VOLUME 117/5 | JUNE 2025

VOLUME 117/5 | JUNE 2025

FUEL MANAGEMENT

PILBARA MINERALS’ GLOBAL EXPANSION

Day in, day out — the Komatsu PC1250-11 proves itself where there’s no room for compromise. With consistent performance, the PC1250-11 delivers the reliability, durability and support that crews count on, shift after shift.

✔ Efficient hydraulics

✔ Heavy-duty build

✔ Backed by Komatsu nationwide

Scan the QR code or visit komatsu.com.au for more information.

Discover what the PC1250-11 can bring to your site.

As ESG (environmental, social and governance) imperatives continue to shape the future of mining, the June edition of Australian Mining explores how the sector is rising to meet the challenge of producing more – but doing so responsibly.

The mining industry currently stands at a critical juncture. According to FLS head of innovation and MissionZero Lucy England, “the mining sector will need to meet most of the increased demand for minerals, but it must do so while reducing its own environmental and social sustainability”.

It’s a daunting balance to strike, but one that’s increasingly nonnegotiable for operators, investors, and communities alike.

The June edition of Australian Mining speaks to those on the frontline of sustainable mining. We sit down with PLS chief executive officer Dale Henderson –who also graces our front cover – to discuss the company’s ongoing growth and how ESG considerations are integrated into its strategy.

Once known as Pilbara Minerals, PLS has firmly cemented its position as a global lithium leader with its biggest production

expansion to date – the P1000 lithium project in Western Australia.

The P1000 expansion isn’t just about adding tonnes; it’s about adding significant infrastructure and process improvements to help optimise recovery, improve efficiency and prepare the site for future flexibility.

Brokk Australia also shares how its remote-controlled demolition robots are being deployed at a fully electric underground mine in Greece – a clear example of how safety, efficiency, and sustainability can go hand-in-hand.

presence in Western Australia through its flagship Pilgangoora mining operation, South Korea and Brazil.

In fact, PLS recently acquired Latin Resources and the Colina lithium project to signal its entrance into the South American lithium industry.

CHIEF EXECUTIVE OFFICER

JOHN MURPHY

CHIEF OPERATING OFFICER

CHRISTINE CLANCY

MANAGING EDITOR

TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ALEXANDRA EASTWOOD

Email: alexandra.eastwood@primecreative.com.au

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

DYLAN BROWN

Email: dylan.brown@primecreative.com.au

ELIZA FREEMAN

Elsewhere, we shine a light on technology providers and OEMs reimagining the mining process. From digital optimisation to electric mobility, the tools for transformation are here – it’s now a matter of adoption and scale.

This edition showcases the companies embracing these shifts, and the leaders helping to redefine what responsible mining looks like in 2025 and beyond.

Happy reading.

Tom Parker Managing Editor

Email: eliza.freeman@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

BUSINESS DEVELOPMENT MANAGERS

JAMES PHIPPS

Mob: 0466 005 715

Email: james.phipps@primecreative.com.au

ROB O’BRYAN

Mob: 0411 067 795

Email: robert.obryan@primecreative.com.au

ART DIRECTOR MICHELLE WESTON michelle.weston@primecreative.com.au

SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00 For

“One of our strategic pillars is to diversify revenue beyond the Pilgangoora asset,” PLS chief executive officer Dale Henderson said.

“As PLS matured as a business and we were in a position to consider an acquisition, we looked at many lithium assets around the world.”

It was the Colina orebody, existing regional infrastructure and expected low operating costs that drew PLS to Brazil.

Cover image: Pilbara Minerals

The Schlam Barracuda range of mining buckets is regarded for extending the payload performance of excavators and loaders operating in hard rock mining environments.

Renowned by leading miners in Australia, our comprehensive product range includes models compatible with major OEM mining excavators and loaders.

Each Barracuda bucket is individually engineered by a team with global OEM expertise, to overcome site specific challenges and to ensure the optimal performance of your mining equipment fleet.

With Barracuda’s dedicated after-sales support, our team is with you every step of the way to enhance your load and haul productivity and to help extend the life of your assets.

schlam.com/barracuda

8 LITHIUM

PLS powers ahead

PLS chief executive officer Dale Henderson speaks to Australian Mining about the ramp up of the P1000 lithium project and the company’s wider global ambitions.

20 ESG

becoming an esteemed services provider just as the energy transformation accelerates.

A blind spot for lost gold Dredge Robotics has added a new string to its bow, with the recovery of valuable minerals complementing its liner-safe dredging capability.

22ESG

Embracing ESG

Bureau Veritas is helping mining companies set themselves up for an ESG future.

Sustainability at its core Sefar is propelling a more sustainable mineral processing industry, delivering filtration media that stands the test of time.

42 INDUSTRY EVENTS

A larger-than-life conference

AIMEX’s free-to-attend conference will be the epicentre for industry leaders to discuss mining trends and challenges.

operation in WA.

52 INDUSTRY PARTNERSHIPS

Sharpening after-sale support

Truflo Pumping Systems is committed to providing top tier service to its clients, partnering with ITT Blakers in WA to help make a difference.

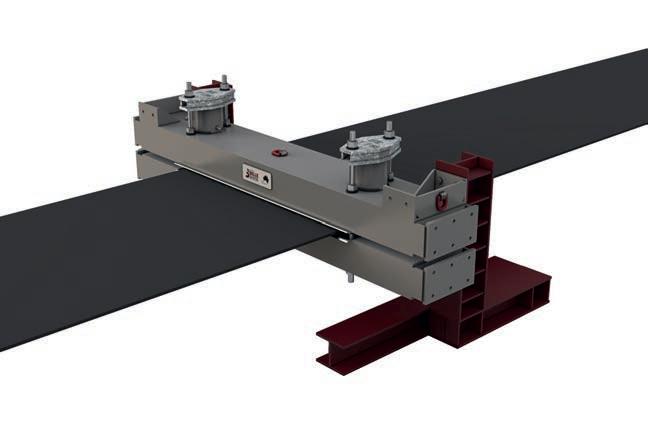

66 FUEL MANAGEMENT

The fuel-management experts Veridapt is a recognised expert in fuel management, delivering solutions that can significantly enhance fuel control.

ANTHONY ALBANESE WILL SERVE AS AUSTRALIA’S PRIME MINISTER FOR ANOTHER THREE YEARS. WHAT DOES IT MEAN FOR THE RESOURCES SECTOR?

On May 3, Anthony Albanese was re-elected as Prime Minister for a second term.

The win made history, with Albanese being the first full-term Prime Minister to be elected for a second term since John Howard in 1998.

“Australians have chosen to face global challenges, the Australian way – looking after each other, while building for the future,” Albanese said on May 3.

“When it comes to Australia’s future, all of us have so much reason to be optimistic. When we look at everything going on around the world today, when we consider the changes that will shape the future of the global economy, when we think about our people and their smarts and skills ... there is nowhere else you’d rather be, than right here in Australia.”

Albanese pointed to the resources sector, highlighting its role in a greener future.

“Every Australian who knows that climate change is a challenge we must act together to meet, for the future of our environment, and knows the fact

that renewable energy is an opportunity we must work together to seize for the future of our economy,” he said.

The Federal Government has several plans to seize this opportunity, and several of them run through the resources sector.

A second term will allow the Federal Government to continue its ‘Future Made in Australia’ policy, which aims to maximise the economic and industrial benefits of the net-zero transition and secure Australia’s place in a changing global economic and strategic landscape.

THE FEDERAL GOVERNMENT BELIEVES A STRONG RESOURCES SECTOR MEANS A STRONG AUSTRALIA.

“The Albanese Government has put the resources industry at the heart of its policy making because it knows a strong resources sector means a strong Australia,” Federal Resources Minister Madeleine King said of the plan in May 2024.

A total of $22.7 billion will be invested in the plan over the next decade across five areas:

• skills and training to build Australia’s future workforce

• renewable energy

• supporting investment in Australia

• utilising natural resources and critical minerals

• industrial innovation and technology.

Future Made in Australia will allow eligible entities to claim 10 per cent of expenditure for the processing and refining of Australia’s 31 critical minerals.

The policy will also allocate $3.2 billion in investment over a 10-year period to support the commercialisation of technologies critical to achieving netzero, as well as $1.7 billion to establish a Future Made in Australia Innovation Fund to deploy innovative technologies and facilities linked to priority industries such as mining.

Mineral exploration is also a priority, with a $556 million investment over a ten-year period to support Geoscience Australia in mapping the nation’s endowments of critical minerals.

Australia has also been navigating recently imposed US tariffs, which involve a 25 per cent tariff on Australian aluminium and steel imports into the US.

The Federal Government has outlined a five-step plan to counter the tariffs. The plan involves: •strengthening Australia’s antidumping regime •supporting affected sectors to expand our trade relationships with new markets

•establishing an economic resilience program through the National Reconstruction Fund •encouraging people to buy Australian products •establishing a $1.2 billion Critical Minerals Strategic Reserve.

The latter is particularly significant for the resources sector, at a time where global trading involves greater uncertainty.

The Critical Minerals Strategic Reserve will be based on two new mechanisms: voluntary national offtake agreements and selective stockpiling.

The Federal Government will acquire agreed volumes of critical minerals from commercial projects or secure the option to purchase at a set price.

“It will mean we can deal with trade and market disruptions from a position of strength,” Albanese said in April.

As the world continues to look towards a greener future, Australia is positioning itself to be at the forefront of the movement.

And with the newly re-elected Federal Government, the resources sector is poised to be at the heart of the transition. AM

Innovativedesignsfocusingonpower,efficiency,andoperatorcomfort. Eco-friendlyoperationswithsmartconnectivityforoptimalfleetmanagement.

CONSTRUCTION OF THE

CHIEF EXECUTIVE OFFICER DALE HENDERSON SPEAKS TO AUSTRALIAN MINING ABOUT THE RAMP UP OF THE P1000 PROJECT AND THE COMPANY’S WIDER GLOBAL AMBITIONS.

Pilbara Minerals (PLS) has firmly cemented its position as a global lithium leader with the completion of its biggest production expansion to date – the P1000 lithium project in Western Australia.

At the heart of this momentum is a clear vision on market cycles, operational excellence and disciplined growth.

These are principles that PLS chief executive officer Dale Henderson said positions the company well for the next upswing in lithium prices.

“Construction of the P1000 expansion project was completed in January, marking the end of a transformational two-year investment cycle,” Henderson told Australian Mining

“Ramp up is now complete and we’re entering the optimisation phase of the project with a focus on achieving higher production volumes and lower unit cost.”

P1000, located at the company’s flagship Pilgangoora operation in WA, adds approximately 320,000 tonnes per annum (tpa) of spodumene concentrate production capacity.

It builds on the infrastructure and capacity added through the earlier P680

expansion, bringing the Pilgangoora operation’s total nameplate capacity to about 1Mtpa when including both the Pilgan and Ngungaju plants.

“This is in lock step with our phased growth plan to optimise production rates and remain a low-cost producer,” Henderson said.

“We’re moving from a growth to consolidation and optimisation phase, ensuring PLS remains in a strong position to thrive as demand for lithium grows in the future.”

The P1000 expansion wasn’t just about adding tonnes; it also included significant infrastructure and process improvements to help optimise recovery, improve efficiency and prepare the site for future flexibility.

“The P1000 expansion project leverages our earlier investment in additional primary rejection, crushing and ore sorting capacity from the P680 expansion project,” Henderson said.

“It involved a series of upgrades to the Pilgan plant’s concentrator and a range of supporting infrastructure which will be tied into the existing flowsheet.”

These upgrades included the duplication of the tertiary crushing, ball mill and flotation circuits, plus

the addition of pre-flotation magnetic separation, secondary tantalum recovery, heavy media separation tailings, and a new split water circuit and concentrate dewatering circuit.

Non-process infrastructure investments included the construction of a new 15-million-litre raw water storage dam and extension of the borefield pumping and piping network to increase water supply.

Notably, PLS completed construction and achieved first ore ahead of schedule.

“We had an excellent team on this project and high-quality contracting partners working with us, so pleasingly we were able to complete construction and achieve first ore two months ahead of schedule,” Henderson said.

“That’s no mean feat, and I’m extremely proud of the team’s effort on this one, led by our project director Paul Laybourne.”

Henderson added that while the project was a success, it came with a timely reminder of the environment PLS operates in.

“Just as we achieved first ore, a tropical cyclone formed and was predicted to hit close to our operation,” Henderson said.

some things you can’t control.”

With the expanded capacity now online, PLS is confronting a very different market than the one that drove the original expansion.

Lithium prices have corrected sharply from their 2022 highs, prompting

mass energy storage.

“These conditions are setting the stage for the next phase of the cycle,” he said. “We’re preparing our operation and business for this future state by preserving our current position and maintaining our options for future growth.”

While Pilgangoora remains PLS’ core asset, the company is actively pursuing international diversification.

Its recent acquisition of Latin Resources gave PLS control of the Colina project in Brazil – a move that helps broaden the company’s revenue streams and geographic exposure.

“One of our strategic pillars is to diversify revenue beyond the Pilgangoora asset,” Henderson said.

“As PLS matured as a business and we were in a position to consider an acquisition, we looked at many lithium assets around the world.”

Henderson said PLS was attracted to the Colina project due to the quality of the orebody, existing regional infrastructure, expected low operating costs, government support for the industry and the reputation of the Minas Gerais region as a Tier 1 mining jurisdiction.

“We see Brazil as a strategic hub for Latin America and South America in strengthening global supply chains,” Henderson said.

PLS

TO

“The pro-mining jurisdiction, fast-tracked permitting regime and supportive local government in Minas Gerais provides us with near-term production optionality at Colina, making Brazil an attractive investment area.”

PLS believes Colina offers compelling economics and an opportunity to deliver meaningful local impact.

“Colina is a low capital intensity project that has the potential to provide attractive returns and unlock new battery end markets for PLS in North and South America,” Henderson said.

“We also recognise the opportunity to create generational change for the local community near the Colina project and surrounding areas by providing new job and business opportunities that will have lasting social and economic benefits to the community.”

The Colina acquisition doesn’t just expand PLS’ geographic reach, it also provides a new platform to apply the company’s proven technical expertise.

“As the developer and operator of one of the world’s largest hard rock lithium operations at our Pilgangoora operation, we have significant technical and operating experience to bring to the Colina project,” Henderson said.

“We will leverage our existing capability in exploration, resource development, project delivery, operations and lithium marketing with the local and project-specific knowledge of our Brazilian team as we advance Colina.”

Closer to home, PLS has also resumed

demonstration plant in partnership with Calix.

The project, paused in late 2024 due to market conditions, is back on track and will test the world’s first industrial-

“The project aims to construct and operate a demonstration scale plant featuring the world’s first industrial scale electric spodumene calciner,” Henderson said. “This

local jobs in Western Australia while producing a higher-value, lithiumenriched product at the mine site which would support decarbonisation by reducing transport volumes to our customers.”

A leading force for the future

With a strengthened production base, growing international footprint and ongoing innovation efforts, PLS is preparing to extend its lead in the lithium market.

“PLS is recognised as a pioneer in the lithium sector, with a strong balance sheet, proven track record, and (a profile that sees us) operating at the lower end of the cost curve,” Henderson said.

“We are well positioned in the global market with an expanding portfolio of global assets, integration into the supply chain and market optionality.”

Henderson said everything PLS has been working on recent years has been part of the company’s long-term growth strategy.

“On a five-year outlook, we have significant growth optionality within our existing asset portfolio and a strong balance sheet and team to deliver it, when market conditions support supply growth,” Henderson said.

“We believe we are incredibly well positioned to extend our position over time as a leading supplier in this futurefacing industry.” AM

Through our expertise, brilliant network, and unique customer focus, we make brilliant digital solutions simple.

Backed by a team of leading network experts, solution architects, dedicated account teams and strategic partners, our reliable and secure network provides connectivity across Australia and into Asia Paci c.

Fibre network purpose built to connect the Pilbara

Vocus Satellite - Starlink connecting remote locations

24x7 network monitoring with local support

LTE network connectivity built for the mining industry

EVOLUTION MINING’S MT RAWDON PUMPED HYDRO PROJECT IN QUEENSLAND IS AN EXAMPLE OF HOW A MINE CAN BE REPURPOSED TO BECOME A CLEAN ENERGY GENERATOR.

A PUMPED HYDRO SYSTEM SEES WATER MOVE BETWEEN TWO OR MORE RESERVOIRS TO STORE AND GENERATE ENERGY.

Like the old saying goes, all good things must come to an end.

That is the case for Evolution Mining’s Mt Rawdon gold operation in Queensland, which ceased mining operations during the September 2024 quarter.

Once the final ore processing is complete at the end of the 2024–25 financial year, Mt Rawdon will be converted into a pumped hydro project via a 50:50 joint venture between Evolution and ICA Partners.

The Mt Rawdon pumped hydro project is expected to provide up to 20 gigawatt hours of renewable energy storage – an amount equivalent to providing power for two million homes each day during times of peak demand, regardless of weather conditions.

According to feasibility studies that commenced in 2021, Mt Rawdon could be one of the most advanced, lowest capital intensive pumped hydro projects in Australia. The transition comes as Australia works to achieve net-zero by 2050.

Australian Mining explores how Mt Rawdon pumped hydro will work and its benefits.

A standard pumped hydro system sees water move between two or more reservoirs to store and generate energy. When electricity demand is high, water is released from the upper reservoir and the force of the falling water spins the turbines. As the turbines spin, electricity is generated and fed into the grid, and water that passes through the turbines is kept in the lower reservoir until it can be pumped back.

When excess electricity is in the grid, the turbines use the excess energy to pump water from the lower reservoir back to the upper reservoir.

In Mt Rawdon’s case, the existing open-cut pit will turn into a lower reservoir, and an upper reservoir will be constructed alongside an underground powerhouse, underground water tunnels and underground access tunnels.

This infrastructure will form a closed loop pumped hydro energy storage (PHES) system. Energy produced by the PHES will feed into the Queensland electricity grid through high-voltage transmission lines spanning 27km, connecting the project site to a new substation at Morganville.

The PHES facility will be able to complete a full cycle within 24 hours,

comprising 10 hours of generation and 14 hours of pumping, allowing for continuous operations seven days a week, even amidst extreme weather events.

The facility’s plant systems and equipment will also be able to operate both automatically and remotely to further enhance efficiency.

Equipped with a regular maintenance program, Mt Rawdon pumped hydro has a design life of 50 years and an operational life of up to 100 years.

The project is expected to create about 800 jobs during the construction phase and 30–50 permanent jobs to support Mt Rawdon’s ongoing operations once construction is complete.

It’s these benefits that caught the eye of the Queensland Government, which announced it would invest $50 million into Mt Rawdon through CleanCo, the state’s publicly-owned energy generator and retailer, to progress the project towards a final investment decision (FID).

“We welcome the (Queensland) Government’s interest and involvement in this landmark project, which is set to facilitate low-cost green power and provide jobs to the community and Queensland for decades to

come,” Evolution executive chair Jake Klein said.

Evolution, ICA and CleanCo also entered into a development investment agreement.

CleanCo agreed to provide $30 million in initial funding to Mt Rawdon pumped hydro for further feasibility work, which is expected to be completed by September 30.

CleanCo also has the option to acquire the project from Evolution and ICA via an upfront payment of $50 million, which would be shared equally between both companies. The option is exercisable on or before September 30.

If CleanCo exercises the call option and if a FID is made on or before June 30, 2028, then CleanCo would make another of $100 million payment for the acquisition.

“(Mt Rawdon pumped hydro) will be instrumental in the transition of the Queensland energy sector to renewable energy by providing low-cost, longterm energy storage for Queensland’s abundant solar resource,” ICA executive director Michael Siede said.

Regardless of the company that ends up owning and operating Mt Rawdon pumped hydro, it is clear the project is one to keep an eye out for. AM

The multi-billion-dollar algae industry could soon play a crucial role in helping miners achieve net zero carbon emissions while boosting economic opportunities for local communities.

Algae technologies are emerging as a game-changer for improving mineclosure outcomes, capturing carbon dioxide, removing pollutants, boosting plant growth and suppressing dust on mine sites.

A recent report published by the Cooperative Research Centre for Transformations in Mining Economies (CRC TiME) and led by CSIRO senior principal research scientist Dr Anna H. Kaksonen has shown how algae could support the global green transition and reshape rehabilitation practices in Australia’s mining sector.

“We found that there are plenty of opportunities where algae could be used for beneficial uses or applications at mine sites. It could provide opportunities for mining companies to move towards the net zero target and achieve environmental goals,” Kaksonen said.

The collaborative project between CSIRO, the University of Queensland

and Murdoch University revealed that cultivating algae in contaminated mine water could provide a sustainable path forward for mining operations.

The report found that algae could be used to treat mine water by removing nutrients, salts, and acidity, while its biomass could serve as a carbon and electron donor in sulfate reduction-based processes to remove metals and sulfate.

“Algal biomass can be used as an organic material to cover sulfidic mine wastes that would otherwise generate acid mine drainage, and also has the potential to support dust suppression or create topsoil for rehabilitating mine sites,” Kaksonen said. “Algae can also enhance plant growth and be used as a fertiliser for that purpose.”

Depending on whether micro- or macro algae are used, algae can be grown on-site using raceway ponds, bioreactors, or floating culture systems, for example.

Harvested algae can then either be processed further, including to extract high-value components or used directly for mine site rehabilitation and water treatment.

Major miners including Fortescue, Rio Tinto and South32, along with the Minerals Research Institute of Western

Australia (MRIWA) and Heidelberg Minerals have supported the project, recognising the potential environmental and economic gains.

According to a CSIRO report prepared for CRC TiME, 240 Australian mines are projected to close by 2040.

Algae-based rehabilitation offers a way to reduce the environmental footprint of these closures while creating regional and Indigenous business opportunities.

Implementation could be straightforward with existing mine pit water redirected to algal cultivation systems during operations

Traditionally, mine water has been treated with alkaline chemicals to neutralise pH and precipitate metals, a process that generates large volumes of sludge needing disposal.

By contrast, algae-based sulfate reduction allows for the removal of metals as metal sulfides, which could potentially be recovered for use as smelter feedstock.

Other advantages of algae cultivation include its ability to be easily developed on-site, while algae naturally capture and fix atmospheric CO2 during photosynthesis, helping further mitigate mining-related emissions.

Producing algae on-site reduces transportation emissions and logistical

challenges – critical factors for remote mine sites where sourcing traditional organic materials for topsoil creation can be difficult.

Beyond environmental benefits, Kaksonen said algae technologies could deliver economic opportunities for local and First Nations communities.

“There could be opportunities for First Nations people and other communities to cultivate algae, which could then be applied on-site or used to create businesses focused on algae-based products,” she said. “These products could include pigments, bioplastics, feed for aquaculture or agriculture, or even biofuels. Algae can be used to create a range of valuable bio-based products that could be marketed to various industries.”

A stage one project report exploring algae cultivation on mine sites has been completed, alongside a short fact sheet outlining key findings.

The plans for stage two include developing a compendium on regulatory and biosecurity considerations for algae cultivation and use at mine sites, and for the use of algal products outside mines.

The team also plans to characterise naturally occurring microalgae in mine water samples from partner companies, determine the potential for cultivating algae in mine water, and evaluate the performance of algal biomass in selected applications such as mine water treatment and topsoil creation.

Depending on available funding, stage two could also include a technoeconomic assessment and lifecycle analysis to determine the economic viability and environmental impacts of selected applications, as well as community engagement to identify opportunities for Traditional Owners.

According to Kaksonen, algae technologies offer real opportunities for mining companies and communities alike.

“I’m hoping that through algal technologies, mine sites could be turned from what might be a degraded environment to something that’s productive and green, and that provides bio-based opportunities and green environments for local communities beyond a mine’s life,” she said.

The project team welcomes new mining companies and government agencies to join the next phase of the project. AM

FLS IS TAKING A HOLISTIC VIEW OF THE ENTIRE METALLURGICAL PROCESS TO UNLOCK VALUE ACROSS RECOVERY, EFFICIENCY AND SUSTAINABILITY.

According to the International Energy Agency (IEA), mineral demand is expected to triple by 2050, fuelled by economic growth, urbanisation, and a rising global population.

At the same time, the green transition will further drive demand for minerals like copper and lithium.

While recycling will play a role here, FLS head of innovation and MissionZero Lucy England said mining will be the key driver.

“The mining sector will need to meet most of the increased demand for minerals, but it must do so while reducing its own environmental and social sustainability,” she told Australian Mining

“Driven by this challenge, we at FLS are committed to delivering solutions that shape tomorrow’s mine.”

FLS is doing this via its MissionZero Mine, which aims to empower miners to maximise productivity while reducing environmental impact across the mineral processing flowsheet.

At the heart of this approach is the company’s life-of-mine methodology, combining ore characteristics and customer needs to create flowsheets tailored to the mining site and application.

“At FLS, we like to say the secret is in the rocks,” England said. “By taking a holistic view of the entire metallurgical process and working in a fully integrated manner, we unlock value across recovery, efficiency, and sustainability.”

This approach enables operations to access lower-grade resources once deemed uneconomical, while reducing energy, water and land impacts.

“And it’s not just about having the best equipment – it’s about deploying it where and how it truly matters,” England said.

“That’s how we help shape a mining industry that is more future-ready, responsible, and resilient.”

The FLS Minerals Testing and Research Centre is central to this approach. Located in Salt Lake City Utah, the centre delivers state-of-the-art mineralogical and metallurgical testing services that underpin proper equipment selection, flowsheet design, plant troubleshooting, and research.

“No two deposits are the same, so this detailed testing ensures our flowsheets listen to the rocks to deliver an optimised, sustainable solution,” England said

While FLS is most known for its equipment offering, its MissionZero Mine incorporates various innovations – some evolutionary, some revolutionary – that create a more sustainable mineral

processing flowsheet of the future.

This includes a suite of grinding technologies.

“Advanced grinding technologies, such as high-pressure grinding rolls (HPGR), vertical roller mills (VRM), the FLS Tower Mill (FTM), or our Eccentric Roll Crusher (ERC), have the potential to reduce energy consumption in certain mineral processing flowsheets compared to traditional grinding methods,” England said.

“They may have a particular role as ores get harder and more disseminated, requiring more control over particle size to ensure effective liberation.”

Meanwhile, dry grinding processes like HPGR and VRM also improve water management.

SEVERAL FLS REFLUX-BASED SOLUTIONS ARE NOW AVAILABLE TO THE WIDER MINING SECTOR.

“Dry grinding means the water added during post-grinding repulping can be tailored to optimise recovery in the flotation circuit,” England said.

“This compares to traditional flowsheets, where the grinding circuit determines the water content of slurries.”

Beyond the grinding equipment, FLS’ REFLUX family of technologies offers the opportunity to revolutionise mineral

separation efficiency while significantly reducing energy and other inputs.

“The REFLUX concept was developed in collaboration with the ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals at the University of Newcastle, New South Wales,” England said.

“Combining inclined lamella plates with a fluidised bed, the REFLUX concept improves recovery of off-size particles, offers high throughput in a much reduced footprint, and cuts energy and water consumption, perfectly aligning with our goal to do more with less.”

Several REFLUX-based solutions are now available to the wider mining sector, including the recently commercialised REFLUX Flotation Cell (RFC) and coarseAIR coarse particle flotation technology.

The latter is a lynchpin of the MissionZero Mine, as coarse particle flotation significantly reduces comminution energy consumption and facilitates faster and more effective dewatering, enabling filtered or dry tailings.

Other dewatering solutions under development include advances in the design of high-rate and paste thickeners with the introduction of:

• new rake designs for thickened tailings

• the AFP2525 tailings filter press, which uses high pressures and low cycle times to achieve significantly larger single-machine capacities

• EcoTails filtered tailings

• EcoPaste tailings.

“We are also investing in research to address the issue of chemical build-up

in recycled process water, which can impact flotation efficiency,” England said, noting the company offers MaxR systems and reactor clarifiers to treat acid water and heavy metals build-up in tailings water streams.

Tailings are also increasingly being recognised as an essential source of mineral production, as mining companies reevaluate what is economically viable to extract.

“We expect to see greater reprocessing of tailings and a sharper focus on co-products in mineral processing flowsheets of the future using our REFLUX classifier (RC) and Reflux GradePro classifier,” England said.

FLS KREBS pumps are common sights at many mines, but they might not be the first things called to mind when thinking about sustainability.

The significant energy consumption of KREBS pumps makes them an important target for improving energy efficiency and reducing energy-based carbon emissions.

“A recent life cycle assessment demonstrated that the adoption of KREBS pumps can lead to significant reductions in greenhouse gas emissions, primarily through their enhanced energy efficiency when in operation,” England said.

Driving this benefit is the pumps’ patented wear ring technology. According to FLS, this minimises recirculation, reduces grinding losses, and extends the lifespan of wear components.

“Performance studies conducted at real-world mining operations have documented energy efficiency improvements ranging from 5.3 per cent to 34.1 per cent, depending on operating conditions,” England said.

An essential – if sometimes overlooked –part of the mineral processing flowsheet is pyrometallurgy.

FLS has a long and distinguished history in pyroprocessing, having pioneered the coal-fired rotary kiln in the late nineteenth century.

Today, the company’s Pyro Technology Centre of Excellence in Allentown, Pennsylvania is leading the development of more sustainable pyrometallurgical processes for producing critical minerals, particularly lithium.

“Our innovative lithium pyro island for spodumene concentrate conversion is the culmination of our most advanced technologies working together and features our state-of-the-art preheaters and coolers,” England said.

“It enables us to extract the maximum amount of lithium from the spodumene concentrate while minimising energy use

and reducing carbon intensity – again doing more with less.

“Meanwhile, our multiple hearth furnace supports circularity in lithium processing (as well as cutting Scope 3 carbon emissions) by enabling lithium producers to recycle the lime used in lithium hydroxide production.

“Our pyrometallurgical equipment can also run using alternative (non-fossil) biofuels, hydrogen, and electric heating technologies.”

Shaping the future, today

FLS firmly believes the future of mining is cleaner, more nature-positive, and more efficient.

“How individual mines achieve this will vary greatly,” England said. “There will be many flowsheets of the future, each contributing to a sustainable mining industry that not only provides the world with the minerals it needs to thrive.” AM

THE DUST CRAWLER IS AN ECO-FRIENDLY ALTERNATIVE TO TRADITIONAL WATER TRUCKS AND OTHER DIESEL VEHICLES.

AS MINERS LOOK TO MAINTAIN HIGH SAFETY STANDARDS WHILE REDUCING THEIR ENVIRONMENTAL FOOTPRINT, THE DUST CRAWLER’S AUSTRALIAN DEBUT COULDN’T HAVE COME AT A BETTER TIME.

Miners often work in tough environmental conditions, including those with high levels of dust.

This dust exposure can lead to the development of respiratory illnesses such as pneumoconiosis and silicosis if a site doesn’t take a proactive approach in managing air quality.

To combat this challenge, Tecpro is bringing the Dust Crawler to the Australian mining sector.

Developed by Italian emissions control equipment manufacturer EmiControls, the Dust Crawler is the world’s first fully electric dust control vehicle designed to tackle dust suppression on mine sites, quarries and other industrial operations.

“In 2018, I was visiting a site in the northern part of Scandinavia, where there was this large extraction company with lots of mining and quarries,” EmiControls dust division manager

Alverman Soster told Australian Mining

“We were installing another system for them, and we spoke with the site manager, who explained they were having an issue with their tailing pond as it was filled with large amounts of mud because they were pumping with water.

“The problem with that was the material becomes dry and it’s so fine that even light wind creates this cloud of dust going for kilometres.”

The only way the company could manage this issue was to use a helicopter to spray water over the area.

“Because the material was so soft, it was impossible to go in with traditional tractors such as a bulldozer as there’s a high risk of getting stuck over there,” Soster said.

“This got me thinking about how EmiControls technology could help find a solution, as we manufacture equipment and machinery for dust suppression.”

Around this time, EmiControls’ parent company TechnoAlpin manufactured a fully electric crawler to groom snow on ski slopes. Soster looked at this machinery and had the idea to combine it with EmiControls’ dust control technology.

This is how the Dust Crawler was born, with its first prototype developed and delivered in November 2022. By April 2023, the vehicle was launched to market.

THE DUST CRAWLER OPERATES AUTONOMOUSLY TO DELIVER TARGETED DUST CONTROL WITH MINIMAL WATER USAGE.

“The main advantage of a solution like the Dust Crawler is we can design it to the dimension the customer needs,” Soster said.

Other benefits of the Dust Crawler include its all-terrain crawler chassis, 5000-litre water tank, and six-hour battery operating time.

Alongside the fog cannon, a spray bar with nozzles is installed at the rear end of the tracks, which moistens the soil and seals the haul roads surface.

“If you’re able to catch the wind and spray water with it, you could even reach 200m in distance,” Soster said.

“If you use the Dust Crawler alongside the V22 dust control turbine, you have up to six hours of autonomous operations with the battery. If you leave the vehicle in one spot and just spray, you can operate for 10–12 hours. You only need water; the main concern is having water available.”

The Dust Crawler’s advanced misting technology ensures fine water droplets effectively capture airborne dust particles, preventing their spread and improving air quality on-site.

The Dust Crawler can also be equipped with the V12S dust controller or the V22 fog cannon, the latter of which has a throwing range of up to 90m, enabling the Dust Crawler to easily control dust over large areas.

“The benefit of the Dust Crawler being a tracked and mobile vehicle is through one vehicle, you can cover several areas throughout the mine that you would need multiple systems to reach otherwise,” Tecpro Australia director Patrick Cooper told Australian Mining

“If the wind’s blowing in a particular direction, you can move the vehicle upwind of where dust is being generated, dramatically improving the amount of area that each cannon will cover.”

The Dust Crawler is suited to mining applications that generate high levels of

dust, including tailings, drill and blast, and stockpiles.

Soster said those currently using the Dust Crawler appreciate how easy it is to maintain.

“The vehicle is really comfortable; the seat, the heating system, the cooling system, the monitor and the display are really ergonomic,” Soster said.

“The filter, special pump, heating system, pressure sensor and temperature sensor are managed automatically by the machine, so it’s not possible to cause any damage.”

Above all, EmiControls aims to create solutions that guarantee less emissions.

“All our equipment and everything we do is designed to help more people comply with ESG (environmental, social, and governance) standards,” Soster said.

“EmiControls is here to tremendously decrease dust emissions, especially those from silica and asbestos. We have also developed our sophisticated CURT (control of remote turbine) system where we can monitor the emissions with our sensors and automate dust control without any human interface.”

As mining companies look to decarbonise their operations, EmiControls and its Australian partner Tecpro are here to provide dust control solutions that enhance personnel safety and sustainability compliance. AM

DREDGE ROBOTICS HAS ADDED A NEW STRING TO ITS BOW, WITH THE RECOVERY OF VALUABLE MINERALS COMPLEMENTING ITS LINER-SAFE DREDGING CAPABILITY.

The upkeep of lined ponds is an important but sometimes overlooked process on a mine site.

Mine operators have an obligation to hold storage in their lined pond as part of their mining license. If it gets to the point that they have limited or zero storage available, they could be violating their license and require a quick fix.

Enter Dredge Robotics.

Mining companies across Australia have turned to Dredge Robotics for a range of services, with the heavy dredging of lined ponds key among them.

Dredge’s patented robotic technology can, while operations remain online, safely dredge ponds back to bare liner, enabling these critical facilities to look like new again.

“Our robots can access all areas of

DREDGE’S PATENTED ROBOTIC TECHNOLOGY CAN, WHILE OPERATIONS REMAIN ONLINE, SAFELY DREDGE PONDS BACK TO BARE LINER.

“A miner digs up ore, which is then crushed, screened and processed, but before the material gets to the tailings facility, there’s typically a lined pond in the middle somewhere.

“Material enters the pond before being discarded to tailings, which means valuable minerals not picked up during processing can end up in a lined pond.”

Dredge has also helped lithium and lead miners recover lost minerals deposited in lined ponds, with a nickel project ongoing.

As Dredge Robotics grows, with the company recently surpassing 100 employees, its technology is also expanding through the adoption of artificial intelligence (AI).

“The primary focus of the machines for liner-safe dredging is to recover material from lined ponds and free up space for clients,” Old said.

“Sometimes those environments might have a challenging liquor, like high or low pH, and sometimes there might be complicating factors, with some clients dealing with stringent regulator control or compromised liners.

“The technology must be able to reliably navigate those challenges and still remove the product at a rate that’s economical. This has seen us add new features into the robots so they can do more complicated things.

“In order to tie together new functions, we’ve created a unified

software platform that can be integrated with third-party programming, providing a seamless operating system for the pilots and the entire Dredge organisation.”

Old said Dredge pilots and employees can log into an app and monitor the progress of active dredging operations, with insights made available to clients.

“AI has opened new doors to be able to process big data really quickly in real time,” he said. “And we’re putting our developments into practice, with our AI-led control systems now entering real-world environments, with fantastic results achieved so far.

“We’re able to easily pattern and integrate new hardware, software and capabilities into our machines and automate functionality, so that if we want to make the machine repeat a pattern, or make it respond in a certain way, depending on what the environment is doing, we now can.”

Never has the Australian mining sector needed to be more environmentally conscious, with past events underpinning tightened regulations and a new era of environmental, social and governance (ESG) standards.

This has seen Dredge Robotics step in and become an important partner for mine operators, enabling new technologies to blossom and a new circular economy to be implemented. AM

BUREAU VERITAS IS HELPING MINING COMPANIES SET THEMSELVES UP FOR AN ESG FUTURE.

The Australian mining industry is facing tighter regulations than ever before, with heightened decarbonisation and disclosure reforms being imposed amidst the cleanenergy transition.

Stakeholders are demanding greater transparency in sustainability performance and corporate governance, seeking a demonstration of intent, progress, and integrity.

While there’s a lot the modern miner must digest and scrutinise, the mining equipment, technology and services (METS) sector is stepping up to support a new era of operational stewardship.

Enter Bureau Veritas.

A global leader in testing, inspection and certification (TIC), the near-200year-old company has a headcount of 84,000 employees operating in 140 countries.

In line with its compliance, risk management and business improvement roots, Bureau Veritas is also a specialist ESG and sustainability services provider offering independent auditing and assurance services.

“Mining companies are facing pressure to accurately disclose their ESG performance to an increased number of stakeholders,” Bureau Veritas general manager – certification and sustainability Jeremy Leu told Australian Mining

BUREAU VERITAS IS A SPECIALIST ESG AND SUSTAINABILITY SERVICES PROVIDER.

“Through our assurance engagements, we verify ESG claims and issue independent statements that stakeholders, including investors, can trust and rely upon to make wellinformed decisions.”

Leu said most assurance engagements were conducted against generic ESG frameworks, including the Global Reporting Initiative (GRI), or against customised criteria often requested by banks as an ongoing condition of their sustainability-linked loan (SLL).

“To further support our mining clients’ sustainability goals, we’ve expanded our assurance services into more specialised, commodity-specific frameworks such as the Responsible Gold Mining Principles (RGMP) and The Copper Mark, which advocate for responsible practices in these respective commodities,” Leu said.

Complementing its independent assurance services is Bureau Veritas proprietary ESG audit framework for mine sites and refineries, developed in the context of the European Union (EU) Battery Regulation.

“The EU Battery Regulation imposes due-diligence obligations on economic operators,” Leu said. “If you’re an electric vehicle (EV) manufacturer, you’ve got an obligation to ensure your supply chain and upstream suppliers, including suppliers of raw materials, are conducting business in a responsible manner.”

BUREAU VERITAS PROVIDES ASSURANCE SERVICES TO HELP MINING COMPANIES ACCURATELY DISCLOSE THEIR ESG PERFORMANCE.

and cost-effective.

“In response to market demand and in the absence of an affordable compliance solution, we’ve developed our own ESG audit framework, trained specialist auditors globally and successfully tested our methodology in several lithium, cobalt, nickel and other battery chemicals mines and suppliers globally.”

Bureau Veritas covers off a large range of topics to ensure its ESG audits are thorough, with questions centred on ethical business, impact management, responsible sourcing, health and safety, labour and human rights, community engagement, and environmental stewardship, to name a few topics.

In addition to its ESG auditing and assurance services, Bureau Veritas is also known for its modern slavery riskmanagement offerings. The company works with mining companies to help them combat modern slavery within their supply chains.

“Our service enables companies to identify their modern slavery risks based on a number of criteria, from inherent country and industry risks to continuous AI-powered screening of supplier’s ESG controversies and risks from the web, and review of evidence from targeted questionnaires,” Leu said.

“When the risk is high, our global footprint of experienced social auditors enables us to conduct cost-effective onsite audits against customised modern slavery-related criteria, such as labour conditions and health and safety, or against social schemes such as SMETA (Sedex Members Ethical Trade Audit).”

Leveraging its experience in this domain, Bureau Veritas also provides independent assurance over the information disclosed in clients’ modern slavery statements to ensure the reliability of the reported information.

“As the industry continues to grapple with heightened expectations around sustainability, Bureau Veritas’ suite of specialised services can enable mining companies to build credibility, manage risks, and align their business strategies with the growing demand for sustainable development,” Leu said.

“We are well-positioned to serve as a trusted intermediary, leveraging our global expertise, extensive experience, and commitment to impartial verification to help mining firms navigate this evolving landscape of ESG reporting and stakeholder demands.

“Maintaining their social license to operate is crucial, and our services can be instrumental in enabling mining companies to demonstrate their environmental and social responsibility to a wide range of stakeholders.”

In mining, every delay comes at a cost and reliability is key to staying productive. At MASPRO, we don’t just manufacture parts; we engineer performance into everything we create. Our components are built to handle the harshest mining conditions, so your equipment keeps moving, your teams stay on schedule, and your targets stay within reach. When productivity matters most, MASPRO helps keep your mine moving.

ADOPTING A FLEXIBLE APPROACH WHEN IMPLEMENTING RENEWABLE ENERGY SOLUTIONS IS KEY TO HELPING MINERS ACHIEVE THEIR ESG GOALS.

Decarbonisation has long been a crucial aspect of ESG (environmental, social and governance) standards across the globe.

This is especially true for Australian mining companies looking to reduce their emissions to 43 per cent below 2005 levels by 2030.

However, the sector will not be able to meet this goal, and the larger push to net-zero by 2050, without adopting strong ESG standards.

“There is increased demand for industry-leading ESG performance,” Aggreko head of ESG, APAC (Asia-Pacific) Matt Hunter told Australian Mining

“The key stakeholders of mining organisations are driving improved ESG performance, whether it be via investors, shareholders, government bodies or internal commitments.”

While decarbonisation is a priority for several mining companies, there are some factors posing difficulties,

such as the Safeguard Mechanism,” Hunter said.

“The Safeguard Mechanism covers facilities that emit more than 100,000 tonnes (t) of carbon dioxide equivalent (CO2-eq) per financial year and aims to ‘predictably and gradually over time’ reduce baseline emissions to contribute to Australia’s 2030 and 2050 emission reduction targets.

“This will be achieved either through the implementation of technology to reduce pollution or through the purchase of carbon credits.

“While many technologies such as hydrogen- and battery-powered haul trucks still require further development, renewable energy and hybrid power solutions offer a proven and costeffective solution to assist organisations in meeting decarbonisation targets.”

Renewables refer to energy sources that aren’t depleted when used, like wind and solar, while hybrid technology refers to one renewable energy system being integrated with another.

Benefits of hybrid power outside of

hybrid energy solutions is that they can achieve both.

“As a result, the majority of new mines are looking to implement hybrid energy solutions as they provide the lowest cost of energy.”

Aggreko, a leading independent power producer in Australia, has over 60 years’ experience in providing a wide range of innovative and flexible modular energy solutions.

The company’s energy solutions include hybrid power stations, solar farms and battery energy storage systems (BESS).

“Aggreko develops tailored solutions to provide better and cleaner energy solutions for our customers,” Hunter said. “It’s not so much about turning away from traditional power generation but adopting renewable solutions as a cheaper and cleaner alternative.

“While operating on 100 per cent renewable energy is ideal, it’s not always a feasible solution. We work with our customers to develop solutions that maximise emission reductions while

AGGREKO HAS A LONG-TERM POWER PURCHASE AGREEMENT WITH RIO TINTO’S AMRUN BAUXITE PROJECT IN QUEENSLAND.

“We are able to pair our modular and rapidly deployable traditional power generation and BESS units with renewable energy solutions, including solar and wind,” Hunter said.

“Our engineering team works closely with our clients to develop a customised solution that will maximise emission reductions and minimise costs.

AGGREKO DEVELOPS

“In most cases, hybrid renewable power stations provide significant cost savings over the life of the project by comparison.”

Aggreko has an expansive global track record, successfully implementing renewable energy solutions at mine sites owned by Rio Tinto, Gold Fields and Northern Star Resources.

At Rio Tinto’s Gove bauxite operation in the Northern Territory, Aggreko is building two 5.25-megawatt (MW) solar farms which, when complete, will have a combined capacity of 10.5MW.

The solar farms will be built on Rio Tinto’s leases on Gumatj and Rirratjingu Country, as per an agreement signed by Rirratjiu, Gumatj and Galpu Traditional Owners, the Northern Land Council and Rio Tinto in May 2011.

Aggreko will construct, own and operate the solar farms for Rio Tinto for

up to 10 years. Construction of the farms commenced in July 2024 and completion is scheduled for 2025.

Once operational, the solar farms are expected to reduce the Gove region’s annual diesel consumption by about 20 per cent, or 4.5 million litres per year, as well as lower annual carbon emissions by over 12,000t.

Aggreko will also build, own and operate a 12.4MW solar farm and 8.8MW/2.1MWh BESS under a longterm power purchase agreement for Rio Tinto’s Amrun bauxite project in Weipa, Queensland.

The project, which was awarded to Aggreko in December 2023, will supplement power currently supplied by diesel generators and will help reduce Scope 2 emissions at Weipa by up to 10 per cent.

Once operational, the solar farm and BESS are expected to reduce Amrun’s diesel electricity consumption by 37 per cent or approximately 5.5 million litres of diesel fuel per year. This will reduce annual CO2 emissions by approximately 14,000t.

“Aggreko recognises it has an important role to play in the energy transition,” Hunter said.

“We’re continually investing in more sustainable products, fuels and services to make greener solutions accessible to customers, helping them wherever they are on their energy transition journey.

“Our sustainability framework, Energising Change, supports our vision of a low-carbon world in which businesses can grow and communities can thrive, both through the benefits of our energy solutions and our commitment to developing skills.

“Energising Change translates this opportunity into clear actions in the areas where we believe we can make the biggest difference: accelerating transition, promoting development and taking responsibility.”

Aggreko is also on its own decarbonisation journey, targeting net-zero emissions for its facilities and operations by 2035.

“As part of our commitment to accelerating transition, Aggreko has set an ambitious target to reduce the emissions intensity of our energy solutions by 30 per cent by 2030,” Hunter said. Through the increased uptake of renewable

hybrid energy solutions, combined with growing availability of alternative fuels such as renewable diesel, we feel that this is a challenging but achievable goal.”

As the demand for electrification and decarbonisation increases around the world, Aggreko expects the demand for renewable energy and hybrid solutions to grow along with it.

“The mining industry is increasingly electrifying its operations to reduce emissions, improve safety and lower

“As the demand for electrification grows, we expect to see a significant uptake in renewable energy adoption as a cost-effective solution.

“Locations that currently rely on grid connectivity may transition to microgrid solutions due to challenges associated with grid capacity and the need for a reliable energy supply.”

Able to leverage its global expertise, Aggreko is bringing energy solutions tailored to the unique needs of the mining industry, supporting the sector’s

GENUS IS RAPIDLY GROWING ITS RENEWABLE ENERGY FOOTPRINT.

GENUS HAS TIMED ITS RUN PERFECTLY, BECOMING AN ESTEEMED SERVICES PROVIDER JUST AS THE ENERGY TRANSFORMATION ACCELERATES.

The energy transformation is reshaping the power and communications landscape, with the demand for green technologies opening new commercial pathways for service and infrastructure providers.

This has seen clean-energy adopters, whether it be government entities, energy providers or mining companies, to name a few, turn to Genus to help set them up for a new era of power generation.

To keep up with its growing customer base and reputation in energy circles, Genus understands that it needs to continue adding talent at both executive and operational levels.

Enter David Fyfe.

Having spent 10 years at Western Power, culminating in him serving as acting chief executive officer (CEO), and serving as CEO of Western Australia’s largest energy provider, Synergy, Fyfe recently joined Genus as chief operating officer.

Fyfe, who lives and breathes energy in both a leadership and operational sense, has made a habit of delivering large-scale energy projects on-time and on-budget.

Having achieved plenty at Synergy, Fyfe felt it was time for a new chapter.

“Synergy was getting a lot of recognition for the work we were doing, and I’d set the company up to deliver

its decarbonisation projects,” he told Australian Mining

“I felt the business was in good shape, so I thought it was time to explore a new opportunity. This is where Genus entered the picture.”

Fyfe said he was attracted to Genus’ “phenomenal growth profile”, where revenue has grown significantly in recent years and the forecast looks strong, with the company winning several landmark contracts in recent months.

Genus’ culture was another drawcard.

“I love the culture here,” Fyfe said. “There are no egos – Genus is about building relationships both internally and externally.

“The company is experiencing profound growth, has listed on the ASX, is rapidly growing its reputation in the eastern states. So it felt like a fantastic new challenge for me.”

The power sector is calling on reliable, multi-disciplined partners to support it through the energy transition. This is seeing providers turn to Genus, which can provide end-to-end renewable energy and transmission capabilities.

“Genus is the local supplier for stage one and two of Synergy’s Kwinana Battery Energy Storage System (KBESS) project – the first project of its kind in Western Australia,” Fyfe said.

“So we’re seeing Genus’ experience in delivering batteries become increasingly known across Australia, while the

company also has a strong history of building solar farms for clients.

“Most of these projects require access to transmission networks as well, which has long been Genus’ bread and butter. So you’ve got an organisation that can do a lot more than most and has great end-to-end experience in building renewable projects.”

Genus has made several acquisitions in recent years to further advance its strategic objectives, which Fyfe said leaves the company in good stead for the future.

“Through the addition of Partum Engineering (acquired in December 2024), we can better handle the engineering and design of future energy projects, while CommTel (acquired in October 2024) is a leader in large-scale, mission-critical communications technology for power utilities,” he said.

“These acquisitions further enhance Genus’ end-to-end offering, which in turn reduces risks for clients as they can rely on the one organisation to deliver an entire project.”

Many of Genus’ recent contract wins will see the company deliver energy projects in the eastern states. This includes contracts with Ausgrid for the Hunter-Central Coast Renewable Energy Zone sub-transmission line works, TasNetworks for stage one of the North West transmission developments project, and Transgrid for the

HumeLink transmission project.

“With the work that we’re now doing with Transgrid, Ausgrid and TasNetworks in the eastern states, our brand is now getting traction at the right levels right across Australia,” Fyfe said.

And having partnered with the likes of Rio Tinto, Fortescue, Roy Hill, BHP and Northern Star Resources, Fyfe said Genus is strongly placed to grow its presence in east-coast mining sectors.

“This will no doubt help Genus’ cause as we expand into the east-coast mining sector,” he said.

As part of its expansion, Genus will be able to call on its experience building four substations and a 220kmlong power grid as part of stage one of Fortescue’s Pilbara Generation project.

This complements the company’s longstanding partnership with Rio Tinto, having worked with the major miner on ongoing projects since 2010. AM

•

• Rapid response service teams

• Back up and running in no time

• One call. One team. Zero hassle.

Australia’s mining sector is no stranger to transformation, but the industry now stands on the cusp of its most significant evolution yet – decarbonisation.

Leading this charge is Fortescue, with its impressive goal to eliminate diesel usage and transition its operations to zero-emissions technology.

At the heart of this vision lies a groundbreaking collaboration between global original equipment manufacturer (OEM) XCMG and local service support powerhouse Force – part of the Emeco Group.

XCMG, one of the world’s largest construction and mining equipment manufacturers, has been selected as a key provider of electric mining equipment for Fortescue’s heavy mobile equipment (HME) decarbonisation project.

To deliver this, XCMG is partnering with Emeco’s Force, Australian leaders

in managing heavy earthmoving equipment maintenance, which will provide comprehensive aftersales service, on-site support, and maintenance solutions for this next-generation fleet.

For XCMG’s Australian customers, transitioning from diesel to batteryelectric power is a complex journey that goes beyond simply delivering new machines – it requires a full ecosystem of operational support, technical expertise, and change management.

XCMG is fully committed to supporting its customers and ensuring these machines perform reliably in the demanding, high-production environments of the Pilbara region in Western Australia.

Success demands deep industry expertise, quick response times, and dependable local support – and that’s exactly where Force plays a vital role.

“We are proud to be working with Fortescue on their decarbonisation HME project and are equally proud to be supported by Force as our service and support partner, for the project,” XCMG Australia business development manager Jason Keays said.

“The strength of this partnership provides the confidence our customers need when transitioning to electrified fleets. It’s not just about the machines –it’s about the capability behind them.”

Emeco, with over 50 years of experience supporting Australia’s mining sector, brings an unmatched combination of scale, technical depth, and logistical agility.

Its Force workshops, strategically located across the country, offer specialised diagnostics, component rebuilds, fabrication, and field service for heavy mining assets. This makes Force the ideal partner for emerging technologies like batteryelectric HME.

For Force, the partnership with XCMG signals a strategic move into a rapidly evolving sector.

As the mining industry seeks innovative solutions to reduce emissions and meet environmental targets, Force is positioning itself as a key enabler of that transition.

“We’re excited to be partnering with XCMG on supporting the deployment and growth of its innovative electric mining fleet in Australia,” Emeco managing director and chief executive officer Ian Testrow said.

“The collaboration not only allows us to support this ambitious decarbonisation effort, but also represents Emeco’s first step into next-generation battery-electric technology and provides a pathway for us to become a leading Australian provider of maintenance services for electrified fleets.”

Force’s role in the partnership goes beyond fleet maintenance. Its offering also includes operator training, commissioning assistance, real-time diagnostics, and performance analytics –all designed to ensure maximum uptime and performance of the electric fleet from day one.

A new era for Fortescue and the industry Fortescue’s HME decarbonisation project is one of the most ambitious of its kind.

With a target to eliminate diesel consumption across its operations, Fortescue is investing in electric HME solutions and associated energy infrastructure.

The introduction of XCMG’s batteryelectric mining equipment marks a significant milestone in this journey, combining cutting-edge technology with zero-emissions performance.

XCMG’s electric HME products, developed through years of research and innovation, are designed specifically for large-scale open-pit mining.

Featuring lithium iron phosphate (LFP) battery technology, regenerative braking, and intelligent control systems, these products not only reduce greenhouse gas emissions but also cut down on noise, heat, and operational wear and tear.

These benefits are crucial in extending component life, improving safety, and reducing total cost of ownership.

The partnership with Force ensures these machines will be provided with the same level of responsiveness and reliability that mining operators have come to expect from traditional diesel fleets – a key factor in building customer confidence in the transition to electric.

A major challenge in the electrification of mining fleets is the perceived risk associated with untested technology and new operating paradigms. By partnering with Force, XCMG is addressing this challenge head-on, offering a compelling value proposition to customers: industryleading electric equipment, backed by trusted Australian service.

“Our partnership with Force helps de-risk the transition to battery-electric equipment for our clients,” Keays said.

“By combining our OEM expertise with local support and partners, we’re able to offer an end-to-end solution that’s built for the demands of Australian mining.”

This level of collaboration is already paying dividends. Fortescue has welcomed the partnership, confident the support structure behind its decarbonised fleet will ensure a smooth and sustainable operational rollout.

As mining operators face increasing pressures to reduce emissions, collaborations like the one between XCMG and Force are proving vital.

Electrification of HME fleets is no longer a future concept – it’s happening now, and it’s happening in the Pilbara.

XCMG’s investment in clean technology and its willingness to partner with local expertise sends a strong message: decarbonisation in mining is not only possible, but also practical, and partnerships like this will pave the way.

“As we look towards a net-zero emissions future in mining, we know delivering the right technology is just one piece of the puzzle,” Testrow said.

“Matching the technology with trusted and reliable service is what brings it to life. We’re proud to be playing our part in that transition.”

In a rapidly changing mining landscape, the XCMG–Force partnership is a shared commitment to innovation, sustainability, and operational excellence. With the Fortescue HME project leading the way, it’s clear that Australia’s mining future is electric. AM

WITH THE AUSTRALIAN MINING INDUSTRY HONING ITS FOCUS ON ESG, A FULLY ELECTRIC MINE IN GREECE HAS REIMAGINED HOW BROKK REMOTE-CONTROLLED ROBOTS CAN BE DEPLOYED.

As the Australian mining industry sharpens its focus on environmental, social and governance (ESG) performance, worker safety and operational efficiency, one international example offers a powerful blueprint.

A fully electric underground mine in Greece has reimagined how Brokk remote-controlled robots can be used far beyond their processing origins roots.

Grecian Magnesite has leveraged Brokk’s compact electric machines to overcome many challenges familiar across Australian mining – from underground gold and base metals to selective mining, development and rehabilitation projects.

Under mine manager George Boumas, the operation has not only improved safety and cut emissions but also dramatically lowered processing costs by removing waste rock at the face before it reaches the mill.

These lessons offer Australian miners a chance to rethink how they approach some of their toughest ESG and productivity challenges.

Grecian Magnesite’s narrow drives, veinlike deposits, and challenging ground conditions demanded a new approach.

“The Brokk is a small machine, highly manoeuvrable, and you can execute lots of auxiliary works,” Boumas said.

“But it can also be used as your main excavation machine and in many types of works; for example, selective mining of vein-like deposits. The possibilities are endless.”

The Brokk robots are operated remotely, allowing the team to scale, break and clear material in tight areas while keeping workers out of harm’s way. Importantly, they enable the separation of waste and ore right at the face, transforming the safety profile and the cost base of the operation.

One of the most striking outcomes at Grecian Magnesite has been the impact on processing costs.

“We minimise the production of waste rock in the run-of-mine material. The Brokk machine is dedicated to that work, so it’s very strong, it’s very reliable,” Boumas said.

“We’ve been operating for four years now, with something like 4000 hours, and we’ve had no big issues.”

Using Brokk machines to selectively break and remove waste

AN UNDERGROUND MINE IN GREECE HAS DEMONSTRATED THE COST AND PRODUCTIVITY BENEFITS OF GOING FULLY ELECTRIC.

rock underground has allowed the Greek operation to avoid hauling and processing unnecessary material, significantly reducing energy use and improving plant efficiency. Waste rock is then removed into the old stopes.

Boumas is clear on the benefits to the bottom line.

“If I had to follow the traditional way of mining – drilling, blasting, working with diesel machines and ventilation networks – I would definitely have a cost that would be six to seven times bigger than the operational cost I have right now,” he said.

For Australian mines under pressure from rising energy prices and tightening margins, this offers a compelling costsaving model.

The Grecian Magnesite represents a major milestone, offering further advantages beyond those related to ESG.

“Everything is electric (so) we have very low ventilation costs,” Boumas

THE BROKK ROBOTS ARE OPERATED REMOTELY, ALLOWING THE TEAM TO SCALE, BREAK AND CLEAR MATERIAL IN TIGHT AREAS.

said. “The electricity cost per month is less than €2000 ($3500). It’s just like operating a workshop, not a mine.”

Combining electric mining fleets with Brokk’s remote-controlled robots helps the operation reduce emissions and improve energy efficiency, aligning with growing ESG expectations from

regulators, investors, and communities.

Australian miners looking to lower Scope 1 and Scope 2 emissions can learn from this integrated approach, which delivers both environmental and financial wins.

Grecian Magnesite’s safety record since adopting Brokk technology has

also been especially impressive. Boumas proudly reports that, the operation has recorded zero near-misses, not even minor rockfalls, since 2021.

“That’s because we designed it first in the geotechnical scheme, and then executed it with the Brokk machine,” he said.

Removing workers from high-risk underground zones while maintaining operational productivity is a key ESG achievement and one that resonates strongly with Australian miners under intense safety scrutiny.

While narrow vein mining is an obvious fit for Brokk’s machine, Boumas highlights that the potential extends much further.

The machines’ precision and compactness make them valuable not only for selective mining but also for ground control, development work, and rehabilitation in small and largescale operations.

This broadens Brokk’s relevance across a wide range of areas within Australian mining, including gold, copper, nickel, lithium and even coal, where underground challenges often limit the use of conventional mobile equipment.

The Greek mine’s achievements were not accidental, with Boumas and the team carefully piloting Brokk systems, investing in operator

training, and adjusting operations to maximise value.

For Australian mines, adopting this model means taking a thoughtful and phased approach: testing Brokk performance in targeted trials, building operator expertise, and rethinking underground processes to unlock the full potential of compact, precision equipment.

With safety, ESG and cost pressures mounting, the time is right for Australian miners to explore how remote-controlled electric systems like Brokk’s can reshape operations and set new industry benchmarks.

Grecian Magnesite is paving the way, demonstrating what’s possible when a mine reimagines its approach.

“If we want to build the mines of the future, we need to be open to new ways of thinking and willing to take the steps to make them a reality,” Boumas said. Brokk technology offers Australian miners a pathway to smarter, safer and more sustainable operations helping to meet the challenges of today while preparing for the mining future of tomorrow. AM

BLUE DIAMOND MACHINERY IS HELPING TO RESHAPE THE MINING INDUSTRY’S ENERGY LANDSCAPE WITH INNOVATIVE, DATA-DRIVEN POWER SOLUTIONS DESIGNED TO SUPPORT THE SECTOR’S PUSH TOWARDS NET ZERO.

BLUE DIAMOND IS TRANSFORMING MINING’S ENERGY FUTURE WITH SMART, DATA-DRIVEN POWER SOLUTIONS.

Splayer in power generation, now making significant strides in helping the mining industry meet its sustainability targets.

“Blue Diamond was started in 2012 by myself, my brother Brad, and our school friend Chris,” marketing director Justin Pitts told Australian Mining. “We began by importing high-quality OEM (original equipment manufacturer) power generators and other equipment to address what we saw as a gap in the market.”

Strategic expansions into Melbourne and Brisbane enabled Blue Diamond to shift from a Western Australian operation to a national distributor.

Pivotal moments in the company’s growth came through strategic partnerships and key acquisitions, including securing the Australian agency for Japanese generator manufacturer Denyo.

This partnership helped reposition Blue Diamond from a broad-based equipment supplier to a serious player in the construction and mining power markets.

“The Denyo partnership gave us a strong, internationally recognised brand to leverage,” Pitts said. “Until then, most of our sales had come from our own developing OEM product line, but Denyo’s reputation elevated us from the

supply diesel systems, its long-term focus is firmly set on net zero.

“As we progressed on our journey, we came to realise that the key to net zero isn’t just batteries, solar, or hydrogen – it’s data and information,” Pitts said.

“Accurate insights allow us to optimise performance, validate results, and help clients meet their sustainability targets.”