SMARTER SAFETY

OFFICIAL MEDIA PARTNERS

OFFICIAL MEDIA PARTNERS

IN AN INDUSTRY AS DYNAMIC AND DEMANDING AS MINING, SAFETY HAS ALWAYS BEEN THE MEASURE OF PROGRESS.

While productivity and innovation often take the headlines, it’s the everyday actions that keep people safe – the quick decision to step back from a hazard, the right piece of personal protective equipment (PPE) worn at the right moment, or the alert raised before a near miss becomes something worse.

Hazard avoidance has long been the cornerstone of safe mining practice. Yet, as the sector continues to modernise, what we mean by “avoidance” has evolved dramatically.

Across Australian mine sites, hazard avoidance now begins well before a worker enters the pit or processing plant. Advanced analytics, automation and real-time monitoring have changed the way hazards are identified and managed. Artificial intelligence (AI) systems are analysing fatigue patterns, vehicle telemetry and environmental data to predict unsafe conditions before they happen. Drones and remote inspection tools are taking people out of dangerous environments altogether.

But for all the advances in digital safety, one truth remains constant: people are at the centre of every safe

JOURNALISTS

LUKE DODEMAIDE

Tel: (03) 9690 8766

CEO CHRISTINE CLANCY

EDITOR

PAUL HAYES

Tel: (03) 9690 8766

Email: paul.hayes@primecreative.com.au

ASSISTANT EDITOR

PREALENE KHERA

Tel: (03) 9690 8766

Email: prealene.khera@primecreative.com.au

operation. The best technology in the world still relies on the awareness, judgement and diligence of the person using it, and that’s where PPE continues to play a crucial role.

Hazard avoidance and PPE innovation are helping to shape the future of the workforce.

Ergonomic strain, heat exposure and mental fatigue are now part of the conversation alongside the traditional risks of heavy machinery or confined spaces.

As Safe to Work continues to explore the people, products, and programs driving safer operations, one thing is clear: Australia’s mining industry isn’t waiting for safety to happen. It’s designing it, embedding it and wearing it. Because when it comes to hazard avoidance, prevention is not just better than cure; it’s the definition of progress.

Paul Hayes Managing Editor

Email: luke.dodemaide@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

ART DIRECTOR

MICHELLE WESTON

RESOURCES GROUP LEAD

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGER

JAKE NIEHUS

Mob: 0466 929 675

Email: jacob.niehus@primecreative.com.au

SUBSCRIPTION RATES

Australia (surface mail) $140.00 (incl GST)

New Zealand A$148.00

Overseas A$156.00 For subscriptions enquiries please call 03 9690 8766

Emesent describes itself as “a world leader in drone autonomy, LiDAR mapping, and data analytics”. Founded in 2018 after a decade of research at the Robotics and Autonomous Systems arm of CSIRO, Emesent has built a reputation for delivering highquality data capture, working with customers to provide efficiency, safety and operational insights. Its expertise covers robotics, autonomy, AI, machine learning, data analytics, and developing innovative technologies as we advance the autonomous digitisation of the physical world. Cover image: Emesent

PRIME CREATIVE MEDIA

379 Docklands Drive

Docklands, VIC 3008 Australia www.primecreative.com.au

© Copyright Prime Creative Media, 2016 All rights reserved. No part of the publication may be reproduced or copied

30 Chemical risk recast Safe to Work unpacks events that led to an underground fire at a NSW metalliferous mine site.

39 Skill meets grit Why Komatsu’s field service starts from within, and what that means for mining companies. 46 Tailored fire safety

MusterFire has redefined fire safety underground with

52 Safety mindset awarded Hancock Iron Ore nabbed several accolades at the recent Australian Mining Prospect Awards.

54 A significant celebration

The 2026 Queensland Mining & Engineering Exhibition is set to be another blockbuster event.

57 Expo enters new phase

The PNG Industrial and Mining Resources Exhibition and Conference is poised for a successful return.

AS WORKPLACE SAFETY CONTINUES TO REMAIN A TOP PRIORITY, THE MINING INDUSTRY HAS EXPERIENCED A SERIES OF DEVELOPMENTS AND INCIDENTS OVER RECENT MONTHS.

SAFE TO WORK HIGHLIGHTS SOME OF THE MOST SIGNIFICANT UPDATES.

From regulatory updates and corporate safety milestones to high-profile campaigns and operational incidents, September and October offered another busy chapter in mine safety. Here’s a snapshot of the developments that stood out over those two months.

SAFETY INSIGHTS

Glencore’s Oaky Creek mine rescue team claimed top honours at the 2025 Queensland Mines Rescue Service Open Cut Challenge at Peak Downs, demonstrating outstanding emergency response capabilities.

Anglo American’s Grosvenor mine marked a major milestone, as crews returned underground for the first time in a year following an explosion at the Moranbah site.

Ravenswood, Queensland’s largest gold mine, earned a key mental wellbeing accreditation, reinforcing its commitment to supporting worker health and safety.

Pilbara Ports completed Stage 5 of the Utah Road Pavement Rehabilitation Project, improving safety along one of the region’s busiest freight corridors.

Mine safety featured prominently at AIMEX 2025, with industry panels exploring strategies to embed a positive safety culture at mining operations.

National Safe Work Month kicked off in October, with Safe Work Australia urging all industries, including mining, to renew efforts towards safer workplaces.

Rio Tinto reaffirmed its commitment to safety following the death of a contractor at the SimFer iron ore project in Guinea earlier this year.

New Queensland work health and safety regulations now require mining managers and operators to provide audiometric testing for workers exposed to high noise levels while using PPE.

National data from Safe Work Australia showed encouraging progress in reducing workplace fatalities, with 188 incidents recorded in 2024 – down from 200 in 2023 and below the fiveyear average.

Perseus Mining celebrated a full year without lost time injuries across its West African operations, reporting a 12-month rolling lost time injury frequency rate of 0.00.

SAFETY INCIDENTS

A loader fire during tele-remote operations prompted the NSW Resources Regulator to issue recommendations and stress the importance of managing fluid power risks.

Operators are being urged to review safety systems for raise-boring operations following a court ruling related to a 2022 underground rock fall incident in WA.

A tracked dozer rolled during haul road construction at an open-cut coal mine, prompting regulators to remind operators about hazard identification and management.

A collision between a dozer and haul truck at a mine loading zone reinforced the need for stronger segregation controls in high-traffic areas.

An excavator at an open-cut coal mine caught fire after an oil leak from a high-pressure pump hose, highlighting critical maintenance and safety lessons.

A bulldozer at a Queensland coal mine sank into an open coal valve void, underlining important safety considerations for stockpile operations.

The journey towards recovery at Anglo American’s Grosvenor mine in central Queensland has entered a new and significant phase. For the first time since an underground explosion halted operations at the Moranbah site one year ago, crews have returned below the surface. The re-entry was carried out through a staged and carefully managed process that followed the successful completion of mine re-ventilation activities and critical safety preparations in August.

Grosvenor mine general manager

“This marks a significant milestone in our restart journey and is a testament to safety, innovation and teamwork at Grosvenor mine,” he said.

“Our crews have stepped up in amazing ways – solving problems, adapting technology in innovative ways, and rethinking how we do things underground.”

Queensland Mines Rescue Service was also on site in August to carry out preliminary reconnaissance inspections before the staged deployment, where crews progressed 1500m underground.

with Resources Safety and Health Queensland and industry safety and health representatives, with the safety of our people our highest priority – always.”

Before anyone went back underground, the team at Grosvenor had already seen what awaited them.

Using advanced technology and “out-of-the-box thinking”, the mine’s recovery team built a virtual picture of the underground environment, mapping conditions and infrastructure in detail.

According to McDowall, one of

atmosphere underground.

“This allowed us to see and understand the environment before anyone set foot back inside the mine,” he said. “These innovations helped provide unprecedented visibility of the underground environment, helping us plan [the] re-entry with confidence and clarity.

“Now we are working to validate the conditions indicated by our remote sensors with direct visual inspections as we work to recover the mine safely.”

The approach demonstrates how technology is helping reshape mine safety.

Instead of relying only on direct physical inspection, Anglo American’s teams used a range of digital and remote systems to gather accurate data while minimising risk.

The team at Grosvenor used this technology in a new way by lowering it down boreholes to map underground workings from the surface. It supported infrastructure inspections and damage assessments while monitoring the underground atmosphere. Handheld SLAM (simultaneous localization and mapping) LiDAR may also be used later to map underground workings following mines rescue reconnaissance.

North mine as a potential tool to visually inspect Grosvenor mine safely.

Drone use

Drones supported recovery efforts through high-resolution imagery and videography, methane detection, thermal imagery and airborne LiDAR.

Laser scanning

High-resolution laser scanning of critical surface infrastructure supported modification and fabrication for shaft ducting and fan installations, forming a critical part of the reventilation process.

For McDowall, the success of Grosvenor’s re-entry effort is as much about the workers as technology.

“What’s really stood out for me is our people. They’ve stepped beyond their usual roles, taken on new challenges, and grown in ways that make me incredibly proud,” he said.

“That team spirit, people from different backgrounds coming together, has been at the heart of our progress. And because so many of our people live in Moranbah, we know how important it is to get this right for the community, too.

“Our team will continue to work side-by-side with the Queensland safety regulator and safety representatives to ensure every step we take at Grosvenor is safe and considered.”

The collaboration at Grosvenor has been mirrored in another of Anglo American’s Queensland operations, guided by a landmark gathering.

Senior coal mining leaders recently came together for a first ever tripartite safety and health forum to consider a high-potential incident at Anglo American’s Moranbah North steelmaking coal mine.

The incident, which occurred on March 31, involved an underground explosion that triggered dangerously high carbon monoxide levels, forcing the evacuation of all workers. No injuries were reported.

Chaired by acting commissioner for Resources Safety and Health Ken Singer, the forum was the first of its kind in Queensland, with representatives from Anglo American and the Mining and Energy Union, site safety and health officials, and government mine inspectors among those present.

“This is the first time a tripartite forum like this has been held in Queensland to investigate a highpotential incident and this forum, established by Anglo American, has set a benchmark for industry collaboration and transparency into the future,” Singer said.

Held in April and June, the twopart forum provided a platform for discussions aimed at uncovering the root causes of the incident

and identifying industry-wide improvements. During the sessions, Singer emphasised that attendees needed to commit their energy to discovering lessons from the event while leaving no stone unturned in the investigation process and applying proper diligence to the investigation of the incident.

“Right up front we discussed refraining from using phrases such as, ‘someone should have’,” he said. “We know that circumstances involving unplanned events of this nature are never simple and they often involve complex chains of events.

“Hindsight bias can influence how we approach these matters, and it is more productive to understand the circumstances which led to the issue.”

By bringing together government, union and company representatives, the process reflected a shared commitment to improving safety and learning from incidents through collaboration rather than criticism.

Singer valued the opportunity to lead a process that included such broad participation.

“In tripartite forums, we are more likely to really dig into the issues and more likely to recommend changes

event occurring in the future,” he said.

“The forum examined the draft findings of Anglo American’s comprehensive s201 report investigation, which was supported by some of the pre-eminent industry experts, sought tripartite input into potential causes, and considered additional controls that could be put in place to allow the safe resumption of mining operations.”

Singer said one of the key outcomes of the forum was to document a pathway to allow extraction to recommence at Moranbah North mine.

Anglo American’s Australia chief executive officer Dan van der Westhuizen told Safe to Work the forum “represents a significant step toward fostering a more collaborative and transparent approach to safety”.

“Anglo American was proud to design, initiate and participate in this industry-first tripartite safety and health forum to review the findings of its investigation into the recent incident at Moranbah North Mine,” he said. “The forum has been described as setting a new benchmark in safety collaboration, enabling all parties

to explore potential regulatory and structural improvements that could benefit the entire coal mining industry.

“This collaborative approach reflects a shared commitment to continuous improvement and safer outcomes for all coal mine workers in Queensland.”

From the re-entry at Grosvenor to the tripartite forum at Moranbah North, Anglo American’s work in Queensland reflects a strong emphasis on safety.

At Grosvenor, advanced technologies such as LiDAR, drones and robotic systems have been used to create a safer path forward for workers returning underground. At Moranbah North, the company has helped lead an open and constructive conversation about incident investigation and prevention across the broader coal sector.

Both examples show how safety leadership can take many forms, from engineering and data-driven solutions to collaboration and knowledge sharing. For those working on the ground and across the state’s mining industry, the goal remains the same: to make every operation safer through teamwork, transparency, continual learning and innovation.

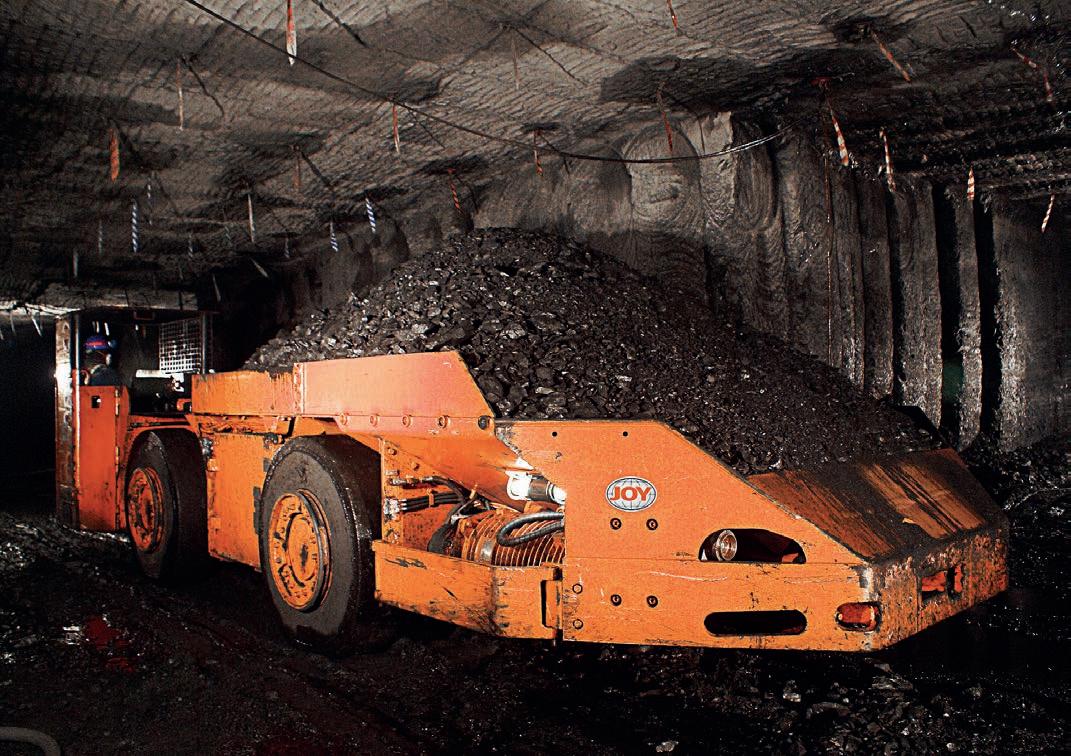

Advances in remote operation have helped keep workers out of harm’s way.

AUSTRALIA’S MINING INDUSTRY IS TAKING HAZARD AVOIDANCE TO THE NEXT LEVEL.

In Australian mining, hazard avoidance has evolved from being a technical consideration to a defining philosophy of workplace safety. The emphasis is no longer on responding to incidents but on preventing them entirely, a shift that has reshaped how miners design sites, train people and invest in technology.

Mining has always been one of Australia’s most complex and highstakes industries.

Heavy machinery, remote environments and dynamic geological conditions make it an inherently challenging workplace.

Yet the past decade has seen remarkable progress in improving safety outcomes, thanks to smarter engineering, stronger regulation and a steady embrace of innovation. The industry’s focus on avoiding hazards, rather than just managing them, is setting new benchmarks for worker protection and operational excellence.

The rationale for hazard avoidance is simple: when a hazard is prevented or neutralised before exposure occurs,

the potential for injury, disruption or loss disappears with it. That philosophy has become central to how Australian miners operate.

From pit design and haulage planning to vehicle interaction management, today’s operations are engineered to remove people from harm’s way.

Safety leaders across the sector have been clear that this shift is about a proactive culture of care, not just about new tools or compliance targets. Regulators, contractors and mining companies have collaborated to foster this culture. When hazards are identified early and eliminated through smarter design, sites become safer and more efficient.

Technological advances have accelerated this cultural shift over recent years. Once reliant on manual oversight and static procedures, modern mine safety now leverages real-time data, intelligent systems and automation to detect and prevent hazards before they can cause harm.

One of the most significant developments has been the widespread adoption of proximity detection and collision avoidance

systems. These systems use sensors, GPS, radar and radio-frequency identification (RFID) technology to alert operators when vehicles or personnel enter unsafe zones. Many are now capable of automatically slowing or stopping machinery to prevent impact.

While early iterations were sometimes limited by false alarms or patchy connectivity, advances in communications networks and software integration have transformed their reliability. As a result, mines across Australia are deploying these systems at scale, significantly reducing the risk of vehicle-related incidents.

Autonomous and remote operations are another area where hazard avoidance has taken a major step forward.

Remote-controlled drills, trucks and loaders are now commonplace in the Pilbara and other major mining regions, allowing workers to operate equipment from secure control centres hundreds of kilometres away.

This technological leap removes people from the most hazardous parts of the mine entirely. As regulatory frameworks have evolved, operators have gained greater confidence

in deploying these systems safely and effectively.

Digital transformation has been just as important to hazard avoidance as the hardware itself. Mining companies are increasingly using integrated data platforms to connect sensors, vehicles and workers in a single digital environment. These systems provide a real-time picture of site conditions, allowing supervisors to see where people and machinery are at any moment and intervene before conditions escalate.

The growing use of digital twins, virtual models that replicate mine operations, is further enhancing predictive safety.

By simulating everything from haul road gradients to fatigue patterns, these systems allow teams to identify hazards in a risk-free digital space before they appear in the field. The result is more informed planning, faster decision-making and a measurable reduction in high-risk scenarios.

Wearable technology has also played a growing role in worker protection. Devices that track fatigue, body temperature and location help supervisors spot early signs of risk and ensure workers are fit for duty.

Combined with strong privacy protections and consultation processes, these systems are improving wellbeing while reinforcing safety culture.

Unmanned aerial vehicles, or drones, have quickly become another indispensable part of modern mining safety. Tasks that once required workers to climb, enter confined spaces or approach unstable areas can now be done from a safe distance using high-resolution cameras and sensors. Drones are now routinely used for geotechnical monitoring, high-wall inspection and post-blasting assessment, providing richer data while keeping workers out of harm’s way.

Similarly, advances in robotics and remote sensing are enabling safer maintenance and inspection of critical infrastructure. Robotic crawlers can now inspect pipelines, conveyors and underground spaces without human

entry, allowing hazards to be identified and addressed earlier than ever before.

What distinguishes today’s safety technologies from those of just a few years ago is the scale and maturity of their use.

In 2022, many of these tools were still in trial stages. By 2025, however, they’ve become part of standard operating practice.

Improvements in battery life, durability and network connectivity have made equipment more reliable in the harshest mine environments.

Crucially, mining companies are no longer implementing technology in isolation. Systems are instead being integrated into broader safety management frameworks, where technology supports rather than replaces strong human oversight.

Operators are sharing lessons across sites, while vendors are working with industry bodies to align equipment standards and training requirements. This cooperative approach is helping to ensure the benefits of hazard avoidance technology are being realised consistently across the sector.

Even as technology takes on a greater role in identifying and eliminating hazards, people remain at the heart of mining safety. The effectiveness of any system depends on how well it’s understood, trusted and maintained by the workforce. For

this reason, training, consultation and leadership remain critical.

Many companies are investing in upskilling programs that help workers adapt to new systems and technologies. The emphasis is on building confidence and capability so technology becomes a tool of empowerment. This alignment between people and innovation is helping drive the next stage of Australia’s safety evolution, where advanced systems and skilled operators work in harmony

The industry’s progress in hazard avoidance is already being reflected in improved safety performance. Serious injury frequency rates have continued to trend downward, and while every incident is one too many, data suggests that proactive prevention is paying dividends.

As Australia continues to lead in mining technology and automation, the safety lessons learned here are influencing global best practice. What’s emerging is a model of mining where risk is systematically designed out, and where technology and human insight combine to create safer, more sustainable operations.

Hazard avoidance will always be a journey. As mines go deeper, equipment grows larger and operations more connected, new challenges will emerge. But the direction is clear: the Australian mining industry is not standing still. It’s continuously innovating, learning and investing to protect its people.

WHEN A DANGEROUS ROCKFALL RENDERED VAST SECTIONS OF AN UNDERGROUND QUARRY UNSAFE, EMESENT’S HOVERMAP STEPPED IN TO DO WHAT NO HUMAN SAFELY COULD.

Offering a solution described as “mine-saving” is not a small claim. Living up to that reputation is even harder. Yet, in the heat of a high-stakes situation, Emesent’s Hovermap did just that. When a major rock fall occurred in an active limestone quarry in Iowa, US, Unmanned Aerial Surveys (UAS) turned to Hovermap’s autonomous drone technology to safely explore, navigate and map the unstable underground workings.

The goal was to cover several kilometres without putting a single person in harm’s way.

Underground mines are already some of the most dangerous work environments, with loose rock, flooding, unstable ground and the constant threat of collapse creating serious hazards. The Iowa event was on another, “extreme” level.

It involved a significant collapse covering roughly 22 acres, blocking off passages and leaving large sections of the mine destabilised – making it not just risky, but impossible to send people in to assess the damage.

Hovermap, however, offered a way forward.

With versatile mounting options, Emesent’s system uses light detection and ranging (LiDAR) sensors and advanced simultaneous localisation and mapping (SLAM) technology to build detailed three-dimensional point cloud maps of underground spaces without relying on GPS signals. Add-on 360° cameras give operators an immersive visual view alongside precise spatial data.

This combination is critical when dealing with the complexities of unstable underground structures, similar to those found at the Iowa site.

Over multiple autonomous flights covering more than 5km, Hovermap navigated tight drifts, avoided hanging rocks and carefully skirted flooded sections.

The drone maintained a strong data connection nearly 800m underground even as the team above heard a dozen rockfalls echo in the distance, which added to the urgency and danger of the operation.

In less than 48 hours from the first emergency call, UAS and the Emesent Hovermap had completed several flights and delivered comprehensive 3D maps. The data provided mine owners with immediate insight into the extent of the collapse, the condition of surrounding drifts and signs of water impoundment which likely contributed to the instability.

What made the mission even more valuable was layering this new scan

over a detailed map created almost a year earlier. Together, the two scans offered a detailed picture of how the underground environment had changed over time. These insights were invaluable for ongoing risk assessments, operational planning and proactive safety measures.

“Without doubt, the ability of Hovermap to enter areas that are completely inaccessible, capture data and return to safety autonomously opens up new opportunities for mine incident analysis and response,” UAS founder and president Matt Mackinnon said.

According to Mackinnon, while Emesent’s solution is already a powerful tool for building fast and accurate 3D maps of underground environments, another trait sets it apart.

“It is the ability to do [what it does] with little to no human intervention that can ensure life-saving decisions can be made in real time,” he said.

Hovermap is transformative because it operates autonomously in GPS-denied spaces where traditional surveying methods either fail or require people to enter high-risk areas.

By removing the need for human entry, it dramatically reduces exposure to potentially life-threatening hazards.

The LiDAR sensor on board captures almost two million points every second, creating intricate highdensity maps that reveal geological formations and structural details with exceptional clarity.

This technology is changing how mining companies approach emergency response as well as routine monitoring. The Iowa incident was an emergency but Hovermap’s strengths also shine in regular change detection and baseline condition documentation. Regular scans allow mining teams to spot shifts in ground conditions long before they become dangerous.

The safety and operational benefits are undeniable. Workers no longer need to crawl through hazardous environments to perform

surveys or inspections, while faster and more accurate data collection reduces downtime and helps maintain productivity without compromising safety.

“Emesent’s AI-powered autonomous mapping technology for GPS-denied environments represents a significant step change in the way surveying is done underground,” Emesent co-founder and chief strategy officer Stefan Hrabar said.

“Our capabilities shift the focus from how the data is captured –automating the most challenging aspects of the process – and instead, shifts attention to what really matters: the interpretation and understanding

of the data, and how these insights can be used to better manage the mine site and the resources deployed there.”

As these autonomous systems become more common, mining’s digital transformation will continue to also deepen.

Regular automated scanning will create living models of mine sites that are constantly updated, making it easier to detect changes before they develop into safety hazards.

Hovermap will be instrumental in that transition – not only making mining a smarter endeavour, but also significantly safer, owing to its proven ability to remove people from harm’s way.

Powered Air Purifying Respirators, or PAPRs, play a critical role in mining and other industrial settings, where protecting workers from hazardous airborne particles, and gases is not optional – it is essential.

These systems deliver a high level of respiratory protection, helping safeguard health in environments where even a single unprotected breath can be risky.

compatibility in mind. To help bridge this gap, many mining operations are now turning to integrated offerings such as 3M™ PELTOR™ Protective Communication Solutions.

Pairing PAPRs with 3M PELTOR Protective Communication Solutions creates a more complete approach to protection; not only for the lungs, but for the entire team’s ability to hear, speak and stay connected.

Noise reduction is another key advantage. Many 3M PELTOR Protective Communication Solutions include level-dependent functionality, which filters out background noise while still allowing users to hear important sounds in their environment, such as alarms, 3M PELTOR Protective Communication Solutions ensure

But while PAPRs offer substantial health benefits, they can create barriers of a different kind.

Across mine sites, particularly those with high noise levels or limited visibility, clear communication is just as vital as clean air. This is where PAPRs often introduce new challenges.

The very design that keeps harmful substances out, such as a full-facepiece or helmet, can also muffle the wearer’s voice. This makes it harder for others to understand spoken instructions, especially in the middle of a noisy shift. The physical structure of the unit can also make it difficult to use standard tools like phones, which are not typically designed with respirator

The 3M PELTOR Protective Communication Solutions are

designed to improve speech clarity while wearing respirators. Using microphones and speakers, they can help voices be heard without shouting, which may improve communication and reduce misunderstandings.

vehicle movement and nearby voices. The ability to hear clearly while staying protected is essential for maintaining situational awareness in hazardous conditions. Hands-free operation also adds value, with voiceactivated transmission (VOX) allowing workers to speak without reaching for buttons or controls, which can be especially useful when wearing gloves or handling equipment.

This helps to make communication seamless and efficient, even in challenging conditions.

3M PELTOR Products compatibility with a wide range of communication devices is designed to ensure workers remain connected to their teams and supervisors without needing to remove their PAPR. This not only improves efficiency but supports uninterrupted protection.

Finally, comfort is a critical factor, and 3M PELTOR Protective Communication Solutions are designed to be worn comfortably

Pairing Powered Air Purifying Respirators with 3M’s PELTOR creates a more complete approach to protection.

Are you an employer managing workplace drug testing or a service provider, distributor, or reseller in the industry? Your perspective matters.

Complete survey and redeem your gift

• Get in quick, first 60 entries receive a Swiss Peak portable speaker + exclusive Thermo Fisher Scientific colour changing cup.

Mining’s march toward autonomy is reshaping operations worldwide. But even amid this technological evolution, safety remains the top priority.

Rather than allowing those two forces to diverge, Hexagon, as a leader in measurement and autonomous solutions, is carving out a path where human operators and autonomous machines can work side by side – incurring zero harm.

At the core of Hexagon’s strategy is an integrated platform that brings together a range of safety tools into one unified system.

Whether above the surface or deep underground, this ecosystem combines the Collision Avoidance System (CAS), Vehicle Intervention System (VIS), Operator Alertness System (OAS), and Personal Alert into a tightly connected network that tracks and reduces risk in real-time.

This multi-faceted protection doesn’t just prevent collisions between vehicles or between vehicles and people; it also addresses less obvious dangers like driver fatigue and distraction, which remain major concerns even as automation grows.

Recognising these risks, Hexagon has developed technologies that account for the complex reality of mines, where manned and autonomous vehicles operate in close proximity.

While CAS and VIS primarily support manned equipment by detecting hazards and automatically applying brakes or slowing vehicles, the latter also extends critical protections to autonomous units by controlling propulsion as needed.

This seamless cooperation is vital in high-risk areas like haul roads

and loading zones, where even a second of hesitation can have serious consequences. Dealing with unreliable GPS signals or low-visibility conditions – common in underground tunnels or foggy open pits – is another challenge Hexagon’s systems are built to handle.

By integrating 4D radar with CAS and VIS, Hexagon’s technology can detect untagged vehicles, personnel, and infrastructure without depending on the global navigation satellite system (GNSS) or visual cues. This helps to ensure the system keeps a constant watch, even in fog, dust, or underground settings where traditional cameras might struggle.

However, it’s not just about individual systems.

Hexagon ties all this safety data together in a central platform called Safety Insights, which offers thorough analytics and incident reporting. This not only supports quick incident

OAS ensures that when signs of distraction are detected, operators receive real-time notifications.

responses but helps mines plan better for the future.

For operations juggling mixed fleets of human-operated and autonomous equipment, this unified data is invaluable for coordinating movements and improving overall site awareness.

Hexagon’s suite of products has already yielded a range of benefits, having helped leading mines like Rio Tinto’s Oyu Tolgoi, MMG’s Rosebery, and KAZ Minerals’ Bozshakol.

According to Oyu Tolgoi superintendent – mine support Khorolsuren (Khoggy) Ganzorig, the decision to adopt Hexagon’s CAS was an easy one.

“Rio Tinto and Oyu Tolgoi have a really big ambition to eliminate fatality incidents related to vehicle interaction,” Ganzorig said.

“To fulfil that ambition, we looked for a good system that can contribute to our journey.”

Hexagon was the obvious choice.

“The way Hexagon develops their product is very good,” Ganzorig said.

“They not only reflect the technology trends, but they also try to incorporate the industry trends and then also the user needs.”

That understanding and ability to anticipate the sector’s requirements is propelling Hexagon into the future, with the company pushing the boundaries of hazard avoidance through new innovations.

Some of these upgrades include the implementation of Real-Time Kinematic (RTK) positioning, a technology that improves GPS precision from several metres down to just a few centimetres by using correction signals from a fixed base station, helping vehicles know their exact location in real-time. With RTK integrated into CAS, Hexagon’s system now offers significantly enhanced location accuracy.

updates to VIS include features like lane-keeping, advanced fatigue monitoring powered by machine learning, and artificial intelligence (AI)driven analytics, adding another vital layer of protection.

These measures not only enhance immediate wellbeing but also lay the foundation for what a fully connected and autonomous mining operation could look like. By unifying data

streams and automating hazard responses across mixed fleets, the company is providing the “confidence that vital industries rely on to build, navigate, and innovate”.

In the relentless drive for safer and smarter mines, Hexagon’s integrated, intelligent safety systems are paving the way, helping the mining industry move towards what matters most: zero harm.

Early in his career, Andrew Jones had to inspect a cracked mine wall, a job that required him to stand directly under the hazard.

Jones’ experience highlights the critical difference between risky manual measurements and safe, constant monitoring, which Aptella’s technology now makes possible,

is key, according to Jones. A measurement is a single snapshot taken at a moment in time. Monitoring is a constant process, requiring sentinel-like observation that once demanded significant, and often dangerous, manual labour.

With 12 years of experience in mine rescue and emergency services, Jones has a keen appreciation for hazard management. Measurements, can still be human. Monitoring, however, is ideally suited for nextgeneration technology, allowing workers to tackle more complex tasks while remaining safe.

“This is about smart people doing smart things,” Jones said. “Instead of having trained, very competent people doing very manual, repetitive work, let’s automate that, and then let’s get those people doing the more cerebral kind of things where they can be better deployed.”

Aptella offers a comprehensive suite of solutions that provide a complete picture of a site’s stability. Rather than relying on a single technology, the company equips miners with a toolkit designed to detect both immediate threats and slow-moving changes over time.

One of the most popular systems Aptella distributes is from Senceive, a London-based leader in wireless condition monitoring.

While renowned for its work on global rail networks, Senceive’s technology has proven especially well-suited to the Australian mining industry.

Users have described Senceive as “reliable, robust and repeatable”.

Senceive’s wireless, low-powered and long-range systems are a ‘plug-

and-play’ solution that often only require socket set. A common tool, the popular triaxial tilt sensor, can make very small measurements on movement and transmit that data in near real-time.

If any values are measured outside a specified threshold, a range of alerts can be triggered, which can transmit notifications as serious as evacuating an open cut or ceasing work in an area. Jones recalls a mine site where this technology proved critical.

“One of their tailing dams was reaching a high level of internal pressure – a leading indicator of a potential failure,” Jones said. “The Senceive system was showing that the water pressure inside the dam wall was at a hazardous level.”

Thanks to the early warning, the team deployed more sensors and used remote bulldozers to reinforce the dam wall. Increasing data reports to every two minutes helped prevent a potential disaster and eliminated downtime. For a large site with heavy vehicles and many workers, those kinds of delays can be debilitating.

“A family of sensors that can make very small measurements on movement and displacement, and then from a sensor which is 100 millimetres square, will transmit that information back to a central receiver,” Jones said.

Aptella’s solutions stretch beyond Senceive, with the recent attainment of distribution rights for Basetime’s Locator One, a high-precision global navigation satellite system (GNSS) receiver.

Its purpose is to make monitoring large-scale ground movement accessible and easy to analyse.

“Where Basetime becomes really useful is when you need to monitor subsidence,” Jones said.

“For example, after the tailings dam has been built on a mine site, one of the parameters engineers are most interested in understanding is how the walls are settling under their own weight.”

With fully visualised graphics, diagrams and spreadsheets available

through its Parvamoti software, the Locator One is an all-in-one product that focuses on a gradual, singular task.

The two systems are highly complementary. Senceive excels at detecting the sudden, tiny flinch of a dam wall under stress, providing an immediate warning. Basetime, on the other hand, tracks the slow, inevitable sigh of the ground settling over months or years.

One is for the acute threat, the other is for the chronic condition.

Whether it’s the high-precision tiltsensing of Senceive or the 3D spatial awareness of Basetime, the goal remains the same.

The days of sending an employee to stand under a cracked wall are over. Aptella’s technology is creating a mining environment where safety and efficiency are built into the environment.

“I’d also like to think that at Aptella we’re known for our experience in mining in general,” Jones said. “We have a very good understanding of the underlying business operation of the mine site.”

Nome is doubling down on its commitment to keeping miners safe, partnering exclusively with global safety leader Strata Worldwide to expand its “next-generation monitoring solutions” across international mining markets.

Nome managing director Nathan Owen said the mining solutions company is “extremely proud” of the collaboration with Strata after successfully distributing Nome’s cutting-edge RockMonitor XR realtime strata monitoring system across Africa, which has been credited with dramatically improving worker safety and modernising efficiency.

Now, with this distribution agreement, Strata Worldwide will market, install, repair and provide authorised service and support for the RockMonitor XR in Australian hard rock mining and tunnel construction environments.

“Strata’s proven track record in underground safety and technology makes them an ideal exclusive distributor to deliver our nextgeneration monitoring solutions to more mining and tunnelling operations,” Owen said.

“This collaboration reinforces Nome’s commitment to improving safety and operational insight underground, while supporting the continued innovation and reliability our clients expect from us.”

At the heart of the system is the intrinsically safe RockMonitor XR telltale, engineered for coal, hard-rock and tunnelling environments.

When rock moves, this telltale provides two forms of measurement at once: a physical indicator moves along a highly visible scale for immediate checks by miners underground, while the same sub-millimetre data is captured digitally and sent to the central system in real-time. This data is fed to a central RockMonitor XR controller, with a single unit capable of managing up to 150 individual telltales across a 10km monitoring distance.

The controller pushes the information to Nome’s CORE software platform, which logs all events, provides automated alarms, and delivers detailed graphs and historical data, allowing operators to optimise roof support and prevent ground control incidents before they occur, keeping miners safe in the event of rockfall or base instability.

Building on their products’ momentum, Nome and Strata have also announced they are commencing integration trials to connect the RockMonitor XR with Strata’s firstrate proximity detection and collision avoidance (HazardAvert) platform.

According to Nome, this development will mark the world’s first strata monitoring system designed for seamless integration with proximity detection and collision avoidance technologies.

“By combining Nome’s real-time geotechnical monitoring with Strata’s proven proximity and safety systems, we’re setting a new benchmark in proactive mine safety,” Owen said.

“This integration means alerts are sent directly to workers’ cap lamps and equipment operating nearby, automatically preventing entry into unsafe zones. It’s about connecting the physical and digital safety layers, protecting miners through both realtime data and responsive action.”

To help ensure maximum flexibility, the RockMonitor XR platform is designed with an open API architecture. This allows operations to integrate the system not only with HazardAvert but also with any thirdparty hazard-avoidance or digital mine system for automated alerts and predictive analytics.

Strata Worldwide’s APAC managing director Tony Napier notes that userfriendly elements like the open API architecture help to make RockMonitor XR extremely versatile, and an easy ‘plug-and-play’ offering.

“The RockMonitor XR is an excellent addition to our portfolio of advanced networking and monitoring technologies, and we look forward to supporting Nome’s expansion into the mining and tunnelling markets,” Napier said.

The principle is simple: the deeper the mine, the greater the risk. Hazards escalate in terms of worker safety and operational costs, with dangers such as ground fall and expensive equipment losses becoming more common. Yet these mines cannot afford to stop.

In massive underground mines that can stretch 1500m deep, any shutdown will have significant financial impact. This presents a fundamental conflict: gathering the detailed inspection data needed for safety and routine inspections requires halting production, which is a pricey and disruptive process.

“As mines go deeper, hazards like rock bursts, mud rushes, and higher temperatures intensify,” Australian Droid and Robot (ADR) chief executive officer Joe Cronin told

“Traditional inspections are slow, expose people to hazards and are labour-intensive, often requiring production shutdowns that can cost over $250,000 per week. This creates a direct conflict between production uptime and essential monitoring.”

during Cronin’s tenure at Rio Tinto, where he observed autonomous trucks and loaders in operation.

This industry-wide trade-off prompted engineers at ADR to develop a solution. The Explora XL remote data acquisition system is designed specifically to remove personnel from production areas and reduces their exposure to the hazards of the underground environment.

“By deploying the robot for routine monitoring, our system saves over 12 people annually from exposure to critical risks at a typical site, turning hazardous zones into remotely managed areas,” Cronin said.

ADR’s technology had its first major test in 2021 when the

high-precision light detection and ranging (LiDAR) payload to perform scans without halting the fleet. For blast re-entry, it uses multi-gas sensors and high-resolution video, providing clear, actionable data before re-entry crews ever set foot in the area.

But the technology’s true leap forward lies in its ability to persist in the underground environment with no requirement for manual deployment.

The full remote data acquisition system (RDAS) includes a permanent docking station, creating a genuine ‘set and forget’ infrastructure.

This allows the Explora XL to autonomously return to base to recharge its batteries and clean its sensors, enabling it to perform scheduled missions 24–7 without requiring personnel to enter hazardous areas for routine maintenance or retrieval.

“ADR facilitates the shift to predictive safety by providing a stream of consistent, high-resolution data that simply isn’t possible with manual methods,” ADR’s chief technology officer Mat Allan said.

“The ADR system delivers up to nine times more data recovery at four times the resolution compared to traditional methods.”

While robotics is already popular in the mining industry, Allan predicts a more fundamental shift.

He believes that within a decade a dedicated fleet of inspection robots will be so essential that companies will not be able to operate without one.

“This change will be driven by the industry’s need to overcome a skills shortage and meet stricter ESG (environmental, social and governance) requirements, which demand a reduction in both environmental footprint and personnel exposure to hazards,” Allan said.

“Additionally, as mining gets more complex, a higher frequency of higher resolution data is required to complete the analysis to operate sustainably and profitably.”

Cronin touched on one of the mining industry’s greatest phrases, and a key goal for the future of safety within the industry, zero entry mining, which itself is an evolving definition.

Zero entry mining has shifted from the absolute concept of having no humans on-site to the more practical

goal of minimising hazard exposure by keeping personnel outside of designated autonomous operations zones (AOZ).

“Autonomous inspection will become standard as the cost savings from eliminating lost production become undeniable,” Cronin said.

“ADR is shaping this future by developing the Explora RDAS, which delivers the core elements: remote sensor mobility, secure data transfer, and accessible data for third-party analytics.”

Essentially, the system provides the crucial ‘eyes and ears’ for a mine that can be run entirely from a safe, remote location.

“This capability is recognised as essential for zero entry mining, the ultimate goal of removing humans from operational areas,” Cronin said.

“Investment in this market is expected to accelerate, reaching $4.2 billion by 2030.”

Muster brings unmatched fire protection to your world. With cutting-edge systems and advanced technology, we stand as your steadfast defense against the unexpected. From engine bays to critical spaces, the Muster range offers multiple agents to provide the best solution to your specific risk.

Our detection options allow for rapid detection in the risk areas identified during the fir e risk assessment, thereby protecting your machinery and your all-important personnel. 24/7 Fully Monitored

WITH THE LA40 AND LA80 LIFT ASSIST ARMS, NIVEK INDUSTRIES IS TAKING ON-SITE SAFETY TO ANOTHER LEVEL.

When a bulldozer belly plate slipped and narrowly missed landing on Kevin Cant, it inspired him to make a change. He developed TED to save lives and protect the wellbeing of heavy industry workers.

Nivek Industries, a Hunter Valleybased company was launched in 2011. Starting with TED, the world’s first low profile remote-controlled scissor lift, Niveks’ product range has grown to include a variety of complimentary machines including the Lift Assist range of arms.

The primary focus of the lift assist arms is on mitigating the risks associated with awkward, and repetitive lifting. The original LA40 is a spring-assisted gravity arm design to support the weight of heavy tooling, allowing operators

to simply point the tool in the required direction. With continued development, this technology reached a new level with the introduction of the power LA80 in 2023, designed to lift and hold heavy components for installation and removal.

“The Lift Assist range has been purpose-built with the mining industry in mind,” Nivek Industries general manager Derrick Cant told Safe to Work. “Beyond their lifting capacity, the arms are highly manoeuvrable, which means they can access tight, awkward, and hard-to-reach spaces commonly encountered during heavy plant maintenance operations.”

The Lift Assist arms are highly adaptable to the tough, tight spaces found in mining. Designed to be robust and reliable, with a simple

and low-maintenance design, their strength and low upkeep allow operators to focus on the task at hand instead of on the equipment.

“This combination of strength and low upkeep makes them highly adaptable to confined spaces and challenging work conditions, allowing operators to focus on the task at hand without worrying about equipment failure or frequent servicing,” Derrick said.

In mining, the best ability is often availability, and Nivek Industries’ growing range helps to keep valued employees on the job, and free of injury risk.

“Fatigue and musculoskeletal injuries aren’t limited to underground operations. They’re a concern in any

workplace where heavy tools and components are handled,” Derrick said.

Engineered to withstand the full weight of a load, the Lift Assist arms enable an operator to focus on guiding the tool instead of physically supporting it. This significantly reduces body strain and fatigue, helping to eliminate overexertion injuries altogether.

“It means operators can work more safely and efficiently, while also maintaining their long-term health and wellbeing,” Derrick said.

By designing equipment that no longer requires high physical strength, Nivek is also breaking down barriers in a traditionally male-dominated industry.

As a result, fitter positions are becoming more accessible to a diverse workforce, including more women and people of various physical abilities.

While the primary benefit of the Lift Assist arms is removing the physical strain of lifting, their design goes much further to address the complex tasks of heavy maintenance.

The areas where these arms are used are often “crowded with other components, and not always perfectly aligned,” Derrick said.

To counter this, the arms feature multiple articulation points that allow operators to manoeuvre the arm smoothly in and around these challenging spaces. A swivel boss and various attachments provide the precise control needed to align heavy tools and components accurately with the job at hand.

This engineering is designed to withstand harsh conditions. The arms are designed to be robust, durable, and reliable with a simple design that keeps maintenance requirements low.

Perhaps the most significant innovation is the hydraulic torque wrench attachment, which Derrick describes as a feature he is “particularly excited about”. It is designed to securely hold any type of hydraulic torque wrench, removing

the need for an operator to physically hold the tool during high-pressure hydraulic functions.

According to Derrick, this single feature eliminates the risk of finger crush injuries and reduces the risk of oil injection injuries, as the operator is positioned safely away from the tool.

To ensure these safety features don’t slow down the workflow, a quickrelease mechanism allows operators to swap out connected tooling in under 20 seconds.

For Nivek Industries, building bestin-class safety equipment means going beyond baseline regulations. “At Nivek, safety is at the core of everything we do,” Derrick said.

To provide customers with an extra layer of confidence, “all our products are independently certified by a thirdparty engineering firm,” Derrick said. Nivek also provides comprehensive after-sales support, servicing, and custom solutions.

This commitment to leading the industry is driven by real-world application. The company has received extremely positive feedback from operators, which plays a key role in ongoing product development. This collaborative approach extends to custom solutions.

A direct result of this feedback is the upcoming launch of a new powered version of the LA40 arm. Unlike the current spring-based model that allows for some vertical movement, this enhanced version uses linear actuators to lift and hold components, offering a different type of precision for specific tasks.

Derrick said Nivek is “more than happy to work closely with clients to develop bespoke tooling or attachments that suit their specific operational needs”.

This ensures that the Lift Assist arms are tailored to the unique challenges of each workplace, using high-quality parts, local suppliers, and skilled local labour.

The Integrated Communications Cap Lamp Echo is a multi-purpose tool.

Aminer’s cap lamp is more than a source of light. It is a constant companion through long hours in some of the most demanding work environments anywhere.

For Mine Site Technologies (MST), that sparked an innovative question: what if the cap lamp could take on more responsibility?

The result is the Integrated Communications Cap Lamp (ICCL) Echo, a compact, Wi-Fi-enabled device that combines a cap lamp with communication, tracking and safety functions. While it looks like a standard light, the Echo operates as a multi-purpose tool designed to make underground work more efficient and secure.

For miners, the Echo changes how they interact with both their gear and their safety systems.

Instead of relying on multiple devices, the Echo incorporates an LED cap lamp, personal emergency device (PED) messaging and Wi-Fi tracking

radio frequency identification (RFID) into a single, intrinsically safe unit.

“This unified capability drives adoption and connectivity, advancing mine safety and readiness,” MST global product manager Conrad Aitken told Safe to Work.

One of the most important upgrades in the Echo is its return-path messaging capability. Traditionally, through-the-earth alerts worked in one direction only. A control room could issue a warning or an evacuation notice, but they had no way of knowing if the message was received. With the Echo, messages sent to the wearer can be acknowledged with a quick reply via the AXON Wi-Fi network. In practical terms, this turns static messages into dynamic conversations.

The ability for employees to confirm and respond improves situational awareness for surface teams and underground workers.

To further support underground safety, the Echo can be equipped

with a proximity-detection module. This optional feature sends alerts when workers enter restricted zones or approach mobile machinery. For operators and nearby personnel alike, the added awareness reduces the likelihood of collisions and improves spatial coordination in confined areas.

Knowing where each worker is located underground has long been a logistical challenge. The Echo helps solve this with integrated Wi-Fi RFID tracking tags. Each unit provides realtime location data, giving control room operators and supervisors a clear picture of who is where. Whether it’s a routine drill, a shift change, or an emergency evacuation, the system improves planning and execution.

According to Aitken, its dual role as both lamp and tracker helps teams “manage safety more effectively without deploying additional PPE [personal protective equipment]”.

Battery performance has also been addressed. The Echo runs on a rechargeable lithium-ion battery that

offers over 24 hours of continuous use. That kind of longevity helps to ensure the device remains functional throughout even extended shifts or delays underground.

Some of Echo’s practical benefits go beyond the technology itself for mine operators.

Reducing the number of devices each worker carries means less maintenance, fewer charging stations, and fewer potential points of failure. It also simplifies training. With only one device to learn, crews can onboard more quickly and operate more confidently. Over time, that supports a stronger and more consistent safety culture across the site.

“From a safety management standpoint, consolidating critical functions into a single unit like the ICCL Echo reduces complexity and streamlines compliance,” Aitken said.

Looking to the future, MST views the Echo as a flexible platform that can evolve with the needs of modern mining.

“As mining becomes more digitised, devices like Echo will evolve to collect richer environmental data, support analytics, and integrate with autonomous systems,” Aitken said.

The idea, he said, is to turn the lamp into a broader health and safety hub

that supports both individual wellbeing and operational insight.

“This aligns with MST’s broader vision of a connected mine, where wearable tech drives smarter decisions and safer operations underground,” Aitken said.

Take your lifting to the next level with the Lift Assist 80 (LA80).

Engineered to make light work of heavy parts, the LA80 reduces fatigue and minimises the risk of musculoskeletal injuries, helping your team work smarter, not harder.

An evolution of the trusted LA40, this upgraded lifting arm delivers smoother, more controlled movement and pinpoint precision for large component installation or removal. Mount the LA80 to Big TED or any certified attachment point for e ortless, reliable support that takes the strain out of the job.

With six points of articulation, dual 8,000N actuators,

removable batteries, a machined aluminium body, and customisable mounting, the LA80 keeps you working longer, safer, and with total control.

SAFE TO WORK UNPACKS EVENTS THAT LED TO AN UNDERGROUND FIRE AT A NSW METALLIFEROUS MINE EARLIER THIS YEAR, AS WELL AS THE FAR-REACHING RECOMMENDATIONS THAT FOLLOWED.

Afire broke out underground at Perilya’s Southern Operations in Broken Hill, New South Wales, on January 12, with the incident occurring during a planned remediation project to fill a void within the haulage shaft, a section of the mine about 1000m below the surface.

The void was being filled with a two-part polyurethane (PUR) foam product, which is commonly used in underground mining for its ability to rapidly expand and strengthen ground conditions, a high-stakes task designed to stabilise a previously mined section of the shaft.

But soon after the foam was applied, heat generated during the chemical reaction is believed to have either self-combusted or ignited flammable materials in the shaft.

Smoke and fumes began to build, and an emergency evacuation call was issued. Forty-six workers made their way to the surface; however, five remained in a fresh air base until conditions were declared safe by mine rescue personnel.

Although no injuries were recorded, the mine was shut down for an extended period.

In response to the event, the NSW Resources Regulator immediately launched an investigation, with its final causal report recently released.

It concluded that the fire was the result of a complex set of conditions; not a single error but a combination of planning gaps, oversight challenges and shortfalls in risk management.

Several contractors were involved in the planning and execution of the remediation task, adding additional layers of complexity. According to the report, the remediation work had

been planned without a physical inspection of the void due to known geotechnical risks. As a result, combustible materials like timber supports and ventilation materials were not identified before the foam was applied.

Nearly two tonnes of PUR foam were pumped into the space, enough to fill roughly 80 per cent of the void. The product had not been previously used on the site and had not been confirmed as licensed for use in the NSW coal industry, contrary to the belief of staff at the time.

In addition, the regulator’s report states that no one was aware of a safety bulletin published in 2021, which clearly iterated that polyurethane foams should not be used to fill

large voids due to their exothermic properties and flammability.

The report also found that while some contractors raised concerns about heat and fume emissions on the night of the incident, there was hesitation to sound an alarm.

This contributed to a delay in the full evacuation and pointed to a need for stronger emergency protocols and a more open reporting culture.

Importantly, no workers used their self-contained self-rescuer units during the incident, despite the presence of smoke.

Investigators noted that while all personnel escaped without harm, the event highlighted opportunities to strengthen training, equipment confidence and emergency planning.

There are several challenges in managing complex chemical systems in underground environments.

Based on the outcomes of the investigation, the regulator has issued five targeted recommendations to guide future practice. These are aimed at helping mine operators prevent similar events, while reinforcing oversight and response systems across the sector.

The first recommendation calls for a thorough review of riskmanagement processes, particularly when it comes to using polymeric products. Operators are encouraged to ensure that all foreseeable hazards – chemical, environmental and operational – are assessed with clearly defined corresponding measures.

This should be supported by subject matter expertise and consultation with the workforce.

Appropriate contractor management is also highly recommended. Mine operators are encouraged to strengthen the way they engage, assess and supervise

contractors. This includes verifying competencies, aligning contract scopes with risk assessments, and ensuring that work cannot begin until controls are clearly defined and authorised.

In its third recommendation, the regulator addressed chemical management systems. Operators are advised to conduct rigorous evaluations before any new chemical is introduced to site.

This includes confirming the safety of multi-part products individually and in combination, and making sure all hazard information is reviewed against site conditions.

The fourth recommendation focuses on emergency preparedness.

The regulator advises mine operators to regularly review and update their emergency management plans (EMP). Revised EMPs should improve communication systems, guide the appropriate use of selfcontained self-rescuers (SCSR),

and ensure every worker is trained, assessed and competent in emergency procedures.

The fifth and final recommendation looks beyond individual sites. The regulator proposed a coordinated national review of how polymeric products are used, licensed and understood in mining. In collaboration with other jurisdictions and industry bodies, this work will aim to produce clearer guidance, improve training pathways, and ensure consistent safety standards across Australia.

The incident at Perilya’s Southern Operations has shed light on the challenges of managing complex chemical systems in underground environments.

It also offers valuable lessons.

While the fire at Broken Hill halted operations temporarily, it has the potential to lead to longer-term efforts to better align chemical use, risk governance, and emergency readiness.

At a sequestered pharmaceutical lab in Europe, assistants would routinely end their shifts feeling drained and exhausted. The unexpected culprit was an innocuous paper face mask, worn for hours on end in a tightly controlled environment.

“They were totally tired,” CleanSpace global technical product director Jon Imms told Safe to Work.

“So we got them to try our product and the feedback that came back was really unusual.”

After long days on the job, many workers said they previously barely had the energy to enjoy the things they cared about most – like spending time with their families. But something changed after switching to a powered air purifying respirator (PAPR).

“We love that we can actually go home at night and play with our kids,” one assistant said, encapsulating CleanSpace’s commitment to ‘freeing the way customers breathe’.

This ethos drives the company’s mission to create small, easy-to-wear respirators that provide protection without sacrificing comfort.

These respirators haven’t just found their footing in clinical and laboratory settings; their impact has been just as profound in mining, where heat, dust

and long hours create some of the most challenging working conditions.

On exposed mine sites and underground tunnels, traditional personal protective equipment (PPE) can quickly become hot, humid, uncomfortable and burdensome.

On top of physically demanding work, miners carry heavy equipment, from protective clothing and gear to cap lamps and hand-held equipment, all of which add to their physical load and heat strain.

Traditional respiratory protection can make this worse. Negative pressure masks, like disposable paper masks or elastomeric respirators, trap heat, moisture and carbon dioxide in a small space around the face, creating what Imms calls a “heat sink”.

“It’s like you have a hot and moist micro-environment around your mouth, which can be quite unpleasant,” he said.

This trapped heat and moisture not only cause discomfort but also

CleanSpace has some of the lightest respirators in the market.

increase the wearer’s overall heat burden, making it harder to stay cool and focused during long shifts.

While exhalation valves on traditional masks help vent some heat, they can only do so much.

Breathing through these masks also becomes more difficult over time. As filters clog with dust and particles, miners have to work harder to pull air through, accelerating stress.

In contrast, CleanSpace respirators feature a patented AirSensit system that delivers air in response to the wearer’s breathing – automatically adjusting airflow for optimal

discomfort, because they feel they can move more freely.”

Here’s where CleanSpace said it sets itself apart from the rest. By removing the belts, hoses and bulk, its compact PAPR design delivers the same level of respiratory protection but in a lightweight, ergonomic package that’s far better suited for active mining environments. For miners, it represents a smarter solution that doesn’t wear them down with added gear.

CleanSpace respirators essentially also streamline the backend logistics.

CleanSpace’s innovative range is helping mines rethink what respiratory protection can look like.

With fewer parts to clean, charge, and store, they’re easier for teams to manage on-site, reducing downtime and ensuring consistent compliance with safety protocols.

“We are the lightest and easiest respirator out there; it’s a no-brainer,” Imms said.

With systems that buckle down on both the physical and operational barriers that have historically held PAPR adoption back, CleanSpace is helping mines rethink what respiratory protection can, and should, look like.

pressure masks, despite the heat and

Since launching its first range of industrial protection glasses in 1950, Bollé Safety has kept its eye on the ball.

Back then, it showed the world what safety could look like. Today, mine operators across the globe can see it for themselves – in every lens, frame and hazard-ridden shift.

This achievement comes from a constant push to innovate, pushing the boundaries of technology to create eyewear that protects without sacrificing comfort or style.

“Our journey is driven by a relentless passion to design eyewear that people love to wear, while never losing sight of our ultimate mission: protecting people’s vision,” Bollé Safety said on its website.

As a personal protective equipment (PPE) eyewear specialist, the company is highly adept at crafting the right shade for the right job.

But when the demands of the job change, so too must the gear. Taking its PPE eyewear “beyond the edge”,

Bollé Safety has evolved one of its most popular offerings to keep pace with that transition.

In the world of PPE, few products achieve iconic status. But Bollé Safety’s RUSH+ line, launched in 2015, is well on its way.

The range has long been a staple on mine sites, its bold red and black frames signaling a trusted shield for millions of operators worldwide.

A decade on, Bollé Safety is again pushing the envelope with the unveiling of RUSH+ 2.0 – a transformed flagship that honors its heritage while embracing the future of safety eyewear.

At first glance, RUSH+ 2.0 is a visual refresh, yet this upgrade is much more than cosmetic. It captures the pulse of modern mining with sharper lines and a contemporary silhouette that still carries its predecessor’s and Bollé Safety’s unmistakable DNA. Behind the streamlined aesthetic lies

The nose piece now offers greater flexibility, improving fit across diverse users, while the temples feature a bi-material design to balance grip with comfort over extended wear.

These updates arrive against a backdrop of evolving challenges in mining workplaces.

Increased automation and heavier machinery have brought efficiency gains, but they have also introduced new safety risks. Dust, particles and unpredictable hazards remain constant threats, making reliable eye protection more critical than ever.

At the same time, workers are demanding gear that supports long hours without discomfort or distraction.

Sustainability has become a central concern, too. Bollé Safety’s decision to incorporate recycled materials into RUSH+ 2.0 reflects a wider shift in the PPE sector, where mining companies are no longer judged solely on safety records and environmental responsibility is increasingly part of procurement decisions. Delivering protection that meets stringent standards while also

reducing environmental impact marks a significant step forward.

More than a single model, RUSH+ 2.0 is a versatile range tailored to specific environments. Whether it is managing dust with foam-sealed options, shielding from overhead hazards, or accommodating prescription lenses, Bollé Safety is addressing the realities workers face.

Another standout alongside the legacy model is the RUSH+ 2.0 XP, a hybrid version delivering extra protection from particle exposure on sites. Like the original 2.0 model, the XP is available in clear, copper and smoke tints, and features Bollé Safety’s platinum anti-fog and antiscratch coating solution.

This latest evolution is not about superfluous innovation but practical refinement, listening to users, adapting to real-world conditions and responding to the complexities of modern mining work, according

to Bollé Safety product designer Cédric Peillon.

“[The] new RUSH+ 2.0 generation perfectly reflects our approach: evolving our iconic products while preserving their strong identity,” Peillon said. “We’ve rethought every technical and aesthetic detail to offer professionals enhanced protection and optimal comfort.”

In an industry where the stakes are constantly high, RUSH+ 2.0 is a powerful example of how thoughtful design continues to raise the standard for eye protection, helping miners keep their focus where it matters most.

It also shows how the company has constantly adapted to the future while building on the strengths that made it a trusted name in the first place.

Bollé Safety first set its sights on protecting workers 70 years ago, and today, keeping an eye on the ball still means keeping worker safety at the heart of its mission.

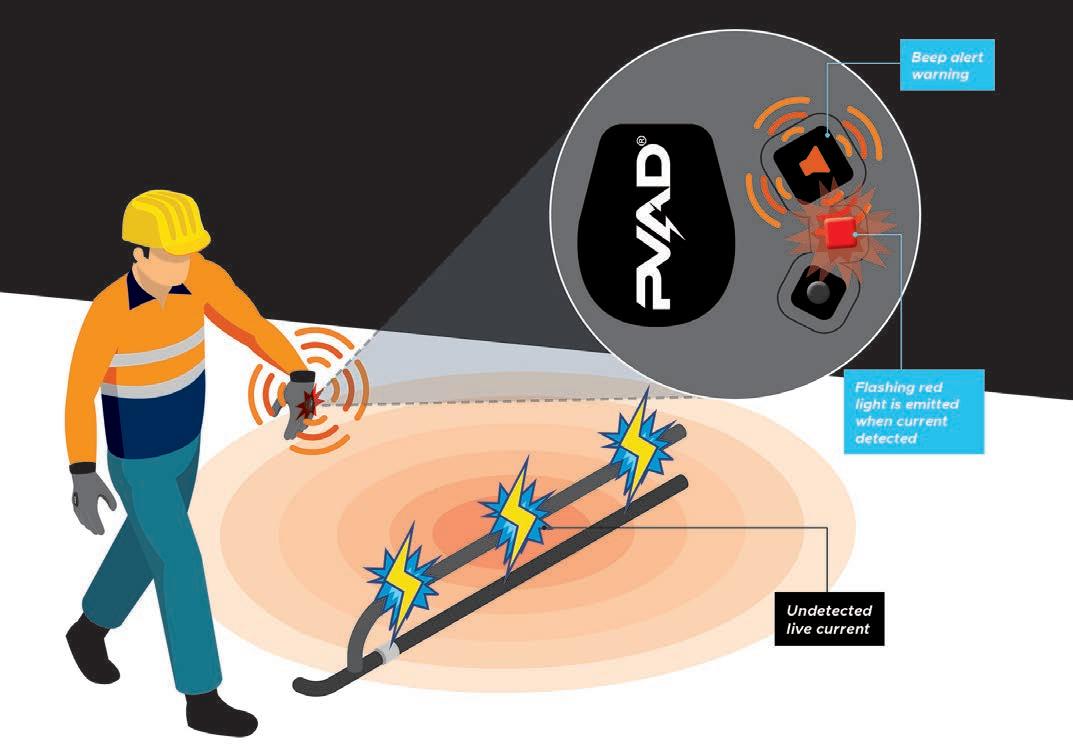

HUMAN ERROR AND UNKNOWN ELECTRICAL HAZARDS CAN BE RISKY. THE GLOVE COMPANY’S PVAD TECH GLOVE

For founder Grant Staples, the idea for The Glove Company began with a jolt.

As a young apprentice on an unfamiliar jobsite, Staples suffered a severe electric shock on a narrow landing. The charge tore through him, throwing his body to the ground, and that incident became his motivation.

“Since then, I’ve always been interested in safety,” Staples told Safe to Work.

Drawing on his engineering education, Staples developed a groundbreaking wearable technology to help minimise the risk of electrical

Most trades, when working near electricity, rely on others to ensure the site is dead, but too often it’s not the case. On job sites, electric shocks can come from a variety of unexpected sources, such as a piece of wood that would not typically prompt an on-site worker to check with an electric pen or voltage tester.

“I knew we could figure out a way to explore a new aspect of safety that wasn’t covered,” Staples said. “We could also help electricians and other trades that aren’t really trained in electricity.”

To combat the statistics, Staples

The wearable technology detects electrical hazards and alerts the wearer to hidden dangers in their vicinity without requiring them to touch the circuit. In recent trials, 20 per cent of participants reported that PVAD tech gloves prevented an electrical injury.

THE POWER OF THE PVAD

These wearables operate as hands-free, continuous safety monitors that detect the invisible energy field generated by live electricity. Unlike traditional tools that require a user to actively test a surface, the PVAD is always on, providing a crucial secondary failsafe against hidden electrical hazards.

The technology’s core function is its ability to sense the radio frequency (RF) emitted by an active alternating current (AC) electrical circuit without direct contact. The system is powered by a replaceable coin battery, which lasts between six and 12 months, depending on use.

As Staples said, the glove “picks up on the radio frequency in AC electrical current”. This is achieved through small RF capacitors embedded in each of a glove’s fingertips. When these sensors come near a live voltage source, effective within a range of 110–440V AC, they detect the RF signal.

Once a signal is detected, the information is sent to a small processor housed in the glove’s cuff, which instantly triggers a dual alert system.

“It gets a beep and a red light so you can see. If you can’t see, you can hear,” Staples said.

One of The Glove Company’s sceptics took part in a trial working on a 1960s lift. Although his team had isolated

every circuit they knew of, he initially refused to wear the “weird-looking” glove because he didn’t believe in it.

It turned out the old lift had a separate, hidden circuit that was still live. The glove saved him by sounding an alert just as he was about to cut that live wire, an example of the glove protecting workers from unknown electrical hazards they wouldn’t even think to check for.

“Traditional tools rely on the user actively needing to check an area, but if you don’t think you need to check, you won’t,” Staples said.

The Glove Company has also conducted trials in the mining industry where the focus is on a “solid, wellcreated product”.