THE original fine imposed on Minus1 Refrigerated Transport Pty Ltd, after a worker was seriously injured, has more than doubled following an appeal.

In June 2023, a forklift was being used to unload a van in the driveway of the company’s Dandenong depot when it reversed into a worker walking in the same direction.

The worker’s right leg was dragged under the forklift and then run over again when the forklift was driven forward.

The worker suffered partial de-gloving to his calf, a fractured ankle and fractured tibia.

In October 2024, Minus1 Refrigerated Transport Pty Ltd was fined $20,000 without conviction in the Dandenong Magistrates’ Court after pleading guilty to a single charge of failing to provide or maintain a system of work that was safe and without risks to health.

But after Minus1 appealed

the fine, the original sentence was set aside.

The County Court imposed a conviction and a $50,000 fine on Friday February 28. The company was also ordered to pay $4575 in costs.

WorkSafe’s investigation into the incident found the driveway area was not a designated loading and unloading zone, however, the practice had occurred there previously.

According to WorkSafe, it was reasonably practicable for Minus1 to have implemented a traffic management plan that ensured a three-metre exclu sion zone was maintained be

tween pedestrians and mobile plant; and to ensure that vehicle loading and unloading only occurred in designated areas.

The court also heard the company was previously fined $20,000 without conviction over a similar incident, when a truck driver suffered broken ribs and fractured vertebrae after being struck by a reversing forklift in 2022.

A spokesperson for the company told Big Rigs that steps had been taken following the “Subsequent to the incident,

Safe and have sought to take every possible step to minimise risk to staff, customers, and the public going forward.

“In its sentencing comments, the Court noted that we are of good character; work diligently on safety in a heavily regulated industry; have an impressive and dedicated OH&S team; and have cooperated with WorkSafe.”

Minus1 continued, “Over our 35-year history we are very proud of our industry-leading ‘lost time injury frequency rate’ which has been sustained notwithstanding recent substantial operational growth.

“The safety of our staff, customers and the public is at the forefront of everything we do, within an industry that we recognise carries the potential for serious harm.

“This regrettable incident has served to reinforce how critical it is that we continue to do all

we can to make our workplace safer.”

The Minus1 spokesperson added that the company remains focussed on learning from the incident and continuing to support the staff members and their families who were involved.

WorkSafe Executive Director of Health and Safety Sam Jenkin said there were no excuses for failing to adequately separate forklifts and pedestrians.

“Our data shows that on average more than one worker every week is seriously injured in incidents involving forklifts, which is simply unacceptable when the ways to control the risk are easily adopted and relatively low cost,” Jenkin said.

“It is incredibly disappointing that a second person has been injured due to this company’s failure to implement basic safety measures to keep pedestrians out of harm’s way.”

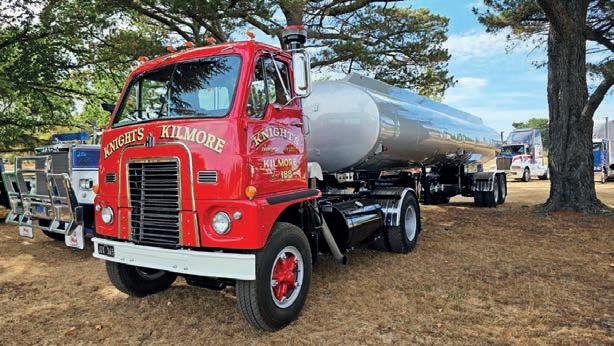

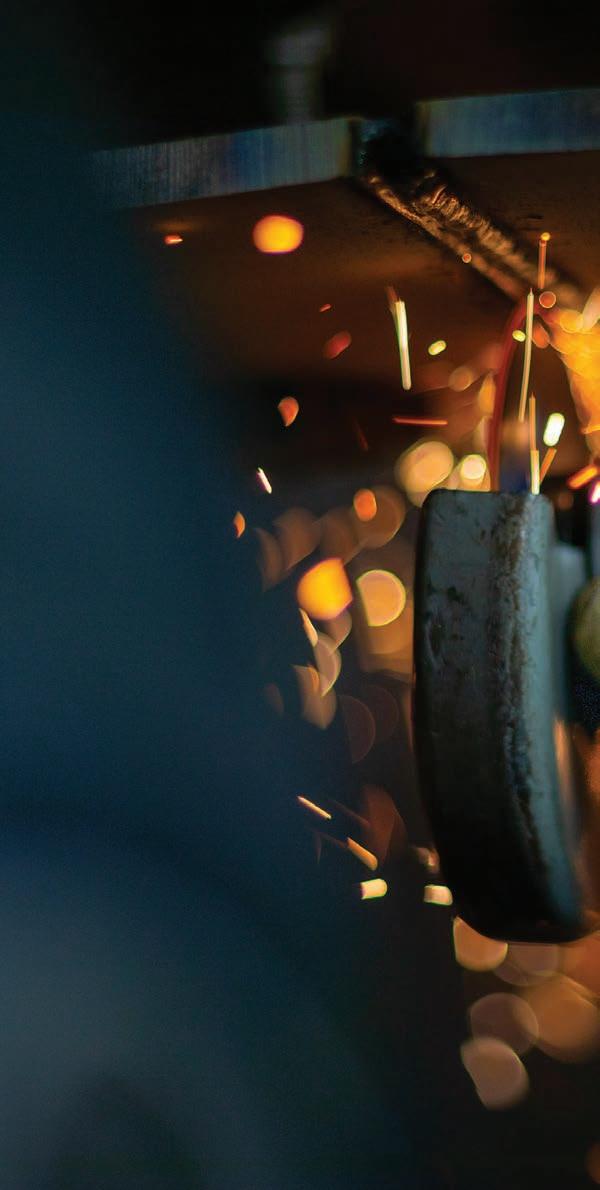

A truck and three-axle dog was intercepted at the Mareeba Shire in Queensland recently after staff from the National Heavy Vehicle Regulator (NHVR) noticed an issue with how the load was restrained.

According to the NHVR, “Queensland Safety and Compliance Officers promptly intercepted this vehicle that was fully loaded with aggregate

and topped off with a couple of large protruding pipes, completely unsecured on the top of the trailer – with no reasonable explanation from the driver about the loading methods.”

The regulator says further checks revealed the vehicle was defective and incorrectly registered.

“Due to the severity of the overhang at the vehicle’s rear

and no load restraint in place, no immediate penalty or fine was issued as the matter has been referred to our Prosecutions unit,” said an NHVR spokesperson. “The maximum court penalty is $15,000.”

In terms of registration, the NHVR said, “This vehicle was not registered to tow with a trailer.”

The NHVR did not provide

detail on the vehicle’s defects.

The regulator also issued a reminder to drivers about load restraint best practice.

In sharing details of the intercept, the NHVR also pointed to its load restraint guide, which details best practice load restraint systems. It can be accessed at nhvr.gov.au/ road-access/loading/load-restraint-guide. caught the attention of NHVR officers. Image: NHVR

BY DANIELLE GULLACI

ARVA Investments, trading as Melbourne-based ARVA Transport and Logistics and ARVA Freight, has gone into liquidation, with creditors facing an uncertain future.

According to an ASIC notice published last month, at a general meeting of the company members on Wednesday, February 25, it was resolved that the company be wound up and that Glenn Crisp, from Jirsch Sutherland, be appointed liquidator(s).

A RVA was founded in 2008 by Agustinus ‘Gus’ Arief with just one truck. Within 15 years, he grew his business to a fleet of over 100 vehicles, servicing the eastern seaboard and Adelaide.

Shortly after news began circulating of ARVA’s demise, the company’s website was taken offline, with a “website undergoing maintenance” landing page in its place.

Big Rigs approached ARVA management for comment but did not hear back.

A former employee of the company – who asked to remain anonymous – approached Big Rigs to share what he claims to have experienced during his time there.

“ARVA has always had a history of not being able to pay their debts,” he said.

“They’d have drivers coming into the office pleading to be paid so they could pay their rent. There were people coming in and asking for money they were owed for loads. A lot of people have been affected by this. A lot of employees are owed a lot of super too.

“ARVA owed a lot of money to a lot of people. There was one driver there who had been getting paid inconsistently. He left when they bought a brand new Mack.

“ARVA was pulling in good revenue, they just couldn’t manage their debt.

“What I don’t understand is, if you’re constantly at a loss and can’t pay people, why not scale back. Instead they kept committing to more work and getting more gear.”

Managing Director at Ezi Loads Australia, Jason Ajdani alleges his company is owed $30,360 from ARVA for work that was completed but never paid for.

Ezi Loads provides taxi truck services, as well as supplying one tonne vans through to B-doubles. As Adjani explained, “We started working with ARVA around March 2024. They had a client that was a furniture company and to service that contract, they required the use of 4 tonne pan-techs, so we were supplying those trucks to ARVA. We also did

a lot of their local deliveries around the Sydney metro area too,” explained Ajdani.

“After we performed all the work, we found out they weren’t paying any of their bills. They promised over and over that they would pay us, and that went on for a good four months.”

To assist ARVA in paying off the money owed to Ezi Loads, Ajdani said they came up with a plan.

“We said let’s try to get them to pay off their bills by supplying their trucks, so we weren’t out of pocket. They agreed. Then every time we called and asked for trucks, they told us there were none available.”

Ajdani says he wanted to share his experience as a warning to others.

“If we were a smaller business, something like this would have sunk us.”

ARVA Investments was also part of a business deal with Atlantic Container Lines Australia Ltd (ACL) –to form ACL-ARVA Logistics Ltd (ACLAL).

A RVA Investments was a minority shareholder of ACLAL, holding 8 per cent.

ACL, a leading warehousing and freight-forwarding company that is still very much in business, owns the remaining 92 per cent of ACLAL, with Rudy Suharto serving as the sole director.

The two shareholders are in

dispute. In November 2024, ARVA Investments was ordered to pay $32,500 on or before January 31, 2025. ACL says that debt has not been paid and served a statutory demand for payment on February 5, 2025.

ACL alleges this demand was ignored until February 25, when Arva Investments’ sole director and shareholder put Arva Investments into voluntary liquidation and appointed Glenn Crisp as liquidator. W hen the liquidator calls for proofs of debt, ACLAL

Crisp said the financial position of Arva is still being investigated, as are the reasons for the company’s failure. He said Jirsch Sutherland will be issuing a creditors’ report in due course.

“Jirsch Sutherland will also be assisting employees with claims they may have with the Fair Entitlements Guarantee scheme.”

told Big Rigs it will be lodging a proof to the value of over $500,000 for money had and received and for diverting some of the new racking ordered for the Broadmeadows site and paid for by ACLAL, to ARVA Investments’ warehouses in Queensland and NSW. Proofs by ACL will include $32,500 for legal costs and up to $250,000 under a general security deed that ARVA Investments signed during November’s court proceedings. Big Rigs also contacted the liquidator Glenn Crisp from Jirsch Sutherland for an update on what money creditors may be owed and if they’re any chance of getting any of it back.

BY JAMES GRAHAM

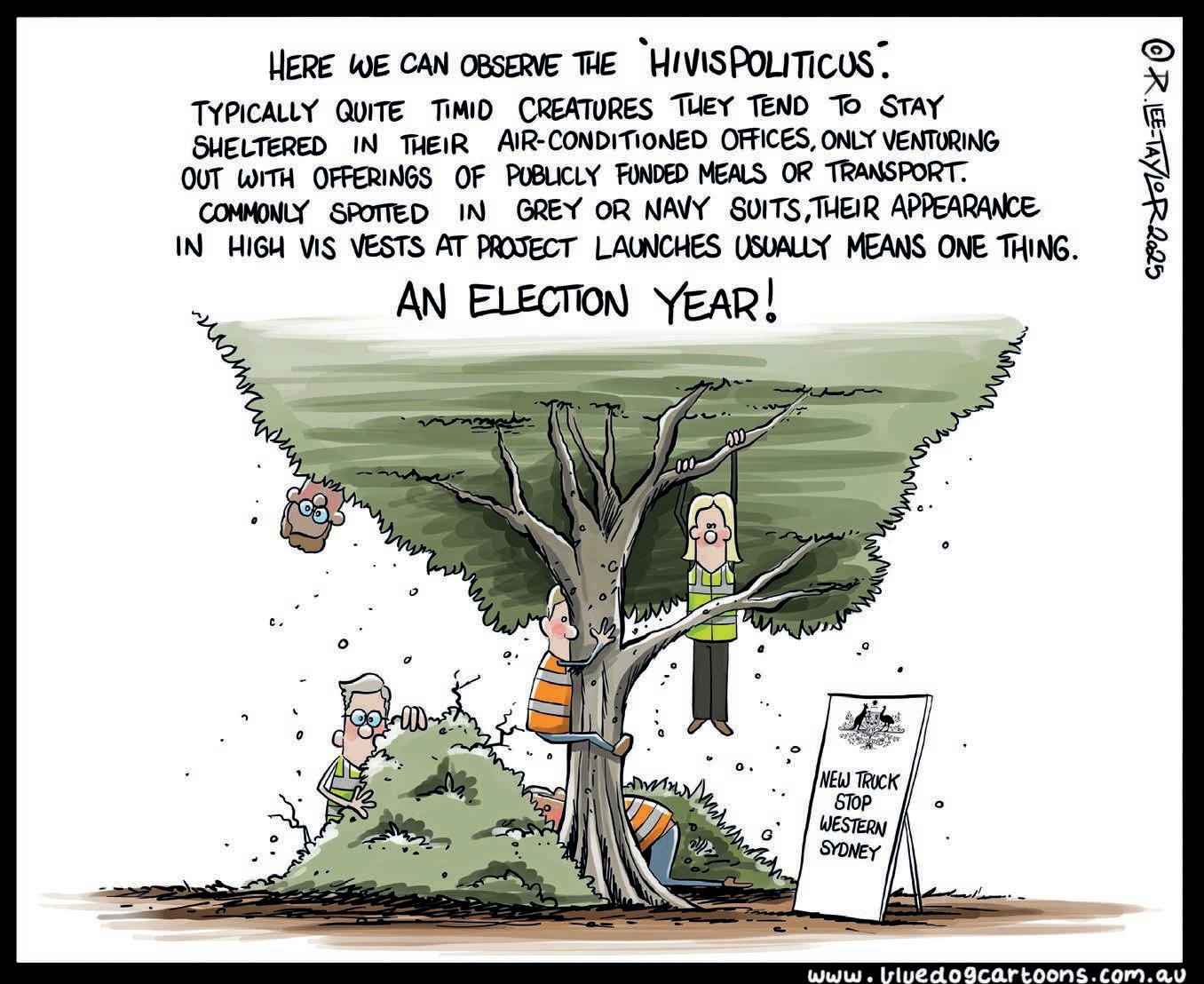

WHILE the new location for the much-anticipated rest area for truckies in western Sydney has been revealed, an opening date is still up in the air.

No VIPs or officials that Big Rigs spoke to at last month’s Erskine Park media launch could shed any definitive light on when truckies would start rolling into the six-hectare site on the corner of Lenore and Archbold Roads.

An emailed statement from Transport for NSW (TfNSW) later confirmed that the open ing date is still some way off – and could also suggest that the location is by no means certain to get an official tick of approval.

“We aim to have planning and design completed within a year and that work will de

work includes undertaking site-specific analysis, a Strategic Business Case, an environmental assessment, geotechnical investigation and concept

stakeholders as the project progresses.

According to the media release announcing the location, a TfNSW survey of 800 truckies would also help inform the facilities at the proposed site.

“Overwhelmingly, longhaul drivers of B-doubles and semi-trailers – found safety and security was their highest priority for a rest area, as well as the provision of separate toilet and shower facilities for female drivers,” the statement said.

“Based on driver feedback and industry consultation, the rest area will provide flushing toilets, clean drinking water, hot showers, ample available parking, including secluded bays for sleeping, and shaded areas for time outside the cab.”

All that is known for now is that the state and federal governments have committed $40 million each into the project, and when finished, it’s expected to be big enough to accommodate 100 trucks and trailers.

Assuming it passes the planning and assessment phases, the government-owned plot will be ideally placed for interstate drivers, being five minutes from wthe M7 and 10 minutes from the M4.

“I think it’s going to make a huge difference,” said Ann Lopez who runs Sydney-based Lopez Brothers Transport with her husband Phil and has been at the frontline of lobbying for a facility of this type in the city as Road Freight NSW members.

“We’re crying out for more people to join our industry and to have something that’s safe and respects the drivers, especially women entering the industry, it’s another point of difference that will enhance the opportunities to join.

“Everyone’s workplace should have these sort of facilities available.”

A lthough the proposed site won’t impact Lopez Brothers as much as others – its business focuses mostly on local container transport – Phil said a facility such as the proposed one in western Sydney would also help retain the older drivers for longer.

“It is exciting, but it is only

getting us to a baseline of where we should have been years ago,” said Phil, as he also reflected on the Covid days of staff drivers being refused access to toilets.

Added Ann: “We have a responsibility as employers to make sure our staff have good facilities and that they’re well respected and cared for and this will give us that opportunity to add another layer of protection.”

RFNSW CEO Simon O’Hara, a long-time advocate for another rest area for truckies in Sydney, said the proposed site is a win for the association’s long-running advocacy for more dignity and respect for the trucking industry.

He said the idea for a dedicated truckies’ rest area was first sparked by an industry roundtable with NSW Minister for Transport and Roads John Graham that highlighted the many issues facing drivers in Sydney.

A new truckies’ rest area in Sydney was also one of 11 asks put forward by RFNSW in its election platform for the last state election.

He said a three-year wait between pitching the concept and announcing the location is a “good result” for an $80 million project like this.

“There’s a two-way street between the community and truckies,” O’Hara said.

“The community expects that the truck drivers are well

rested, and truck drivers expect to be well rested, so we see this as a big, big improvement on the current situation.

“This is great initiative, and we thank the state and federal governments for pitching in $40 million each. Sydney needs it, the trucking community needs it – it’s been generations that this has been asked for.”

O’Hara also said the site will make a significant difference for truckies, particularly those coming into Sydney from regional areas.

“Western Sydney is the beating heart of the freight industry. You get a lot of fully-loaded trucks in here every single day coming from all around the state – and from different states.

“This is a great place to rest up and go on your way or come back to and load up again.”

O’Hara also talked about the mutual safety and health benefits the site affords the community and truck drivers.

O’Hara said he was only talking to an operator the day prior to the site announcement who told him about a young driver who had died from a heart attack in his cab at nearby Wetherill Park while waiting to pick up from a customer.

“Perhaps if he’d been here [at the new rest area], maybe someone would have noticed him,” O’Hara said.

At the site announcement, John Graham thanked the

federal government for getting on board with his push to quash Sydney’s reputation as the least truckie-friendly city in Australia.

He also reserved praise for former truckie, WA Labor Senator Glenn Sterle who “led the fight” for better rest area facilities for truckies during Covid and was instrumental in securing federal support for the new Sydney site.

“This has been a call for a long time; finally, we’re delivering,” Graham said.

Sterle said he can’t stress the importance of the site an nouncement enough.

“This facility will provide up to 100 truck drivers a safe haven to pull over and manage their fatigue,” Sterle said.

“It was an election promise and it is going to be delivered.”

Federal Transport Minister Catherine King said the safety of truckies is a priority for the Labor government and the quality of heavy vehicle rest areas is critical for that.

“We’ve listened to our truck drivers, and will deliver what they’ve asked for – shelter, toilets, hot showers, drinking water, shade and bays to sleep,” King said.

“These are things that we often take for granted at our own workplace but are not easily accessible for our truckies while they are working on the road.

“Availability of adequate rest areas helps truckies to better manage fatigue and avoid incidents on the road, ultimately saving lives.”

Mayor of Blacktown City, Brad Bunting, told Big Rigs that the local council welcomes

the rest area announcement and is ready to play its part.

“Blacktown City has long advocated for a wellplanned, properly funded, and well-maintained rest area for heavy vehicle operators,” Bunting said.

Council has previously written to the NSW Government highlighting the urgent need for such a facility.

“As one of the largest transport and logistics hubs in Syd-

ney, Blacktown City is home to more than 14,000 residents working in the transport, logistics, and warehousing sectors.

“With direct access to the M7, M4, and M2 Motorways, the proposed site is ideal for a Sydney-based rest area.

“This will serve as a vital hub for drivers, reducing the need for them to take significant detours off major motorways to find suitable rest stops.”

Tony Stephens

New depot for all the local trucks with no depots of their own. At least the BP will have a few more places to park. They will need a rego check camera on the gate so they can track who is local and who is genuine interstate and overnight.

Stuart M Baker

Here’s an idea.....heaps of room at pig farm hill to double the size of the southbound rest area......and build one on the northbound side exactly the same size and do something about the dirty filthy disgusting facilities there.

Brad McDonogh

I think it’s a great idea and it’s gonna make life a hell of a lot easier for truck drivers. However, the issue you gonna have is all the local drivers and subcontractors that use the dedicated area as their depot or parking area. You look around the local streets everywhere now and you watch because they’ve been kicked out of the BP at Eastern Creek and councils are restricting parking everywhere for they will end up in there. If it’s POLICED and actually enforced, it will be good.

David Oxley

I’m not keen on this idea, but if it helps us interstate drivers having a spot to park for a 7x hour break then maybe they should bring in a rule where you come to a gatehouse and boom gate. Show them your logbook (proof you’ve driven from Queensland or Melbourne for example) and they let you into the “interstate drivers only” section.

Craig Ward

They’ll get three more election promises out of this, then shelve it. Even if it did get done, showers and toilets will be cleaned max once a week and the lot will be full of tippers parked up for the night while their operators go home.

James David

How is it 80 million for a flat graded area that’s probably on unusable land and asphalt.. unless it’s time lic plate recognition monitored with exit boom gate that reads trailer rego plates ... Then be a dumping ground.

Tristan Michel

Sounds great in theory. It MUST have a mandatory 14hr tow away so as big companies and other smaller operators don’t park their gear up for long periods taking up space. Also, NO CARAVANERS should be permitted to use. Should also include a 24hr on-site mechanic and there should be a shop to purchase tools, and other things we need and frequently lose out on the road.

Ivor Nelson

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110 Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

BRISBANE NORTH

1/259 Cullen Av, Eagle Farm QLD 4009 Ph 1300 11 4774, email: seats@isrinb.com.au, www.isrinb.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020 Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY

110 – 120 Maggiolo Drive, Paget QLD 4740 Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH

408 Welshpool Rd, Welshpool WA 6106 Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

NEWCASTLE/HUNTER VALLEY

Ph 02 4932 0600,

Unit 2/13 Hinkler Ave, Rutherford NSW 2320 email: sales@hvss.com.au www.isri.com.au

New speed camera on M4

A new average speed camera has been installed on the M4 motorway in NSW – specifically targeting heavy vehicles.

The new cameras, which capture the stretch between Eastern Creek to South Penrith, are still in warning mode for the next few weeks, said Transport for NSW.

Heavy vehicle drivers caught speeding at 30km/h or less over the speed limit will be sent a warning letter to encourage them to change their behaviour.

Truckies caught speeding at more than 30km/h over the speed limit will receive fines and demerit points as usual.

At the end of the warning letter period, offending heavy vehicle drivers will be sent fines and demerit points.

Lindsay’s expands to WA

Lindsay Australia has announced the acquisition of Western Australia-based business GJ Freight, which operates six sites in the state’s south-west.

The transport giant revealed that a sales agreement had been reached this month, with operations set to commence on April 1.

As part of the sale, Lindsay Australia will acquire the assets and staff of GJ Freight.

Lindsay Australia says this is part of a strategic move that will allow it to further diversify and expand into the growing horticultural market in southwest Western Australia.

Started in 1992, GJ Freight is an integrated logistics and packaging business, with its head office located in Donnybrook, WA. It currently generates over $20 million in annual revenue.

Lindsay Australia also has a new Perth depot due for completion later this year.

SA bridge opens

South Australia’s new Aldinga Bridge has opened to traffic, marking a major milestone for the duplication of Main South Road between Aldinga and Sellicks.

The Aldinga Bridge is a key feature of the new Aldinga Interchange, which realigns the junctions of Aldinga Beach Road and Aldinga Road. Traffic is now also travelling on parts of the newly constructed northbound carriageway on Main South Road.

The stage 2 Main South Road duplication includes intersection upgrades at Hart and Colville roads, Norman and Rogers roads, Hahn and Cox roads and Sellicks Beach Road, as well as the installation of wide centre medians and wire rope barriers to improve safety by separating northbound and southbound traffic. It also includes three U-turns to facilitate local access.

Correction to flood story

Our page 3 story in the last issue, ‘Calls grow for support after Qld floods’, incorrectly called Dave Morgan the owner-director of Townsville-based Morgan’s Long Distance Transport, and also published a picture of the same fleet.

Morgan is the owner-director of Townsville-based Morgan Transport Group.

BY DANIELLE GULLACI

POOR communication and an administrative error led to two massive wind turbines being perilously routed through the narrow streets of a small Victorian country town.

The operator charged with moving the oversized blade, from Geelong to Bulgana Wind Farm in Joel South on February 18, was following an approved Oversize Overmass transport route when it became clear the convoy was not going to make it through the town of Ararat smoothly.

Traffic came to a standstill as two trucks and the massive blades they were transporting were manoeuvred through the residential streets of the town, damaging trees and road signs along the way.

Planning for the journey involved the input of a number of councils affected by the convoy, the operator and the NHVR, which was tasked with approving the route once it was was formally lodged on its online permits portal.

Big Rigs contacted the National Heavy Vehicle Regulator (NHVR) following the incident to ask what went wrong.

A spokesperson said “the NHVR is aware of the incident in Ararat, Victoria, where t wo trucks transporting wind turbines were unable to safely navigate the approved route on their permit.

“All processes were followed in attaining and approving permits, with an approved Traffic Management Plan also in place detailing how the

Oversize Overmass (OSOM) movement was going to be safely carried out.”

Ararat Rural City Council was one of several councils and stakeholders involved in the permit approval process.

On February 25, the council shared a statement revealing it had consented to an OSOM permit application, lodged through the NHVR Portal, for the transport of four wind turbine blades. As part of the permit application, a Traffic Management Plan (TMP) was supplied to the NHVR and road managers.

“Consent to the permit was granted by council based on the TMP provided by the operator, which detailed how the OSOM movement would be safely carried out,” Ararat Rural City Council said.

However, Council claims delays caused when the first two blades got caught out in nar-

row residential streets resulted in disruptions to municipal services and school bus operations, as well as extended road blockages.

“These circumstances were compounded by mechanical issues experienced by the operator,” Ararat Rural City Council added.

W hile the operator followed the NHVR-approved route, Ararat Rural City Council told Big Rigs it had suggested an alternative route option.

In its statement, council said it is seeking to recover costs from the transport operator for damages to its assets, including the loss of a street tree and several street signs.

The council is also pushing for a penalty to the operator for breaching permit conditions relating to times of operation within school bus routes.

“Council proposed an alternate route to the one which

COUNCIL APPROVED THE OPERATOR’S PERMIT WITH CONDITIONS, ONE OF WHICH WAS AN ALTERATION TO THE ROUTE WITHIN ARARAT.” ARARAT RURAL CITY COUNCIL

was taken, however this proposal was unheeded,” a spokesperson said.

“Council approved the operator’s permit with conditions, one of which was an alteration to the route within Ararat.

“This proposed route alteration was logged within the NHVR portal by council, and shortly thereafter cancelled by another party, resulting in the originally submitted route being used. Moving forward, council will not be issuing approvals (even conditionally) without absolute confirmation that proposed alterations will be adhered to.

“Council’s rejections or proposed alterations to operator permits have historically received pushback from the NHVR and operators, placing pressure on our resources to justify the decisions we are making to protect our community and infrastructure.

“Council has requested immediate withdrawal of its consent for this particular permit and is working with both the NHVR and the transport operator to help identify a more suitable route for delivery of the remaining two blades.”

On March 4, Ararat Rural City Council issued another statement:

“Ararat Rural City Council have engaged in discussion with the National Heavy Vehicle Regulator (NHVR) to address an administrative error with council’s approved consent that resulted in miscommunication affecting the transport route of wind turbine blades through Ararat Rural City,” it said.

“The primary focus of Council and the NHVR remains the safety of all road users, and we are working collaboratively to implement measures that ensure heavy vehicle movements are conducted safely and efficiently within our region.”

The NHVR said it will continue working with the operator and the Council to understand how the incident occurred and to ensure the safety of future heavy vehicle movements on these roads.

A range of new technology and truck turning areas at the Tugun Bypass tunnel are helping to get drivers of overheight vehicles out of trouble if they slip past warning signs and find themselves stuck at the northbound or southbound tunnel entrances.

Though it has been a rare occurrence, when an overheight vehicle gets caught out here, it becomes a highly disruptive problem for those travelling on the Pacific Motorway.

Minister for Regional Transport and Roads Jenny Aitchison revealed that this was a particular issue approaching the tunnel from the north, because if an overheight vehicle reached the tunnel from the Queensland side, the driver would have to reverse their rig

four kilometres back up the motorway before they could turn around.

Now if an operator happens to go past the warning signs, they will only have to reverse a short distance up the highway to reach an area where they can cross over.

Most of the work to fix the issue was carried out over two years during the quarterly maintenance tunnel closures to minimise impacts to motorists.

“With the investment from the Minns Labor Government, overheight vehicles should never reach the tunnel, but if they do, they can be turned around with help from the Tugun incident response officer or a single police officer,” Aitchison explained.

“The time and cost savings from this change are enormous and it will mean the lengthy delays when an overheight vehicle inadvertently entered the tunnel are a thing of the past.”

The project has been completed with the support of Transport for NSW, Transport and Main Roads Queensland and the police forces of both states.

Aitchison added, “Transport for NSW put in new overheight detection systems to notify staff of a vehicle approaching the tunnel, so they can immediately activate variable speed limit signs to stop them reaching the tunnel.

“We’ve also installed five new advance warning signs and new traffic lights just short of where we’ve put in new heavy vehicle crossovers.

“The Tugun tunnel goes underneath the Coolangatta Airport, with the southern end of the tunnel in NSW and the northern end in Queensland, and we had great collaboration with the Queensland authorities to get the work done.

“The project has improved advance warning technology as well as the infrastructure, so if any overheight vehicles did get past the advance warning systems, they would be stopped and able to turn around at the entrance to the tunnel.”

THE first stage of a $13.9 million upgrade to the Sturt Highway at Wagga Wagga is now underway.

This will involve upgrades to a 1.8 kilometre section of the Sturt Highway (also known as Hammond Avenue) on the eastern approach to Wagga Wagga’s CBD. Work will include completely reconstructing the road with a new surface and new kerb on the northern and

southern sides, lane widening and configuration changes to provide dedicated turning lanes.

The changes aim to provide a smoother surface that is less prone to road damage and potholes.

Shoulders will be provided for cyclists on the northern and southern sides of the highway.

The first stage of this project – between Tasman Road

and Blaxland Road – started on March 4 and is expected to take 11 weeks to complete.

The second stage – from east of Blaxland Road to Stuart Road – will be delivered in the 2025-26 financial year.

All work will be carried out under traffic control with lane closures and reduced speed limits in place.

“The Sturt Highway provides a strategic freight and access link from Sydney

via the Hume Highway to Mildura in Victoria and on to Adelaide in South Australia,” said Minister for Regional Transport and Roads Jenny Aitchison.

“It also serves as a local and regional access corridor to and from regional centres along the route.”

Member for Wagga Wagga

Dr Joe McGirr added: “These works, coupled with the work now underway to redevelop

the Marshalls Creek Bridge, are welcome improvements that will deliver a safer, smoother Sturt Highway for thousands of users every day.

“A renewed east/west link means better travel for local business and residents, and moving forward, I’ll also be advocating for major north/ south improvements, including a second river crossing which will be critical to Wagga Wagga’s future.”

EDITOR JAMES GRAHAM

eraman in the opposite seat.

When I casually remarked that I didn’t know that so many officials cared about truckies’ welfare, he shot back with the best quote I heard all morning.

“It wouldn’t happen to be an election year, would it?”

We’re a cynical bunch in the media – it comes with the job.

But I do hope that the concerns raised in our story on pages 4-5, and again in Ryan Lee-Taylor’s brilliant toon on the right, are wide of the mark.

Truckies desperately need this site to open sooner than later. I just don’t understand why it took three years of ‘roundtables’, committee meetings and surveys to get us to this point. We now hear that the next hurdles include a site environmental assessment and a business case study. What numbers do you now need to crunch to save lives?

OUR recent story about operators needing more financial assistance after the devastating North Queensland floods got plenty of reader support.

Brotha Trucka said governments don’t care about what cost that transport companies face in floods or any other major issues.

“They only care about looking good when communities

are in a CRISIS,” he wrote.

“They don’t fund outta pocket expenses for those to get supplies through they expect the transport companies and drivers to carry the country with NO HELP footing the bill ..

“The transport industry is only a cash cow for law enforcement!”

David Oxley with the price of diesel being cheaper in Brisbane than out west.

“BP Caboolture twin servos around $2.02- 2.05. But Mobile at Roma is $1. 75

and the self-serve BP at Emerald around $1.80,” he said.

Tony Reigos called for $1500 per day for every truck stuck in flood waters, “so the driver can get paid as well.”

Last Minute Freight wondered why companies don’t just put up their prices when doing quotes.

“Just up the prices and keep it up there so they are in front when that stuff happens. Stop cutting cost and then complain about it when it floods.”

THE latest instalment of the National Heavy Vehicle Regulator’s (NHVR) We All Need Space road safety campaign sees truckies stepping into the spotlight.

Under the title A Truckie Knows, the regulator was reminding all road users about the importance of respect for other drivers, as well as the risks of speed and tailgating.

Veteran truckie Clem Wheatley said he’d witnessed some horrible driving by drivers of all vehicle types.

“No one group of drivers can claim perfection,” he wrote.

“Sadly over the past few years the standard of driving behaviour and attitude by drivers

of heavy vehicles, has declined noticeably, which is one of the reasons many long term truck drivers are getting out of the industry.

“My point being, no one group should be criticising another, take a good look at those driving vehicles like yours before criticising others.”

Niell Graham said a car calls it tail-gating: “A truckie knows that they are getting into position to overtake the slow car safety as he can. A truckie knows that as soon as they are in the overtaking lane the car will speed up not allowing the truck to overtake and then slow down again when the overtaking lane ends.”

Craig Masefield-chips said the general public only show respect when there is floods , major storms ( cyclones ) or the pandemic

“Yes, there are some people in the public sector that do appreciate what we do but the majority don’t care as long as they can buy clothes, food etc we are nothing to them

THE column by SARTA’s

Steve Shearer in our last issue about restarting the conversations around suicide by truck sparked plenty of reaction online.

“An excellent article,” wrote Pilbara Heavy Haulage Girls Group. Thank you SARTA, Steve Shearer and Big Rigs for bringing this out in the open. A serious problem that keeps being swept under the carpet.”

Graeme Walker agreed: “Steve Shearer is the only one that has raised this issue and while everyone talks about the importance of mental health they refuse to discuss the af-

termath for drivers involved in suicides… I’m aware because it happened to me.”

For truckie Georgie Edwards, the column also struck close to home: “It happened to me, my counsellors have given up on me.”

Stewie Smith said the only time drivers are cared for, or appreciated, is when there is a flood: “And they go the extra mile to stock ya selves.”

Added Adsee Mac Maca: “Used and abused thats all we are.”

A series of NSW safety information days this month to educate caravanners certainly got the interest of our online readers.

“Bit of extra labour involved, but how about forcing them into existing weigh stations and instead of education with words, educate them with their wallet,” Shane Gibbs suggested.

“These type of roadside checks that pop up in different states, don’t seem to be getting message across.

“Check licences as well. Someone recently got done

here driving the bigger RAM ute that required an LR on a C licence, because they thought it was a car.”

Roz Nanna Turner reckons “the fools” who are overloading won’t even turn up to get weighed.

“Because they already KNOW EVERYTHING & wouldn’t want to be told otherwise.”

David Roll wondered if they were giving out free pineapples too?

“One good way to edumacate ‘em [sic]

“Don’t get these freebies in

trucks....so why not hit ‘em like they do trucks.” Added David Muller: “Should be doing them all the time day and night no exception.”

Rob Prideaux would like to see ‘permit to tow’ licence needed for over a 6x4 trailer.

BY DANIELLE GULLACI

A truck driver has had a lucky escape after stopping on the Hume Highway at Narellan, New South Wales, due to a hub fire.

Things could have ended very differently if it wasn’t for the quick-thinking actions of Cameron Taylor, National Manager – Gases at Toll, who just happened to be passing through. Thanks to his experience and training in dangerous goods, he knew exactly what to do to get the situation under control.

He told Big Rigs he just happened to be in the right place at the right time. “And knowing how to deal with this as it often tests people when it’s an emergency situation. I sensed the driver was in trouble so stepped in to help.

“It was very serious – I think within a couple of minutes that whole trailer would have

been fully alight. It would have caused traffic chaos and closed the Hume.”

The incident occurred during peak hour, at around 8.50am on Monday March 3, with a lot of traffic on the road.

“I was on my way to Port Kembla in the Toll vehicle and could hear chitter chatter on the UHF. I kept hearing people asking the driver, ‘Are you okay?’ As I got up over the hill, there was smoke billowing across the highway. Straight away I thought it was a hub or a brake fire. So the emergency response side of me kicked in immediately.”

Cameron said the truck was stopped in the emergency lane. “I raced up to the vehicle and as I approached the second drive axle, there was heavy flame that was coming from the inner tyre being well alight.”

As he continued, “Hub fires

generate such intense heat and even when you think you’ve got it out, it can flare up. Had I not stopped, within 5-6 minutes max, I think that trailer would have been fully alight. In a hub fire, you’re talking hundreds of degrees.”

The Toll vehicle Cameron was driving was equipped with one 9kg, two 4.5kg and one 1kg dry powder fire extinguishers, so he quickly jumped into fire-fighting mode.

“I had four extinguishers in total and had to use the fourth one sparingly to keep flare-ups under control until emergency services arrived,” he explained.

“You know you’re not going to put it out on the first extinguisher, it will flare up – and it did flare up three times.

“There were some very hairy moments but thankfully the fire brigade arrived in time as I was exhausting the last available fire extinguisher.

“Where we were on the

Hume Highway is several kilometres south of Narellan Road, so even with a priority call, I knew it would take at least 15-18 minutes for emergency services to get there. I had to keep it under control, because I knew if it got out of control, there was no return.

“I do carry fire extinguishers, as in our fuels and gases space, it is critical for safety. I carry everything on board in case it’s needed in an emergency response situation or a community assist incident like this one.”

He says the first thing he asked the driver was what he had on board the trailer –particularly if there were any dangerous goods or flammables, so he knew what he was dealing with. The trailer was however empty.

“The emergency response side of me kicked in straight away, I knew I had to act immediately – there was concern

for the driver, so I had to step in. It’s second nature for us working in the dangerous goods space. A lot of people think it won’t happen to them, but if it does, it’s important to know how to react.

“The driver was very shaken up but very thankful for my help. I had to take charge and become the first responder. It’s a daunting and challenging situation. It was really nice that the company also reached out and were really thankful for my help,” Cameron added.

IT WAS VERY SERIOUS – I THINK WITHIN A COUPLE OF MINUTES THAT WHOLE TRAILER WOULD HAVE BEEN FULLY ALIGHT.”

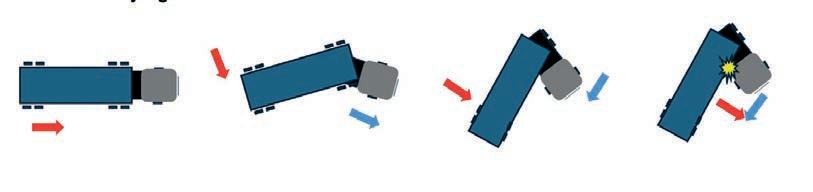

IN the early hours of February 20, an unattended truck rolled out of the driveway of the Shell Roadhouse at Buronga and into a home across the Sturt Highway.

As a result, the prime mover has crashed through a fence and into an elderly lady’s home, crashing into her bedroom – not long after she had gotten up.

The National Heavy Vehicle Regulator (NHVR) shared the incident on social media after

one of its safety and compliance officers (SCO) were the first on scene.

The regulator said its staff member was fuelling up at the service station when he saw what was unfolding.

“He noticed an unattended truck rolling down the servo driveway across the highway, before it crashed through a fence and into someone’s home,” the NHVR said in an online post.

“The SCO immediately ran

to the house where he found an elderly lady who had narrowly escaped a very scary situation – having just got out of bed to make a coffee. The front of the prime mover was in her bedroom with the bed under the bullbar.”

The SCO contacted police to notify them that the highway was completely blocked, before calling other SCOs in the area to assist in traffic control until police arrived on the scene.

“Well done to NHVR team

members involved on keeping the area safe and diverting traffic around the site to help avoid a more serious safety issue,” the NHVR added.

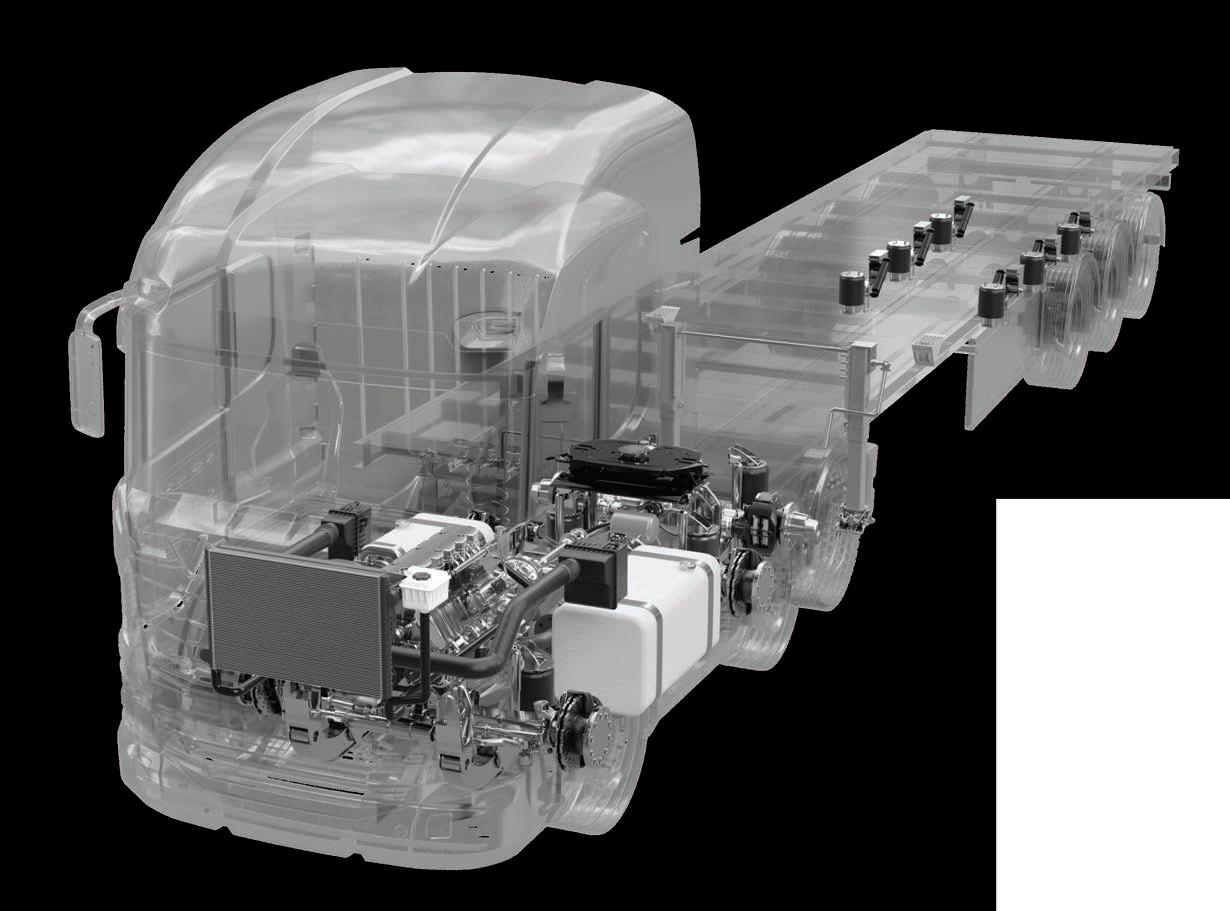

THE Healthy Heads Road Show will return in 2025, travelling to venues across Australia, to provide free health checks to truckies and those in the road transport, warehousing and logistics industry.

The Road Show truck, a

medium DAF rigid supplied by PACCAR Australia, was launched at the Brisbane Truck Show in 2021.

Kicking off in March, it will travel across Victoria, New South Wales, Queensland, Northern Territory, Western

Australia and South Australia.

The Road Show team will provide a range of industry specific resources to help support mental health and wellbeing. The team at WFR will a lso be there to provide free health screenings.

The first public events for 2025 are:

• March 25: BP NorthPoint, Victoria, 8am – 12pm, 1 Scanlon Drive, Epping

• April 4: BP Eastern Creek, NSW, 6am – 10am, 1 Wallgrove Road, Eastern Creek

Those who download the Healthy Heads App will also receive free coffee and poached eggs on toast. Further dates will be announced at healthyheads.org. au/get-involved/attend-a-roadshow-event

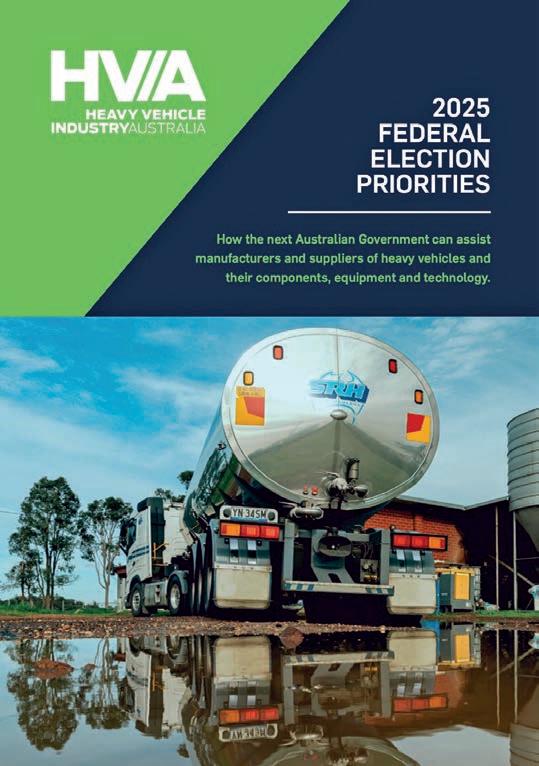

HEAVY Vehicle Industry

Australia (HVIA) has distributed a detailed list of federal election priorities to all 227 federal MPs and senators.

The peak trucking body calls for government assistance to support the heavy vehicle industry and to address pressing issues such as international competitiveness, the transition to net zero emissions, growing the future workforce, enhancing road freight productivity, and optimising Australia’s road infrastructure.

“The Australian heavy vehicle sector, one of the country’s most vital industries, is at a critical crossroads, confronting both substantial challenges and opportunities as it transitions into a future marked by significant change,” writes HVIA CEO Todd Hacking in his document forward.

“Representing over 300 corporate organisations, HVIA members range from Australian manufacturers and importers of trucks and trailers to heavy vehicle dealerships, repairers, and suppliers of equipment, componentry and technology throughout the supply chain.

“As the sector undergoes transformation, these organisations are navigating the challenges of maintaining competitiveness, adapting to new technologies, addressing changing skills needs, and managing industry-wide disruptions.”

Hacking said the Australian heavy vehicle sector requires government assistance to address pressing issues such as the transition to cleaner, more sustainable vehicle fleets, the development of infrastructure for new technologies, support for workforce upskilling and measures to boost productivity.

“We recommend five key actions to strengthen the resilience and competitiveness of the heavy vehicle sector.

“These actions are essential to not only improve the safety of the fleet but also in securing a sustainable future for Australian heavy vehicle manufacturers and importers while driving innovation and achieving government objectives.”

Recommendation 1: Assist Australian manufacturers of trucks and trailers

• Facilitate access to financing and investment via government programs.

• Guarantee affordable and reliable energy supply.

• Encourage local sourcing and supply chains via government policies; and

• Support workforce development by working with state and territory governments to remove apprenticeship wages from payroll tax.

Recommendation 2:

Support the net zero transition of heavy vehicles

• Publish a heavy vehicle-specific net zero roadmap that outlines strategies and initiatives to:

• Remove regulatory barriers to adoption of zero-emissions vehicles;

• Support the private sector

to deploy battery electric charging and hydrogen refuelling stations nationwide;

• Fund R&D of low carbon liquid fuel alternatives such as renewable diesel;

• Provide incentives to offset the higher cost of purchasing LZEHVs;

• Ensure energy infrastructure that can meet the future demands of LZEHVs; and

• Use and publish data to support evidence-based policies that reward the adoption and use of higher productivity vehicles.

Recommendation 3:

Grow the future heavy vehicle workforce

• Fund fee-free TAFE placements in all trades listed on the Core Skills Occupation List.

• Expand apprenticeship pathways by introducing tailored apprenticeship programs specifically focused on emerging technologies.

• Upskill the existing workforce and create a new pipeline of skilled workers.

• Incentivise RTOs to offer courses in trades listed on the CSOL and others facing shortages.

• Launch a public awareness

THESE ACTIONS ARE ESSENTIAL TO NOT ONLY IMPROVE THE SAFETY OF THE FLEET BUT ALSO IN SECURING A SUSTAINABLE FUTURE FOR AUSTRALIAN HEAVY VEHICLE MANUFACTURERS AND IMPORTERS WHILE DRIVING INNOVATION AND ACHIEVING GOVERNMENT OBJECTIVES.”

campaign to highlight traditional trades as a foundation for a lucrative and rewarding career; and

• Reform the VET sector to develop alternative educational pathways that recognise and support hands-on, school-based learners.

Enable higher productivity heavy vehicles

• Harmonise regulations across all states and territories.

• Expand the number

of routes accessible to high-productivity vehicles.

• Boost adoption of PBS combinations by transitioning proven designs into general regulations.

• Enact direct financial incentives to drive uptake of safer, more efficient and less polluting vehicles; and

• Improve data collection to enable evidence-based decision-making that drives better policy outcomes relating to safety and productivity.

Recommendation 5:

Optimise Australia’s road infrastructure

• Ensure roads and bridges are properly designed and funded to meet the needs of the freight sector now and

into the future.

• Adopt a risk-based approach to asset management rather than focusing solely on preservation of roads and bridges.

• Protect future freight corridors from incompatible development that may hinder their use.

• Foster greater interoperability within the network to improve efficiency by standardising regulations, vehicle requirements, and operational practices across states/territories; and

• Address the future fuelling and recharging needs of the road freight industry with an infrastructure plan that aligns with the Net Zero Roadmap.

PEAK trucking industry body

NatRoad is calling on the government elected at the upcoming federal election to focus on road safety and stopping the rising rate of crashes, injuries and deaths on our road network.

This was just one of the recommendations that Australia’s largest road transport association announced in a national reform agenda called Road to 2028 launched earlier this month.

Australian roads have seen a 27 per cent increase in the overall incident rate for heavy vehicles over 12 months.

It has been previously shown that it takes raising road standards by just one star on the AusRAP rating system to reduce deaths by 50 per cent, said NatRoad in a release announcing the reform agenda. Seventy-nine people died

in fatigue-related crashes in NSW alone last year, a 47 per cent increase on 2023, and the data shows 20 – 30 per cent of all crashes across all vehicle types are caused by fatigue.

NatRoad is also recommending a portion of the funding a lready earmarked by governments for road improvements should be redirected to rest areas.

Additionally, heavy vehicle rest areas should be incorporated into the criteria within the star rating system, said NatRoad.

NatRoad has also urged the government to deliver on its commitment to lift 80 per cent of national highways to at least 3-stars by 2030, while requesting an extended commitment towards achieving 100 per cent by 2035.

“Both federal and state governments needs to lift their

game to save lives. In 2024, 1,324 lives were lost on Australian roads, and that number has been steadily rising for the last four years,” said NatRoad CEO Warren Clark.

“The budget has $120 billion allocated for infrastructure improvements over the next decade, and in 2013 the cost of lifting all highways to 3-stars was estimated at just $4.7 billion. The money is there.”

NatRoad said its Road to 2028 national reform agenda aims to deliver a safer, more sustainable road freight industry for all Australians.

NatRoad has flagged that Australia is also short of at least 26,000 freight drivers.

The projected increase in road freight volumes by 77 per cent from 2020 to 2050 is placing Australia’s growth and prosperity at considerable risk.

“The road freight industry is

already at breaking point with a perfect storm of rising costs, escalating interest rates and increasing wages.

“We can’t afford to put drivers and other road users at risk with the continued underinvestment in highway infrastructure,” Clark said.

“With the upcoming elections, NatRoad is calling on the government to step up to their commitment to road safety.”

The Road to 2028 covers five key outcomes to address the most pressing concerns of the road transport industry.

“There are serious challenges facing trucking operators right now, and we’ve been calling these out for some time. We can’t and won’t wait for change. We must make it happen,” Clark explained.

“That’s why I spent considerable time in Canberra, meet-

ing with Labor, Coalition and Independent members during the first sitting week of Parliament in February, taking them through the Road to 2028 priorities.”

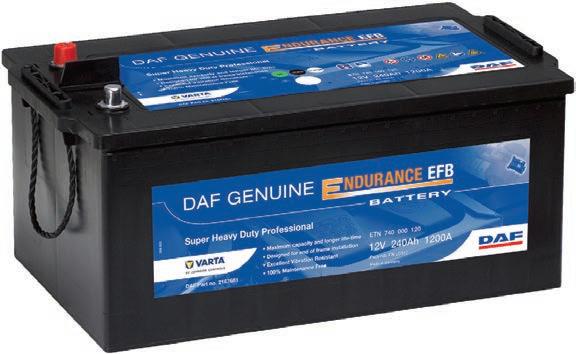

EFB

MEMBERS $ 462 NON-MEMBERS $ 482

I First fit on DAF CF models

I Enhanced Flooded Battery (EFB) technology provides increased capacity, longer lifetime and excellent vibration resistance over conventional batteries

I 16 month, unlimited kilometre warranty

2167682

Suits all DAF CF models

I 12V Maintenance Free Heavy Duty Battery

I 12 month warranty

TRP-24HD $135 $140

L260 x W173 x H225 mm

600CCA, 140RC, 75AH

Suits smaller vehicles, including Japanese trucks, four-wheel drives, diesel vans and utes

TRP-24LHD $135 $140

L260 x W173 x H225 mm

600CCA, 140RC, 75AH

Suits smaller vehicles, including Japanese trucks, four-wheel drives, diesel vans and utes

I 4000W peak power, 2000W continuous rated power

I Provides 240V AC power from a 12V DC battery source

TRP-700HD

L303 x W172 x H200H mm

700CCA, 160RC, 82AH

Suits heavy duty trucks, including Kenworth, Mack, International and Iveco

TRP-31HD $184 $189

L330 x W173 x H240 mm

900CCA, 160RC, 100AH

Suits heavy duty trucks, including Kenworth, Freightliner, Sterling and Iveco

I LCD Display shows power draw, voltage and battery capacity

I Dual 240V AC output sockets dedicated for running two appliances

I 2.1A USB dual ports for charging

AP12000P

2000W Pure Sine Wave Maintenance Free Battery MEMBERS FROM $ 135 NON-MEMBERS FROM $140

Inspired by a desire to make his late dad proud, Adelaide truckie Andrew Thorpe takes a now or never leap to follow his dream.

BY JAMES GRAHAM

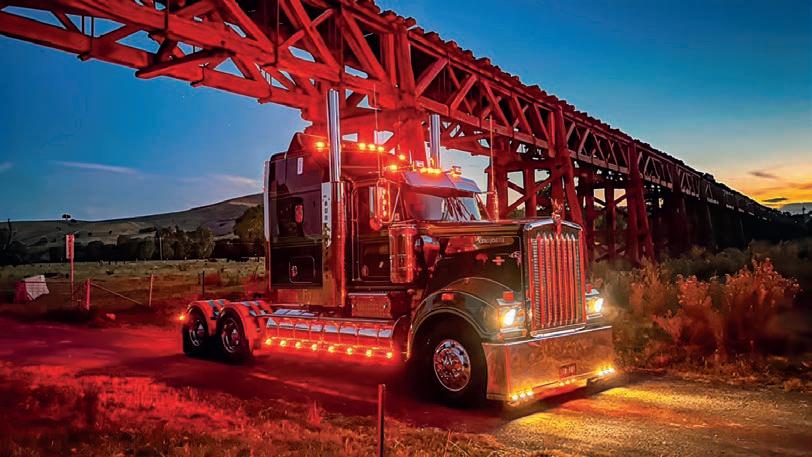

OWNER-DRIVER Andrew Thorpe, 36, couldn’t wipe the smile from his face when he was handed the keys to his first truck, a stunning new T909 Kenworth, in Adelaide last month.

Right alongside him sharing in the excitement and posing for pictures on delivery day at CMV Truck Centre – Kenworth DAF Adelaide were wife Zoe Jones and their blended family, Sophie,14, Ava,11, and Reya,11.

The truck had taken longer than expected to arrive due to Covid-related supply chain issues, but after building up to this milestone moment for nearly half his life, Andrew figured a few extra months wasn’t going to hurt.

CMV, meanwhile, bent over backwards to play their part, picking up the tab to fly him and father-in-law Mark Wilkins to Kenworth’s Bayswater plant last year for a factory tour before the pair drove the truck back to Adelaide on cloud nine.

It was another five months or so, however, before the custom work was finished [see sidebar story], but when the covers finally came off Andrew’s T909, he instantly knew it had all been worth the wait.

“I just couldn’t wait to get down there on the day,” Andrew said.

“Getting my Kenworth T909 was a big milestone for me, a day I’ll remember forever. I didn’t just want any truck. I wanted to do it right from the start, making it something special.

“It’s been a huge step, not just in business but personally as well, and convincing my wife to join me in this venture has been an adventure of its own!”

Andrew said one of his biggest inspirations for making the ‘now or never leap’ was to honour the memory of his late father, Craig, who sadly took his own life just days before Andrew’s 17th birthday.

Andrew admits he had a “rocky run” after his father’s death but got himself back on track through his love of truck driving and the desire to one day go out on his own.

“After spending over 15 years on the road, I see firsthand the importance of mental health, particularly in our industry.

“But more than anything, I want my dad to be proud of what I’ve built.”

Andrew grew up tagging along with his truck-driving father, a third-generation owner of an SA drilling company, every chance he got.

“When I was a kid I used to sit on dad’s lap and have a drive and always had the love for it.”

After Craig died, Andrew tried his hand at a variety of roles hoping to find something that would stick - diesel mechanic, forklift mechanic,

driller, off-sider - you name it, he gave it a crack.

much in that side of things, but I thought one day I’d get my truck licence, and I’ve never looked back since.”

Even so, Andrew admits that it’s taken him 15-16 years to acquire the skills and confidence to take the next step as an owner-driver.

“It’s an industry where it’s always going to be a gamble; you’re buying the equivalent of half a house, and you’ve got to keep it working to make money off it so you can pay your other bills off.

“So, it was a challenge. I came close once before, about seven or eight years ago, to buying a secondhand K200 but I got cold feet and I changed my mind.

“Finally I thought, if I’m going to give it a go, I’m going to have to give it a go now.

“If I don’t, I’m never going to do it.”

Andrew is also encouraged by the contacts he’s built up over the years and is hoping that will help get Thorpe Haulage off to the best possible start.

“You really have to start at the bottom when you’re driving your own truck – it doesn’t matter how many years you’ve been driving for.

“People have to get confidence in you that you will do the job, work hard and get the job done with no damages. You have to work hard to get your name out there.”

So far so good. Just a few weeks into having his own name on the side of theT909, Andrew is already chipping

the help they’ve been giving me and they’ve been giving me good advice – I’m always on board to learn.

“In this industry you never stop learning, it doesn’t matter how many years of experience you’ve had driving, I learn something new every day.”

Andrew enjoys tipper work – “I’m good on tippers” – but he’ll happily turn his hand to towing any combination if the numbers stack up and the invoices are paid on time.

“I can do anything; long hauls, tankers – anything that comes my way I’ve done before.

“But I have a family at home, and I try and get home to see them as much as I can, and that is hard in this industry because you have to obviously make money too.”

At present he’s towing other people’s trailers. He hopes to one day have his own, but level-headed Andrew wants to “put some money in the bank first” before he gets too excited.

“If I get a contract and I need trailers, then that’s what I’ll do. I just have to work out what direction I’m going to go in.”

Ideally, Andrew would like to pick up a full-time contract, so he doesn’t have to keep looking for work and knows ahead of time what he’s doing each week.

But already those initial nerves are calming as he hits

He’s taken plenty of mental notes over the years about where others have gone wrong in preparation for this day and is drawing confidence from his mechanical skills and life experience.

Andrew also prides himself on treating everyone with the same respect he hopes they will give back to him in return.

“I think my dad would be really proud of what I’ve accomplished,” he added.

“There is money to be made, but you’re not going to become a millionaire owning one truck. For me, it’s a ll about the love of the job more than anything.

“As long as I’ve got money to pay off the truck and my mortgage, I’m happy.

“I don’t really care if eat Fruit Loops or Weet-Bix the whole week, as long as I’ve got my pride and joy.”

CMV Truck Centre Sales Consultant Jed Kerin said the moment he met Andrew he struck him as an easygoing but very determined guy.

Jed and the CMV team sat down with Andrew to design his ideal T909 which took some time as Andrew didn’t want to miss any minor detail during the build.

Bruze Custom Trucks took charge of the impressive stainless steel work on the truck, delivering on Andrew’s request for all stainless wraps and a diamond-pattern decking plate on the back.

“I’ve also got a nice big light bar down the bottom, and I’ve put a stainless visor on it and bullet lights on the roof and round horn covers, so I’ve done a fair bit of custom work to it,” Andrew said.

The CMV Truck Centre Pre-Delivery Team and HydraMech Customs added the finishing touches to the hydraulics, Chris Barron Engineering created yet another “strong, purpose-built bulbar”, and CP Detailing provided the winning shine for delivery day.

“Andrew has been great to deal with and wasn’t pushy towards the build once it arrived which our predelivery team really appreciated,” Jed added.

“He was more concerned about it being built exactly to what he wanted from the get-go.

“We’re all very happy with the final product and are very proud to put our name to it.”

The first charity convoy of its kind celebrates its 10th year by smashing all fundraising records thanks to the massive support from the trucking industry.

BY GRAHAM HARSANT

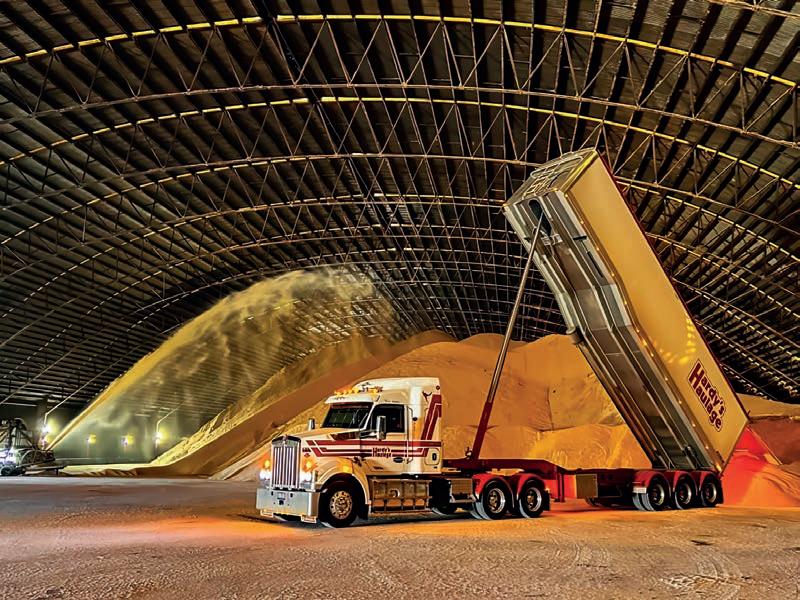

IN its 10th year, the Geelong Convoy for Kids on Sunday, February 24, has broken records – both in trucks at tending and in money raised.

One of four convoys held around the country each year, Geelong is where it all started, and the support for Camp Quality by the truck ing community continues to a maze and humble founder, Vera Entwistle.

More than 270 trucks turned out for this year’s event, raising more than $296,000 by issue deadline.

Vera’s instigation of Camp Quality 42 years ago, to bring joy to the children un dergoing cancer treatment, came from her own heart ache.

“My dad committed sui cide and left me devastated,” Vera said.

“I was feeling of no worth it all. I was hunting for something to do that would restore my self-worth and I was lucky enough to read a magazine article about a child with cancer and what happens with the family when the child is diagnosed.

“It deeply touched me that this little girl was dealing with their own life-threatening illness and here I am, an adult not dealing with my own dad’s death. So I jumped in the deep end. I wanted to set something up to support kids with cancer.”

Vera admits that she wouldn’t want to repeat the first couple of years, however, because everywhere she went there was negativity.

“Believe it or not, I had more than one comment along the lines of, ‘Who wants to volunteer for children with cancer, after all you might catch it’. Truly, back in1983 I was faced with that everywhere. People constantly said to me they would give a little donation but didn’t want anything to do with it. So, it was tough the first couple of years.

“Making it worse, the very first cancer doctor I spoke to in Sydney, when I told him what I wanted to do said I needed to find something else to do, because kids with cancer in Australia don’t need your programs – go and find something else.

“I left that hospital in tears. Here is a man who works 24 hours a day with kids with cancer and he couldn’t see the benefit.

“So, I wallowed in grief for a couple of days then I went to the Prince of Wales Children’s Hospital in Sydney and I got the exact opposite response from a doctor who said anything you can do to encourage our children through treatment we will back you. And we were off!

“At the first camp there were 38 children, and parents who trusted us when we were nobody.

“Now, today, when I look at the response of the community and the trucking industry, I can’t express my gratitude enough for their support.

“Days like today where we can connect the trucking community, their families and their supporters directly with our kids and their families who are also here as part of this fun day – when you bring everyone together it really creates magic and it shows these guys why they have been working so hard to

raise much needed money.”

The lead truck in the convoy this year was Brad Drew from Corio in his 1990 Mack V8 Value-Liner. Brad individually raised an astounding $16,090. Brad is the third owner of the Mack, having bought it out of Tasmania and having spent the past five years, “getting it into shape.”

Brad was closely followed by Gavin Calleja, raising $14,492, and Rodney Light who collected $11,915

Brad Drew’s business,

Drew’s Plant Hire was the Highest Fundraising Corporate Team, collecting $33,872.

The Highest Fundraising Community Team award was – for the third year in a row – The Colac Crew, with an amazing $45,741.

The efforts of these persons, companies and communities is astounding, but just as important is everyone who raises any amount – big or small –and takes part in the convoy.

Some like Prixcar arrived

with 27 trucks, Riordon Group had 10 and Wettenhalls had eight of their fleet turn up.

Others, such as Mick Whitty arrived from Springfield with his cheque and his 1980 W-Model KW named ‘Hay Fever’.

“She works on a farm,” said Mick. “One of my very good mates lost a childhood friend to cancer and I’ve lost a family member recently as well. It’s not just about that but I think it’s just a tremendous

thing to do to help these families that are going through a really tough time.”

The work of Vera Entwistle and the team from Camp Quality is simply wonderful in giving kids hope, joy and meaning.

That they are so supported by the trucking industry is spectacular.

To the some 270 trucks and their drivers who supported Geelong Convoy for Kids, stand up and take a bow. We salute you all.

BY DANIELLE GULLACI

DESPITE being around trucks her entire life, it wasn’t until 2022 that Kate Morris, 30, finally took the plunge and began her own career in transport – though it was something that had always been in the back of her mind.

“My Dad, Greg Morris, is about to retire but he has been a truck driver for over 45 years,” said Kate. “I actually have photos from when I was a baby in the trucks with him for UTO and Douglas transport. I remember he worked for W&M at one stage doing a daily run to Townsville and back for Woolies and that’s where I have a lot of my earliest memories with him. When I was little I’d jump in the truck with him every chance I could – and that continued even when he had his own haulage company.

“Dad didn’t buy his first truck until 2007 and at one stage was running an MR and two utes for hotshots and piloting for McAleese transport and three trucks subcontracting to McAleese and Kalari transporting ammonium nitrate to the mines. Eventually he sold up and has been driving for Emerald Carrying for a few years now, carting fuel into the mines.”

As Kate fondly recalled, “Every weekend when he was home, it was time spent with him cleaning and servicing the truck. For my 12th birthday he actually bought me one of those mechanic’s creepers to make it easier for me to grease the trucks.”

With her father being a truckie and her mother, Camille, a high-school chemistry teacher and deputy principal, Kate was torn about which career she would pursue.

“Mum and Dad always wanted me to do as well as I could at school so that I’d have more opportunities when I finished. I did a 12-month traineeship with Hastings Deering in boiler-making in year 10, and then did a school based apprenticeship to complete a certificate III in pharmacy and got a decent OP. I was never pressured to go to university but it seemed like the logical thing to do,” she said.

“I started three different courses because I never found my niche or could stay focused when courses got bor

But being stuck inside was never for me.’’

“At the end of 2021 I was diagnosed with ADHD, so looking back, that probably had a large part to do with why I didn’t do well at uni. I wouldn’t change any of it though – apart from the HECS debt,” she laughed.

That was when she knew it was time to follow her heart.

It was in 2022 that Kate decided to go for her medium rigid licence as she needed to drive a bus to do some volunteer work she was involved in.

She went through R2B Training School, where she was being taught by Rod Becus. It was quickly obvious that Kate already knew a thing or two about being the behind the wheel of a truck.

“When I went in, Rod convinced me to go for my heavy rigid crash box licence instead. He said I may as well

if I’m capable of doing it. So that’s what I did and then oning test, he offered me a job. He runs the truck school and his wife Daisy, owns Venus Couriers,” explained Kate.

“I mentioned how I had a bit of experience in courier work for my dad’s company back in the day. I used to drive to the mines with my mum sitting beside me while I was on my learner’s permit, and then on my own when I got my license.’’

“Rod said he had a heavy rigid truck sitting there – so he offered me a job. I accepted and started there a few weeks later. That’s where I stayed for the next two years. Rod and Daisy took me in and trained me with a couple of their long term, experienced fellas until they gave the green light for me to run solo.”

Within 12 months, Kate was able to upgrade to her MC licence. Though she stayed on with Venus Couriers for some time before starting in her

WHEN I WAS LITTLE I’D JUMP IN THE TRUCK WITH HIM EVERY CHANCE I COULD – AND THAT CONTINUED EVEN WHEN HE HAD HIS OWN HAULAGE COMPANY.”

KATE MORRIS

already dealt with them on a daily basis. They built a new shed in Mackay and contracted myself and the other HR driver with Venus to move their stock and saws from the old shed to the new one. That took about two weeks going up and back. I personally did more than 100 loads over two weeks, over 1000 tonne all up,’’ explained Kate.

“Venus had always treated me like family, Rod had noticed I always wiped over my truck before leaving of an afternoon and always asked to come back to wash my truck if business was slow instead of parking up for an extended paid break. So he offered me overtime on Saturdays to clean the trucks. That cleanliness and pride in my presentation is something I attribute to weekends with my dad. When I got my MC, Daisy and my manager Pam were worried I was going to leave straight away. It took some convincing but I told them I wasn’t going to leave until I found the right fit, they had taken a chance putting me on and I wasn’t going to betray that loyalty, I loved it there and leaving a year later was one of the hardest things I’ve ever done.”

Running since 1995, Vulcan Steel is a metals distributor and processor, with facilities across Australia and New

Based in Mackay, each week she does a run into Brisbane to pick up steel from Vulcan’s Crestmead and Carole Park sites; followed by a trip into Townsville once back in Mackay. She also tacks on a run into Cairns about once a month.

“The truck is great, I really enjoy driving it and find it really comfortable. It’s funny because Dad never liked the Volvos or autos when I was growing up so I was a bit like that too. Then the last truck he ever bought was a Volvo just like mine and he says it was the best truck he’s ever had. The technology in the Volvos is fantastic, especially the adaptive cruise control.’’ Kate said.

“I still love driving the crash box and I would love to get back in one. I know a lot of truckies give people who drive auto a bit of flack, but nothing beats it for long haul, especially when stuck in traffic – except of course for the sound of a Kenworth jake brake!”

When asked what she enjoys about the work, Kate responded, “Every day is different, even though I might be doing the same run every week – the traffic is never the same, the combination of my load is never the same and the weather is never the same. I

notice something new every

fore and it wasn’t for me. I as constantly almost falling asleep from having to sit there for hours looking at a screen. I like anything that gives me the freedom to be out on my own but also has structure, so truck driving is the perfect job for that.”

Still relatively new to the job, Kate says she continues learning every day.

“It was definitely tough at the start with Venus – just getting used to being in a really labour-intensive job and getting the strength in being able to do what was required for the role. But I was never going to use my strength or gender as an excuse not to be able to do the job competently. The first couple of months were tough, then you get used to it, and it becomes easier,” she said.

“When I started at Vulcan, I already knew load restraint and the product but I’ve had to learn how to tarp too because we deal with some sensitive product that can’t get wet,” Kate added.

“I’m getting better and faster at it each time. It’s a huge sense of satisfaction when I get it done.

‘’I have no plans on leaving my current job anytime soon, as I want to get more experience in HC before taking the next step. But I would love to eventually get the opportunity to work in heavy haulage and oversize loads.’’

This remote Queensland road transport and general civil construction company is proudly giving Indigenous employees a pathway into lifelong industry careers.

BY ALF WILSON

GULF Regional Services

(GRS), a local Indigenous enterprise based in Normanton, Queensland, is one of the most remote road transport and general civil construction companies in the country.

GRS employs an average of 67 full-time equivalent staff, with nearly 100 individuals on the payroll throughout the year.

The company employs truck drivers, civil construction workers, roller, loader, grader and excavator operators, traffic controllers, labourers and diesel fitters.

Prides of the fleet are two near new Kenworth C509 road trains and two new Mack Metroliner water trucks.

The diesel fitters are vital as the machinery travels to many isolated jobs.

A group of workers travelled from Normanton to Melbourne to pick up the new Macks and travelled back.

The trucks are busy being used for civil construction, mostly road remediation work which is plentiful especially with many dirt roads in the coverage area.

Other plant equipment includes three 150 graders, one 966 next generation loader, one 323 2d excavator and 20 traffic control vehicles.

Big Rigs spoke to Shane Busch who drives one of the Kenworths and had just returned from a trip to Cairns where he picked up cars.

“It rained coming back from Cairns and we went through Mount Surprise, Georgetown and Croydon before arriving back at Normanton,” Shane said.

Shane said the Kenworth was powered by a powerful 650hp Cummins motor and with an 18-speed road ranger manual gearbox.

and now has 50,000km on the clock,” he said.

Shane was born at Mount Isa and moved to Normanton in 1992.

He moved to Sydney after that and earned a contract with the now defunct NRL Club the North Sydney Bears.

“After that I moved to Melbourne and had my own trucking company called Bushy’s Excavations and had a Ford Louisville truck which I sold to a bloke at Millaa Milla and returned to Normanton in 2022,” he said.

“I mainly carry dirt and road base and have travelled on some very rough roads up here. Two of the worst are the dirt one between Cloncurry and Pioner and another around Dunbar on the Kowanyama run.”

The company is owned by Wade Richardson and Kahli Corporal, dedicated members of the Gulf community and descendants of Kukatj and Waanyi tribes, GRS reflects a profound connection to the land, culture, and people of the Gulf.

“Our company proudly services various local shires, including Carpentaria (Normanton & Karumba), Kowanyama, Burketown, Doomadgee, Mornington Island, Georgetown, and Croydon. We employ an average of 67 full-time equivalent (FTE) staff, with nearly 100 individuals on the payroll throughout the year, accommodating many on shorter contracts to meet project demands,” Wade said.

Normanton is located 2086km north-west of Brisbane, is 679km west of Cairns and 849km west of Townsville.

Workers travel far and wide including to the Westmoreland Road outside of Doomadgee heading towards NT.

Wade said 88 per cent of the workforce identifies as Indigenous and comes from the local lower Gulf area, underscoring the company’s commitment to

significant impact on the local economy. Beyond providing substantial wages, the com pany has supported two local Indigenous entrepreneurs in launching their own businesses, fostering economic growth within their communities,” he said.

Looking toward the future, Gulf Regional Services is set to establish an industry-specific training academy.

“This initiative aims to enhance training and employment pathways for individuals within the civil construction industry in the Lower Gulf, leveraging partnerships at local, state, and federal levels to maximise its impact. Recently traffic controllers flew across from Mornington Island and spent the week in Cairns doing the theory and on the job training,” Wade said.

Wade said remote communities also benefit economically from the success of these large

early stages of their professional careers, reflecting a diverse age range within the company.

“GRS prioritise targeted training and workforce development to enhance skills and career progression. Established Indigenous companies, like Bynoe, Morr Morr Pastoral Company, Great and Gulf Labour-Hire and many more have set a precedent of success for Indigenous organisations and businesses in the Gulf region.

“Local Gulf councils such as Carpentaria, and many more in the region are fostering authentic partnerships with Indigenous entrepreneurs, paving the way for collaborative growth and truly working towards closing the gap,” Wade said.

In keeping with its priority in employing Indigenous people, one of their Mack trucks has excellent artwork by a Mount Isa Aboriginal Justin Butler.

“A quarter of GRS workforce consists of individuals in the