“Our products are undeniably great, but it is the exceptional calibre of our people that distinguishes us from others”

6 Up Front with Pace Cranes New ‘game changing’ Meadas have arrived.

15 CICA Work Health and Safety CICA examines the risks when working closely to powerlines.

diquip

Hardiquip grows Jarlway brand.

tEx Gold Coast

LiftEx Gold Coast is a resounding success.

ove and Boom Logistics

More Groves to Boom Logistics.

Cranepower’s growth

Cranepower continues to gather momentum.

Zoomlion’s vision

The team at Zoomlion’s optimistic look.

utt Bryant

Sany’s SCC300TB’s major astructure role.

CMG

XCMG looks to EV and hybrid power as it reveals its new range.

ampson Australia

A deep insight into one of Australia’s ongest crane fleets.

not to put 27,000 new jobs at risk

The Australian Resources & Energy Employer Association has underscored the strength of the mining and energy industry in a new report that identifies more than 100 new projects set to come online, creating almost 27,000 jobs over the next five years.

The Resources and Energy Workforce Forecast: 2024-2029 breaks down the estimated labour required to operate new, expansion and restarted mining and oil and gas projects.

The report shows there are 107 major resources and energy projects in Australia’s investment pipeline – either already committed or considered advanced – expected to enter production between the second half of 2024 and end of 2029.

These projects are worth about $131 billion and are forecast to drive demand for around 26,810 new production-related jobs.

While estimates are slightly down on last year’s 2023-2028 report (103 projects worth $142 billion and 28,000 jobs), the consistency reported across AREEA’s past five editions demonstrates the ongoing attractiveness of Australia as a place for investment.

Mining commodities retaining their traditional strengths include coal (13 projects for 4,836 workers), iron ore (eight projects for 4,495 workers), gold (13 projects for 2,830 workers) and critical minerals (14 projects for 3,078 workers).

AREEA chief executive Steve Knott says the strength of Australia’s resources sector has driven new economic surpluses for Australia, and has urged the government not to stand in the sector’s way.

“Approvals for major ventures such as the McPhillamys gold mine in New South Wales – which offered 1,000 jobs (construction and production) and had the full support of the local community – are being pulled from underneath investors at the eleventh hour.

“Several multi-billion-dollar LNG projects, offering much needed domestic gas supply and further export earnings, are being frustrated by continuous environmental and

cultural heritage lawfare.

“Thousands of workers will soon be paid according to bargained terms and conditions of other businesses, and unions have been given a legislated leg-up to force themselves into workplaces and entire industries that have long since left them behind.

Resources and Energy Workforce Forecast: 2024-2029 reports that while the major project pipeline remains strong, the sector in May 2024 directly employed 287,600 people, which was 35,300 or 11 per cent fewer than the historic high (322,900) of May 2023.

WA remains the powerhouse of Australia’s resources and energy industry, with 48 major projects expected to increase the workforce by 11,065 workers by 2029.

Meantime, NSW has cemented its position as the nation’s second-most attractive destination for resources and energy investment capital. The report shows 18 projects are forecast to create demand for 5,152 new production employees in NSW by the end of 2029 – an increase of 800 on last year’s figures and over 1,600 more than Queensland’s current projections.

“That data shows Queensland is slowly but surely losing its investment edge and being well overtaken by NSW. In 2022, this report forecast 5,560 new jobs in Queensland’s major project pipeline. In 2023, the figure was 4,470, and this year, just 3,527,” Steve said.

As a major consumer of craneage, the resources sector is critical to the wellbeing of our industryand there are plenty of positive signs for the forseeable future. As always the team at Cranes and Lifting has worked hard to bring what we hope is a news filled issue and we hope you enjoy the read.

Simon Gould Editor, Cranes and Lifting

Published by:

379 Docklands Drive, Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

CEO

John Murphy E: john.murphy@primecreative.com.au

Chief Operating Officer

Christine Clancy E: christine.clancy@primecreative.com.au

Managing Editor

Andrew Hobbs

E: andrew.hobbs@primecreative.com.au

Editor

Simon Gould

E: simon.gould@primecreative.com.au

T: 0404 865 109

Journalist

Jacob Lynch

E: jacob.lynch@primecreative.com.au

Business Development Manager

Emily Schlegel

E: emily.schlegel@primecreative.com.au

T: 0466 317 555

Client Success Manager

Louisa Stocks

E: louisa.stocks@primecreative.com.au

Art Director

Bea Barthelson

Imaging Assistant

Paul Breen

Subscriptions

Frank Rapone

T: 03 9690 8766

E: frank.rapone@primecreative.com.au

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

At Harvey Norman Technology for Business, we hear it all the time from small business owners —

We don’t need Cyber Security. They won’t target us, we’re too small.

The reality is, cyber threats don’t discriminate. We’ve helped many small businesses who thought they were safe — until they weren’t.

When the big IT companies won’t help because you’re too small, that’s where we come in. We specialise in robust, affordable cyber security for businesses like yours.

24/7/365 Monitoring: Continuous protection through our Security Operations Centre (SOC)

Managed Threat Detection & Response: Non-stop defence against ransomware and malware

Proactive Monitoring & Management: Fixing potential issues before they impact your business

Security Awareness Training: Keep your staff one step ahead of cyber threats

Compliance Management: Stay legally compliant with industry standards

BONUS OFFER!

Not sure if your business is Cyber Compliant?

Sign up for a Free Cyber Security Assessment. Protect your business with enterprise-level solutions at unbeatable prices. Contact us today to secure your business’s future.

Sign up to any Cyber Security Plan in November and get a bonus iPad valued at $499!

Scan to arrange your FREE Cyber Security Assessment

Email info@harveynormanbusiness.com.au or call 1300 781 865 for assistance.

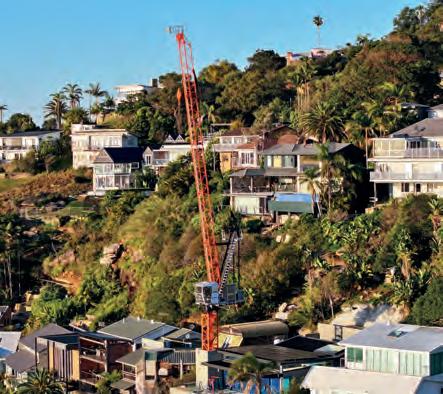

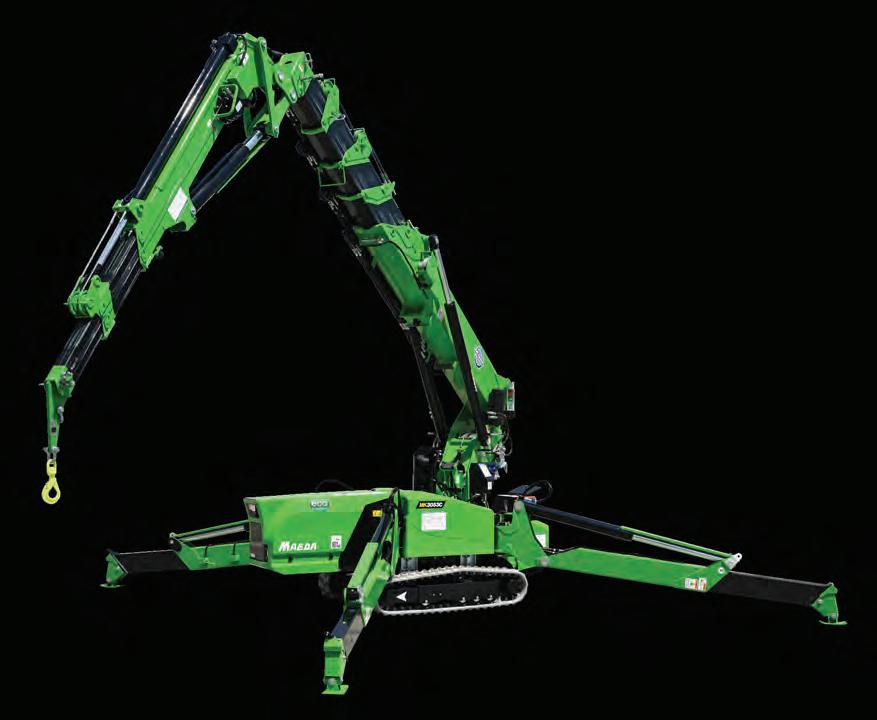

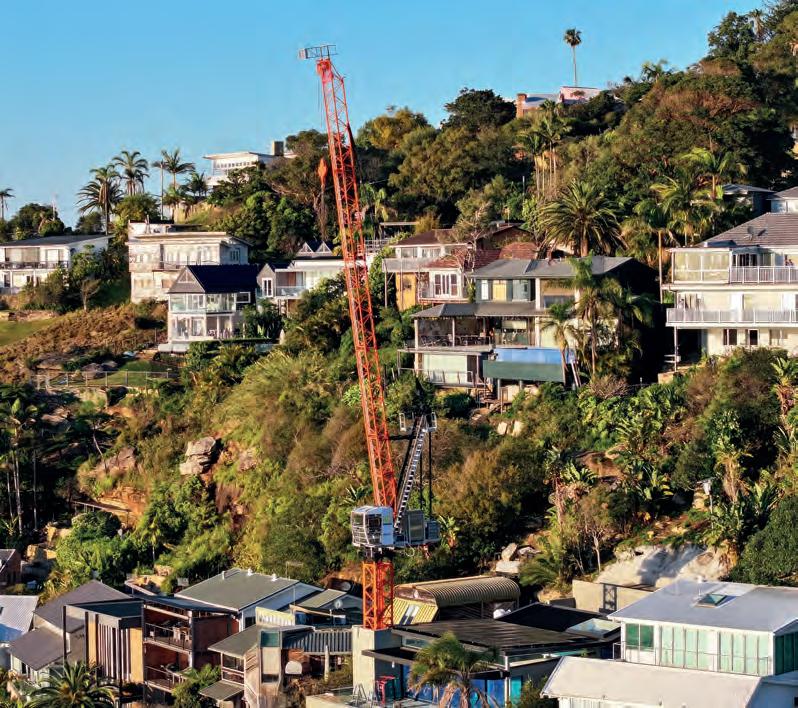

The first shipment of Maeda’s MK3053C knuckle boom mini crawlers recently arrived in the Sydney yard of Pace Cranes. Featuring 12 metres of main boom, just under 17m with the hydraulic jib, and a lifting capacity of 2.98 tonnes, Michael Cawston, National Sales Manager Pace Cranes explains the difference they will make to the Australian market.

THE MAEDA KNUCKLE BOOM MODEL has been several years in design and development, says Michael.

“Maeda has actually had a knuckle boom machine for approximately 10 years, and it proved to be quite successful in Europe. It has taken Maeda some time to fully develop this machine to get the best possible reach and lifting capacity,” he said.

The MK3053C features a telescopic boom with a knuckle that folds out from underneath the main boom. The knuckle features a telescoping luffing boom with a telescoping jib attached. The 12m main boom features a four falls hook mode as well as a detachable negative angle jib. The model also features automatic and stepless multi outrigger settings, variable crawler gauge, diesel/electric and battery electric options as well fully proportional radio remote control.

“Maeda have designed this model like the other machines in the range and offer a standard diesel engine

option, diesel-electric or full battery lithium-powered for those companies wanting a 100 per cent ‘green machine’. The battery-powered option has the capability of running from the mains for unlimited working hours,” said Michael.

“Maeda displayed a prototype of the MK3053C at Bauma three and a half years ago and it was well received. At Bauma the European dealer sold numerous units and we’ve been pretty successful here having sold multiple units prior to arrival,” he said.

Michael goes on to discuss applications the MK3053C is typically suited to.

“The applications are going to be similar to those where you will typically find our spider cranes. These include glazing applications, getting product up to balconies and pushing them through windows. Lifts can be air conditioners, benchtops, glass, fish tanks, safes, anything you need to lift up and over and then push into an area where your traditional straight boom can’t reach,” he said.

“Enquiries have come from a whole range of interested parties including ‘one-man band’ glass installers up to the big crane hire companies. I’ll say it now, there’s more to the MK3053C when compared to a traditional Maeda spider crane and it will likely need a specialist operator to manage the machine.

“Some customers that have a small MC285 and an MC305 have said the MK3053C can pretty much replace those models. Sure, this model is a little more expensive, but it’s cheaper than having two cranes to manage multiple applications. We believe steel erectors will love this machine. It’s a very compact machine with a smaller setup area than the 285 but you can lift more than a 305 with the main boom. It’s a game changer for us,” said Michael.

Michael adds the jib is very easy and simple to operate, a one-person

The MK3053C features the next generation of outriggers which are stepless meaning there’s no pinning system.

The MK3053C features an expandable undercarriage for the stability of the machine, but the undercarriage also retracts enabling the machine to fit through doorway access.

operation to take on and off, with all functions remotely controlled.

“Depending on what you’re lifting, you might need the winch application. You can pre-rig the jib with the single fall hook fitted and then pull the boom out and you’re ready to go. Or you can take the jib off, depending on what is required.

“Everything is remote controlled, which comes as standard. The MK3053C features an expandable

undercarriage for the stability of the machine, but the undercarriage also retracts, enabling the machine to fit through doorway access.

“The MK3053C features the next generation of outriggers which are stepless - meaning there’s no pinning system. If there is an obstacle in the way, you can stop the outriggers at any angle and the machine automatically sets up the load chart to suit,” said Michael.

“The controls feature a one touch setup, and from one button you can completely set the machine up. It swings the outriggers, extends them and puts them down, and it also selflevels the machine which is pretty exciting.

“The load charts are set up to work at multiple angles, and the LMI will read that setup and be tell the operator before the lift what you’re good for and at what particular angle, so it features

When Capital Cranes’ Digger Misner first heard about Maeda’s MK3053C, he knew he had to have one in his fleet.

very smart technology,” he said.

Hayden Roper, whose Cranes 4 Hire specialises in glass lifting and handling, purchased his first Maeda almost six years ago.

“I’d been operating Maedas previously and that’s before they had LMIs, but the 285 is where it all started for us. We run two Meadas and went with their brand for reliability, and over the last six years, reliability is what we’ve experienced,” said Hayden.

Hayden has been waiting for the MK3053C for sometime.

“I enquired about this crane before we bought our 305. I’ve been chasing a crane that’s skinnier, smaller and lighter with more lifting capacity, and Maeda have managed this with the MK3053C.

“It’s one tonne less in weight than the 305, half a metre skinnier and yet features 17m of reach, which is going to be handy. It has a good chart out to nine metres radius, so it’s going to be a very handy lifter in the domestic market.

“There are a few things coming up for the Australian Open, which require battery powered machine, and this has already been specified so we can now help them out with this crane, which is good,” said Hayden.

“Battery powered equipment is the

way everything’s going moving forward and Maeda is offering this option across the range. Government projects are specifying zero emissions and so the MK3053C ticks all their boxes. It’s also going to be nicer not having to listen to a motor humming all day,” he said..

The knuckle boom will provide more versatility when it comes to projects says Hayden.

Cranes and the ensuing conversation led me to the Maeda MK3053C.

“They informed me that Maeda had a new mini crane in the design stage and were willing to take me to Japan to visually inspect the machine. After seeing the MK3053C in its design and testing stages, I instantly knew this was the crane we needed,” said Digger.

“The engineering behind the new concept knuckle boom was impressive, and witnessing its rigorous testing gave me confidence in its performance and safety. While I know that Maeda isn’t the first or the original concept designer of this type of machine, what truly matters to me is the relationship I have with Pace Cranes and Maeda. Over the years, I’ve built a solid trust in their advice and the quality of their equipment. It’s not just about the specs; it’s about knowing I can rely on them for support and that I’ll get a machine that meets my business needs,

“The new concept detachable telescopic jib on the MK3053C makes it a standout choice, especially for handling heavy loads in confined indoor spaces or tight outdoor areas. Its compact design allows us to manoeuvre

“Government projects are specifying zero emissions and so the MK3053C ticks all their boxes. It’s also going to be nicer not having to listen to a motor humming all day.”

“Currently we use a truck crane for a lot of our glass installations, and that features the knuckle boom which helps us get inside the building a lot further, which is important when we are working with glass. With the MK3053C we can now can go up and push inside which is going to be a game changer for us, the mini crawler crane market and for Maeda,” said Hayden.

Digger Misner from Canberra’s Capital Cranes also took delivery of the new Maeda MK3053C. “When a customer asked if there was a machine that could handle some tough requirements, I reached out to Pace

through standard doorways and operate in spaces where larger cranes just can’t fit. Whether we’re lifting inside a gallery or working in a narrow outdoor location, this crane provides the flexibility and control we need,” said Digger.

“Being fully battery-powered and featuring non-marking tracks makes it ideal for sensitive environments where we want to avoid any damage. In the end, it’s about choosing a machine backed by a trusted relationship. That’s why I’m confident that the MK3053C will be a valuable addition to our fleet,” he said.

SPECIALIST IN HARD CHROME PLATING

• Long stroke & large bore specialists

• Large turning work up to 1500mm in diameter, 10 metres between centres and 530mm spindle for extra length

• Cylinders manufactured to specifications

• Complete cylinder repair facility

• Quality service with experienced & qualified staff

Contact Sermet Gurisik

Email: sales@athydraulics.com.au

Phone: (02)9756 3077

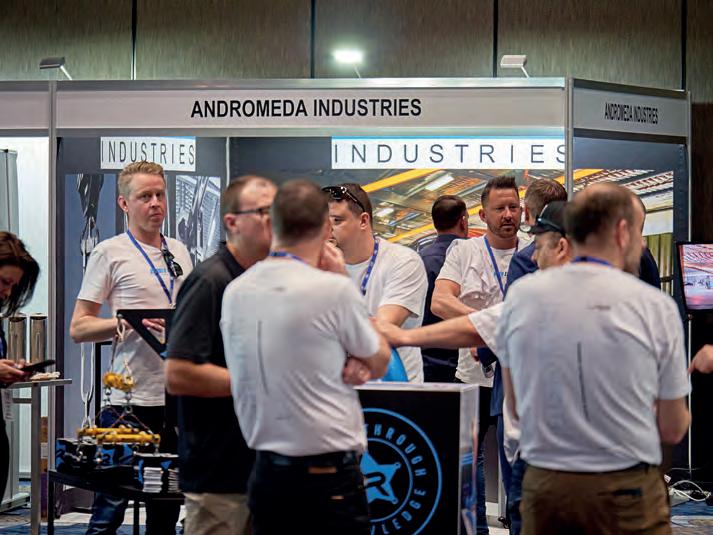

THE POST-EVENT HAZE IS LIFTING, AND looking back on the 2024 CICA Annual Conference, Exhibition & Crane Display brings a sense of satisfaction. It was fantastic to see so many professionals from across the country come together to share ideas, showcase innovations and strengthen connections. The energy in the room was palpable and the interactions between attendees fostered a collaborative spirit that is vital for our industry. A big thank you to everyone who attended and contributed to making this year’s conference such a success.

This year’s event not only provided a platform for learning but also emphasised the importance of networking within the crane community. The discussions and workshops offered practical insights that participants can take back to their workplaces, helping to drive progress and improvement in the industry. The enthusiasm and engagement shown by all attendees reaffirmed our shared commitment to advancing the crane sector. We appreciate the dedication of everyone involved, and we look forward to building on this momentum for future events.

I would also like to extend a special thanks to our platinum sponsor, Franna. Your continued support was instrumental to the event’s success, and we appreciate your commitment to advancing the industry. And to the team at WISE Connections for making our vision for the conference come to life: thank you. Always a pleasure to work with, and you bring an incredible passion to our conference that is incredibly appreciated. We’re already looking forward to what the 2025 conference will bring.

This year’s program was packed to the brim. Our keynote speaker

The attendance and engagement in this year’s technical and business workshops was a highlight. From implementing AI to practical guides to on-road access for cranes, to cybersecurity and succession planning - there was something for everyone.

our shared knowledge, ultimately benefiting everyone in the crane industry.

I’d also like to acknowledge the incredible entrants for Lift of the Year and Photo of the Year. The skill, creativity, and dedication on display

through these entries were truly inspiring. Congratulations to everyone involved— you continue to set the bar high for excellence.

CICA is an association that continues to evolve, much like the crane industry itself. Following our recent AGMs, we’ve seen some exciting changes within our leadership, with fresh faces stepping in and seasoned leaders moving on. This blend of new perspectives and experienced insight is exactly what helps us stay ahead in a rapidly changing industry. I’d like to thank every Branch Chair, Vice Chair and committee member, both new and outgoing, for their hard work and dedication. Your contributions are what keep CICA strong and forward-thinking.

CICA couldn’t function without the collaboration and passion of its members. It’s your commitment and support that enable us to keep pushing forward, advocating for the industry, and delivering valuable resources. Together, we’re driving progress, and I’m excited to see how these new voices will continue to shape CICA and the crane industry in the years to come.

Brandon Hitch Chief Executive Officer

“The attendance and engagement in this year’s technical and business workshops was a highlight. From implementing AI to practical guides to onroad access for cranes, to cybersecurity and succession planning - there was something for everyone.”

CICA BOARD

Ben Pieyre – President

Marcus Ferrari – Vice President

Danny Adair – Director

Danny Black – Director

Andrew Esquilant – Director

David Solomon – Director

Karli Sutherland– Director

CICA OFFICE

Brandon Hitch Chief Executive Officer

03 8320 0444 0428 228 048 ceo@cica.com.au

Alice Edwards Road Technical Engineer 03 8320 0440 alice@cica.com.au

Patrick Cran

CICA Site Operations Advisor 0488 004 274 pat@cranesafe.com.au

Sharon Pearce

Crane Crew Competency Officer, Sharon@cica.com.au ph: 0491 134 533

Damien Hense

CICA Road Policy Advisor 03 8320 0460 0488 007 575 damien@cica.com.au

Julie Turner CICA Executive Assistant/ Board Secretariat 03 8320 0411 julie@cica.com.au

Kate Galloway Traineeship & Industry Engagement Coordinator 0491 047 118 Kate@cica.com.au

Shane Coupe CraneSafe & CrewSafe Administrative Assistant Officer shane@cica.com.au 0491 047 134

Michelle Verkerk Communications and Special Projects Advisor michelle@cica.com.au

Justina Blackman Member Events and Engagement 0403 717 626 justina@cica.com.au

Ashleigh Gould Office Operations Coordinator, ashleigh@cica.com.au 03 8320 0466

Unit 10, 18–22 Lexia Place, Mulgrave Vic 3170

Phone: 03 9501 0078

Fax: 03 9501 0083

Email: admin@cica.com.au

Website: www.cica.com.au

For information, please visit our website or call the CICA office.

IN THE PAST FEW YEARS, THE LEGAL position surrounding independent contractors has fluctuated as a result of various case law judgments culminating with the landmark High Court decisions in 2022. Recently, the Fair Work Legislation Amendment (Closing Loopholes No. 2) Act 2024 (Cth) (Closing Loopholes No.2) introduced a number of key reforms that came into effect on 26 August 2024 which implement protections for independent contractors into the Fair Work Act 2009 (Cth) (FW Act). It is important that organisations that engage independent contractors are aware of these changes to ensure the arrangements they enter into are compliant.

“EMPLOYEE” AND “EMPLOYER” DEFINITION WHAT’S CHANGED?

A significant change is the introduction of section 15AA in the FW Act, which establishes a new statutory definition of “employee” and “employer” which impacts the distinction between employees and independent contractors.

Until recently, courts in Australia considered the totality of the relationship between the worker and the principal, by reference to various indicators of the day-to-day relationship to determine the nature of the relationship. This is

sometimes referred to as the “multi-factor test”. That changed in 2022 following the High Court’s decisions in Construction, Forestry, Maritime, Mining and Energy Union v Personnel Contracting Pty Ltd and ZG Operations Australia Pty Ltd v Jamsek, which set aside the totality of the relationship approach in favour of one that focused primarily on the terms of the contract between the parties.

The introduction of section 15AA largely “reverses” the High Court’s decisions, and once again puts the focus primarily on the real substance, practical reality, and true nature of the relationship between the parties. Section 15AA provides a statutory guideline that courts and the Fair Work Commission (FWC) must consider when interpreting whether a worker is an employee or a contractor.

Section 15AA brings the “multi-factor test” to the forefront. Although the terms of the contract remain relevant, the test will apply to the whole relationship including how the contract is performed in practice rather than relying solely on the terms of the contract.

The multi-factor test considers all relevant factors to determine whether a person is an employee or an independent contractor. Each case is determined on a

case-by-case basis. The factors considered often include, but are not limited to:

• the degree of control an employer/ principal has over the employee/ independent contractor. Previous case law has placed significant weight on this factor, although courts have previously found that no single feature determines the totality of the relationship;

• the existence of a written employment contract or independent contracting agreement;

• whether the worker can refuse work;

• whether the worker maintains a high level of flexibility or control as to how work is performed;

• whether the worker is paid or entitled to paid leave entitlements;

• whether the worker operates under an ABN or interposed entity; and

• the extent of the integration of the worker into the business, for example, the requirement to wear a uniform.

Misclassification can lead to significant legal and financial repercussions, including penalties, back payments of entitlements and potential litigation. It is crucial to review your contractor agreements and ensure that your categorisation of workers aligns with the new interpretative framework.

As the new definition applies to both pre-existing engagements and engagements entered into on or after 26 August 2024, it is important that organisations review both their existing engagements and new contracts entered into moving forward.

The new laws provide for high earning contractors, that is those currently earning in excess of $175,000 per annum, to opt out of the application of the section 15AA definition and retain their contractor status in circumstances where elements of the relationship may indicate they are an employee. Importantly, only one opt out

notice can be provided per relationship and the opt out notice only applies to the relationship from the date on which it is given. In effect, depending on when the opt out notice is given, there may still be a period of exposure to misclassification risks. The opt out notice can also be revoked at any time.

For the first time, the FWC will be able to intervene with respect to the terms of engagement between principals and independent contractors. A new unfair contract regime has been introduced in Part 3A-5 of the Fair Work Act 2009 (Cth) (FW Act), targeting independent contractors who earn under the contractor high-income threshold (as at the date of this article, $175,000 per annum). The provisions allow eligible contractors to apply to the FWC to vary or set aside all or part of a contract if it is deemed unfair.

In order to be eligible to make an application, the sum of the contractor’s annual rate of earnings must be less than

the contractor high income threshold –currently $175,000 per annum. The FWC specifies that the contractor high income threshold should not be confused with the ‘high income threshold’ which only applies to employees. With that said, at this stage, there is limited guidance on how the contractor high income threshold and the contractor’s annual rate of earnings will be worked out and/or whether it will be prorated across the year.

Notably, only terms that would relate to “workplace relations matters” in the context of an employment relationship, can be challenged due to unfairness. It is yet to be seen how the FWC will interpret this limitation however workplace relations matters are defined in section 536JQ to include without limitation remuneration, hours of work and termination.

When determining whether a term in a contractor agreement is unfair, the FWC will consider:

• the relative bargaining power of the parties to the contract;

• whether the contract as a whole displays a significant imbalance between the rights and obligations of the parties;

• whether the contract term is reasonably necessary to protect the legitimate interests of a party to the contract;

• whether the contract term imposes a harsh, unjust, or unreasonable requirement on a party to the contract; and

• whether the contract as a whole provides for a total remuneration for performing work that is less than what employees performing the same or similar work would receive; and

• any other matters the FWC considers relevant.

For example, terms which provide a unilateral right to vary the terms of the contract or terminate the contract may be deemed to be unfair by the FWC.

(IC ACT)

The IC Act has contained similar protections for independent contractors against unfair contract terms for some time. However, given a claim must be initiated in the Federal courts, the IC Act has been criticised for being inaccessible.

With the introduction of the FW Act provisions, the IC Act jurisdiction has been narrowed whereby the unfair contract remedies will only apply to contractors earning above the contractor high-income threshold.

We anticipate the FWC will seek to rely on earlier decisions under the IC Act jurisdiction to inform its approach to assessing whether a term in a contractor agreement is unfair. If the FWC does take this approach, there may be limited grounds to establish unfair contract terms given there a small number of substantive decisions made under the IC Act and of these, a number of the decisions in the IC Act jurisdiction have been overturned either in whole or in part in favour of the Respondent. Notwithstanding these earlier outcomes, considering the background to the FWC and the approach taken in unfair dismissal cases to factors demonstrating “harsh, unjust or unreasonable” conduct, the FWC is likely to take a broad view as to whether a contract term is unfair.

Contracts that were previously considered enforceable might now be subject to scrutiny under the new regime if the contractor is earning below the contractor high income threshold. The FWC also provides a more accessible avenue for contractors to dispute their agreements which may lead to increased claims from contractors.

Further, there is no specific reference to costs orders in the new Part-3A-5 of the FW Act as it relates to the unfair contract provisions. In effect, the approach to costs in these matters is likely to be similar to the IC Act jurisdiction, which provides that costs do not follow the event and costs orders are unlikely to be made unless the application is vexatious or unreasonable. This approach to costs would also be consistent with the general rule in the FW Act that all parties must bear their own costs. As such, the lack of an adverse costs order will make it unlikely to dissuade a contractor from making a claim in the FWC.

The new provisions only apply to contracts entered into on or after 26 August 2024. Organisations should review their

templates and all new contracts entered into with independent contractors to ensure they meet the new fairness standards. Caution should be exercised if you are amending an existing agreement as it may be considered a new contract in some circumstances. Considerations of fairness might include the balance of power between the parties, the clarity and transparency of contract terms and whether the contract imposes undue disadvantage on the contractor. If you need advice on the terms of your contracts, you should seek legal advice.

Failure to adjust your terms for individual contractors could result in contracts being set aside or varied by the FWC, which could disrupt your business operations and lead to unforeseen costs.

and accurately reflect a principal/contractor relationship. In the absence of a written agreement, organisations are exposed to a finding of employment.

A written agreement for a contractor should clearly define the nature of the relationship and the terms and conditions of the relationship, including payment, termination and services to be provided. The terms of the written agreement should also aim to be fair and balanced.

3. Review template independent contractor agreements (new definition of employee and unfair contracts)

Organisations should review current written agreements with independent contractors to ensure

“Failure to adjust your terms for individual contractors could result in contracts being set aside or varied by the FWC, which could disrupt your business operations and lead to unforeseen costs.”

In line with these changes, we recommend organisations consider taking the following steps:

1. Review current engagements (new definition of employee)

Organisations should review current engagements and written agreements to ensure independent contractors have not been ‘labelled’ as independent contractors where the duties and obligations reflect an employment looking at the multi-factor test. You should develop a process for reviewing arrangements at regular intervals to ensure the engagement accurately reflects one of an independent contractor. Organisations who pay contractors above the contractor high income threshold can also consider whether the opt-out notices should be utilised.

2. Ensure each engagement of an independent contractor is confirmed in a written agreement (new definition of employee and unfair contracts)

It is important that all independent contractors are engaged according to a written agreement, with terms that are fair

that the terms of the agreement reflect the principal/contractor relationship. For example, a contractor agreement should not include any entitlements such as annual leave.

The templates should also be reviewed in the context of the unfair contract regime to ensure no terms could be perceived as unfair.

As above, it would be prudent for companies to ensure all precedents for on-boarding are up to date and accurately reflect the new changes.

If you need assistance in navigating these changes and preparing your business to ensure compliance, please get in touch with our team below.

Disclaimer: The information in this article is of a general nature and is not intended to address the circumstances of any particular individual or entity. Although we endeavour to provide accurate and timely information, we do not guarantee that the information in this article is accurate at the date it is received or that it will continue to be accurate in the future.

Authors: Michael Selinger and Julia Wyatt

WORKING NEAR OVERHEAD POWER LINES

is an inherently dangerous proposition. It only takes one mistake with a crane or mobile plant coming into contact with live wires to end with catastrophic injury - or death. The most frequent causes of fatal accidents in the crane industry in Australia were those involving strikes by load, and electrocution. Staying alert, compliant and knowing where you and your crew should be in relation to the poles and wires is vital to keeping everyone safe.

When working near powerlines it’s important to know the rules that determine how close a person or machine can safely get. No Go Zones, also called exclusion zones, provide limits on how close cranes, crew and mobile plant can get to powerlines. The rules are not the same for all powerlines, or all states, and change based on the voltage of the lines.

Victoria has the most stringent guidelines on zones regarding work around power lines. For distribution overhead powerlines, which carry voltages from 240V to 66kV, the No Go Zone is anywhere above the powerline, within 3 metres on either side and 3 metres below. Examples of distribution overhead lines would be those used for trams, and trains.

Transmission overhead power lines carry much higher voltages - 132kV to 500kV, and are installed on towers or steel poles. The No Go Zones for these are larger; 8 metres above, 8 metres on either side, and 8 metres below.

Victoria also uses spotter required/ no spotter required in their zoning. Distribution overhead powerlines must have a spotter when working between 3 - 6.4m of powerlines, while open areas outside of 6.4m do not require a spotter. Queensland by contrast has 3 zones - any

line voltage up to 132kV has an exclusion zone of 3 metres, between 132kV and 330kV is 6 metres, and over 330kV is 8 metres.

Always be aware of powerlines around you. You can use the Look Up and Live app to check the locations of powerlines before you get onsite - it provides overhead powerline locations and imagery, safety guidelines (including exclusion zones), options for planning or performing work, and information about de-energisation or relocation of powerlines.

operators and crew but for the public if lines are contacted.

If you must work near powerlines there are steps you can take to minimise your exposure to danger. Developing a safe system of work before you start any activities can save lives; electricity and lack of planning do not mix. Identify the hazards around you and conduct a site risk assessment. What kind of equipment is being used, what are the conditions and weather on the site - is it windy? Is it hot? High winds could risk being shifted into the exclusion zone and powerlines sag in intense heat. What work is being done, and what is the set-up and packup procedure? Overhead powerlines are often uninsulated, and high voltages can arc (flashover) across air gaps to nearby objects of a different potential, posing a serious hazard if you or your equipment gets too close. Additional factors like lightning strikes and switching can cause sudden spikes in voltage, increasing the risk of arcing.

Cranes and other machinery working near high-tension powerlines can also develop significant induced voltages. Dragging a grounding chain to improve earthing can help minimise potential electrical hazards. Choosing your control measures is deadly serious, not just for

Safework Australia provides a hierarchy of control with measures for safely operating cranes and mobile plant near overhead electric lines, including substitution, isolation, engineering, administrative and PPE controls.

There is no single blueprint for working safely around overhead powerlines.

Each jurisdiction has its own specific rules, and every worksite presents unique hazards. The terrain, foliage, or other visual obstructions can all effect the safety of an operation. Additional factors, like whether scaffolding needs to be erected or dismantled, can further complicate the situation. These sitespecific challenges require a careful, tailored approach to ensure the safety of workers when operating near overhead lines.

Operators and owners must stay informed about the standards in their jurisdiction and take a proactive role in training their crews. Proper planning is crucial, especially for teams working in proximity to powerlines. Regular safety training, clear communication and risk assessments should be conducted to ensure that everyone on-site is aware of potential hazards and follows safe work practices to minimise the risk of accidents.

THE 2024 CRANE ASSOCIATION OF NEW Zealand (CANZ) Conference was, by all accounts, an overwhelming successsetting a high bar for future events. Held in the vibrant city of Rotorua, this year’s conference not only brought together crane industry professionals from across New Zealand but also attracted international delegates. The city’s renowned beauty, cultural heritage and world-class amenities provided a fantastic backdrop for the event, further enhancing the experience for all attendees.

Rotorua’s unique charm, combined with the meticulously planned conference agenda, played a key role in creating an environment where delegates could fully engage in industry discussions, share insights, and network. The 2024 conference proved to be a pivotal moment for CANZ, as it highlighted the strength and resilience of the crane industry, even in the face of recent economic challenges.

This year, delegates were greeted by the newly introduced “Crane Village,” an innovation that showcased the association’s commitment to enhancing the conference experience. Set up outside the main venue, the Crane Village provided a unique space where delegates could interact with suppliers, clients and peers. This initiative allowed for more informal and productive conversations, creating opportunities to foster new business relationships.

One of the standout features of the 2024 conference was the high calibre of its speaker lineup, which received an impressive 95 per cent approval rating in the post-

conference survey. CANZ was thrilled with this feedback, as it underscored the quality and relevance of the content provided to delegates.

Lisa Tamati, the breakfast speaker, set an inspiring tone with her powerful story. Her personal journey, filled with resilience and determination, deeply resonated with the audience. Some delegates were so moved that they requested selfies and hugs following her talk, a testament to the emotional impact she had on the room. Tamati’s session was the perfect way to energize attendees for the rest of the conference.

Other notable keynote speakers included Glen “Cookie” Cook, who shared his vast knowledge on power line safety, and economist Shamubeel Eaqub, who delivered an insightful analysis of the New Zealand and global economy, specifically focusing on its relevance to the crane industry. Both Cookie and Eaqub captivated the audience with their expertise and in-depth knowledge, reinforcing the critical role that

informed discussions play in shaping the future of the crane sector.

Another highlight of the conference was the debut of the new Master of Ceremonies, Jehan Casinader. Filling the shoes of the previous MC, Greg Ward, was no small feat, but Jehan exceeded expectations, receiving a 90 per cent approval rating from delegates. His professionalism, and knowledge ensured a smooth flow throughout the event. CANZ is already looking forward to welcoming Jehan back for the 2025 conference.

Thursday evening’s social event was another resounding success. Striking the right balance with a social gathering is never easy, but this year’s event checked all the boxes. One long-time attendee, with over 25 years of conference experience, even commented

that it was the best social event she had ever attended.

Musical bingo was a unique choice, and while there was some initial scepticism, the entertainment team delivered a knockout performance, turning the event into an unforgettable evening. The buffet meal was another highlight, with many delegates raving about the quality and variety of the food. The opportunity to unwind and connect with industry peers in a relaxed setting was invaluable, especially given the tough year the crane industry has endured.

Friday’s conference sessions were just as impactful, culminating in the prestigious Gala Awards Dinner. The awards ceremony provided a moment to pause and reflect on the successes achieved within the industry, recognising those who have demonstrated excellence, whether as trainees, trainers or as part of larger projects in the Lift and Project of the Year categories.

As CANZ CEO Sarah Toase often emphasises, “Nothing happens without a crane.” This sentiment rings true across all sectors of the economy, both domestically and internationally. The crane industry may be small compared to other parts of the construction sector, but its contributions are critical to the economy and the community. The awards ceremony was a fitting tribute to those who have worked tirelessly to uphold the highest standards in their respective fields.

A significant highlight of the conference was the Schools Day event, where 30 students from three different schools attended an inspiring taster session led by industry trainers Simon Drumm, Norm Kete and Maurice Davis. The event was an overwhelming success, with students enthusiastically participating in the various activities designed to give them a hands-on introduction to the crane industry. Simon Drumm’s tenacity and leadership were the driving force behind the event’s success, as he worked tirelessly to bring together the industry to inspire the next generation. The engagement from both students and

the industry professionals underscored the strong commitment to fostering future talent, and it was heartening to see such a collaborative effort from all involved.

One of the key takeaways from the 2024 conference was the level of engagement from CANZ members. This year saw an unprecedented level of participation, which was heartening for both the association’s staff and council. Members shared their insights and expressed a clear desire for the association to continue its work in removing barriers and enabling the crane industry to thrive in New Zealand.

CANZ has already made significant strides, including the establishment of the PCANZ PTE, a gold-standard training institution for the crane industry. Over the next 12 to 24 months, CANZ will continue to build on this success, further enhancing training opportunities for its members.

Additionally, the conference highlighted the need for clearer, more up-to-date regulation and technical guidance to support the work of CANZ members. In response, the association will be shifting its focus to incorporate a new strand of work aimed at developing this technical guidance.

While conferences require significant investment in both time and money, the value of bringing industry professionals together cannot be overstated. These events provide a unique opportunity to pause, celebrate achievements, share knowledge, and strategise for the future.

CANZ is now eagerly looking ahead to its 50th anniversary celebrations in 2025. The milestone event will be held at the Takina Event Centre in Wellington from July 16th to 18th, 2025 and promises to be an exceptional occasion.

The 2024 conference would not have been possible without the generous support of our sponsors, particularly our platinum sponsors, Cookes and Liebherr, as well as our gold and other category sponsors. Their unwavering support during a challenging year has been instrumental in making the event a success.

As we look to the future, CANZ remains committed to supporting the crane industry in New Zealand, working to ensure its sustainability and success. We are proud to stand alongside our members, and we eagerly await the green shoots of recovery that will propel the industry forward in the months and years to come.

A landslide in April 2017 left State Highway 3 impassable through the Manawatu Gorge. A new highway is being built over the Ruahine Range, to provide a safe, resilient and efficient route between Woodville and Ashhurst. The new highway is due for completion by mid-2025.

THE HIGHWAY IS BEING BUILT BY AN Alliance that includes Waka Kotahi NZ Transport Agency, HEB Construction, Fulton Hogan, Aurecon, WSP, Rangitāne o Manawatū, Rangitāne o Tamaki nui-a-Rua, Ngāti Kahungunu ki Tāmaki nui-a-Rua, Te Runanga o Raukawa (Ngāti Raukawa ki te Tonga and Nga Kaitiaki ō Ngāti Kauwhata). The Alliance was formed in 2019 with construction beginning in early 2021. Project construction has been reliant on significant craneage managed and engineered by the Alliance team, including cranes supplied by Smith

NZ $700 million and has provided work for up to 350 people at any one time, with over 2,500 staff and contractors inducted to the site since the project commenced in 2021.

The project involves the construction of six bridge structures along the highway, with two of the bridges spanning over 300 metres long - the Parahaki bridge over the Manawatu River and the Eco Viaduct over an ecologically significant wetland area.

For craneage, like any major construction project, the team is required to complete thousands of general site lifts, along with many larger and/or more complex lifts to deliver the project.

The site conditions restricted the size, and somewhat the capacity, of the

cranes the team could use. The Parahaki bridge, predominantly constructed from staging limited the crane size to a 280t class crawler machine, due to staging width and span lengths. The Eco Viaduct bridge was consented to and allowed to be constructed from a causeway of limited size (footprint, width and elevation) due to construction in a critical ecological part of the site - this again limited the crane size to a 280t crawler crane footprint to access to all areas for general serving and major lifts. Both major bridges only allowed construction access from one the western side of each bridge, meaning the height of structure compared to the position and elevation of the crane needed to be considered from an early stage through the planning and build of each structure.

Throughout the project to date the team has mobilised nine different lattice boom crawler cranes, two tower cranes on static bases, two telescopic crawler cranes along with five mobile/rough terrain cranes to undertake all works from site set up, piling works to major beam and component installation and removal works across all the six bridge structures.

When it came to crane choice and selection, daily crane needs and configuration options were considered, along with engineered solutions to undertake the major lifts the project required, with consideration of the restrictions the team had to overcome. Smith Crane and Construction was able to supply efficient crane solutions to the project which included three LR1280 Crawler cranes, with all configuration options available to the project team. The use of two remote control Liebherr static based tower cranes was a smart, cost effective solution the team used on the Parahaki bridge to service day to day works on the bridge where appropriate.

The success of the crane solutions and engineering on the project was largely due to the configuration options the team had available to them, from the use of superlift, luffing and fixed fly configurations along with many

boom length changes. The project’s engineering team was challenged to design or adapt the design of the temporary staging structures, lifting locations on the components, crane pads and causeway designs to take the different loadings that the crane configurations produced across the project.

To date the team has completed over 60 lifts requiring the Superlift on the LR1280 machines, with 30 of these from the temporary staging bridge over the Manawatu River. At the Eco Viaduct bridge 14 of the 21 beam pairs, being 70t and 100t weathering steel beams, required Superlift from the causeway. Six of the Superlift operations have been with tandem lift operations and numerous complex lifts including superlift operations required pick and carry cranes for completion across the project. Many lifts required full crane capacity and were deemed engineered lifts prior to being undertaken.

The Parahaki bridge is situated at the base of a wind farm and also crosses the Manawatu River at the western entrance to the Manawatu Gorge. The site posed many challenges, from wind to river level limitations and flooding.

Parahaki Bridge was predominantly constructed from a temporary staging bridge over the Manawatu River. Height and reach requirements from limited access posed a challenge to the construction works. Limited space to operate and work with construction plant and cranes was also a challenge. The staging was initially designed to suit a 250-280t class sized crane.

The Staging Capacity for heavy lift operations requiring superlift from the staging was a challenge that pushed the staging capacity and required further analysis, which led to staging modification early in the project for the team to be able to make efficient program gains due to crane capacity and configuration gains.

On early review cranes were required

For Craneage, like any major construction project the team are required to complete 1000’s of general site lifts, along with many larger and or more complex lifts to deliver the project.

to be centred over headstocks due to the capacity limitations within the staging spans when using Superlift. This was not a solution the team was able to work with. The decision was made to strengthen the staging to handle the loads required, however the same width needed to be maintained. Three areas of staging, ranging from 15m to 20m in length adjacent to Piers one, two and three, were strengthened to handle a 50t load at 40m radius with a suspended rear ballast load of 120t at 13m. The team also allowed for pick and carry operations with suspended superlift in these areas on the LR1280 machine.

The Eco Viaduct is a 7-span steel girder bridge built over a large wetland that is significant to the local ecosystem. A 250m long causeway was constructed to allow construction works within a limited and controlled area. This was generally 12m wide along the mainline with three 9.5m wide fingers and a

small laydown area under where spans 4 and 5 were to be placed. The restrictions on the causeway included limited ground pressure and offset from the edge for plant operation.

The ground pressure significantly reduced within one metre of the causeway edge, meaning no loading was allowable within 500mm of this causeway edge. This was overcome by choosing cranes that had a small footprint, configuration options for all phases of construction including false work, beam install, deck precast panel placement and finishing works.

The TAAT Project employed and engaged skilled crane and rigging personnel and contractors to undertake key roles within the project planning team and on the ground as required for certain complex crane and lift operations. The construction team was able to integrate these people to ensure an understanding of the constructions team’s requirements, ability and limitations within complex lift operations.

Being a multi disciplined major infrastructure project, the integration of

Smith Crane and Construction was able to supply efficient crane solutions to the project which included three LR1280 Crawler cranes with all configuration options available to the project team.

many engineered and creative lift solutions, from lifting frames to lowering systems and everything in between, all done considering the constraints with staging, causeway and crane pad designs to allow the team to manage difficult lifts and loads.

The project undertook numerous rigging designs required to handle the bespoke loads, the team delivered many studies on complex lift designs and technical assessments. Most importantly, the team successfully performed these lifts on site on a regular basis and without incident.

The planning and design of lifts considered the safety of the team and plant itself. Full risk assessments in this planning phase ensured potential risk exposure was identified and managed.

A key philosophy for the project was “It was better to undertake a larger

“The project undertook numerous rigging designs required to handle the bespoke loads, the team delivered many studies on complex lift designs and technical assessments.”

skilled ‘crane specialists’ into the dayto-day construction operations and the upskilling of some of the construction team to aid in the complex crane works has been a major success of the project and has led to an efficient crane and construction outcome.

The team recognised the need for integrated crane and heavy lift operations within the day-to-day construction due to the complexity and interrelation of the works, coupled with the engineering to make it all work.

The TAAT team was able to choose a crane supplier in Smith Crane and Construction that was committed to making sure the project had the required cranes and crane attachments whenever needed, along with a team that was committed to the project.

Access to crane works called for

complex lift than to have a prolonged exposure to working at heights for a greater number of people to achieve the same outcome.” Cranes were critical in achieving this and this approach was the most program-efficient and cost effective, making it the best for the project both as a target and for the outcome achieved.

As we approach completion of the project we can begin to reflect on what has been achieved on some of the most challenging structures built in New Zealand. While the outcome is clearly visible in what has been constructed, the journey to get there is something we are extremely proud of and is only visible as we review what has been done. The complexity from the beginning to end has been a constant to address with all challenges successfully met with great people and great plant. Craneage was critical to enable us to be successful on all fronts.

McPhan Cranes and Transport recently took delivery of a ‘colour popping’ new MAC254. The hard-to-miss Franna is part of a fleet renewal process and also an introduction to operating pick and carry for the next McPhan generation. Tony McPhan explains more.

“THERE ARE A NUMBER OF REASONS FOR purchasing the new MAC25-4. With Dré and now Lila working in the business, we have experienced significant growth and the new Franna will help share the increased workload,” said Tony.

“Also, we are constantly examining the fleet and investing in new cranes to increase the size of the fleet and replace older machines. As with most crane hire businesses, our Frannas have proved to be the ‘work horses’ for our fleet and I’m sure the new MAC25-4 will be no different.

“But probably the main reason for the new Franna, and certainly the ‘colour popping’ paint scheme, is down to Lila. When we decided on the new MAC25-4, Dré, Lila and I sat down and discussed the colours. We are always looking at different themes for the cranes and Lila came up with this ‘colour popping’ concept. We haven’t branded the crane as yet, we’re still working on this, but we are super

grateful to Franna for the way they’ve been able to deliver the colours.

“Lila and Dré have made such a huge difference since joining the business and Lila has decided she wants to learn the business from the ground up, so, she’s taking her Dogman ticket and Operator tickets and she’s going to drive the new Franna,” said Tony.

“Both Lila and Dré continue to juggle their university commitments whilst working full time in the business. Our new ventures like the traffic control business are going from strength to strength and we have more ideas for the business which will be explored in due course,” he said.

The Franna MAC25-4 features a maximum lifting capacity of 25 tonne and offers maximum safety, excellent roadability, intuitive operation and unmatched versatility. Its design has been tried, tested and proven in a range of difficult lifting applications and is still a

customer favourite today.

McPhan’s MAC25-4 comes with the Superlift (SL) upgrade which increases load chart improvements by up to 30 per cent and works in tandem with the existing counterweight, adding a low slung additional counterweight piece to the rear of the machine, increasing the rated capacity of the machine. It also features a maximum boom length of 18.4m and a maximum hook height of 18m.

Other features on the McPhan MAC25 -4 include:

• Rear Body Handrails

• Auto Grease System

• 15t Spreader Bar with the Deck Mounting system

One of the key safety features on the MAC25 is the Franna Safety Radar system. This offers a ‘real-time’ calculation of the crane’s rated capacity throughout the full range of articulation and boom extension, giving the operator feedback of what level of articulation or boom extension will bring the crane into a danger zone where the crane would be overloaded.

Taking as much of the “human element” out of the lift as possible is central to Franna’s safety objectives.

Unlike conventional Load Moment Indicators (LMI), which only tell you the percentage of rated capacity for the current lifting position, Franna’s Safety Radar shows the operator a simple and clear visual radar map of the safe working area for the load being lifted and, most importantly, for the actual working environment of the crane - i.e. its front/ rear and side slope. Franna’s Safety Radar will help to predict the safest options for the next stages of the lift.

Increased resolution of rated capacity is made possible by finer measurement of articulation pitch and roll angles, allowing for improved machine capability.

Another key safety feature is the Franna emergency bridging key which provides an additional layer of safety that complements the existing safety features of each crane.

The emergency bridging key has been designed to maintain operational flexibility, while providing an additional

through the provision of a removable key which can be held by authorised site personnel, providing greater control of site lifting practices.

The McPhans worked closely with Matt Mills, Terex Franna’s Sales Manager.

“Matt has been awesome. He’s very thorough, very easy to deal with and he makes the whole sales and delivery process very smooth. If there were more people like Matt to deal with, the world would be a much better place,” said Tony.

The McPhans’ renewal of the fleet won’t be stopping with the MAC25-4 with a new Franna AT40 also on order.

“We are operating in a very competitive environment and although we tend to focus on what we are doing and not pay much attention to our competition, we do like to stay a few steps ahead where we can. The MAC25-4 is the largest capacity Franna on the Central Coast and we are really looking forward to the arrival of the new AT40. We think this will be a game changer for the business,” said Tony.

Western Australian engineering and manufacturing business

DRA Engineering launched the Humma pick and carry range 28 years ago. Cranes and Lifting (CAL) recently sat down and discussed the Humma project with DRA.

CAL: Why was 1996 chosen for the launch of the Humma Crane Project?

DRA: The 1996 year was chosen for a number of reasons. DRA Industries was celebrating 25 years and had become one of the largest abrasive blasting and coating companies in Australia, with treatment plants in most states and with site crews. Construct Engineering, acquired in 1984 as mechanical design build and install of all types of conveying systems, had completed the largest sheep slaughter line in Europe, capable of processing 4,000 sheep per day. The design not only involved a conveyor system, it also included a number of automatic and semi-automatic machines reducing the workforce by up to 35 per cent. Not only was the cost of processing per animal reduced, the facility cost was recovered within a year. The success of this project led to similar projects in Botswana, Africa; Doha, Qatar; and Chalingah, India. We quickly realised the success was attributed to smart design, not manufacture.

In 1996, with a group of engineers with no new projects and many companies closing or liquidating, we decided to find a new market where innovation could be applied to achieve similar results, expanding Construct Engineering old technology.

CAL: Both DRA and Construct Engineering were very successful with innovative concepts, why not grow the business instead of looking to go into a complete new industry?

DRA: With our existing businesses we

had a limited life of acceptable profit. The steel treatment could be done inhouse by the fabricators as the automatic descaling plant existed but was expensive leaving an increase in site work and a decrease in factory processing. Construct technology was innovative but could be copied, which indeed happened. Low quality copies had destroyed our export market. Had we expanded our market as you suggest,

we may not be here today, and we do very few projects in conveying systems now. Moving into a new industry has a high level of risk to succeed. I refer to it like going into a dark room trying to find the light switch. When you find it, which requires persistence, the level of satisfaction quickly overcomes the numerous setbacks needed to achieve the intended results. Once experienced, it is addictive and you look for more challenges. This explains why many Humma owners often say the Humma team has a real passion for the Humma brand.

CAL: You chose to build a pick and carry crane with your engineers and yourself having no knowledge or experience. The financial risk would have been high with an equally high the chance of failure.

DRA: When DRA decided to develop a new range of pick and carry cranes, the

The Hanchard trials over two years on the 25T and 35T resulted in 2016 release of Humma 35 Mk3,

thought of failure was not a consideration as success was obvious when you consider our approach. Linmac, the developer of the tractor pick and carry, with over 3,000 cranes in the market and 30 years of development, had ceased to operate in 1994, leaving Franna the only manufacturer. We carried out an Australiawide market survey, establishing an Australian market of 85 units per year and growing and there was a strong preference for the Linmac 18T equivalent to Franna 18T because of its sturdy construction.

There are still a number being used today. Franna was considered a low quality high operating cost range, consisting of three models, 15T, 18T and the newly released MAC25. Both manufacturers were building cranes with 1980 technology and the potential existed to build a new generation of pick and carry cranes which we assessed the crane market would welcome. We later

found the Frannerised buyers believed Humma, with all its defects, was a safer buy. We liked the Linmac concept and layout with an unobstructed front view for safe driving when in crane mode - and at the same time it was robust compared to the Franna models. We needed crane design experience, so we employed the Linmac engineer who was involved in the Linmac 18T design and the Technical Sales Director who brought to the project 30 years of knowledge and experience on pick and carry cranes. We were ready to launch the Road Crane (RC) Project. We knew the market size, we had established from Franna and Linmac owners the defects and what our design had to rectify and we had 30 years of crane design added to our team and the specification we expected to achieve with an RC.

By 1996 Franna was the only manufacturer with the AT15, AT18 and the newly released MAC25. We saw the

opportunity for our crane to take a share of the developing crane hire market. We later found this assumption was wrong as Franna owners were not prepared to purchase Humma for a variety of reasons which still exist today. We saw this obstacle necessitated us to find a solution which we did. We developed a Humma market which Franna could not meet.

CAL: The RC Project later became the Humma Project because the crane looked like the American Hummer. How did that happen?

DRA: Accidently, the first 18T and 20T were on hire and the drivers referred to them as Hummer. We later got approval from the owners of Hummer to use Humma, provided it was not a car. We are the registered owners of the Humma trademark.

CAL: For some years Humma 20 and Humma

25 were the only models available, then in 2010 you released Humma 35 which was the largest pick and carry available at the time. What was the reason behind this development?

DRA: We made a big mistake with both models when I accepted the ex Linmac engineer to build the pick and carry and let the crane buyer find the problems and fix them under warranty. There were issues and this was ammunition for Franna sales who pointed out to buyers ‘Don’t Buy a Humma, they are full of defects.’

This nearly resulted in the closure of the Humma project after having spent many millions of dollars on development. We could not sell a Humma 25 even when offered at cost. Franna’s position in the market became stronger but so did the list of unhappy Franna owners. We really have Franna to thank for the position we are in today. We went back to basics, stopped trying to sell 20T and 25T and produced the current Humma series design. After two years the new design was used on Humma 35 Mk1 with six cranes placed in our newly created Dry Hire Division and tested on the new Chevron Gas Project for four years where debugging occurred, followed by the release of Humma 35 Mk2. The crane hire industry, quite separately from the owner operators construction industry, was showing interest. The Hanchard trials over two years on the 25T and 35T resulted in 2016 release of Humma 35 Mk3, our fastest selling Humma. Our Humma design used on all models is Humma Class according to long term Humma owners.

The resistance encountered with the 20T and 25T we successfully bypassed by producing a low operating cost, highest level of safety in our range of heavy lift Humma cranes, 35T and 55T. I assume Humma users compared results with Franna and called them ‘Humma Class’.

CAL: I can see your approach was quite methodical and now you have ‘Humma Class’ not Franna Class. Frannas have been manufacturing and selling pick and carry cranes since the early 1980s and are still the market leaders. Humma has been in the market since 1996, how have you managed to compete?

DRA: Franna certainly sell far more cranes per year, but Humma has a much longer operational life,with a life cost 25 per cent of MAC25, two year warranty and 15 years to the first major service. Humma, with the rigid chassis design plus air suspension, has allowed the design on all models to safely drive at over 100km/h with little to no vibration, which means low maintenance and longer operational life. All electronics on the pick and carry were developed by Humma, with many copied until we patented the Autoleveller technology. Humma quality, reliability, safety and robust design is world class, and it is with this quality where we plan to continue to achieve.

SCAN QR CODE FOR MORE INFORMATION

The course instructors are seasoned professionals who will mentor course participants through real-life scenarios, preparing them for the challenges and responsibilities of a Crane Lift Supervisor.

Crane Lift Supervisors are in high demand globally. Completing this course enhances employability and opens doors to a wide array of job opportunities and career growth.

The curriculum covers a wide range of topics, including lift planning, load calculations, safety protocols, communication strategies, and legal compliance.

Scan the QR code to book in now

Melbourne 5-6 February 2025

Sydney 19-20 February 2025

Brisbane 5-6 March 2025

Perth 19-20 March 2025

Melbourne 4-5 June 2025

Brisbane 10-11 July 2025

Perth 16-17 July 2025

Sydney 17-18 September 2025

Harvey Norman Technology For Business (HNTFB) recently partnered with The Crane Industry Council of Australia (CICA) with the aim of offering members solutions to the increasing threat from cyberattacks. Rutland Smith, Director of HNTFB, provides a detailed overview into the threats posed and how the household name brand can assist.

“HARVEY NORMAN TECHNOLOGY FOR Business has been in existence for almost five years. We realised that a number of our business customers were purchasing computers and hardware from our retail stores and were also looking for cyber security services. Because they were not big enough, they weren’t able to purchase the services they needed and HNTFB was created to fill that gap and provide services to small to medium businesses,” said Rutland.

Rutland explains why small to medium sized business owners should be concerned about cybersecurity and why it isn’t just a ‘big business’ issue.

“A lot of small business owners make the assumption that big businesses are at risk and their business is too small to be a target. The reality is it’s the other way around. Cyber criminals tend to focus on smaller businesses, and that’s because they are more vulnerable and have much lower defenses.

“We know from the Australian Cyber Security Centre statistics that 43 per cent of attacks in Australia actually happen to small businesses. So the first thing I’d say is the assumption that ‘I’m too small to be attacked’ is actually incorrect. The second thing I’d say is small businesses have the most to lose,” said Rutland.

“There are statistics out of the United States that confirm 60 per cent of small businesses who suffer a major breach go out of business within six months. That’s because of the costs, the loss of business, the damage to the reputation and, of course, there’s also the compliance regulations. All businesses have a duty of care to protect their customer data,

including small businesses,” he said.

Rutland explains how complicated cybersecurity can be for small to medium sized businesses and how HNTFB simplifies the process.

of implementing that by themselves.

“One of the challenges for all businesses is to meet the standard of the courts. They have to implement the government risk mitigation framework called the ‘Essential Eight’. That’s an incredibly complicated framework to implement, and almost no small business, that I’m aware of, is capable

“By getting HNTFB on board as their IT department, we are able to provide a small business with all the support that they need and also ensure they are compliant with that framework and provide the cybersecurity that the government has mandated,” said Rutland.

He goes on to discuss how HNTFB can help a crane hire business in practical terms.

“We are fortunate that we’ve entered

into this relationship with CICA and we’ve created a landing page that’s been created specifically for CICA members https:// www.harveynormanbusiness.com.au/ pages/cica

“From this page, members are able to make contact with our team. They’re also able to see the special offers that are available to CICA members only, and they’re also able to learn more about cybersecurity by reading the ‘tips and tricks’ on the page.

“One of the topics that everyone will be confronted with over the next 12 to 24 months is businesses trying to sell Artificial Intelligence (AI) solutions to small and medium businesses for a whole range of different purposes.

“The first thing is to be aware of is the potential damages of implementing AI incorrectly and how that can lead to sensitive data being made available, which is something you just don’t want to happen.

“Secondly, I think it’s really important that in evaluating all of these different AI offerings, that you are working with a partner such as HNTFB which has the time and the dedicated resources to research the various options and understand what makes sense and what doesn’t make sense to your business,” said Rutland.

“We are asking owners of small to medium sized businesses to imagine how

much more you can achieve with Harvey Norman as your IT department? We are just like a really large IT department for a big company. But we don’t just provide IT support and services, we also provide our customers with advice on what they should be doing with their IT moving forward,” he said,

Rutland explains the risks to small and medium sized crane businesses involved in government work such as Tier One projects.

“The first issue to be aware of is that most large government departments, and certainly most large corporations, are now insisting that you have a certain level of cybersecurity before they’ll allow you to tender for their business. If you don’t meet the requirements, you won’t be allowed to tender or quote for the business. You’ll simply be prevented from even participating.

“The second issue is if you are dealing with a major corporation and a breach occurs in your business that ultimately affects their business, you’re not only legally liable for the damages that occur, it is also highly unlikely that you will ever do business with that company again, and you will lose perhaps one of your biggest and most important clients. It can be absolutely disastrous for small businesses,” he said.

The federal government has a department called the Australian Cyber Security Centre, and they have published

a cybersecurity risk mitigation framework called the Essential Eight. Think of it as similar to Occupational Health and Safety Guidelines, but instead of physical security, this is about cybersecurity. Rutland explains more.

“Under the findings of the courts, all businesses have a duty of care to protect their customer data, and the measurement for whether or not that duty has been discharged is whether or not the business has made the appropriate effort to implement the recommendations of the Essential Eight. The Essential Eight framework is complicated and it’s not something that you can implement by yourself, you need someone like us help you,” he said.

Working with CICA and its members is exciting for Rutland and his team at HNTFB.

“We’re really pleased that CICA have approached us for this partnership, it is great that they’re taking the initiative in trying to protect their members from cyberattacks. We are keen to show CICA and its members what we are capable of and as a show of goodwill we are offering to provide an ‘Essential Eight Business Assessment’ free of charge. This normally retails for $499.

“There is nothing to be lost by having HNTFB conduct this assessment. We will provide members with an independent view that confirms everything is dandy and there is nothing to worry about, or we will provide you with a list of things that are missing and recommendations on how you can fix it. You don’t have to do that with us, you can go and do that with any provider you want,” said Rutland.

“With the various industry sectors we work in, there are always owners of small to medium sized businesses believing they are too small to be the subject of a cyberattack. We are here to tell you these criminals do not discriminate, they are targeting vulnerable businesses no matter the size, and as I’ve said, many businesses simply don’t recover from an attack. So, we are asking CICA members to take the FREE ‘Essential Eight Assessment’ and ask, ‘can you afford not to?’” Rutland concluded.

The last four years has seen dramatically changing market conditions in the construction sector. Stan Alexandropoulos, Chief Executive Officer UAA Group, reminds the crane sector about the critical nature of ensuring the right policies are in place to cover both new and particularly used equipment.

has led to crane hire businesses examining the benefits of purchasing quality used equipment.

With long lead times on new

purchase more secondhand equipment. In today’s business environment, including the recent downturn in the construction sector, and with supply gradually catching

and a new one that needs to come on. This lack of diligence can certainly impact on insurance costs because you could have assets that you no longer own on the

schedule and not have the appropriate asset actually covered,” said Stan.