Issue 5, Volume XXXIV, September/October 2023

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

Our preview of what’s new at this year’s PPMA Show covers 70 pages of this issue, and it is complemented by a comprehensive sustainable manufacturing feature

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

The seminar programme at this year’s PPMA Show includes a presentation from Amazon Web Services and Cumulocity IoT on Packaging Transformed: AI, IoT and smart industrial innovations

GEA UK has launched a scheme to support customers aiming to increase productivity and also reduce waste and energy usage by upgrading their old machinery to more efficient equivalents Find out more on page 15

A tailored VFFS unit has delivered a 400% capacity increase for a snack firm

The PPMA Show returns to the NEC, Birmingham this September (26-28), so register now for your free visitor badge www.ppmashow.co.uk

The Made Smarter Adoption programme is a government funded, industry-led movement equipping SME manufacturers with the technology and skills to boost growth, productivity, efficiency, decarbonise and create high value, well paid jobs of the future.

Launched in the North West in 2019, it has provided specialised support to over 2,500 SMEs, including expert, impartial technology advice, digital transformation workshops to help them take their first steps to identify practical solutions to overcome business challenges, and embed new digital leadership skills.

Businesses have also accessed grant funding to invest in new technologies. These include: data and system integration tools to achieve real-time visualisation of their processes, robotics and automation to increase productivity and efficiency; Industrial Internet of Things (IIoT) to collect production data for operational insights; and analytics and artificial intelligence tools to get more value from their operations. Some makers have adopted additive manufacturing to reduce waste and fast track prototyping, while others are using immersive technologies to add value to their services and pave the way for emerging technologies like the industrial metaverse.

This support is forecast to deliver an additional £209M GVA for the North West economy over the next three years, create 1,300 new jobs and upskill 2,400 existing roles.

The successful adoption programme is now active in the North East, Yorkshire and the Humber, the West Midlands, East Midlands, and West of England.

For more information and to contact your region’s adoption programme visit madesmarter.uk

Brainboxes, based in Liverpool, designs, manufactures and ships 100,000 electronics products globally for a variety of uses including by the British Antarctic Survey and in the Large Hadron Collider. Its challenge was that with 100 different types of products and multiple batch sizes, the task of applying one to eight labels was extremely labourintensive and time consuming.

With the support of Made Smarter, Brainboxes designed a bespoke solution which automated the whole process combining a UV print solution, which prints a label directly onto the product, and an industrial robot to enable high speed and repeatability.

The solution has driven up productivity, profitability, and sustainability. Robotics to load and unload the printer has reduced manual labour five-fold. Meanwhile, visualisation of energy consumption via a dashboard means Brainboxes can drive efficiencies and reduce their carbon footprint.

Brainboxes’ adoption journey is also a great example of the importance of putting people at the heart of change. Production staff who feared what a robot would do to their livelihoods are now embracing the technology.

Bury Black Pudding, based in Bury, has used its traditional recipe for more than 100 years and has expanded its range to include vegan, vegetarian and gluten free versions.

It approached Made Smarter with a vision of creating the world’s first smart black pudding factory and has created a digital roadmap to get there.

One project has automated a previously manual, inefficient and inaccurate method of producing its main stick and chub consumer packs by introducing a Handtmann Filler VF 838s8/HCU/Weight Regulator Machine, which connects the weighing and filling process.

Now every clipped product that is weighed by the operative will automatically correct the filler machine portion control to a preset giveaway ‘allowance’, ensuring a more consistent product.

The improved accuracy of its process has reduced product giveaway by one percent, a saving of around 750Kg for a 60-ton production run, which can be reused, and improve consistency for the customer. It will also significantly reduce the labour associated with the process, redeploying staff to other areas of the business.

September/October 2023

12 NEW MACHINERY

26 INSTALLATIONS

36 SPECIAL FEATURE PPMA SHOW PREVIEW

In our 70-page preview of this year’s PPMA Show exhibition, you will find details of the very latest equipment to be launched

106 SPECIAL FEATURE SUSTAINABLE MANUFACTURING

PPMA members demonstrate in this feature that there’s no kind of greenwashing with their eco machines and services on offer 106

It is true to say that ISO 14001 is the most widely recognised environmental management system (EMS) standard, and supply chain sustainability is a key outcome. By achieving ISO 14001 certification, an organisation can demonstrate to stakeholders its commitment to prevent pollution, to fulfil its compliance obligations and to strive for the continuous improvement of its performance

EDITOR:

Gail Hunt gail.hunt@ppma.co.uk

PUBLISHING MANAGER:

Bill Lake bill.lake@ppma.co.uk

ARTWORK CONTRIBUTOR:

Barry Heath

HEAD OF PUBLISHING:

David Chadd david.chadd@ppma.co.uk

A PPMA PUBLICATION

PPMA Ltd

New Progress House, 34 Stafford Road, Wallington, SM6 9AA

TEL: +44 (0) 20 8773 8111

E-MAIL ADDRESSES: publishing@ppma.co.uk show@ppma.co.uk technical@ppma.co.uk

WEBSITE: www.machineryupdate.co.uk

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from specifiers, managers and purchasers of processing and packaging machinery in the UK.

ANNUAL SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

ISSN 0969-4145

HepcoMotion’s new configuration tool guides customers through the configuration of multi-axis systems in just minutes. Technical support throughout all stages of the design and selection process is provided

120 WHO WHAT WHERE People, events and diary dates

121 MACHINERY FINDER Machinery and also services

PRINTED BY: John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

Publishers: PPMA Ltd

IMPROVE

your sales,

your products

THE BENEFITS OF OVERWRAPPING:

Excellent appearance

On-pack promotion with printed film

Cost reduction

Closed packaging

No heat radiation

Efficiency

Ease of operation

Flexibility

Low maintenance

Easy opening with tear tape

01256 896930 Sollas MU S-O 2021 artwork

In this issue, you will find a feature on sustainable manufacturing that reports on the latest developments by PPMA members that deliver environmental benefits to their customers. And this is despite the undisputable fact that the Government is currently showing a woeful lack of leadership in this area.

It’s almost impossible at the moment if you are in manufacturing to know what on earth you should be doing to address the very real sustainability challenges that lie ahead. Businesses are trying to do the right thing by doing more with less, but increasingly the policy framework is in absolute chaos.

Earlier this year, for instance, Scotland was effectively forced to abandon its plans for a deposit return scheme, then in July, DEFRA delayed the long-awaited launch of the UK-wide extended producer responsibility scheme and with a general election looming, politicians across the board are seemingly backtracking on our country’s net zero commitments.

Despite the Government showing no clear direction, PPMA members are continuing to take a longer-term view to support their customers by offering innovation and technological solutions to the pressing sustainability challenges that all manufacturing companies will face (whenever the politicians eventually get their act together). And, I would argue, our members have been doing this for many years.

For instance, equipment is being produced that can handle all types of packaging materials, including recycled and even compostable, that weren’t around ten years ago. And they have done this without much, or any, fanfare! They are also making their machines more efficient in terms of the energy used, the water used and the materials used, while also preventing product giveaway and extending product shelf lives.

As we all head to Birmingham in September (26 – 28) to visit the PPMA Show 2023 in Hall 5 of the NEC (you can find our major preview between pages 36 to 105); I challenge you all to ask every one of our exhibitors about sustainability and what their product range contributes to the debate. I believe you will be impressed by the genuine depth of detail their answers will contain. And, I believe that not many industries have facilitated such environmental change in the last ten years as the packaging and processing machinery sector. You will find proof of this in our sustainable manufacturing feature (see pages 106 – 115). n

The sensors for the washdown area are ideal for use in washdown applications in the food, beverage and packaging industries. The high-quality stainless steel 316L housing makes them robust and corrosion-resistant

Height and Angle

Measurement of Ice Cream Cups via 2D/3D Profile Sensors

Detection of Cookies with Reflex Sensors with Background Suppression

Detection of Food Trays with Reflex Sensors with Background Suppression

Color Control of Baked Goods with Vision Sensor

At the PPMA Show, Dimitrios Spiliopoulos, the industrial IoT lead for manufacturing at Amazon Web Services (AWS) will be joined by Philip Hooker of Cumulocity IoT for their joint seminar which is called Packaging Transformed: AI, IoT and smart industrial innovations. This is the keynote speech on Wednesday 27 September, while the keynote on Tuesday 26 will see the founder of Proper Snacks

Cassandra Stavrou MBE outline her ‘proper’ rules for business and on Thursday 28, Ross Verrall from NVIDIA EMEA Enterprise Services will talk about enabling the future with accelerated computing. To learn more about the full programme, see page 37.

The PPMA Show returns to the NEC, Birmingham this autumn (September 26 – 28) bringing together well over 300 companies that will showcase the very latest processing, packaging, robotics and vision system options that have been developed in the last year.

The three-day exhibition is timely for end users who are still having to deal with the relentless pressure on margins, continuing supply chain issues and staff shortages.

Visitors to the UK’s largest processing and packaging machinery exhibition will see leading companies gather to launch new products suitable

for many market sectors. Organised by the PPMA Group of Associations, the exhibition takes place in Hall 5 of the NEC.

“Visitors are encouraged to bring their problems and requirements to the show where there will be people who know what to do and there will be plenty of machines to look at actually doing it,” says Richard Little, PPMA Show director.

Our 70-page show preview will help plan your visit and starts on page 36 of this issue. To register for your free visitor badge, visit the show website right away at: W www.ppmashow.co.uk

In response to the latest market demands for more comprehensive packaging solutions, two BW Packaging companies – Accraply and BW Integrated Systems –have combined into a single business which will now be called BW Integrated Systems.

MULTIVAC UK will be hosting an exclusive launch event for its new Innovation Centre between 20 – 21 of September.

The two-day event at its 850sq m facility in Swindon will give visitors the chance to explore the latest trends and innovations for modern manufacturing solutions including machinery, applications and full-line demonstrations, new product launches, keynote speakers and the company’s famous Oktoberfest evening event.

A range of equipment from processing, packaging, inspection, labelling and automation as well as integrated full-line capabilities will be shown. The event will provide a diverse agenda suitable for all visitors across various applications including protein, plant-based and bakery sectors. E events@multivac.co.uk

Acknowledging 90 years of innovation during which Omron has pushed technological boundaries, the global industrial automation firm is set to celebrate its anniversary at the PPMA Show. The company will show its latest solutions which are designed to help industry operate more efficiently and profitably, while prioritising sustainability and the development and wellbeing of the individual.

As part of the BW Integrated Systems business, the Accraply team will now go to market as BW Labeling, emphasising its complete line of labelling, converting and also productdecoration solutions from its range of established brands which include Accraply, Graham + Sleevit, Harland, Stanford and Trine.

Festo has introduced a learning portal that holistically links theoretical learning content with hardware and software solutions from Festo Didactic allowing knowledge to be tested directly in practice. In this way, Festo LX enables learners to develop the necessary skills for high-tech industry employment.

Schneider Electric’s Sustainability Impact Awards are back for a second year and nominations are now open to partners, customers and also suppliers.

This year, Schneider is broadening the scope of eligible companies to include customers and suppliers as well as channel partners. The selection criteria has also been updated to address wider efforts to achieve net-zero targets through electrifying and digitising operations. Submissions are open from now until November 17, 2023, and the global winners will be announced in April next year.

The new award categories introduced this year include:

• “Impact to my Customers”: rewarding partners that demonstrate sustainable leadership by enabling their customers to achieve their decarbonisation goals

• “Impact to my Enterprise”: rewarding customers that exhibit sustainability leadership in decarbonising their own operations.

• “Impact to my Enterprise for Large or Midsize suppliers”: rewarding suppliers that are engaged in the Zero Carbon Project, a Schneiderled initiative aimed at halving the operational carbon emissions of the company’s top 1,000 global suppliers by 2025.

In addition to the above, Schneider has updated the awards selection criteria with a more integrated approach to sustainability. This includes improving energy efficiency and implementing digital tools and technologies as well as other examples of impact and innovation.

W www.se.com/ww/ en/work/campaign/ sustainability-impact-awards/

A Cooking Energy and Cost Rating service has been launched by Campden BRI. The service has been designed to support food manufacturers and retailers, enabling them to provide information – either on-pack or otherwise – on the energy used to cook products, using a range of appliances, to empower consumers to make an informed decision on the cost of cooking their purchase. It follows the rising concern about energy prices.

Phoenix Contact is a leading manufacturer of lightning current arresters and surge protection devices – and has been for 40 years. It developed its first protective devices for signal interfaces back in 1983 and today, can offer a suitable solution for every application. The company says its dedicated team, fundamental research in the company’s own high-current laboratory and at universities, and participation in committees have paved the way to becoming the technology leader for surge protection and also lightning current arresters.

Gerhard Schubert, the founder and shareholder of leading packaging machine manufacturer Schubert, passed away peacefully in Crailsheim this summer at the age of 84. With his passing, the global packaging industry has lost a defining figure and an extraordinary personality.

In 1966, he founded machine manufacturer Gerhard Schubert GmbH and to this day, his visionary ideas of a modular robot-assisted top-loading packaging machine continue to influence modern packaging technology around the world. Gerhard Schubert laid the foundation for the company in 1953 with an apprenticeship as a mechanic. He then spent several years gathering experience as a design engineer at the Strunck and Kugler companies before setting up his own engineering and design office in 1964.

Only two years later, Gerhard Schubert GmbH was founded in Crailsheim.

With his pioneering spirit and entrepreneurial daring, he built the small company into an international group of companies over a period of decades and took the family business to the forefront of the world’s packaging manufacturers. He always remained down-to-earth and deeply connected to the region

surrounding his hometown of Crailsheim. In addition to his two sons Ralf and Gerald Schubert, the next generation of grandchildren is also now working in the company.

Gerhard Schubert’s passing is a great loss. But on his life’s journey, he left traces that will reach far beyond his time with us, says the company.

TNA solutions held an open house in August at its UK headquarters in Birmingham called ‘Feeding Ambitions’.

Visitors to this well attended event saw the tna robag 3e and tna auto-splice 3 form the ‘perfect pair’ of packaging solutions, addressing automation and efficiency demands. The two systems together offer a new CXE integrated display controller and automatic film splicing, which combined can deliver up to a 5% increase in

production uptime with only a 200 mm increase in floor space required.

capable of reaching speeds of up to 250 bags per minute with minimal waste. The tna auto-splice 3 complements the unit as a fully integrated automatic splicing solution. Attendees also saw the tna ropac 5, which is billed as the world’s fastest case-packing system for flexible bags, capable of handling up to 220 bags per minute in operation.

This year’s PPMA Group Industry Awards finalists have been announced and these companies, listed below, will now do battle to win the top prizes across the six awards categories

Innovative Processing System

The Adelphi Group

Alway Loughborough

Cobalt Systems

Emerson Automation Solutions

Faedah Solutions

Friedheim International INFICON

Jarshire

Kemtile

Markem-Imaje

Mettler-Toledo Product Inspection

SMC Automation (UK)

Innovative Packaging Machinery

AddParts (Addition Design)

Elesa (UK)

Ishida Europe

Kliklok International (part of the Syntegon Group)

Linx Printing Technologies

Omori UK

Pace Mechanical Handling

P.E. LABELLERS S.P.A

Robatech Gluing Technology

Samson Nano

Schubert UK

Secomak

TNA Solutions

ULMA Packaging Votech

WestRock Packaging Machinery & Automation

Innovative Robotics Solution

The Adelphi Group

AMP Automation

AROL S.P.A.

Endoline Robotics

Epson (UK)

Mobile Industrial Robots

OnRobot A/S

Robatech Gluing Technology

Innovative Vision Solution

Faedah Solutions

Mettler-Toledo Product Inspection

MultiPix Imaging

Scanware Electronic

Scorpion Vision

Leading the entertainment at the PPMA Awards gala evening will be Romesh’s best mate and top comedian Rob Beckett. During the evening, mind-reader Alex Crow along with swing band JACK PACK will also entertain the guests. Tickets can be purchased for £110+VAT while a table of ten is £990+VAT, but hurry as there’s only a few tickets remaining… https://www.ppmashow.co.uk/awards/the-awards-night-2023-book-now

Outstanding Customer Service

Epson

Faedah Solutions

i-mark uk

Leap Automation

Logopak International

Scayl

Apprentice of the Year Festo

Premier Labellers

Scorpion Vision

VISIT PPMA SHOW 2023 – THE UK’S NO.1 EVENT FOR THE VERY LATEST PROCESSING AND PACKAGING MACHINERY, ROBOTICS AND INDUSTRIAL VISION

SCAN THE QR CODE TO J0IN US

TECHNOLOGY

Showcasing the very latest and best technology in the processing and packaging industry – all under one roof.

KNOWLEDGE

Draw on the unique knowledge of hundreds of exhibitors to tailor the solutions right for your business.

EXPERIENCE

Invest with confidence; experience the latest machines on the market before you buy – only at the PPMA Show.

ABB Robotics is expanding its large robot range with four new models and 22 variants offering more choice, increased coverage and greater performance.

The next generation models include the IRB 6710, IRB 6720, IRB 6730 and IRB 6740, suitable for payloads ranging from 150 kg to 310 kg, with a reach from 2.5 m to 3.2 m, offering customers greater choice and significant performance and energy efficiency improvements.

“Sustainable production is a major priority of automotive manufacturers, with 78% of companies identifying it as important to their business and a further 77% identifying it as a priority for their customers,” says Marc Segura, president of ABB’s Robotics Division. “ABB’s four new robots offer 22 variants and energy savings of up to 22%, responding to our customers’ needs; offering more choice and greater flexibility for more sustainable production.

“These new robots will help our customers build resilience across a range of industries including automotive, general manufacturing, foundry, food and beverage and logistics.”

The improved energy efficiency is driven by ABB’s OmniCore controller, and lighter robot design leading to energy savings of up to 20%. OmniCore also offers high motion control accuracy. Featuring ABB’s TrueMove and QuickMove motion control technology, the robots can achieve repeatability with a minimum of 0.03 mm

deviation in operation.

These capabilities make the new series of robots ideal for complex tasks such as spot welding, laser welding, screwdriving and riveting, allowing automotive manufacturers to achieve high quality assembly.

“Our new robot range meets the needs of the rapidly growing electric vehicle (EV) industry,” says Joerg Reger, who is the managing director of ABB Robotics Automotive Business Line.

T 01908 350300

W www.abb.com

Following last year’s global launch of Markem-Imaje’s 5940 G, Touch Dry highresolution ink jet coder, Markem has introduced a brand-new steel cabinet option to offer a robust solution for extreme environments. Responding to the growing need for coders that can provide reliable, GS1-128 compliant codes in challenging manufacturing surroundings, the stainless-steel case provides protection from rust in wet and damp environments.

The 5940 G has been deployed by manufacturers in fresh produce, meats and for precision printing on polystyrene for frozen foods, often packaged in extreme temperatures, damp environments or field packaging, so the new steel casing is a key benefit for these difficult production conditions.

T

0161 864 8111

W www.markem-imaje.co.uk

Cabinplant introduced several new weighing and packing options at interpack to handle sticky products in ready-to-eat meals along with the Multibatcher which is designed to reduce giveaway and labour costs.

The Multibatcher is an automatic high-speed solution for the weighing and packing of sizable portions up to 35 kg. It is the first batcher based on the combinatorial weighing principle and an alternative to conventional batching with high tolerances and manual processes.

The Multibatcher has the potential to reduce both giveaway and costs through precision and speed, says UK representative Sealpac UK & Partners.

In operation, the raw materials are weighed into partial portions in pans which are combined into batches with giveaway down to 0.25 - 0.7%. “The giveaway can be reduced with up to 900 kg of meat daily for a processing line running two shifts and based on 100 g or less giveaway per portion,” says Michael Falck Schmidt, global sales director at Cabinplant.

The Multibatcher can be fitted into existing packing lines or used as a stand-alone unit.

T 0845 302 3056

W www.sealpac-uk.com

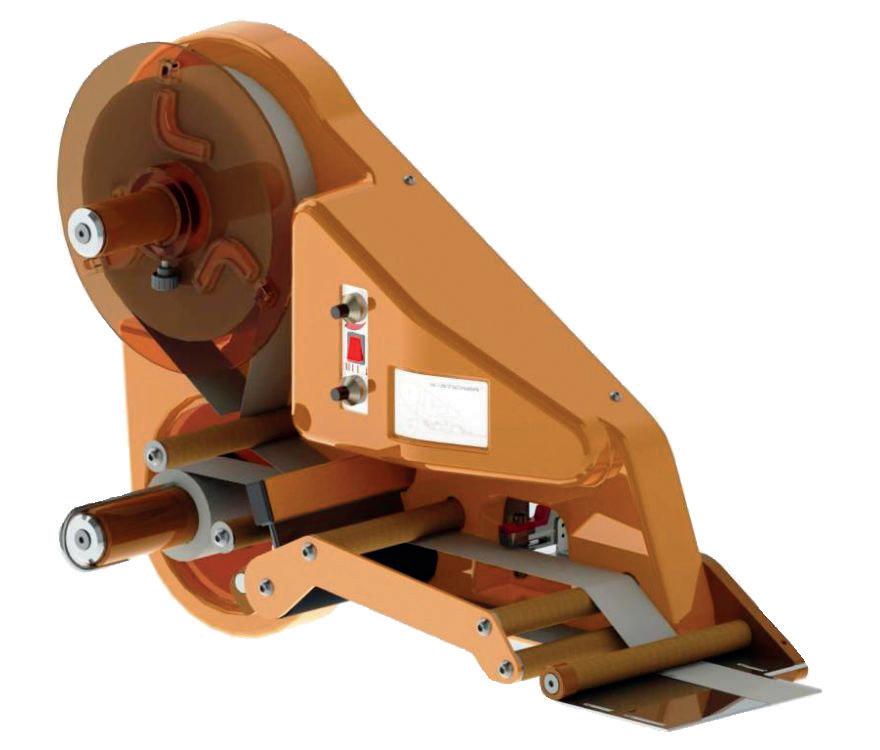

GEA UK has launched a new campaign called GEA Exchange to support customers aiming to increase productivity and reduce waste and energy usage by upgrading their old machinery to more modern and efficient equivalents.

Major benefits of upgrading/ exchanging include access to the most up-to-date technology, increased production throughput and reduced downtime, better energy efficiency and the potential unlocking of Industry 4.0 features on production lines/processes.

The programne will enable food processing and packaging companies to exchange an extensive range of GEA machines for newer models. The company is also targeting users of competitor machinery who are dissatisfied with reliability or productivity issues – as GEA’s technology is billed as robust while offering longevity.

GEA is proud to support its customers through a

machine’s lifetime; but like any older technology, sourcing older parts for existing machines can be prohibitively expensive. By participating in the new programme, manufacturers can save costs on repairs and parts and reduce the risk of an older machine breaking down, interrupting or halting production entirely.

Taking the CrumbMaster as an example under the exchange campaign, customers could upgrade to the new CrumbMaster Gen 2. This new model produces results equating to 90% less waste and giveaway and capacity is improved by 20% over the previous

At the automatica 2023 show in Munich, Danish manufacturer of collaborative robots Universal Robots presented a new software platform specifically developed for machine tending tasks.

Called PolyScope X and through a new, customisable user interface, it is designed to add new levels of flexibility to high mix, low volume machine tending automation. With PolyScope X, machine shop operators can achieve changeover times of less than 10 minutes.

model – resulting in higher product quality and enhanced productivity.

“GEA Exchange is a top tier trade-in programme, and we are very excited to launch it across the UK,” says Sam Cartwright, UK sales manager at GEA Food Solutions.

“It is a truly excellent proposal for both our customers and those of other brands.”

T 01908 513500

W www.gea.com

This, says Universal, will empower users to run more batches in a day and to run them in a more strategic and flexible way which suits manufacturers handling shifting and increasingly diverse order patterns in today’s market.

At the same time, PolyScope X introduces a powerful reworked programming experience and toolset. This enables integrators and OEM partners to structure their program code into operations that can be reused throughout the program.

00 34 933 15 80 76

W www.universal-robots.com T

WMH has worked with belt manufacturer Intralox, to design a twin spiral unit which gives about 300 metres of conveyor length within a small bakery factory footprint. The length of conveyor can be used for product buffering or can be used as a holding facility to allow product to be rested for proving or ambient cooling while maintaining the benefits of an in-line production system.

The spiral is fitted with Intralox’s side drive modular

plastic belt that offers all the flexibility and hygiene benefits of its existing

modular belts with the addition of the side drive features which enable the conveyor belt to be driven from the side rather than the end. This drive arrangement eliminates the need for a long return belt path and spreads tension along the length of the belt.

Driving the belt on the outside edge also makes

access for cleaning and maintenance simple and reduces the moving parts of the machine to a minimum.

The first unit built has twin stacks of conveyor providing low level infeed and low-level outfeed for inline product proving, however the design could easily be configured to offer single stack configuration for elevating, de-elevating or reversible for buffering in case of a fault on the line.

T 01579 383788

W www.wmh-uk-ltd.com

The twin spiral unit is built to benefit bakeriesAM Labels has added a low cost, complete label printing and finishing solution to its portfolio.

The Afinia DLF-220S digital label finisher in line with the Epson ColorWorks C6500 colour label printer enables users to print high quality, vibrant labels, in addition to laminating, cutting, slitting and rewinding, in one simple operation.

When the DLF-220S finisher is used inline with the 1200 dpi Epson ColorWorks C6500 colour label printer, users can print labels of up to eight inches in width, with the added benefit of laminating the labels to provide a protective coating for increased durability, as well as increased scratch and scuff resistance.

The solution, which is ideal for medium volume labelling requirements and for when multiple label sizes and shapes are required, has a maximum media width of 225 mm and accommodates rolls with a diameter of up to 400 mm when used with

an accompanying buffering unit. In addition to converting uncut, continuous-printed media into fully finished labels, the DLF-220S enables users the flexibility to cut labels to any shape or size. Furthermore, cut profiles can be modified as often as required, providing added versatility in operation.

The new easy-to-operate solution, which is now

Automated production solutions individually designed and built for manufacturing sectors, including automotive, FMCG, food & drink, electronic components, medical devices.

■ Vision Systems

■ Inspection

■ Assembly

■ Picking

■ Packing

■ Proof of principle

The Leak-Master Pro 2 from Witt Gas is now available with two new, larger chambers which means that food producers now have four chamber sizes at their disposal to test almost any size of package to ensure the quality of their products.

available from AM Labels, is ideal for businesses looking to produce professional, high-quality labels, while benefitting from ultra-precise cutting abilities. Thanks to this complete solution, companies can produce fullbleed labels without being required to purchase dies, which are often costly.

T 01536 414222

W www.amlabels.co.uk

This new option tests packages for escaping CO2, which features in many modified atmosphere packages. To do this, a vacuum is generated in the test chamber. If there is a leak, the protective gas escapes from the test product, which is detected by CO2 sensors.

Depending on the packaging and the test conditions, even the smallest leaks down to 10 micrometres can be detected.

T

01925 234466

W www.wittgas.com

■ Robotics

■ 6 Axis

■ Delta

■ Scara

■ CoBots

■ Programming

Meech International will be presenting its range of solutions for static control and web cleaning at Labelexpo 2023, demonstrating its commitment to preventing problems and improving productivity within the narrow web, labels, and packaging sectors.

Meech will be exhibiting the Hyperion 650QAC for the first time. It is a high accuracy ionising bar designed for ESD sensitive applications where static charges need to be controlled at very low levels. The titanium emitter pins are driven by a Quasi AC (QAC) high voltage waveform that generates positive and negative ions from each pin.

This is vital for the delivery of rapid charge decay with near-zero residual voltage on the object being neutralised, which reduces the risk of electrostatic discharge (ESD).

Intended for use at operating distances between 50 and 400 mm and including a built-in keypad for setting different configurations, the 650QAC is ideal for applications where ESD may damage electrical components. This includes RFID tag manufacturing where static charges are generated during the unwinding, printing, drying and rewinding processes and stored in the metallic antennae.

The population of the chip onto the antennae can then result in the stored static charges discharging to the chip, causing immediate and ‘catastrophic failure’ or ‘latent defects’.

A range of other Meech solutions for label and packaging printers will also be on display during the show including TakClean, CyClean, CyClean-R and VacClean.

T 01993 706700

W www.meech.com

Meeting rising demand for Shelf Ready-(SRP) and Retail Ready packaging (RRP) in the food and beverage, logistics, pharma & cosmetics or consumer packaged goods industry needs a robot to match.

With fast performance, greater dexterity and flexibility, find out how ABB’s IRB 390 FlexPacker can transform your productivity and help you grow your business.

The low-cost camera portfolio from IDS Imaging Development Systems specifically addresses price sensitive applications and has so far included the camera families uEye XCP (closed zinc die-cast housing, 29 x 29 x 17 mm) and uEye XLE (different variants from board-level models to closed plastic housing).

It is now being expanded to include the uEye XLS camera family. These are tiny boardlevel cameras with dimensions of only 29 x 29 x 7 mm, which are consistently reduced to essential camera functions and can therefore be offered at a particularly low price.

They are available from just 150 euros list price.

The new USB3 cameras from IDS are compatible with the Vision Standard, have a Micro-B connector and are available exclusively as board-level versions with or without C/CS or S-mount lens holders. The board-level cameras are so small that they can be inserted directly into the lens holders.

Users can choose between different sensors from 2 to 12 MP. Thanks to their minimal heat generation, uEye+ XLS cameras are particularly suitable for device construction and embedded vision applications.

T 01252 916656

W www.ids-imaging.com

By developing a new pouch loader for chamber belt machines, Multivac has created a semi-automatic solution which significantly improves pouch filling and the loading in terms of overall performance, efficiency, hygiene and ergonomics. Up to 40% reduction in personnel costs and a significant increase in efficiency can be achieved, when compared to manual loading, and all with maximum product and pack format flexibility.

When packing products on chamber belt machines, the filling of the film pouches and the loading of the machine have often been a bottleneck. Thanks to the development of the latest loader, which has been designed to meet the needs of all customers, Multivac says it has set a new benchmark for the automated packing of products in a range of film pouches.

The operating principle of the new unit is simple: one operator positions the products on the infeed

conveyor of the machine. Two other people then load the products by pulling the film pouches over the loading conveyor, so that the product can be conveyed automatically from the conveyor into the film pouch. Then the film pouch is turned through 90 degrees, before it is placed on the machine conveyor and subsequently vacuum packed and then sealed.

When compared with the manual procedure, which generally requires at least

five people, only three operators are necessary with this semi-automatic solution. And, although personnel costs can be reduced by up to 40%, the cycle output can still be fully utilised.

Another benefit is in the hygiene and ergonomics as when filling the film pouches, the operators no longer need to lift the products and place them awkwardly into the pouches themselves.

T 01793 425800

W www.multivac.co.uk

Omron has added ESD (electrostatic discharge) and cleanroom models to its i4H SCARA robot series for industrial automation applications that require heavy payload handling together with precision and speed. The latest i4H SCARA ESD models are designed to prevent the buildup of static electricity that can damage sensitive electronic components, while the cleanroom models comply with the stringent needs

of environments that require very low particle emissions such as pharmaceutical,

medical or semiconductor industries.

The new ESD and cleanroom models come with the original features of the i4H and users can easily program the robot as part of the company’s total industrial automation solutions.

T 01908 258258

W www.industrial.omron.co.uk

How can packaging be both environmentally friendly and cost-efficient? With our TLM packaging machines. They enable you to use the thinnest materials possible, cutting them to size to reduce consumption and dramatically decrease your use of resources. It’s great for the planet and you benefit from a real competitive edge. We call it Mission Blue and we promise: The mission goes on. www.mission-blue.com

High-intensity magnetic separation equipment from Eriez is gaining recognition among glass manufacturers for its ability to remove tramp metal particulates from the mixing and blending of raw ingredients such as silica, soda ash and limestone prior to the melting process in a furnace.

“The glass industry needs effective magnetic separators to eliminate metallic, magnetic and non-magnetic impurities during the glass-making process,” says Tom Saccamozzone, project manager – heavy industries at Eriez.

“Magnetic and metal contamination not removed from the raw material causes visual and structural defects in finished glass products.”

Eriez magnetic separators are designed to remove or recover metals from three types of magnetic materials used to purify glass: ferromagnetic, paramagnetic, and diamagnetic, according to Saccamozzone. In the process of making silicate glass, for example, multiple Eriez magnetic separators are used to recover trapped metals mixed in with the sand along with other raw materials. Unwanted tramp metals are removed using Eriez ceramic drums, different types of ceramic traps and suspended magnets. “Typically, using these separators reduces the number of large pieces of ferrous, like nuts, bolts and mill scale,” says Saccamozzone.

T 029 2086 8501

W www.eriez.com

Newtec’s laser FlowPack700 offers cost-effective and sustainable technology for users needing high speed, easy machine use, green operations, and fast return on investment.

At a capacity up to 80 punnets per minute and leveraging the benefits of ultra-thin film, the company says it offers the level of automation clients need to make their production processes cheaper, easier and faster. More specifically, the fully automatic machine combines laser sealing and cutting in one operation, simplifying the whole production procedure.

The laser sealing machine

complies with the EU-2025 plastic initiative which calls for reduced plastics use and recyclable packaging. According to Newtec mechanical design engineers Casper Monrad-Jensen and Andreas Mehl, the laser welding machine saves money and waste as it uses a very thin film and maintains speed and effectiveness. Ultra-thin film allows for the usage of an 8μm of pure polyethylene (PE) material that enables companies to save up to 75%-80% on plastics.

Offering a large variety of packaging applications, the laser FlowPack700 can pack fruits and vegetables.

T 01406 426526

W www.newtec.com

Recently, Comau and IUVO, in collaboration with Esselunga, have developed a new wearable exoskeleton specifically designed to reduce lower back fatigue during lifting and repetitive tasks. It is ideal for logistics, fulfilment, manual palletising & depalletising, manual pick & place, bending and lifting from a floor level.

Created with the aim of improving ergonomics for operators engaged in manually moving loads,

it was tested at Esselunga Group, a leading large-scale retail trade company. Without using a motor or batteries, the exoskeleton provides passive assistance to the lower back muscles that are used during lifting and handling. It thus creates short- and long-term benefits for the wearer through the significant

reduction in physical effort and fatigue. The newest Comau wearable exoskeleton stores human energy in a spring. It accommodates the specific needs of workers engaged in moving cumbersome loads by supporting users when bending their backs and during repetitive lifting.

T 01788 815280

W www.comau.com

ACOPOS 6D allows you to move products freely through an open manufacturing space –unbound by the limits of one-dimensional production flow. Magnetic levitation provides six degrees of freedom for unprecedented processing density on a fraction of the floorspace. br-automation.com

Syntegon says it is setting new standards in capsule filling for the nutraceutical industry with the European and US market launch of its GKF Capsylon 6005 machine.

This latest addition to the GKF Capsylon series differs from its predecessors primarily in terms of output and product yield – serving the need for higher production capacities of manufacturing companies. “We are seeing growing interest in products like vitamins, proteins, and other dietary supplements in the European and US markets,” says Andreas Nuessle, product manager at Syntegon. “The GKF Capsylon 6005 combines a significantly higher output rate with the flexibility of the range to fill powders, pellets, granules, and even special products.

“This makes it suitable for a particularly wide range of applications.”

The GKF Capsylon 6005 is based on proven technology but also includes new features.

With 360,000 capsules filled per hour, the output has more than doubled compared to the GKF Capsylon 3005 (175,000 capsules/hour).

The high-speed capsule filling machine has 48 instead of 21 segment bores in four rows instead of two.

“The 6005 also features two dosing stations operating in parallel,” says Nuessle.

“This allows us to fill a larger number of capsule segments evenly without losing any time.”

Operators can learn to use the new intuitive system with minimal effort

Meanwhile, the click system developed by Syntegon ensures significantly faster changeovers. No manual re-adjustment of the format parts is needed which is the ideal prerequisite for processing a wide range of different products on the same machine in a time-saving manner. Operators can learn the use of the intuitive system with minimal effort.

T 01332 626262

W www.syntegon.com

Macsa id UK has launched a small character laser coder – called SPARK – which is billed as an affordable new system that combines maximum marking resolution and definition with reduced downtime for maintenance and set up.

The coder offers advanced laser technology and consumablefree operation to ensure running, maintenance and repair costs are kept to a minimum. Compact, lightweight and easy to connect, it is designed to mark the wide range of substrates used to package today’s FMCG products including labels, cardboard boxes, a wide range of plastics, glass, wood, paper and board, metals, rubber and textiles.

A new handheld colour interface is a key improvement of the unit, says Macsa id UK. 01462 816091

W www.macsa.com/en-uk/ T

• Modular design allows design changes at any time

• Save Money with Long Lifetime, Low Energy Cost & Easy Maintenance

• The light weight design makes it easy to assemble, install, and move

• Available in a wide array of angles and widths

• Easily integrated with additional equipment

Industrial robot manufacturer, Shibaura Machine has expanded its range of SCARA robots with two new models in its THE series. The latest robots, the THE800 and THE1000, offer high-speed operation and a high load capacity of 20 kg.

These new models will be sold in Europe by industrial robot supplier TM Robotics, Shibaura Machine’s sales and service partner.

With an ability to offer a high cycle speed even at payloads of up to 20 kg, the THE800 and THE1000 are an ideal choice for tasks involving heavier components.

These models boast a cycle time of just 0.4 seconds with a 2 kg load, with 8,400 mm per second and 9,500 mm per second joint speed respectively.

The maximum payload of the two models is 20 kg, and they offer a reach of 800 mm and 1000 mm respectively.

These two new models expand upon the existing THE series that is designed

to offer accuracy, speed and an excellent price-to-performance ratio.

An example of the range of applications for the two new SCARAs is the growing battery manufacturing industry. With the rapid increase in electric vehicle (EV) production, the THE800 and THE1000’s features are intended to meet the challenges of EV battery manufacturing — like heavy lifting and also accuracy.

The THE SCARA series is compatible with Shibaura Machine’s TS5000 controller and TP5000 teach pendant. The improved communication capabilities of the TS5000 enable Internet of Things (IoT) ready and fast data communication, while added programming languages make programming easier than ever.

The TP5000, meanwhile, has been designed for ease of handling and operation, with an intuitive, touchsensitive display panel that includes spilt screen display options.

T 01707 290370

W www.tmrobotics.co.uk

Packaging and cosmetics machinery manufacturer Rotzinger has formed a partnership with a provider of industrial wireless automation solutions to deliver advanced capabilities to drive flexibility, throughput and sustainability.

Rotzinger was asked to develop an adaptive secondary food packaging machine to meet high throughput demands along with the ability to support multiple pack and product variations on a single machine. By utilising CoreTigo’s IO-Link wireless based products, Rotzinger was able to control the grippers on the movers wirelessly, without needing additional external

robots, cables or other equipment.

The new machine design results in reduced changeover times, a reduction in machine footprint and maximum flexibility to support the multiple products and pack types required. These ultimately result in less energy usage, less space required and fewer parts needed in the machine.

“We are delighted to partner with CoreTigo and to integrate their technology into our advanced packaging machinery,” says Andreas Graf, Rotzinger PharmaPack ceo.

T 00 49 7151 259 3817

W www.rotzingergroup.com

● Non-return valves for Tri-Clamp fittings.

● A backflow preventer and Tri-Clamp sealing gasket combined.

● Low cost, space saving, spring-free, single-piece design.

● Made from food grade, magnetic elastomers.

● For more infomation email: info@trivalve.com

Beijer Electronics believes its web-based HMI technology offers benefits to machine builders but also to end-users in controlling and monitoring industrial processes.

“As well as delivering flexibility to users, companies can make the technology their own, but customising the look to take on board corporate colours and designs,” says Nigel Dawbarn, sales manager UK and Ireland at Beijer.

For end-users, web-based HMI technology offers a wealth of benefits including improved accessibility, to visualise machine data and control processes from anywhere and at any time, through an internet connection and a web browser. This remote accessibility enhances flexibility and enables real-time monitoring of operations. End-users can easily view performance metrics, receive alerts, and make adjustments as needed, improving overall efficiency and productivity, says Beijer.

Additionally, web-based HMI technology provides enhanced collaboration and communication capabilities. Multiple users can simultaneously access the HMI system, enabling effective collaboration among operators, maintenance personnel, and management. This is billed as fostering better decision-making, as crucial information can be shared and analysed collectively. Furthermore, web-based HMI allows for seamless integration with other digital systems, such as data logging, analytics and enterprise resource planning (ERP) systems. This integration facilitates data-driven

decision-making, enabling end-users to optimise operations, identify patterns, and implement predictive maintenance strategies

The simplified development process, flexibility in updates and customisation, improved accessibility and enhanced collaboration capabilities all contribute to more efficient industrial processes.

“As technology continues to advance, web-based HMI is poised to revolutionise the way we interact with and control machines, elevating efficiency and performance in the industrial sector,” Dawbarn tells Machinery Update.

T 0115 822 4863

W www.beijerelectronics.co.uk

Flexco has added the belt edge protector to its line of light duty belt accessories. When attached to the side wall of a conveyor system, this new product effectively manages the workflow of products from chute to belt by preventing packages from jamming under the receiving belt.

Much like many other Flexco belt accessory products, the protector features a seamless installation process. It has been engineered to be fastened quickly to the side wall of the conveyor system with an Install Kit that minimises unnecessary downtime.

Once installed, packages are less susceptible to slipping beneath the belt at the transfer point, reducing belt jams and also product loss.

01274 600942

W www.flexco.co.uk T

Automation distributor RARUK Automation has announced a new partnership with Vention, a deal that enables RARUK to offer Vention’s custom framework solutions for robots to UK customers.

Vention’s products are designed to help manufacturers automate their production floors quickly and to their exact specifications. This equipment complements and will be offered alongside RARUK’s range of Universal Robots

collaborative robots (cobots), Mobile Industrial Robots’ autonomous mobile robots (AMRs) and other automation products. The custom robot equipment can be used to support applications including surface

finishing, bin picking and machine tending, all of which RARUK currently offer as off-the-shelf application solutions.

In terms of mobile robots, Vention also offer top modules and docks for AMRs. Using Vention’s browser-based manufacturing automation platform (MAP), businesses can design their own

automation equipment. As a result of the new partnership, customers will now be able to receive assistance with the design process from RARUK, as it can be completed entirely in-house by the company’s experienced technical team.

Vention’s design library also features a range of framework options, which can be customised or purchased as standard items.

T 01462 670044

W www.rarukautomation.com

IN STOCK EXTRUSIONS ARE 1000 GRADE UHMW POLYETHYLENE

Aleading contract development and manufacturing company approached RNA Automation to design and develop a fully automated quality control and machine vision inspection system to feed, orientate and inspect pharmaceutical ferrules at a speed of 200 parts per minute.

Increase productivity without losing safety: With us as your partner, you can benefit from safety solutions that make your processes run smoothly, enable humans and machines to work as a team and push the boundaries of what is achievable. Turnkey solutions, safe robots and mobile platforms, outdoor safety and digital solutions thus become one big whole. We think that’s intelligent. www.sick.com/safe-productivity

RNA suggested its MK360 glass disc vision machine which has been developed specifically for 360-degree quality inspection with a novel approach to inspecting items through the use of a rotating disc.

The ferrules are fed from a vibratory bowl feeder onto a conveyor system and fed individually onto a rotating glass disc, where they are presented to the 3-camera system.

Component parts are checked for roundness and diameter of the ferrules, and for anodised/non-anodised surface finish.

An air blast complete with control solenoid valve removes individual ‘good’ components from the disc into a chute; remaining ‘reject’ components continue round the disc being gently ejected from the wheel down a chute into a collection box.

0121 749 2566

W www.rnaautomation.com

Arnott Conveyors has delivered a bespoke conveyor system for confectionery company Plamil to help the family business complete part of its investment plan to add to its B2B chocolate business.

Arnott is a well-established partner with Plamil, having previously worked on the collaborative design and manufacture of a specialised conveyor with the Plamil team for one of the main production lines. This led the company to work with Plamil again, this time to design, develop, build and install a new custom-built conveyor system to increase the variety range and delivery formats of its chocolate production.

Arnotts supplied a similar conveyor about four years ago, but the new 2023 version is double the size of the original conveyor providing a significant increase in the production capacity.

Plamil has been on a three-year expansion journey – with an advanced refinery, its capacity has increased in this time and production is now expanding to meet some of the growth in ingredients and materials capacity.

The new (Chocolate) Drop Line will process up to 6 tonnes per day and will become the main production line for core products, freeing up the existing, smaller line for its range of customer bespoke varieties and smaller volume lines. Indeed, this new facility

will increase volume output by 30-40%. And to deliver this, the new conveyor is a critical component of the expansion.

The new line uses some specific manufacturing processes that are unique to the products at Plamil (and as such have an element of sensitivity in terms of disclosure). However, what can be shared is that the performance and reliability of the Arnott conveyor was critical to the timings and speed of the overall production process, a fact that has been central to its design.

In this multi-phase project for Plamil, the supply of the Arnott conveyor was only one element. With new buildings, factory upgrades, new equipment and other elements to manage and deliver, it was recognised that Arnotts’ flexibility in terms of delivery and install would be a valuable asset. And it has allowed the Plamil team to focus on other areas of the project, safe in the knowledge that Arnott would always flex and deliver.

“The design process with the team at Arnotts has been great – they have been able to translate non-technical input into excellent solutions for us,” says Adrian Ling, ceo of the growing vegan business. “The control and reliability of the Arnott conveyor system is excellent; it runs 24/6 with absolute minimal downtime.”

T 01604 882232

W www.arnott-conveyors.co.uk

• Proven technology

• Sturdy robust design

• Quick and easy set up between size formats

• Supplied in either tape or hot melt application

• Various options available

• UK engineering support/install

modular case erector capable of up to 30 erected cases per minute

The growing e-commerce sector demand requires automatic parcel handling Systems, especially for the last mile, and the new eSorter system combines a Nerian 3D stereo vision system from Allied Vision, neuronal networks and robotics.

In operation, incoming parcels are dumped and channelled to a conveyor. The 3D vision system and neural network detect individual parcels and their position before a robot picks each parcel individually and orients it correctly on an output conveyor.

The eSorter system is equipped with a Nerian 3D stereo vision system. The 3D system consists of the Karmin3 stereo vision camera, which is connected to SceneScan Pro, Nerian’s stereo vision sensor. An additional, LED-pattern projector adds texture to the measurement objects and improves the 3D results on almost any surface.

The projector is triggered

simultaneously through the SceneScan Pro system.

The stereo vision system provides up to 135 fps or can process up to 6 MP.

Meanwhile, a neuronal network segments and detects the parcels.

Learning is done with photo-realistic synthetic data, enabling access to all scene information (parcel dimensions, pose, materials) as well as a fast and unlimited amount of training data. The network training must be supported by real data to close the simulation-reality-gap.

The 3D pose estimation of the bounding box is calculated and then sent to the robot parcel handler.

The Nerian SceneScan Pro is a 3D stereo vision sensor which connects either to Nerian’s Karmin3 stereo camera or two Alvium USB3 cameras in order to get a fully functional 3D stereo vision system. With the USB3 camera support, it is a very flexible sensor which allows configuration and adaption to almost any application.

T 01428 748874

W www.alliedvision.com

When TNA Solutions partnered with Mister Bee Potato Chips to improve its snack production, the redesigned and optimised manufacturing site achieved a 400% capacity increase.

Working closely with Mister Bee’s operations manager, TNA’s engineers identified critical process improvements and proposed a tailored solution to ensure that the revamped facility was optimised for efficiency and productivity ahead of the integration.

Once the space was mapped out, the installation of the TNA robag 3ci, vertical form, fill and seal (VFFS) packaging system, followed. Equipped with the rotary double jaw and patented stripper tube closer, the unit is capable of speeds up to 150 bags per minute (bpm).

“Previous machinery could only run 20-25 bpm, whereas now with my new TNA machines, I can run 100-115 bpm,” says Mary Anne Ketelsen, president of Mister Bee. 0121 628 8900

T

W www.tnasolutions.com

HSV Sonder-maschinenbau is now using Herma 500 label applicators on its filling and packaging lines thanks to their Profinet interface, online configurator and modular design.

The German firm develops and manufactures complete systems, from the removal of the filling goods from drums to the finished pallet with the packed containers such as cartridges, for products as diverse as 2-component adhesives and impression

materials for dental applications to a special adhesive used to affix car windscreens.

“Our filling and packaging plants are highly automated,” says Waldemar Hert, managing director of HSV. “And because batch sizes are getting smaller and changeover processes are increasing, we try to eliminate the human factor as much as possible.”

For label applicators,

The labeller is integrated easily in units

applicator into our own control architecture and with other suppliers, the interfaces often have to be created with a great deal of programming effort, if it’s even possible at all.”

the company now relies exclusively on the Herma 500. “Having a Profinet interface is extremely important for us,” he explains. “This allows us to completely integrate the

The online configurator that Herma has developed is also an advantage for HSV. “In it, we can pre-configure the applicator, including the stand, as we need it,” says HSV operations manager Jörg Leonberger.

T 01440 763366

W herma-labellingmachines.co.uk

When provider of hot-holding and food-to-go solutions

Flexeserve needed to optimise its operations to increase throughputs due to the rising demand for its products and services, it turned to LAC Logistics Automation. The specialist materials handling company has delivered a tailored solution that includes mechanised production lines equipped with an inline automated pallet conveyor system.

Before implementing the automated solution, Flexeserve encountered several obstacles that hindered their efficiency and productivity.

Manual handling of products, reliance on pallet trucks for movement between operators, and the need for repetitive tasks resulted in time-consuming operations. These manual processes also required operators to perform strenuous movements, leading to reduced efficiency and increased fatigue.

VMECA

BRINGING

fatigue. A work complete button was implemented to signal task completion, enabling seamless co-ordination between the operators. Buffer stations minimised operator wait times, while the unload station facilitated manual offloading after final assembly.

The optimised assembly line means Flexeserve delivers its services quicker that effectively addressed Flexeserve’s challenges. The customised solution featured a range of handling components, including a pallet loading ramp, heightadjustable workstations, buffer stations, and an unload station. These elements ensured the smooth and independent progression of products through the production line.

disrupted the flow of the product, contributing to longer cycle times. Additionally, waiting times between operations further decreased operator productivity and overall production rates.

To address these issues, the primary objective was to streamline operations, minimise waiting times, improve production rates, and establish a continuous flow in the assembly line.

LAC delivered a pallet conveyor-based production solution consisting of two mechanised lines

The height-adjustable workstations allowed operators to easily adjust the height using automated controls, reducing strain and

With safety measures in place, the CE certified system also accommodated different pallet types. Each line, integrated with a scissor lift, achieved a throughput of 60 pallets per 8-hour shift, surpassing manual operations. Overall, the project successfully improved productivity and efficiency in the assembly line, fulfilling the desired objectives.

Today, the streamlined production lines, heightadjustable workstations, and buffer stations have improved efficiency, reduced cycle times, and minimised operator fatigue.

T 0115 975 3300

W www.lacconveyors.co.uk

VMECA’s Eco Turtle Pumps reduce energy consumption by up to 90%. This Eco version is electronic and automatically controls the vacuum level between two set points: high and low – these high and low points are manually adjusted on the Turtle Pump controls. This device offers huge energy savings over continuously running electric vacuum pumps.

• Air Saving Kit + vacuum switch + 2 x control valves

• Built in air saving function blocking air consumption when vacuum is reached

• Can be installed with all Turtle Pumps

• Easy and convenient wiring with 1 x M8X6PIN connector and wiring cable

product specialist and UK agent for over 15 years. Vacuum challenges? Simmatic has the solutions.

PNEUMATICS AND VACUUM TOGETHER

PepsiCo bottler MenaBev has utilised Sidel’s experience to deliver seven new bottle formats across two PET lines. Sidel worked closely with MenaBev to convert two Combi PET lines in just one week at its vast MEGA Plant in Jeddah. The quick, efficient and sustainable transition resulted in improved line performance, with deliverables including a new lightweight design for the iconic Aquafina brand. Both projects entailed a wide scope of work to ensure that one of the Combi PET line adaptations catered for three new-look Aquafina formats, while the other could run four new Carolina formats.

ONE OF THE MOST TRUSTED SYSTEMS INTEGRATORS IN THE GLOBAL PACKAGING INDUSTRY

Iconic brand bottle

Although challenged by market-wide component shortages, these two line conversion projects resulted in an optimised workflow and the fast delivery of the parts required. The separate Combi PET lines were both successfully adapted in just one week, respectively. In addition, Sidel’s engineers were able to maximise production performance. The Aquafina line is now capable of running up to 60,000 bottles per hour (bph) compared to its previous figure of 54,000 bph, while the Carolina line has maintained its optimised speed of 48,000 bph.

T 01707 292820

W www.sidel.com

n Full system automation and integration

n Over 800 robot installations globally

n Compact, flexible footprints

n Speciality applications for bags, drums and bales

n Multi-line picking and palletising solutions from a single palletiser

n Sub 0°C freezer environment package options

AGerman salad dressings producer for wholesale has switched to a Mitus metal detector with flexible MiWave modulation from Minebea Intec to reduce erroneous product readings and therefore increase productivity.

Before the finished salad dressing is approved for order picking, the product is checked for metallic foreign objects. This is equipped with the flexible MiWave which generates a variety of modulated frequencies in the transmitter signal, which can then be separated and evaluated using an intelligent algorithm.

Thanks to its high level of detection sensitivity, the metal detector is able to detect and show even the smallest metal contaminations despite a high product effect. But it’s not just the high

detection sensitivity that has impressed customers, it’s also the ease of use of the metal detector, says Minebea.

“I am very happy with the Mitus as it has a high level of detection sensitivity despite high product effects, which has also been demonstrated using our test cards,” said the German manufacturer. “This gives me great certainty that I can quickly and reliably detect any potential metal contamination in my products.”

T 0121 779 3131

W www.minebea-intec.com

Condiments and soups mixed at Baxters Food Group’s Colchester mixing plant are all now back on track following the speedy installation of a new drive by ABB Value Provider Gibbons. A sudden failure on a 750-kilo batch sampling machine used for mixing sauce and dressing recipes threatened potential downtime and lost production. An unexpected failure to a non-ABB drive used to control the machine’s 8.5 kW motor was discovered at the start of what was supposed to be a busy morning shift of batch tests. Since the drive delivers the close control required for mixing the products,

the machine cannot run without it in operation. Gibbons, an ABB Value Provider, were on-site within two hours of the failure being reported and had a suitable replacement ABB drive in stock. It was installed and commissioned by the same afternoon. Once installed, Gibbons optimised the ABB drive to ensure that it was operating at maximum efficiency while delivering the speed range required, and also provided training to Baxters’ engineering team to familiarise them with the drive’s controls.

T 01908 350300

W www.abb.com

Norgren has collaborated with agri-tech start-up Singrow, a genome and precision agriculture business, to drive operational efficiencies, including significant energy savings at its strawberry crop vertical farm facility, based in Singapore.

As a result of implementing Norgren’s control technology, including visualisation tools and system connectivity to oversee irrigation, lighting and ventilation functions, Norgren has delivered a 40%

reduction in energy costs for Singrow –helping the business with its cost base while delivering a more sustainable operation.

Committed to new and sustainable crop production, Singrow’s genome and precision agriculture platform cultivates, grows and distributes produce under controlled conditions by leveraging a deep understanding of plant genomes to improve crop

nutrition and yield with varieties that are disease and climate resilient.

To support Singrow’s sustainability aims, Norgren’s digital multimedia valve

technology, intelligent temperature, and light intensity sensors, as well as data acquisition solutions, provide visualisation and connected system control management so Singrow’s critical processes such as energy use and water consumption are continually monitored, controlled and resource deployment optimised within the growing chambers.

T 01543 265000

W www.norgren.com/en

The manufacturing industry is under pressure to improve sustainability which involves many changes, including the addition of sustainable features on equipment or to services. Responsible supply chain management also plays a vital role.

ISO 14001 is the most widely recognised environmental management system (EMS) standard in the world, and supply chain sustainability is a key outcome. By achieving ISO 14001 certification, an organisation can demonstrate to stakeholders its commitment to prevent pollution, to fulfil its compliance obligations and to strive for continuous improvement of environmental performance.

The main features include:

Strategic Environmental Management

A requirement to understand the organisation’s context is vital to identify and leverage opportunities for the benefit of both the organisation and the environment. Particular focus is on issues or changing circumstances related to the needs and expectations of interested parties (including regulatory requirements) and local, regional or global environmental conditions that can affect, or be affected by, the organisation. Once identified as a priority, actions to mitigate adverse risks or exploit beneficial opportunities are integrated in the operational planning of the EMS.

Leadership

To ensure the success

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE David Goodfellow UK BUSINESS ASSURANCE MANAGER AT TÜV SÜD

of the system, specific responsibilities are assigned to those in leadership roles to promote environmental management within the organisation.

Protecting the environment

The expectation on organisations includes a commitment to proactive initiatives that protect the environment from harm and degradation, consistent with the context of the organisation. ISO 14001:2015 does not define ‘protect the environment’ but it notes that it can include prevention

services, an organisation will need to extend its control and influence on the environmental impacts associated with product design and development to address each stage of the lifecycle, ie acquisition of raw materials, design, production, transportation/delivery, use, end-of life treatment and final disposal. This does not imply a requirement to do a lifecycle assessment.

Outsourced processes

Organisations must effectively control or influence outsourced processes.

Reflecting the evolution of computer and cloudbased systems for running management systems, the standard incorporates the term ‘documented information’. To align with ISO 9001, the organisation retains the flexibility to determine when procedures are needed to ensure effective process control.

of pollution, sustainable resource use, climate change mitigation and adaptation, protection of biodiversity and ecosystems etc.

There is a clear emphasis with regards to continual improvement, from improving the management system to improving environmental performance. Consistent with the organisation’s policy commitments, it would reduce emissions, effluents and waste to levels set by the organisation, where applicable.

In addition to the requirement to manage environmental aspects associated with procured goods and

The development of a communication strategy with equal emphasis on external and internal communications is required. This includes a requirement to communicate consistent and reliable information, and to establish mechanisms for persons working under the organisation’s control to make suggestions for improving the environmental management system. The decision to communicate externally is retained by the organisation, but the decision needs to consider the information reporting that is required by regulatory agencies, as well as the expectations of other interested parties.

While accredited certification to ISO 14001 is not a mandatory requirement, manufacturers can reap many benefits by adopting and implementing the system. With organisations under increasing scrutiny from stakeholders to minimise their environmental impact, ISO 14001 certification demonstrates a strategic commitment to continuous improvement.

The standard uses the High Level Structure (HLS) for Management System Standards (MSS), which is a common framework for ISO management system standards, incorporating identical core text and common terms with core definitions.

By providing a best practice approach, ISO 14001 sets out the requirements for an EMS to help organisations improve their environmental performance.

i For more information contact W www.tuvsud.com

TÜV SÜD Product Service is the PPMA’s technical and legislative partner

ISO 14001 is the most widely recognised environmental management system (EMS) standard in the world, with supply chain sustainability a key outcome. Here, we outline its main features…

By setting out the requirements for an EMS, the standard helps to improve firms’ eco performance

• HIGH SENSITIVITY TO ALL METALS

• INTEGRATED CONTROLS for line speed and rejection

• HIGH IMMUNITY to environmental interference

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

Welcome to our 70-page PPMA Show preview in which you will find details of a vast range of equipment and services to help you plan your visit to the NEC, Birmingham in September (26 – 28).

As well as finding smart new technology being demonstrated, you can also set aside some time to listen to the three-day seminar programme which includes a keynote speech each day.

On Tuesday 26 at 11am, you can listen to the founder of Proper Snacks Cassandra Stavrou MBE who will share her entrepreneurial journey including some takeaway ‘rules for business’ and

Show opening times:

Tuesday 26 Sept: 9.30 – 5pm

Wednesday 27 Sept: 9.30 – 5pm

Thursday 28 Sept: 9.30 – 4pm

W www.ppmashow.co.uk

the importance of innovation in processing and packaging machinery.

At 11am on the Wednesday, the industrial IoT lead for manufacturing at Amazon Web Services Dimitrios Spiliopoulos will be joined by Philip Hooker, VP strategic programmes at Cumulocity IoT for their seminar called Packaging Transformed: AI, IoT and smart industrial innovations. In this joint presentation they will share their vision and expertise in empowering packaging and processing enterprises to tackle critical smart production and smart connected product

challenges head-on.

On the Thursday at 11am, Ross Verrall, EMEA services lead for artificial intelligence at NVIDIA EMEA Enterprise Services will talk about enabling the future with accelerated computing – from ChatGPT to robots. NVIDIA’s Full Stack Accelerated Computing Platform is allowing people around the world to do their life’s work, which until recently was considered impossible or decades away. Verrall will give a high-level overview of recent advancements as he believes business leaders must be aware of and fully evaluate

accelerated computing and how it will impact their business and industry.

A host of other topics will be covered throughout the three days including business sustainability management –what does it all mean? what is the real value of protecting your IP? sales –it’s a process too; food safety requirements; UKCA marking; inventory management, strategic automation strategy and much more…

And don’t forget to register to ensure a quick and easy entry into Hall 5 at the NEC. See you there!

W www.ppmashow.co.uk

At this year’s PPMA Show, visitors to the BW Flexible Systems’ stand will be able to discuss how its range of equipment delivers successful and effective results to meet individual customer objectives. Visitors can also find out about its three new flow wrappers that are currently in development and that will be available soon.

The company offers over a century of combined experience through its brands that include Hayssen, Rose Forgrove, Sandiacre, Simionato and Schib. It says its innovation pipeline is chock-full of ongoing projects that meet the objectives of streamlining the equipment and reducing maintenance costs while offering more options to customers.

Visitors can discuss the CM Verus machine series that are ideal for fresh produce and salad applications. Its high-performance design with high-speed continuous motion optimally addresses

food safety packaging requirements and offers a variety of bag style and re-close options. Changeovers are quick, film threading is simple, and the HMI is intuitive.

In fact, the CM Verus series of HMI upgrades have resulted in faster learning curves, easier navigation for troubleshooting along with animations and videos to offer support during changeovers and also explain basic maintenance tasks.

Stand visitors can also talk about the new Hayssen Mini,