiled its Conveyor Safety System (CSS) in early 2024 to help bridge the knowledge gap. The CSS is a comprehensive safety solution that combines multiple essential safety switches into a single, costeffective system.

One of the key components is the Model RS, a pull-cord safety stop switch, which allows operators to halt the conveyor instantly by pulling a cord along its side.

Supplementing this is the Model TA belt alignment switch, which can act as an alarm or shutoff switch if it detects a belt misalignment.

Also included is the Model DB damaged belt detector, which is used to find belt tears as early as possible. In addition to the safety benefits, finding tears in a belt early means it can be repaired quickly, before a catastrophic repair bill and unplanned downtime can occur.

Carlson said the system alerts a site about any problems before they can escalate into a safety hazard.

“They provide peace of mind and make sure conveyors are working as they should,” he said.

“The other benefit of having a bundle package is that it creates a volume of scale, letting us be more effective in our pricing and delivery to the customer.”

The Conveyor Components Company team will work closely with a site to provide the right advice for companies looking to improve their safety. Using customer-provided information about the application, the Conveyor Components Company will deliver bespoke advice on how many switches are necessary and what will provide the most value.

Carlson said when dealing with international customers, the company will take this collaborative approach to ensure its equipment is the right fit for the job.

“We’ve been working in this industry for more than 60 years and know how to build a robust product,” he said.

“It all comes down to understanding the market we’re trying to go into. What we like to do is research the market and work with customers, because they know everything about their industry. We basically become a team, with us as the manufacturer and them as the subject matter expert.

“We work in tandem – they may come to us and ask for a certain rating or voltage, and we can facilitate those needs with our extensive understanding of the manufacturing process.”

The Conveyor Components Company has spent the past six decades manufacturing a wide range of equipment designed to help its customers keep employees safe and reduce unwanted downtime. The company prides itself on manufacturing rugged, durable equipment in-house at its factory in Michigan. The company takes the raw material and castings, assembling and testing each component for quality before they are sent to the customer.

Carlson said its equipment can last for decades in tough, heavy industry conditions.

“Some systems have been working for more than 20 years before they needed to be replaced. That durability is what puts us ahead,” he said.

“We choose to build everything with high-quality materials, understanding that they are going to be in very harsh and demanding environments.”

The company is no stranger to international trade. It has been shipping its equipment around the world for more than 50 years.

This experience has led to the creation of robust supply chains to make sure the product gets exactly where it is needed, when it is needed.

The Conveyor Components Company plans to expand rapidly into Australia in 2026, with the goal of finding a distributor that can further enhance its understanding of the market.

“We’re excited to introduce the CSS to the Australian market and provide our international customers with peace of mind,” Carlson said.

“We’ve been working in the mining industry for more than 60 years. We’re experts at it – let’s work together to improve safety and peace of mind.”

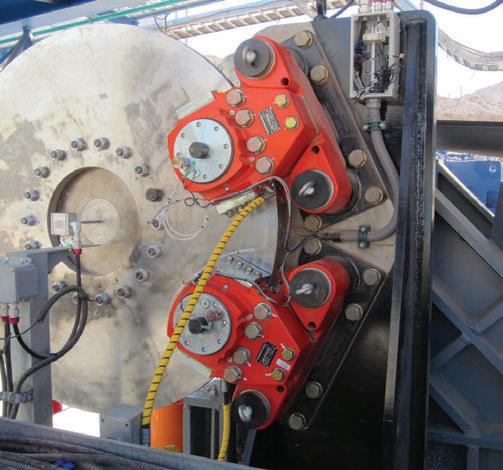

DHHI’s manufacturing capacity has helped Hancock Prospecting reduce risk at its mine sites.

Prospecting’s majority owned multibillion-dollar mega iron ore mine, one of the largest in Australia.

Supporting this mine is a 344kmlong heavy haul railway system, along with purpose-built port facilities.

More than a decade ago, when the project was looking to ramp up production, a feasibility study was conducted to find a supplier for balanced machinery.

Hancock Prospecting chief executive officer, projects, Sanjiv Manchanda,

told ABHR that Roy Hill had consciously aggregated its purchase orders and contracts to a larger value.

“Our project delivery strategy was to consolidate procurement and contracting into large packages to minimise interfaces,” he said.

“We wanted to pick the contractors and suppliers that were capable of managing these interfaces among themselves, rather than making us have to manage that risk.

“It also reduced the add-on costs that we might incur from needing to manage external suppliers – instead of having inspectors at 10 locations, you only need to have them at one. It made the logistics of delivering a project relatively simple.”

As part of a competitive tender process, Roy Hill found a company that could act as a single source for the entire suite of balanced machines – from stackers, and shiploaders, to reclaimers, and car dumpers.

While other suppliers could provide most of the machines, DHHI was one of the few that had the capacity to provide the full range.

DHHI is a specialist when it comes to manufacturing heavy machinery. Each year, the company produces around 600,000 tonnes of structural and mechanical equipment from its facilities in China.

Manchanda said DHHI’s capacity to engineer and fabricate the equipment gave Roy Hill greater certainty that a quality product would be delivered on time.

“DHHI’s shop floor capacity is fairly large and unique in that regard,” he said. “The size of equipment they can manufacture ranges from the smallest of the small to the largest of the large, with vertical integration for sub-componentry.

“Because of this supply chain, DHHI reduces delivery risk, interface risk, and management risk.

“Their engineering capability is also very good. They’re always open to learning. These machines needed to comply with Australian standards, adhering to specific design criteria, and if there was anything that they didn’t know, they stood out in how they applied themselves to acquire that knowledge.”

DHHI’s project teams in Australia and China work closely with each other. The company’s Australian engineers support the quality control, documentation, and localisation processes, ensuring the manufacturing powerhouse is providing equipment that is fit for purpose. While the company’s main products in the

Australian market are balanced machines, its offerings are exceptionally diverse.

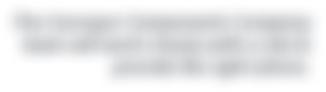

For example, DHHI was a critical part of Hancock Prospecting’s Wet High Intensity Magnetic Separator (WHIMS) project.

The plant used magnets to recover high grade, ultra-fine iron ore from the tailings that would have otherwise ended up as waste.

Manchanda said DHHI played a very different role in the project, taking over the early preliminary design and developing a cost effective iron ore recovery process design, supplying the structural steel and modules required for the plant.

“There was a lot of other process equipment which they don’t manufacture,” he said. “But they aggregated the equipment from other suppliers and modularised everything on their shop floor.”

“The equipment was tested and then shipped as combined modules. They then undertook site supervision to make sure it all came together well.”

DHHI’s flexibility allowed it to reduce the amount of risk in the project overall. The modular design of the equipment meant that less personnel and cranes were required on site, reducing potential hazards.

Manchanda said the aim for project managers in the Pilbara is to reduce as many site-based man hours as possible.

“In remote places in Western Australia, the logistics and accommodation of having a large workforce is always to be avoided,” he said.

“The ability to test the equipment off site means that if you find a problem, you can fix it at the source, rather than finding out that something doesn’t work when it arrives in Australia.”

Following on from the success of the design, delivery and performance of the Roy Hill WHIMS plant, DHHI has retained and imbedded the skills of that

project team into the Perth and Dalian based teams providing a gateway for Australian miners to access the depth of knowledge and experience DHHI has within the Chinese mining environment of single sourced process design technology, modularised fabrication and delivery.

To provide Australian miners like Hancock Prospecting with the best support possible, DHHI has expanded its local presence in WA.

The company’s project execution office in Osborne Park, Perth, has undergone significant expansion, in both balanced machine and materials handling and concentrator plant design and delivery. From here, DHHI’s team of balanced machine engineers and aftermarket personnel can support customers for the whole lifecycle of their assets, while the processing plant teams have been able to provide in-depth EPC style studies to Australian miners.

Manchanda said DHHI’s local support is vital for fast response times. If a technician is required, they can get on the next charter plane up to the site as soon as possible, without needing to deal with international customs and visas.

“DHHI has the people and resources that are familiar with the equipment, staff, and supply chain,” he said.

“Support from the original equipment manufacturer is crucial for any plant that requires a certain reliability and availability. There’s a high level of confidence and trust between the two companies. Both parties have invested a lot into the relationship at various levels of the respective organisations.

“We know that if there’s anything wrong, we can reach out to them and know we will be supported with a timely and appropriate response.”

Martin Engineering training manager Jerad Heitzler

writes about how dust emissions aren’t necessarily an inevitability.

empty, pulls air through the enclosure in the direction it is moving. When the material hits the belt, the impact causes the cargo to splash, particulates to become airborne, and the subsequent air turbulence forces the dust emissions toward the nearest opening. Without a sealed environment that controls airflow, the poor air quality creates a serious workplace safety hazard. Dust emissions don’t just create a harmful environment for those working in the area. Abrasive particulates make their way into exposed machine parts and rolling components, causing them to wear quicker, seize and require replacement sooner. Dust clogs air intakes of nearby equipment and vehicles, raising the amount of downtime and maintenance. Particulates cover walkways, stairs, and control units and obscure signage. And there are serious environmental concerns and increased complaints from nearby communities that trigger inspections from authorities. Safe Work Australia has consistently focused on improving air quality through increased monitoring and fines. Regardless of operators’ opinions about these measures, they have effectively helped decrease illnesses and chronic lung diseases related to fugitive dust emissions.

Many operators often lack understanding of the root causes of dust. Most solutions focus on dust suppression and collection, but decades of field study and experience have shown that controlling air quality at transfer points is more effective when addressing the underlying causes by taking a holistic view of the function and design of the material transfer process.

A transfer chute should have several key components that mitigate material spillage and dust, allow the cargo to settle on the belt’s centre, and facilitate the settling of dust either back into the cargo flow or into a dust collection mechanism. These components include cradles, wearliners, skirting, raised enclosures, and strategically placed dust curtains.

Some manufacturers offer modular transfer chute enclosures that can be quickly and economically retrofitted for changes in production during scheduled downtime. Extending the transfer chute enclosure provides more space for the turbulent air and dust to settle. Externally facing wearliners and skirting allow easy access for significantly safer maintenance. Although the normal lockout/tag-out procedures are required, external servicing eliminates the need for

chute entry and drastically reduces the amount of downtime.

If you can see the particulates floating in the air, they aren’t small enough to be respirable, meaning they don’t surpass the body’s natural defences and enter deep into the lung causing serious damage and health issues. Nuisance particulate matter (PM) smaller than 200µm – roughly the size of normal household dust – is light enough to remain airborne on ambient air currents. It settles on every surface and causes serious abrasion in rolling and mechanical components.

When PM reaches 100 micrometers (µm) – approximately the size of a cross section of a human hair – it becomes invisible to the naked eye. At 10µm or smaller, the particulate is considered “respirable”. These particulates have become highly regulated, having been linked to chronic lung diseases some workers experience later in life, which has drastically lowered the mortality rate.

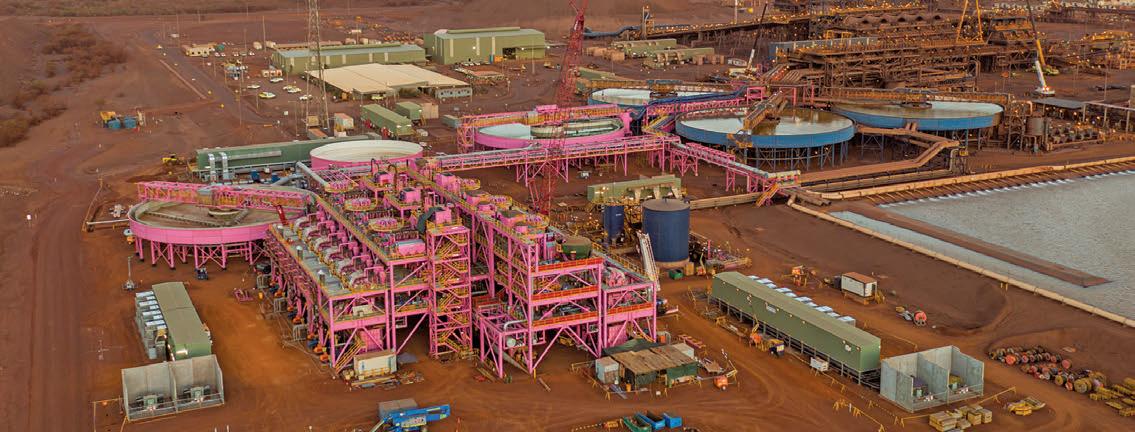

The chute design can have a significant impact on the volume of particulate matter emitted during conveyor transfers. Chutes that are properly sealed and retrofitted with three curtain zones incrementally slow the airflow and allow dust to settle. Field tests show a drastic reduction in emissions of both nuisance and respirable dust.

Many operators have the misperception that, in the inherently dirty business of mining, processing, and handling bulk materials, dust control is a futile battle that can never be overcome.

This is particularly true when experienced maintenance staff gaze baffled at a transfer point engulfed in dust that provides no clue as to the source of the emissions.

Air flow through the transfer point is achieved by adjusting the loading

angle and the proper placement of dust curtains. With a centred and sloped or spoon-shaped loading configuration, the cargo is eased onto the belt with less impact (and associated belt damage), no splashing, reduced air turbulence, and less shifting leading to potential mistracking. Proper placement of curtains creates zones where air is slowed, allowing dust to settle back into the cargo stream or be sequestered into dust collection systems.

Material degradation increases small fines in two ways. As raw material is processed through crushers or mills, it is reduced in size and dust becomes more prevalent. Degradation can also be caused by the impact of material upon transfer resulting in it breaking apart.

Poor transfer point design for current production expectations is perhaps the largest cause of dust. Conveyor systems are generally built for the production demand at the time of construction and leave little room for change.

Increases in production require either a greater volume of conveyed material or higher belt speeds. Often, they result in

both. If the system is not graded for these expectations, dust becomes the bellwether for a host of other issues such as reduced

Telescopic Cable Mast Conveyor

• Versatile, affordable conveyor solution

• Quick and cost-effective installation

• It can be lowered to the ground to provide easy access for maintenance

• No head or tail undercarriage provides greater clearance under the conveyor

• Complies with all relevant Australian Standards, AS1170, AS4324.1 and RPEQ requirements

workplace safety, increased spillage, more frequent equipment breakdowns and excessive downtime.

1. Avoid belt sag. Support the belt the entire length of the chute wall (also known as the skirtboard) so it doesn’t sag away from skirting. The pressure from air turbulence is enough to push dust and fines out of these gaps causing excessive dust and spillage.

2. Wearliners increase the conveyor system’s life. Modern chute design raises the height of the chute, providing more room for dust settling in the stilling zone and also room to place the external wearliner. Without it, the rubber skirting takes the force of abrasive bulk material which lowers the equipment’s life and requires premature replacement.

3. Install belt skirting to seal the environment. Single skirting should be cut to the belt’s trough angle for a tighter seal and mounted externally for easy and safe adjustment. Selfadjusting skirting has spring-driven latches that offer slight downward pressure for reduced maintenance. Dual skirting offers a single skirt with a rubber flap that provides a second layer of sealing and protection from spillage and emissions.

4. Seal before adding dust collection devices. Passive dust control uses engineered design solutions such as controlled loading, wearliners, skirting, curtains, and modular enclosures first. When there are length restrictions for chutes to allow an extended stilling/settling zones, dust bags and mechanical air cleaners are highly effective. They use the airflow to direct dust toward the mechanism and once the conveyor system stops, that collected dust is deposited back onto the belt. However, they can require more maintenance and monitoring, so sealing first will better control the cost of operation.

5. Slow the exiting air velocity. A flow of air is still going to be prevalent exiting the system, but the key is slowing it to under 1m/s, slowing it

enough to reduce emissions. Adding a tail panel and curtains is essential to this, however, just adding them at the ends does not accomplish the proper stilling environment required. Strategic placement is the key to slowing exiting air velocity. Improving workplace air quality seems like a daunting task but eliminating it increases compliance and raises staff morale and safety.

Conveyor transfer points are not the only source of dust. However, as

one of the most prevalent generators of particulate emissions in any bulk handling operation, it is an excellent place to start. By following best practices using modern and well-designed retrofitted components, operators can tackle dust by a process of elimination. Once large emission sources are addressed, it is easier to identify dust from other parts of the operation with the ultimate goal of a clean and efficient operation with high worker morale and an exemplary record of safety.

With an increase in tonnages and declining conveyors with several hundred metres of drop, the installation of intelligent soft braking systems to address the starting and stopping requirements under various load conditions is an imperative.

Svendborg Brakes soft braking control provides

’ unique SOBO a range of safety and durability benefits in harsh mining applications. Decelerating and stopping heavy conveyor loads is critical, and controlled braking is essential for a significant reduction of torque peaks, preventing belt and mechanical component damage.

ESS’s approach to transfer point systems solutions ensures reduced downtime, lower maintenance cost, and improved safety.

and transfer points are the most critical, and most problematic, sections of any bulk material handling system. Without precise control over how material enters and interacts with the belt, operators face a deluge of issues: dust generation, belt misalignment, spillage, premature wear, and unnecessary maintenance.

One of the most persistent challenges is dust control. As bulk materials impact the belt or chute surfaces, particles fracture, producing fine dust that can easily become airborne. The smaller the particles, the longer they remain suspended, contribute to health risks, environmental contamination, and equipment deterioration.

Poorly designed transfer chutes, inadequate sealing, and drop heights all exacerbate the problem, allowing dust to escape the system and spread throughout the site.

Loading at transfer points is another common source of trouble. When material isn’t loaded in the centre of the belt, it can lead to misalignment and material spillage, accelerating wear

on the belt edges and rollers, and can damage idler bearings and structure. Spillage frequently leads to downtime and increased material handling risks.

Excessive drop height also amplifies impact force, damaging the belt and support structure beneath it. High impact loading not only shortens belt life but also increases vibration and shock loads throughout the conveyor system.

Rather than treating each issue in isolation, ESS evaluates the entire transfer point, from how material enters the chute to how it settles on the belt. By controlling airflow, stabilising the belt, and managing impact energy, ESS ensures a smoother, cleaner, and safer material flow.

Dust control begins with understanding why and where dust is generated. According to ESS accounts development manager and training instructor, Tom Stahura, there are three key principles to effective dust management.

“To control dust, you reduce air velocity around the material, increase its cohesiveness so particles stick together, or make the dust heavier so it drops from the air,” he said.

ESS applies these principles through a combination of airflow control, spray systems, and dust containment technologies.

Airflow control systems manage airflow within the transfer point, preventing high-velocity air from lifting fine particles. Dust curtains and settling zones are strategically installed to slow air movement and keep dust contained.

ESS air atomising spray systems further suppress dust by using fine mist or foam to increase particle mass. The spray can be applied directly onto the conveyed material, the belt, or into the surrounding air. This makes particles heavier and more cohesive, reducing the chance of airborne dust escaping the system.

For operations where water conservation is critical, ESS offers foambased and surfactant-assisted spray systems that maintain high performance with minimal water use.

The result is a significant reduction in fugitive dust emissions, which improves air quality, reduces clean-up requirements, and protects workers and nearby equipment.

To complete the sealing system, ESS offers a range of conveyor skirting solutions designed to prevent material spillage and fugitive dust emissions.

The ESS 2000 Series skirting system combines a durable rubber or urethane seal with a weld-on clamp assembly. Mounted to the outside of conveyor load skirts, it provides a reliable, adjustable seal that keeps material and dust contained within the conveyor structure.

On conveyors with multiple load points, the ESS 2000 Series typically handles the narrow primary load area,

while lay-in skirting manages wider downstream sections where there may be less belt support – ensuring that relaxed or settled material doesn’t interfere with the skirt seals. Skirting systems are installed from the load zone through to the end of the settling zone, keeping spillage contained and dust emissions to a minimum.

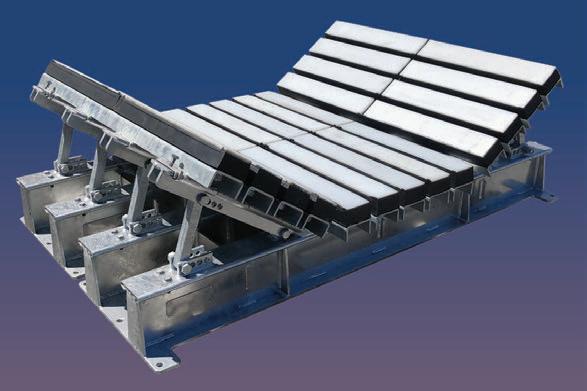

To further create the most effective sealing solutions at a transfer point, ESS recommends impact support and cradle systems, which provide continuous support beneath the belt at critical load points.

Unlike conventional impact rollers that leave gaps where the belt can sag, ESS impact beds offer full-width contact, ensuring consistent stability across the loading zone.

“Stability and alignment are critical when you’re dealing with large lumps

of material dropping onto a belt,” ESS salesman Aden Prisk said. “Our impact beds eliminate belt sag and provide the solid foundation needed for effective sealing.”

This stability is essential for maintaining a tight seal between the belt and skirting, which in turn prevents dust and material from escaping the conveyor structure. ESS’s GS sealing support system complements this by supporting the belt through the settling zone, keeping it flat so that skirting and wear liners maintain constant, even contact.

Excessive drop height is a leading cause of belt damage and structural stress. When heavy or abrasive materials fall from significant heights, they can puncture the belt or damage the conveyor frame.

The GAB impact cradle is designed to absorb and distribute the energy of falling material, preventing direct impact on the belt surface.

These systems are custom-engineered for each site, taking into account factors

such as belt width, drop height, material size, and throughput.

Where lighter materials or lower drop heights are involved, ESS may recommend a combi cradle or (in areas where impact is less of a concern) roller cradle, providing targeted support while maintaining flexibility and cost-efficiency.

“Every impact bed we supply is designed for the specific application,” Prisk said. “We take into account belt speed, drop height, and lump size – and we can insert idler sets between beds if we need to control sag between supports.”

By reducing impact shock, ESS impact beds not only protect the belt but also extend the life of idlers, skirting, and structural components. This leads to less downtime, fewer unplanned shutdowns, and lower maintenance costs.

ESS systems are built to last and designed with maintenance safety in mind. Components such as bars and rollers can

be removed laterally, eliminating the need to lift the belt or work in confined spaces. This makes inspections and part replacements faster and safer.

Regular six-monthly servicing is recommended to maintain peak performance.

“If you maintain them properly, these systems will keep your conveyors running efficiently for years,” Prisk said. “A small amount of maintenance prevents a big repair later.”

ESS also offers quick-change idler frames and modular designs, including guarding, to simplify maintenance and minimise downtime, keeping productivity high even in demanding conditions.

In combination, ESS’s engineered systems form a complete load zone solution – controlling dust, stabilising the belt, managing impact energy, and ensuring safe, efficient transfer operations.

The result is a conveyor system that performs better, lasts longer, and operates cleaner, creating safer and more sustainable mine sites across Australia.

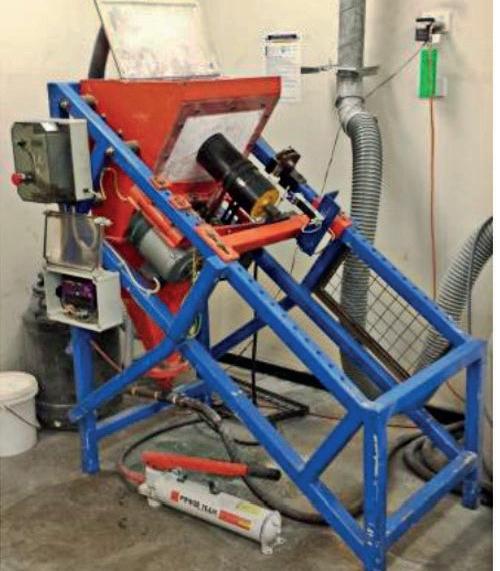

Flowforce Technology’s engineers have designed a new impact weigher to solve engineering and global supply challenges.

will often position the impact plate in the material fl ow stream.

This helps them to measure the material flow in gravity feed applications, but it can put the sensitive electronics at risk of being damaged.

Flowforce Technologies managing director Glenn Jobling said that a load cell can only withstand a certain amount of force before it is irreparably damaged.

“A force-sensing element that has the capacity to handle three kilograms can break if five kilograms of force is applied to it – something that can happen during the production process or during maintenance,” he told ABHR

“That’s why we developed the Magneflo impact weigher 13 years ago.”

Flowforce Technology’s Magneflo series of impact weighers uses magnetic technology to remove the forcemeasuring device from the process stream entirely.

This allows the impact weigher to safely handle hazardous materials, such as explosive dust and grain, and means that cleaning can be done inplace, without risking damage to the sensitive electronics.

However, because the previous system relied on magnets, it meant the Magneflo was unable to handle magnetic materials.

Jobling said the new Series 5 Magneflow impact weigher has solved this issue by moving the magnetic components outside of the process stream.

“This means the weigher can handle magnetic materials, but also means it can handle high temperature materials and sticky, fluffy materials like kiln dust in the cement industry,” he said.

“The new design also features nonstick and high-wear coatings, which have enabled us to add more features.

“It is also one per cent more accurate, which is important for low flow rate processes.”

One of the key reasons the company designed the new Series 5 impact weigher is to help customers replace obsolete impact weighers.

Jobling said Thermo Fisher Ramsey announced it would no longer support the DE 10/20 model impact weigher.

Bulk handling businesses began looking for an alternative, but replacing an impact weigher takes time, and therefore would reduce productivity.

“We decided to create a direct replacement model that could be bolted in,” he said.

“It was developed during COVID-19, but travel restrictions stopped us from launching it to the market.”

“We have successfully installed 24 of the new devices for a South African client,

and they’ve been running for more than two years successfully.”

After having seen global success, the company has set its sights on Australian applications.

The Series 5 impact weigher can be swapped out quickly, fitting into the envelope of the former impact weigher.

Jobling said with Flowforce Technology, the swap can take as little as four hours, with no need to re-engineer anything.

The company can also modify each impact weigher to ensure it suits the application, which helps support the customer’s operations.

“Customers help drive our research and development efforts,” Jobling said. “They may ask us to take certain features from one of our impact weighers and include them in another. They may need a sampler, or they might have simpler calibration methods.

“This has led us to developing innovations like the Magneflow Series 5, which we’re excited to begin distributing throughout Australia.”

Flowforce has also developed a cross cut sampler that can be optioned onto the new Series 5 to weigh specifically for mineral sand and rare earth customers.

Backed by 40+ years of US innovation, the new MATO Australia Medium Duty Fastener Range has arrived. Built for: aggregatesmining agriculturerecycling construction

Supported by MATO’s local service, training, and distribution network.

Kinder Australia is o ering on-site conveyor health checks to highlight how operators can improve productivity, safety, and longevity.

a conveyor, day in and day out, operational issues can start small and potentially go overlooked.

In some cases, these issues can grow to become larger hazards that need to be addressed. This is why engaging a trusted advisor to deal potential hazards before they occur can be priceless.

Kinder Australia field application specialist Jason Whitwell told ABHR that a fresh pair of eyes can reveal much more than expected.

“When someone sees the site for the first time, they can spot the areas of improvement or potential hazards,” he said.

This is the basis of Kinder Australia’s conveyor health checks. Tailored to each operator’s specific requirements, each health check aims to improve performance and minimise risks through a comprehensive site visit.

Starting with a pre-consultation, Kinder Australia’s field application specialists work closely with clients to discuss their specific problems, needs and expectations.

Whitwell said Kinder Australia’s team will then “walk the belt”, inspecting its operation and noting down problems for later attention.

“We go along the length of the conveyor, taking photos and measurements, looking for any potential problem areas,” he said.

“We cover the conveyor from top to bottom, using an iPad to document everything we come across. This means looking at the standard components, making sure there’s no structural damage, spillage, or anything that is not up to standard.

“Sometimes, the issues we find are sitewide, while others could be tracking issues on an individual conveyor.”

The photographs, videos, and other information are then collated into a report that helps form the basis for future reporting. It provides a summary of what issues the site is facing, highlights where the site is performing well, and provides a conveyor-by-conveyor breakdown.

Whitwell said one of the most common issues that Kinder’s specialists find is poor belt condition.

“Across all bulk handling sectors, there is emphasis on increased volumes and conveyor capacities which requires equipment to be in peak condition,” he said.

“Conveyor health checks identify immediate and future wear, plus, we provide a detailed performance analysis.”

Often, poor belt condition is the result of mistracking. Kinder Australia’s team checks to make sure each belt has the right type of tracking system to suit the conveyor belt’s speed, direction, trough angle, and material loading. Specialists also look for any alignment problems and can provide solutions to promote the correct conveyor alignment.

Kinder’s range of idler frames can support this effort, making sure the belt is profiled correctly and not at risk of misalignment.

The K-Retractable Idler/Impact Frames range are suitable for all bulk material handling applications, while the K-HD Retractable Impact Frames are applicable for the toughest quarrying and mining applications.

They allow conveyor rollers to be changed out under transfer loading chutes without requiring the frames to be removed.

Another key part of productive conveyor systems is keeping the conveyed material on the belt. Without the correct spillage control, sites can face safety hazards and potential dust emissions.

Whitwell said dust emissions are becoming increasingly regulated, and operators who fail to monitor and implement emission controls risk being fined for non-compliance, and in extreme cases, forced to halt production.

“Kinder specialists can recommend dust control solutions, like enclosing conveyor belts to mitigate dust emissions,” he said.

The report helps site managers plan their maintenance processes and can assist with budgeting.

Whitwell said it helps sites understand what problems need a simple solution and what ones require a more comprehensive approach.

“For example, some customers think that fixing belt tracking could be hard or an expensive thing to fix, when it is probably a lot more affordable than they would think,” he said.

“The report breaks down what is the highest priority, so site management can gradually roll out improvements over the coming months to keep expenses low.

“We also educate sites on the importance of including belt cleaners and the importance of removing carryback. One major benefit is that carryback on pulleys and return rollers can affect their performance, which leads to a flow on effect. By installing a belt cleaner, the conveyor becomes safer, more reliable, and more productive.”

Carryback can also lead to belt and structural damage as fugitive material can build up to bury idlers, conveyor

components, or structural supports, furthermore, requiring clean-up labour or even the replacement of parts.

Primary belt cleaners, like Kinder’s Micro Eraser Primary Belt Cleaner can play a vital role in reducing carryback and keeping conveyor belts running smoothly and efficiently.

Many of the sites that Kinder Australia’s field application specialists visit are located in Australia’s remote or regional areas.

For these sites, minimising downtime and maintenance is even more important

than usual, as it can take longer to get things up and running again if something goes wrong.

Whitwell said these clients often appreciate Kinder Australia putting in the effort to see the site in person.

“Clients are usually grateful for the report,” he said. “The proactive ones get started on finding ways to improve their plant.

“Anyone can reach out to us to organise a conveyor health check. Our team of field application specialists are ready and eager to help.”

OLI is the world’s top selling manufacturer of electric and pneumatic vibrators. The high level of customer service, guaranteed by 18 trading subsidiaries worldwide, and long-lasting and performing products make us always ahead.

Our vibrators are designed for industrial applications in all sectors, from the most extreme environments such as quarries, mines and foundries to the food and pharmaceutical.

A major acquisition has expanded MATO’s global portfolio, providing Australian operators with greater choice in conveyor belt fastening and maintenance.

UNTIL NOW, MATO HAS BEEN BEST known in Australia for its heavy-duty underground mining fasteners and belt cleaners.

However, following a major acquisition, the company is poised to grow in sectors that demand mediumduty fastening.

“The reality is that not every site requires a heavy-duty underground solution,” MATO Australia general manager David Gilbert said.

“Conveyors operating in quarries, agriculture, construction, and recycling need a fastener system designed specifically for their conditions. The medium-duty range fills that gap.”

MATO Australia has launched its medium-duty belt fastener range after it acquired Conveyor Accessories Inc. (CAI), a US manufacturer with more than 40 years of expertise.

CAI was founded more than four decades ago, building a reputation as a specialist in mechanical fasteners, installation tools, and accessories. Its focus has been on designing fastening systems that reduce downtime, improve safety, and extend belt life - principles that align with MATO’s mission.

For MATO, the acquisition strengthens its ability to serve customers

globally with a more complete and flexible product line. For Australian bulk handling operators, it means access to a fastener system proven in thousands of operations worldwide, now backed by MATO’s established service, training, and distribution network in Australia.

Gilbert said that bringing CAI into the MATO family is about more than adding products. It’s about combining two legacies to create a stronger global supply chain.

“The medium-duty range is already trusted in markets like North America, and by integrating it into our offering here, we’re delivering solutions that meet the needs of a much broader crosssection of industries,” he said.

“Australian operators now get proven US-engineered products with local service and support.

“It’s the best of both worlds: international legacy and expertise, combined with the responsiveness and reliability of MATO Australia.”

The medium-duty fastener range includes a full line of splicing and installation solutions, including: • Plategrip fasteners: versatile fasteners for belts of any width or thickness.

Offered in a wide variety of metals, they provide long life, corrosion resistance, and tolerance to abrasive materials.

• Hinged plategrip fasteners: ideal where belts are separated or rejoined frequently, such as in mines, quarries, and construction sites. The boltsecured-hinge design offers strong holding power while enabling quick installation and separation.

• Connecting pins: available in stainless chromium and special steel.

• Rivet fasteners: designed for highstrength belts with small pulleys, common in construction, agriculture, and mining. The R-2 and R-3 models streamline installation, saving time, labour, and materials

• Custom-engineered installation tools to make splicing efficient and

reliable, whether by hand or powerassisted application.

• Accessories from belt skivers to lacing sets to provide a complete toolkit for safe and effective belt maintenance.

Australia has around hundreds of active quarries, and resource recovery facilities, along with dozens of transfer stations and sorting centres. In addition, there are also thousands of agricultural processing and packing sites, all of which depend on conveyors.

With this breadth of demand, MATO is positioned to deliver fastening solutions, backed by local service and support, across Australian industries.

“Every period of downtime has a cost – up to $75,000 per hour in mining, as an example,” Gilbert said.

“By introducing a fastener system that’s quicker to install and proven in abrasive conditions, we’re helping sites

get back online faster and keep conveyors moving longer.”

Heavy-duty fasteners, such as the U40 series, are already wellestablished in underground mining, while Australian-made belt cleaners deliver efficiency and shorter lead times to the t.

“With this launch, MATO is bridging the gap between heavy-duty and lightduty fastening, giving our customers a complete, fit-for-purpose range,” Gilbert said. “Whether you’re an underground mine or a quarry, there’s now a MATO fastener designed for your needs.”

For Australian customers, the key advantage lies in combining CAI’s product heritage with MATO’s local footprint. With a dedicated team based in Thornton, New South Wales, and Mackay, Queensland, plus decades of experience supporting mining and industrial operations across the country, MATO provides technical expertise, on-site support, and training to ensure maximum system performance.

“This is more than just adding new products. It’s about strengthening our ability to serve customers across industries,” Gilbert said. The mediumduty range brings flexibility, costeffectiveness, and reliability, all backed by MATO’s commitment to keeping technology in motion.”

Key benefits of MATO’s medium-duty belt fastener range

• Proven global legacy backed by CAI’s experience in the US market.

• Suitable for mining, quarries, agriculture, construction, and wood products.

• Corrosion-resistant metals and abrasion-tolerant designs extend the life of splices.

• Complete end-to-end support from fasteners and pins to custom installation tools and accessories.

Pack your cement, building material or chemical products into valve bags at up to 1000 s/h with our new-gen

The Bulk Handling Technical Conference and Expo is returning in 2026, and anticipation is already ramping up for what’s expected to be the biggest yet.

THE BULK HANDLING TECHNICAL Conference and Expo (BULK2026) will return in 2026, once again bringing the biggest names, brightest minds, and the most innovative technologies under the same roof.

On 16-17 September at the Melbourne Convention and Exhibition Centre, the industry will come together, upon the ultimate meeting point for everyone who moves, stores, processes, or manages bulk materials.

“BULK2026 is all about bringing the industry together, showcasing innovation, sharing knowledge, and celebrating the people and projects driving bulk handling forward,” Prime Creative Media general manager of events, Siobhan Rocks, said.

“BULK2026

“Whether you’re an engineer, operator, or supplier, BULK2026 offers insights and connections that you simply can’t get anywhere else.”

The 2026 expo will include a worldclass forum of advanced technical content, curated by the Australian Society for Bulk Solids Handling (ASBSH). Experts and industry figures will explore the latest in research, practical case studies, and innovations shaping the future of bulk materials handling across such industries as mining, agriculture, ports, food processing, construction, and manufacturing.

Exhibitors will be provided with a unique platform to connect with a wide audience, meet new clients, and

is all about bringing the industry together, showcasing innovation, sharing knowledge, and celebrating the people and projects driving bulk handling forward,”

explore the latest and most innovative technologies in the industry.

The event will provide many notto-be-missed conferences, including technical talks surrounding infrastructure investment and the supply chain, sustainable operations and emissions reduction, innovations in automation, food security and agriculture, skills development, workforce safety, and networking opportunities.

Rocks said that BULK2026 is a must-attend event, and the technical conferences further elevate an already premier expo.

“At BULK2026, exhibitors can expect real leads and real projects, engaging directly with professionals who are actively seeking bulk handling solutions,” she said.

“The event offers unmatched exposure, giving your brand the chance to shine in front of one of Australia’s largest industrial audiences.”

Attendees will be given a chance to increase brand exposure to a large industrial audience and generate leads by connecting with potential clients where otherwise you may not be able to.

It’s the perfect setting to strengthen relationships, reconnect with existing clients, and build valuable new partnerships. Plus, you’ll gain valuable market insights to better understand where the industry is heading and how your products fit into its future.

So, is bulk for you?

Rocks said if your business plays any role in the movement, storage, processions, or management of bulk materials, the answer is yes.

“Don’t wait until the floorplan fills up. Book your stand today and get ready to make some serious noise at Australia’s only dedicated bulk handling event,” she said.

For more information, visit bulkhandlingexpo.com.au

Pacific Automation’s Smart Series is eliminating false trips across Australia’s mining industry.

KILOMETRE-LONG

dot the Western Australian landscape, moving iron ore from pit to port.

This critical infrastructure basks in the hot desert sun, reaching 45°C or higher before dropping rapidly at night.

Temperature fluctuations like this cause metal throughout the system to expand and contract. When a high level of vibration is added into the mix, it creates the perfect conditions for the wires inside an emergency stop system to cause a false trip.

Pacific Automation product manager for conveyor controls Johan Blignaut said these false trips can cost mines a lot of money in paused production.

“False trips are a very common problem,” he told ABHR. “Some conveyors will have them once every other week, some may be dealing with them every day, or even multiple times per day.

“Once the safety switch has been tripped, it resets itself, making it difficult to find.

“If you have a 10km belt with multiple loose connections, it can cost a lot of money in lost productivity as maintenance teams undertake hours of fault-finding.”

To find a solution to this issue, Pacific Automation has worked with maintenance teams, safety managers, and control system engineers working in bulk material handling operations.

These discussions revealed exactly where standard pull-wire switches fall short and led to the creation of the Smart Series range.

The Smart Series is a modular conveyor safety system that combines pull-wire, drift, rip, slip, and blocked-chute protection into a single, connected platform. The system has several core features that make it perfect for a variety of different locations and situations. These include scalability for longer conveyor systems, no need for an external power supply.

Blignaut said all of the company’s

switches are manufactured from highquality materials and are IP66 or IP67rated to withstand tough environments.

“Our equipment has never had a contact failure. The chances of it happening are very slim,” he said.

“Because dust cannot enter the components, the maintenance team does not have to open up each box to replace switches. Instead, they can quickly test them during scheduled downtime.

“The quality of our switches and how they are designed is what sets us apart. The switches are engineered to eliminate the problems our clients are facing.”

The Smart Series has also achieved a Safety Integrity Level (SIL) 2 rating. The SIL2 rating is a measurement of a safety system’s reliability, indicating its probability of failure on demand.

Bilgnaut said Australian businesses have come to expect SIL2 ratings for conveyor switches as industries look to improve their site safety.

“Our product is at a level that provides additional safety for the customer, which is important for us. Quality, safety, and reliability are key for us as a company,” he said.

“It’s not just about the cost of a product. We encourage our customers to explore how the system can save time and money over its lifespan.

“Over the past year, we have grown alongside our customers. Trials are ongoing across the country, with mines and ports starting to adopt the system.”

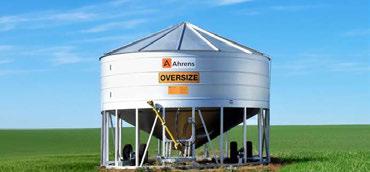

Trusted by Industry. Delivered by Satake

With decades of proven experience, Satake Oceania designs and delivers tailored grain silo and storage systems—built to perform, built to last.

We provide end-to-end solutions for every scale and need:

• Small seed storage to large-scale silo complexes

• Grain handling, bulk storage, and full milling systems

• Feedlots, our, rice, and seed processing solutions

Every project is backed by:

• Local manufacturing in Australia

• Complete design, build, and installation services

• On-the-ground project management and long-term support

Our hands-on approach ensures each solution aligns with your operation—today and into the future.

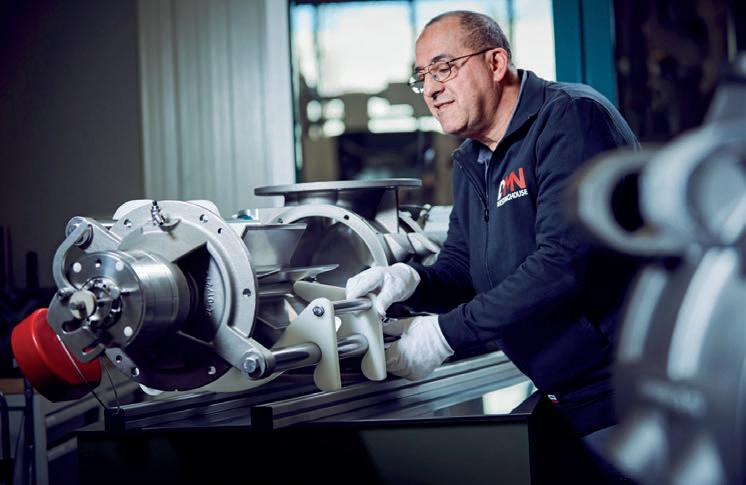

ABHR finds out how the NEPEAN Group grew from a small backyard business into the multinational supplier it is today.

BILL MUNDAY STARTED WORKING for NEPEAN in 1987. At that time, most of the company’s work was overhauling and refurbishing other manufacturers’ equipment.

The late David Fuller founded NEPEAN in 1974 and started NEPEAN Conveyors with the late Peter Gilbert in 1985. Munday said in the early days, NEPEAN Conveyors had about half a dozen employee’s and was turning over around a million dollars each year.

Now, in 2025, the NEPEAN Group has grown into an international powerhouse, employing close to 2000 people and with around a billion dollars in turnover each year.

“NEPEAN Conveyors has grown from a backyard business into the leader in Australia in underground coal conveyors,” Munday said.

“These days, the NEPEAN Group has facilities all around the world and has diversified to handle much more than just coal.”

Munday worked his way up in the business, moving from being a fitter machinist to onsite service technician, and sales manager before serving as the company’s general manager for New South Wales for the past 20 years

This career trajectory is not uncommon within the company, with

many members of the core management team having more than 20 years of experience at NEPEAN.

“The real key to our success over the years is the culture within the business,” Munday said. “You can’t just design culture – it needs to be promoted and cultivated. Being able to keep a stable core team that helps uphold this culture is really important.

“Our business revolves around the NEPEAN DNA. We aim to make the customer successful, take ownership, get things done, be entrepreneurial,

professional, and constantly growing, because at the end of the day, the best team wins.”

Another benefit of having the same core team members at the company is experience. The company can draw on its team members’ depth of knowledge, especially when it comes to the underground coal industry. Customers also appreciate this, as they know who to turn to when they need to talk to someone about an issue they are facing.

One of the things that Munday said differentiates NEPEAN from other suppliers is its approach to engineering.

“When we face complex issues where we need particular equipment, we don’t just go to the market and adapt something to suit our needs. We specifically design something for the requirements,” he said.

An example of this is the company’s wet brake systems that NEPEAN designs and manufactures for underground coal mining applications. Initially, it was developed more than 20 years ago to solve a problem that customers were facing.

Munday said it has now become an industry standard.

“We could have gone out and sourced someone else’s product – but we find it far better from a technical and performance point of view to design the exact equipment we are looking for,” he said.

NEPEAN Conveyors was one of the first companies to introduce variable voltage variable frequency (VVVF) drives to the underground coal industry back in 2000. Today the VVVF drive is the drive system of choice for the majority of high-powered conveyor drives in the industry.

This approach allows NEPEAN to stay up to date with changing industry demands, such as a need for improved productivity and reliability. When Munday first started at the company, a 1200mm belt was the norm for underground mining operations. Now, he said, there are not many mines that would use belts smaller than 1500mm.

In addition to designing the equipment for the customer, NEPEAN

provides an end-to-end service offering.

As part of this offering, the company’s dedicated service department can provide installation assistance, belt splicing and replacement, weekly inspections, ongoing maintenance, and more.

Munday said this hands-on support is something that customers are looking for in their suppliers.

“Our customers need equipment quickly. They can’t afford to wait for unplanned downtime,” he said. “They know they’ll get the right service with us.”

Because NEPEAN is 100 per cent Australian-owned, the company has an extensive network of manufacturing and spare parts around the country.

Munday said he was proud of that fact, especially because it gives the company an edge in the competitive mining industry.

“We’ve gone through difficult times in Australia as a manufacturer, but

we’re glad to keep manufacturing here,” he said.

“It gives us an advantage. Our facilities are located close to our customers, giving us a fast response time.”

There is no end in sight for NEPEAN’s growth at this point. Construction is underway on a new facility for the company’s NSW branch, which is expected to be completed in 2027.

The new 5000m2 building will be located near Wollongong and provide additional space for the growing business.

Munday said similar expansions are happening all around the world.

“Demand for our products is driving this growth. Our revenue has been on a steady increase for many years, and we have a significant market share,” he said.

“It’s an exciting time for us, and we’re looking forward to delivering Australian-made equipment to industries around the world.”

ABHR looks at what Cement Australia’s acquisition of the Buckeridge Group of Companies’ cementitious assets means for the Australian construction materials sector.

cementitious assets of the Buckeridge Group of Companies (BGC) is complete, and it presents a major deal for the country’s construction materials sector.

Cement Australia, a joint venture of Holcim Australia and Heidelberg Materials Australia (HMA), has expanded its presence in Western Australia through the deal but so too have the other key players in the construction materials sector including Heidelberg Materials Australia, Holcim Australia and Adbri.

BGC started as a property development and building company in 1959 before evolving into a construction and manufacturing business with considerable assets, including cement, concrete, quarry, asphalt, and transport operations, as well as a materials

technology centre and a cement grinding unit, which was described as “state-ofthe-art”.

When the acquisition was publicly announced last year, Cement Australia’s co-owners both saw it as a strategic step for their businesses and, by extension, their joint venture.

“The acquisition of BGC complements and expands our growing business in Australia, marking an important strategic step to further strengthen our existing footprint in this attractive core market,” Heidelberg Materials chairman of the managing board Dominik von Achten said at the time.

Holcim region head AMEA Martin Kriegner shared the sentiment.

“The acquisition of this division of family-owned BGC will reinforce

Holcim’s footprint in the attractive market of Australia. With its stateof-the-art facilities, the acquisition will advance Holcim’s leadership in sustainable and innovative building solutions,” he said.

Almost a year on from the announcement of the deal, Cement Australia chief executive officer Rob Davies welcomed the finalisation of the deal.

“I am very grateful to and proud of the [Cement Australia] team who have worked so hard behind the scenes over an extended period to bring the sale to completion,” he said.

“We are all looking forward to working alongside [the BGC employees who have joined CA] to continue to deliver first-class customer experience and to grow our business in Western Australia.

“To the Buckeridge family, thank you for placing your trust in us as we continue the journey Len started and to build on the legacy you all created in BGC.”

A key approval came from the Australian Competition and Consumer Commission (ACCC) in September 2025.

The regulator announced that it would not stand in the way of the acquisition, following all parties’ agreement to changes around the transaction.

The original proposal had raised concerns from the ACCC but a new proposal, which included Adbri alongside the other merger parties, was put forward. The new proposal included Cement Australia, Holcim Australia and Heidelberg Materials Australia (HMA) gaining select cement and readymix concrete (RMX) assets from BGC. Under the terms of the revised deal, Adbri gained select BGC facilities including RMX assets. The overall transaction included aggregates, asphalt, transport and materials technology centre assets.

ACCC commissioner Philip Williams said the regulator conducted a thorough review of the proposal.

“An initial proposed structure for the acquisition of BGC by Cement Australia, Holcim and HMA raised significant preliminary competition concerns for us, particularly in relation to the competitive overlap in RMX and aggregate quarries in Western Australia,” Williams said.

“We examined the amended acquisition proposal very closely. In particular, we looked at both the loss of BGC as a competitor in the supply of RMX and the risk that Cement Australia or Adbri would use their position as cement

suppliers to hinder the ability of rival RMX suppliers to compete.

“While we acknowledge strong concerns from some market participants, we found that Cement Australia and Adbri would be likely to compete with each other to supply cement to RMX competitors after the acquisition.”

According to the ACCC, its investigation looked at several factors including margins of HMA, Cement Australia, Holcim and Adbri Pty Ltd throughout the supply chain, the profit incentives available to those parties’ post-acquisition, the market power

Since 1985, Kinder Australia has been at the forefront of conveyor solutions, delivering trusted, innovative products that improve e ciency, safety and productivity in bulk materials handling.

We support our customers with:

• High-performance products that evolve with industry needs

• Expert advice and genuine customer care every step of the way

• Reliable outcomes that support long-term site success

As we mark 40 years of progress, we continue to engineer smarter, safer and more sustainable solutions for every site we serve.

Discover what Kinder can do for your

those parties would possess following the acquisition. It followed approval from the European Commission earlier this year. The European regulator received notification of the deal on February 12 and, via a note published in March, decided it would not oppose the transaction.

“The European Commission has decided not to oppose the notified operation and to declare it compatible with the internal market and with the EEA Agreement,” the notice read.

The confirmation of the agreement was welcomed by the merger parties, including Holcim Australia, HMA and Adbri.

Holcim Australia confirmed it will take over two BGC ready-mix concrete sites in Canning Vale and Naval Base in Perth.

Holcim Australia and New Zealand chief executive officer George Agriogiannis said the deal will enhance the company’s offering in Western Australia.

“The addition of these facilities –and the talented people who operate them – strengthens our position in the West Australia market and ensures greater security of supply for our customers,” he said.

“This complements our existing footprint in WA and will help streamline

logistics, further enhance our service capability, and expand our sustainable, innovative and high-value building solutions in the West.”

Heidelberg Materials Australia has secured BGC’s ready-mixed concrete and associated logistics operations at Bassendean as part of the deal.

“This acquisition marks a pivotal step in our strategic growth trajectory in Australia allowing us to further strengthen our capability in an attractive, high-growth region and reinforces Cement Australia’s position as a key player in the national cement industry,” Heidelberg Materials

Australia chief executive officer Phil Schacht said.

“[The Bassendean teams’] expertise and commitment will be invaluable as we work together to ensure continuity, quality and service excellence for our customers in Western Australia.”

When the deal for BGC’s cementitious assets was confirmed in October, it closely followed Adbri’s further acquisition in the South Australian market. The Adelaide-based company, jointly owned by CRH and Barro Group, were able to finalise the acquisition of family-owned SA Premix following the

ACCC announcing it would approve the deal following its review.

“The ACCC concluded that the proposed acquisition is not likely to substantially lessen competition in any market. The ACCC’s investigation focused on the closeness of competition between Adbri and SA Premix in the supply of RMX and aggregates, and whether customers would have competitive alternatives for RMX and aggregates post-acquisition,” the regulator wrote in its report.

Adbri were thrilled to add the WAbased and SA-based assets to their operational network.

“These well-respected businesses strengthen our ability to support customers with high-quality products and services across Western Australia and South Australia,” the company posted on LinkedIn.

“Together, with more than 2000 employees nationwide, we’re building a strong future and continuing Adbri’s 140plus year tradition of providing essential construction materials that help build a better Australia.

“We’re excited to have our new team members, customers and suppliers on the journey with us.”

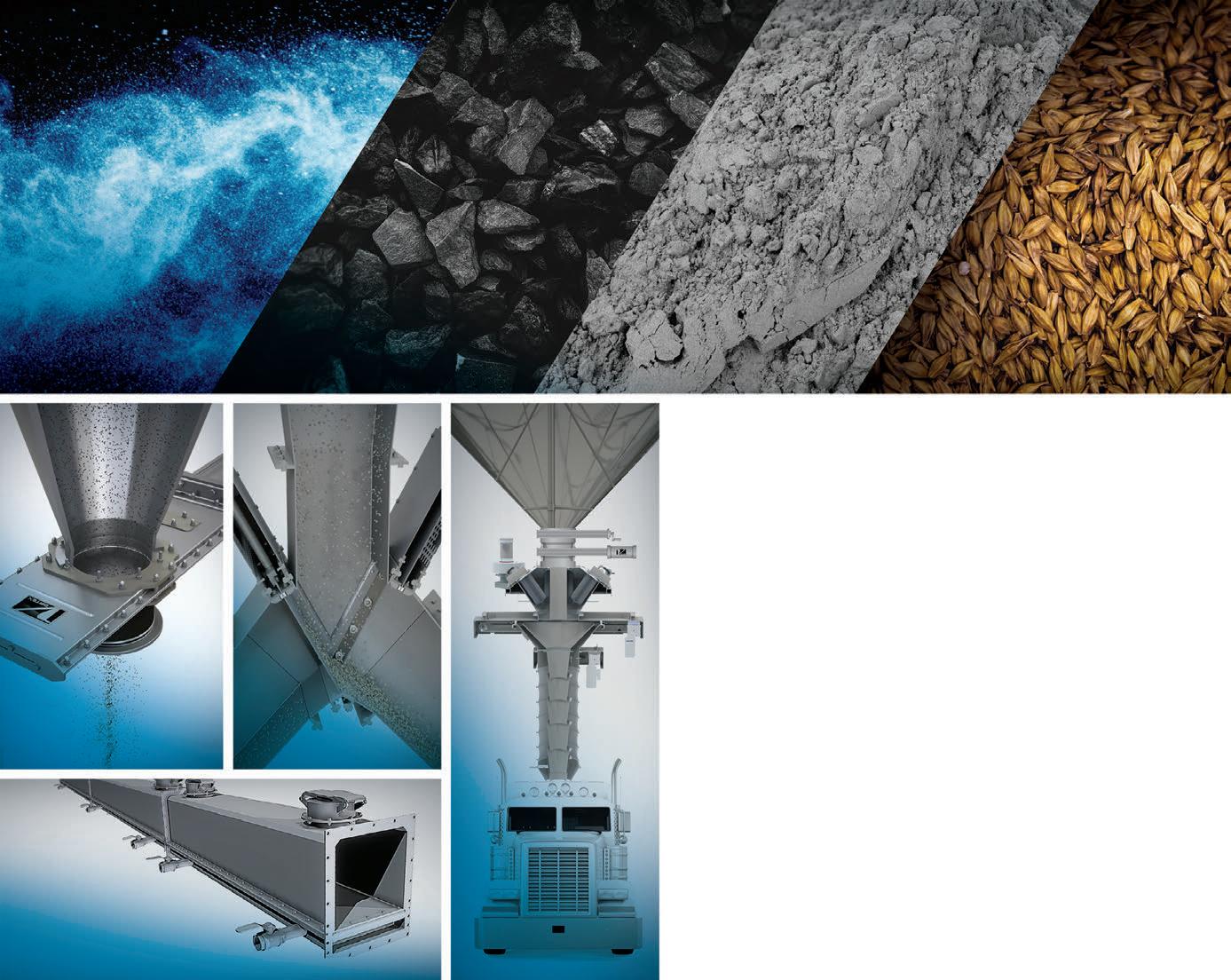

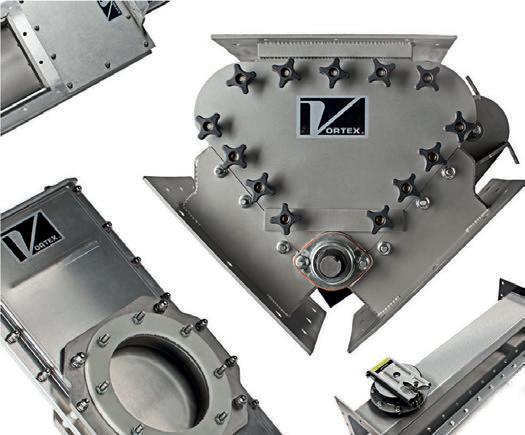

VORTEX DESIGN PHILOSOPHIES:

Vortex believes in offering only value-added products that are designed for purpose, rather than producing off-the-shelf, commodity components. With an in-house team of application engineers, Vortex designs for the most demanding applications.

modifications to ensure reliability, durability and longevity.

components are engineered with in-line service features that accelerate the system maintenance process, saving your team time and money.

Vortex approaches wear parts with simple, durable design. Doing so means maintenance procedures are also kept simple while the need to perform maintenance is infrequent. This leads to a reduction in spare part inventories and a reduction in costs.

End users are often attracted to equipment on the fallacy of low price, ignoring the cost-benefits of reliability and longevity. Vortex believes in designing products that will out-perform and outlast market alternatives – so that end users realize the full value of their investment.

Facilities have an ethical obligation to protect against the hazards of manufacturing. Vortex closely studies trends in air quality, environmental dust emissions, workplace safety and evolving regulations. Our components are designed with these concerns in mind.

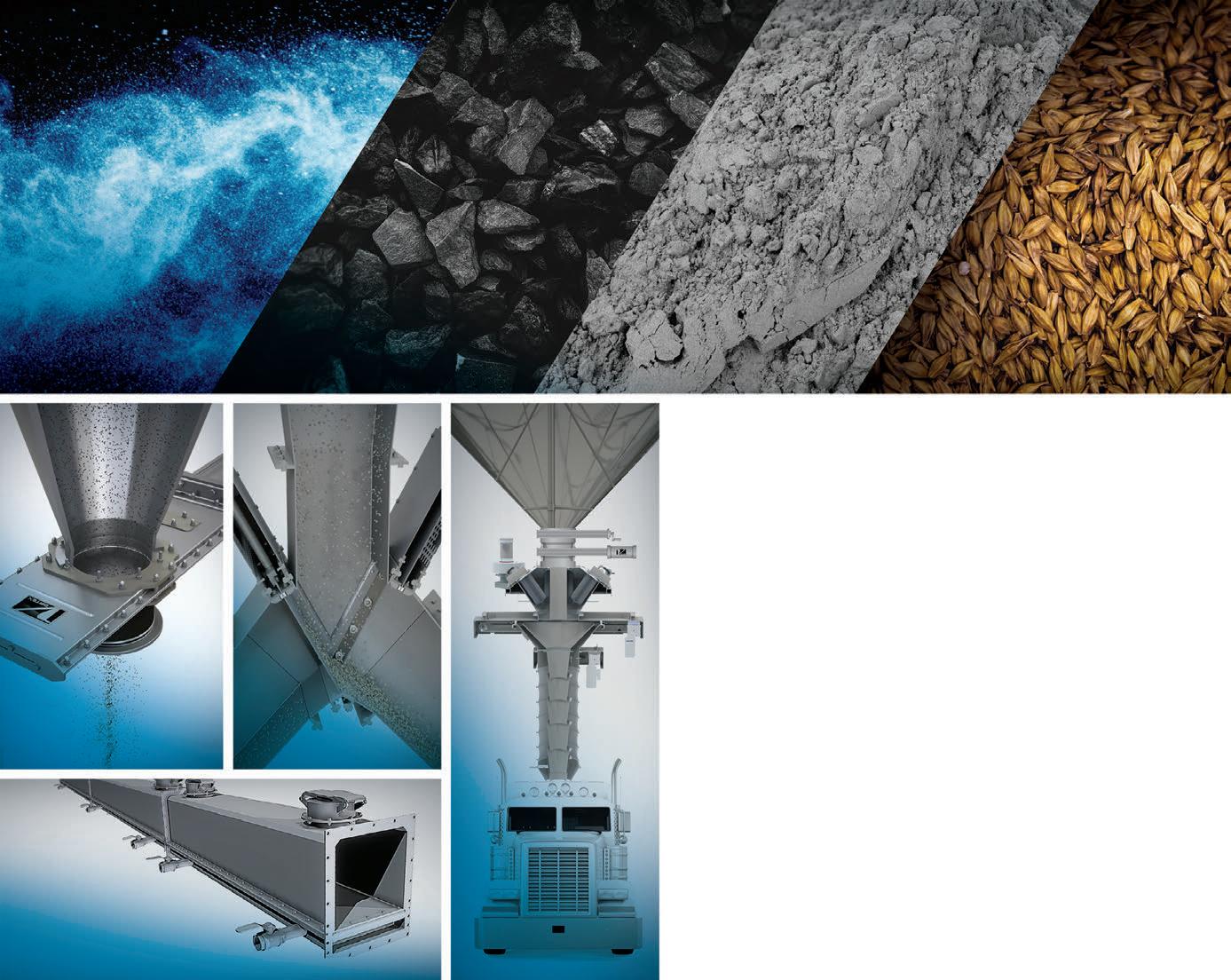

Vortex Global’s extensive range of aerated equipment is helping solve problems for the bulk materials handling sector.

its Northern Michigan operation 15 years ago, it was primarily seeking to establish a foothold as a supplier of loading spouts.

But within its acquisition’s catalogue was a range of aerated equipment, which has become an increasingly large part of Vortex Global’s offering to the bulk materials handling sector.

“When we purchased the company, we primarily focused on the loading spoutside of the business. We developed their loading spouts, positioners and in-line dust collector range,” Vortex Global chief technical officer Mark Schaberg said.

“Once we did that, we turned our attention to what we consider to be accessory equipment to the loading system, so fluidised conveyors, aeration pads, silo aeration bin bottoms and fluid beds.”

Vortex Global’s development group, located within its engineering department, oversaw the development of the aerated product range. It also collaborated with specialists to conduct flow studies, material characteristics studies and additional technical resources throughout the development process.

“We have a lot of ability within that group because for a company of our size, we have a fairly large engineering group,” Schaberg said.

This development group is integral to how Vortex Global operates. It handles customer-focused suggestions and examines how existing products can be adapted to meet the modern needs of the bulk handling sector.

Globally, there has been a trend of operations needing to move high tonnage and volumetric rates at a reduced cost. While the answer to some of these predicaments is to automate parts of the bulk handling operation, this trend has also seen Vortex Global stay true to its design philosophy.

“What Vortex has excelled at, in everything right down to its gates and valves line, is that our products are

designed for ease of maintenance and maintainability. Particularly when it comes to not needing to remove the equipment from its installed position,” Schaberg said.

“I think that maintainability is something that we strive for at the end of the day because it can help our customers increase their productivity and efficiency as well.”

A key part of Vortex Global’s range of fluidised conveying equipment is its AeroSlide. The Aero-Slide is an air-gravity conveyor, which consists of a rectangular chamber separated by an air-permeable, porous media. The media is placed along a horizontal plane to separate the two chambers within the conveyor.

An upper chamber handles the material being conveyed, while the lower chamber handles the compressed air. A positive fan or blower injects lowpressure, dry air into the lower chamber, which then permeates upward through the porous media. When the air is counterbalanced by gravity, the material flows downstream in a fluidised/aerated form, across a surface similar to an air hockey table.

Air-gravity conveyors are used to handle various dry, lightweight, easily fluidised powders, such as activated carbon, alumina, bentonite, calcium carbonate, cement, clays, detergent powders, or talc. A general rule of thumb is that the particle size is usually smaller than 50 mesh.

When designing an air-gravity conveyor system, selecting the right type of metering gates to control material flow is essential. Usually, material is fed from a bin or silo by opening a slide gate at the base of the vessel. The fine material is then aerated and moves into the conveyor.

In conjunction with its Aero-Slide conveyors, the company has built its Aero-Drum valve. The valve can be operated through electric, manual, or pneumatic actuators and does not use the traditional ‘v-notch’. Instead, the drum opening is a parabolic curve that is symmetrical from either side, allowing the drum to be positioned in a full-open or full-closed position.

The internal drum seal is made of needled polyester, increasing rigidity and offering high abrasion resistance. To facilitate maintenance, the valve features a split inlet flange that can be removed independently of the valve body.

The US-based manufacturer also offers a range of aerated bin bottoms, which are utilised in various applications, including cement handling. The aerated bin bottoms support the movement of lighter-weight materials.

It achieves this by allowing air to pass through the dry materials, which causes the material to exhibit fluidlike characteristics.

These products are typically located at the bottom of silos or hoppers, especially in storage silos with large dimensions. Customers can often find that the aeration bin bottoms can eliminate issues like bridging and ratholing, which are commonly found in material storage applications.

They work in conjunction with Vortex Global’s trusted loading system range, which includes its loading spouts and slide gates. Both of these products provide integral support to the loading process by delivering increased flow rate control.

While Vortex Global has a wide range of products it can provide to its bulk materials handling customers, the company still takes a tailored approach when investigating a customer’s problem.

With a global customer base that deals in a wide range of materials, including chemicals, cement, coal, food, grain, minerals, plastics and more, Vortex Global knows that no two bulk handling operations are the same. Each operation can be impacted by a set of variables, including material characteristics, flow rate, temperature, and more.

This is why Vortex Global takes the time to listen to its customers, conduct site visits and understand the minutiae of the client’s operations.

“It is something that takes a lot of communication, and some customers get tired of the questions, but if you don’t answer them, you don’t get what you want,” Schaberg said.

“We maintain close contact with our customer base. We have a dedicated sales team that maintains contact with our customers, and we regularly visit them.

“We’ll bring maintenance people in, we’ll bring operations people in, and demonstrate various pieces of equipment to the customer, even if it’s something they may not have considered before for their system.

“We want to make sure that they understand we’re not just trying to sell them a piece of equipment, we want to build a relationship with them.”

Koch Solutions has designed a conveyor system that has the potential to unlock deeper mines and reduce the need for truck fleets.

GOLD WAS INITIALLY DISCOVERED in Kalgoorlie in the 1890s, forever transforming the region.

Prospectors flocked to the region, which, according to Bill McKay, Ian Lambert and Shige Miyazaki from the Australian Geological Survey Organisation, had become one of the world’s major centres of sustained gold mining.

Mining this gold required deep shafts, machinery, and treatment plants. Tents were soon replaced by towns as confidence in the long life of the mines increased.

Fast forward more than 100 years, and these pits have become some of the largest and deepest in the country.

Koch Solutions head of sales Luke Bennet told ABHR that Australian mines are becoming deeper, raising questions about the profitability of ongoing operations.

“If you look at some of the gold mines in Western Australia, they’ve been mined for decades,” he said. “They drill and find more ore, which leads them to go deeper and deeper.”

“Eventually, they reach a point where they need to start considering whether they go underground or continue as an open pit as it becomes less viable to move the ore out of the pit.”

This problem is what led Koch Solutions to develop the IBEX steep-angle conveyor system.

Traditional conveying systems are limited by the tension that can be applied to the belt. When working with steep inclines, conventional belt system tensions would exceed practicality.

The IBEX system uses multiple drives along the length of the conveyor, along with rail running technology that significantly reduces the friction losses typically seen on traditional idler conveyors. This friction reduction reduces the installed power requirements to overcome friction losses and increases the belt’s longevity.

Bennet said the system uses a flat base, side-walled conveyor system, which at angles above 25 degrees employs cleats to prevent the material from rolling backwards.

“The advantages over traditional truck-based haulage in deep mining are the removal of the energy consumed by the truck while driving empty,” he said.

“There are also significant advantages [compared to] truck haulage over long distances due to tyre heat restrictions. The deeper a mine, the more trucks are needed to maintain production, requiring additional investment and personnel, including operators and maintainers.”

The IBEX system emerged when Koch Solutions identified a gap in the market. Mines were becoming increasingly

deeper, and mine operators were facing environmental, social, and governance (ESG) constraints.