A need-to-grow basis

Our fresh produce feature assesses the latest technologies helping this dynamic sector expand and automate despite labour shortages, tight margins and quality requirements

Lined up for the second half of June are the Automation UK show and Machine Vision Conference co-located in the CBS Arena in Coventry and organised by Automate UK

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

NEW MACHINERY

An x-ray system developed by Ishida is said to have resolved the difficulties of inspecting small flow-wrapped bars which are often extremely light and produced at very high speeds Find out more on page 12

INSTALLATIONS

Under-utilised and new equipment combines for Aston Manor to transfer an out-of-house operation in-house

Check out the new branding for Automate UK on the website and learn more about the goals of the renamed association www.automate-uk.com

INSIDE NEWS

NEWS PLUS

Issue 3, Volume XXXV, May/June 2024

The machinery only journal for processing and packaging; robotics and vision systems

COMPLETE END-OF-LINE PACKAGING SYSTEMS HIGH-SPEED PACKAGING LINES SHRINK WRAPPING SLEEVE WRAPPING TRIMSEALING CASEERECTING &CASETAPING PALLET WRAPPING E-COMMERCE AUTOBAGGING FLOW WRAPPING FEEDING& SEPARATION SYSTEM SPIRAL WRAPPING www.adpak.co.uk 3PENDLESIDE,LOMESHAYEINDESTATE,NELSON,LANCS,BB96RY Tel:01282601444 | Fax:01282612201 | info@adpak.co.uk ADPAK CAN DELIVER END OF LINE PACK AGING SOLUTIONS TH AT ARE RIGHT FOR YOU

May/June 2024

18 SPECIAL FEATURE

As the clock ticks down to the June opening of these bigger, better co-located events, this preview aims to set the scene

23 INSTALLATIONS

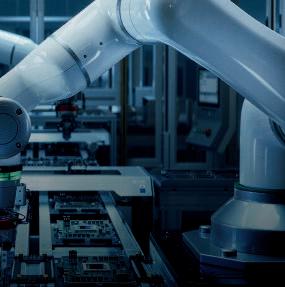

A Greek pharmaceuticals plant has installed eight robots from FANUC to automate packaging sterilisation for key products

29 SPECIAL FEATURE FRESH PRODUCE

An overview of some of the key technologies helping suppliers in this hard-pressed sector to run more efficient operations

48 SPECIAL FEATURE VISION 2024 PREVIEW

10 REGULATIONS

BENEFITS OF

50 COMPONENTS

Ensuring that mobile robots operate safely is important as never before, with standards from ISO requiring that users check the performance levels of safety functions and work to reduce risk as far as this is possible. So, for example, an automatic guided vehicle at risk of colliding with humans will require speed control, as well as personnel detection

Apex Dynamics has launched a servo worm gearbox said to offer low backlash, low noise and an extended service life, whether for use in processing, packaging or other equipment

54 WHO WHAT WHERE People, events and diary dates

56 MACHINERY FINDER Members’ machinery and services

Excellent appearance On-pack promotion with printed film Cost reduction Closed packaging No heat radiation Efficiency Ease of operation Flexibility Low maintenance Easy opening with tear tape Biodegradable film & paper

EDITOR: Paul Gander paul.gander@automate-uk.com

PUBLISHING MANAGER: Bill Lake bill.lake@automate-uk.com

HEAD OF PUBLISHING: David Chadd david.chadd@automate-uk.com

E-MAIL ADDRESSES: publishing@ automate-uk.com ppmashow@ automate-uk.com

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from speci ers, managers and purchasers of processing and packaging machinery in the UK.

SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

PRINTED BY: John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 3

AN AUTOMATE UK PUBLICATION PPMA Ltd New Progress House, 34 Sta ord Road, Wallington, SM6 9AA TEL: +44 (0) 20 8773 8111

23 REGULAR FEATURES 7 NEWS 12 NEW MACHINERY

Contents

AUTOMATION

UK AND MVC PREVIEW

36

ANNUAL

ISSN

0969-4145

THE

IMPROVE OVERWRAP your products Over 10,000 machines sold world-wide! 01256 896930 sollas.com your sales, Sollas MU S-O 2021 artwork

OVERWRAPPING:

n Accurate up to 0.5%

n Gear or Peristaltic Pump available

n 0.5ml to 5ltr Fill

n Torque Transducer available with an accurate resolution of 0.01%

n Easily situated and integrated into already functioning packaging lines with zero disruption

n Torque Transducer available

n Trigger Spray Orientation

Automated Capping & Filling Specialist

Micro Mono Capper & Filler

n Smallest footprint filling and capping solution on the market

n Fully Intergratable with additional packing equipment, such as printers, labellers, collection tables etc

n Can be upgraded to a fully automatic system

n Accurate Fill up to 0.5%

n Torque Transducer

Unit 42, Monument Business Park, Warpsgrove Lane, Chalgrove, Oxfordshire, OX44 7RW T: +44 (0)1865 891466 E: sales@capcoder.com www.capcoder.com 01865 891466

CC570 Capper Fully or Semi Automatic Scan for more information

Deltafill Bench Top Filler

Fully or Semi Automatic Mini Production Line

Automate UK matters

Putting the ‘entice’ into apprenticeship

James Causebrook CHAIRMAN, AUTOMATE UK (INCORPORATING PPMA, BARA AND UKIVA)

We should always welcome any attempt to channel more attention – and nance – towards apprenticeships.

The announcement that, from the start of April, the Government is fully funding small-business apprenticeships for anyone up to age 21 has been noted with satisfaction by Automate UK members (p8).

There are encouraging signs that the £60 million of new funding ‘for next year’ will not be a ash in the pan. Whichever of the main parties is in power by the end of the year, they seem likely to give apprenticeships the respect they are due.

Although its bene ts have never been maximised, the UK in fact has the ingredients of one of the best apprenticeship systems internationally. The fact that options range from schoolleaver entry to MSc and MBA-equivalent level is remarkable.

The new emphasis on small business is important to Automate UK members and their customers. Today, a two-person start-up may be generating as much innovation as the largest international company. Maybe counter-intuitively, smaller businesses will o en give apprentices a far more broadly-based skillset, while in a larger company, specialisation may lead to tunnel vision.

A single-tier system could well repay the cost of each apprentice through tax within just four years

Though new funding can help, the focus really needs to be on working as a collective community to ensure that apprenticeships are leveraged to the advantage of everyone in the supply chain, from the consumer goods manufacturer to the machine parts or so ware sub-supplier. We at Automate UK aim to drive this narrative.

Di erent routes are available to nurture this kind of skillsbased community. Europe has already blazed a trail with the concept of the apprenticeship cluster, grouping di erent companies with complementary technologies, and an experimental prototype is already up and running in the UK. Watch this space.

The Government announced that up to 50% of the Apprenticeship Levy, paid by larger companies with an annual wage bill over £3m, can now be transferred to other businesses. But a uni ed approach that did away with the levy would be simpler to access and would pay for itself with each full-time engineering role it creates. A single-tier system could well repay the cost of each apprentice through tax within just four years. n

The CTS combines multiple functions into one switch with its patented FlexFunction principle.

HIGH LOCKING FORCE OF 3,000N IN A COMPACT DESIGN

SIMPLE AND FLEXIBLE CONFIGURATION WITH A SINGLE BASE DEVICE ALLOWING DIFFERENT FUNCTIONS TO BE ACTIVATED

INDUSTRY 4.0 READY

INTELLIGENCE TO CONNECT TO IO-LINK THROUGH A CORRESPONDING GATEWAY

MAY/JUNE 2024 MACHINERY UPDATE 5

sales@euchner.co.uk +44 (0)114 2560123 www.euchner.co.uk

UK manufacturing will continue

French acquisition sees opportunities for Yorkshire firm

Pennine Industrial Equipment, based in Huddersfield, West Yorkshire, has been acquired by the French-owned Rondot Group.

Pennine’s range of chains, sprockets, plastic extrusions and plastic machined components will still be manufactured and distributed from the same site. “With major connections and leading partners in related sectors, this new chapter will bring all kinds of advantages through an extensive international network of subsidiaries and offices,” says the company.

The Huddersfield business has a 56-year history and says it is looking forward to a promising future of sustainable innovation and growth as part of Rondot.

Co-located events show indications of increasing confidence across sector

Evidence of keen visitor and exhibitor interest in the two June events organised by Automate UK’s BARA (British Automation and Robot Association) and UKIVA (UK Industrial Vision Association) suggest that con dence is creeping back into the robotics, automation and vision sectors.

natural ow between the two events, building those synergies still further.”

Best Distibutor title rewards continuing shrink film success

Shrink film manufacturer Bolloré has named Yorkshire Packaging Systems (YPS) as its Best Performing Distributor for the past year, adding to the same accolade just two years previously.

“By the end of May, visitor registrations were up 80% on the same time last year.

As a combined event, the show will be at least 50% bigger, occupying a whole hall this year, rather than two-thirds of it,” says Automate UK CEO Peter Williamson.

“In terms of layout, too, we feel we’ve designed in

RANGE OF LED HANDLES WINS INDUSTRY AWARD

Recognition

for Italian design

Elesa’s M 2000-SWM handle with monostable switch and LED indicator light was among the products and services recognised in the latest prestigious awards from Italy’s ADI (Association for Industrial Design) in the ‘workplace design’ category. The accolade confirms the high levels of quality in its technology, says Elesa, already recognised by other international awards.

As well as the latest technology, components and applications, visitors will be able to choose from a dense programme of technical presentations.

Automation UK and MVC 2024 will take place at Coventry’s CBS Arena, 18-19 June – and are previewed here on pages 18 and 20.

Swiss conveying group sees signs of recovery despite dip in its sales

Swiss-based Interroll saw a drop in sales values and order intake during 2023, but believes that the downturn has bottomed out.

While it cannot predict when exactly the market will rebound, there are already positive signs of recovery, it says. “We have the right product and solution portfolio in place,” states CEO of the Interroll group Ingo Steinkrüger.

Sales of its rollers, drives and conveyors were down over 16% year-on-year, it says, with order intake falling by over 9% in a challenging market environment.

Managing director Glyn Johnson has enjoyed representing Bolloré. “The range of their products that we can offer covers so many applications, including specialist requirements, that we always have an ideal shrink film to suit our customers,” he says.

The film supplier is said to be an expert in the manufacture of shrink films for food contact, including ultra-thin and highstrength options. This can mean customers benefit from outstanding presentation with reduced environmental impact, says YPS.

German inkjet supplier wins award nomination

The IQJET continuous inkjet printer from Leibinger has been nominated for the 2024 German Innovation Award. It offers downtime-free production without breaks for cleaning, it says, and the lowest operating costs and environmental impact on the market.

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 7 News

The YPS team toasts its success

Visitors and exhibitors will benefit from co-location

CEO Christina Leibinger is proud

Business welcomes government undertaking to fund apprentices

Fruit cup -

FCX50

NA gentle grip on fresh produce from avocado to zucchini

When picking and handling fruit and vegetables, flexibility is key. You need a suction cup able to handle items with difficult textures and various shapes. Piab’s FCX50 cup is all this.

Flexible bellows for off-axis grips and adaptation as well as multi-lip design to ensure great sealing. This allows using a smaller vacuum pump which saves energy.

ew government undertakings since the start of April to fully fund apprenticeships in small businesses have been broadly welcomed both by Automate UK and member companies.

The allocation of £60 million of new investment to fund “up to 20,000 more apprenticeships” was accompanied by new measures to allow larger companies paying the Apprenticeship Levy to transfer up to 50% of their funds to support other businesses, including smaller companies, in taking on apprentices.

Encouraging interest in engineering FANUC UK was among the Automate UK members applauding the move and Prime Minister Rishi Sunak’s objective of reducing costs and administrative burdens for those businesses with fewer resources.

Head of sales Oliver Selby points to FANUC’s track record in engaging with and training young people.

“Apprenticeships are a fantastic way to ensure that the next generation of engineers has the qualifications, skills and experience to really help them to excel in the workplace,” he says. “It will give UK businesses the support they need in finding, adopting and further developing their future talent.”

FANUC has its own Training Academy which, it says, offers accredited courses that can feed into mainstream education.

News 8 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

www.piab.com info-uk@piab.com 01509 857010

SCAN TO CONFIGURE

Industry report brims with insightful vision

We can help our members says Peter Williamson

Automate UK has published a new report highlighting the challenges and opportunities facing the automation sector in 2024 and o ering insights direct from those members and independent analysts that provided them.

The report is based on this year’s survey of Automate UK members, along with wider industry experts and technology end users. Its conclusions underline the value of innovation and collaboration, while rooting them rmly in the context

of today’s tough business environment.

The report reveals how 2023 saw the continuation and worsening of various challenges that emerged during the pandemic. No fewer than 73% of end users reported supply chain issues as having had the heaviest impact, with deliveries of vital components being disrupted and costs driven up. Contributing factors have included the rise in geopolitical tensions and con ict, cyber-security breaches and the lack of labour – both skilled and unskilled –following Brexit.

Over 80% of respondents cited automation as their main challenge during 2023. A similar proportion shared con dence in continued industry growth, with 67% saying they feel optimistic or very optimistic about the coming months.

“As well as demonstrating the desire of end-user companies for the greater adoption of automation, this report also sets out some of the perceived challenges and barriers to success,” says CEO of Automate UK Peter Williamson. “By identifying these challenges, we are helping our members to work more collaboratively with their customers to break down these perceived barriers for mutual bene t.”

W www.automate-uk.com/ industry-insights-2023-2024/

Strategic alliance seeks applications of cognitive robots in manufacturing

US-based Omron Robotics and Safety Technologies, part of the Omron Corporation, has forged a strategic alliance with Germany’s Neura Robotics, with a view to developing manufacturing applications of Neura’s core cognitive robotics expertise.

The idea is to leverage advanced AI capabilities, says Omron, in order to enhance e ciency, exibility and safety in factory automation. Cognitive robots have the ability to learn from their environment, make decisions autonomously and adapt to changing production scenarios.

“We see Neura’s cognitive technologies as a compelling growth opportunity for

Neura’s technology will ally with Omron’s reach

industrial robotics,” says Olivier Welker, president and CEO of the US company. In particular, he underlines the bene ts of combining Neura’s innovative solutions with Omron’s global reach.

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 9

Regulations

Keeping your mobile robot on a tight rein

Stewart

Paul Laidler

Robinson

To ensure reliable performance and safety, manufacturers, suppliers, integrators and operators must assess and validate robot compliance against a range of di erent standards, as well as considering applicationspeci c requirements.

Automatic guided vehicles (AGV) and automated vehicle systems are becoming increasingly indispensable for automated operations as they provide continuous 24/7 service and can be exibly assigned for a variety of applications, their contribution to increased e ciency and productivity is signi cant. ISO 3691-4:2023

- Industrial trucks – safety requirements and veri cation

- Part 4: Driverless industrial trucks and their systems covers driverless industrial trucks and their systems and is a Type C standard because it contains the safety requirements for a speci c type of machine.

A UNIFIED APPROACH

The standard applies to all stakeholders - machinery manufacturers, integrators and operators - to ensure there is co-responsibility to create a uni ed approach towards AGV safety and risk management. It outlines the safety requirements for driverless industrial vehicles and their systems, as well as how to check that they meet those requirements. First published in February 2020, and further updated last year,

BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

PRINCIPAL ENGINEER AND FUNCTIONAL SAFETY

Only just over four years old, the ISO 3691 standard regarding mobile robot safety is as much about the operating environment as onboard systems and control

this standard is still relatively new to the machinery world.

The standard de nes the performance levels that are required of safety functions, as well as describing the necessary procedures to reduce risk and to enable validation of the automated functions. Three key aspects must therefore be taken into account:

• Operating environment

• Associated hazards and risks

• Correct implementation of safety systems

To give an example, an AGV navigating towards a machine in an operating area with a human presence represents a “collision risk”. According to ISO 3691, this risk may be

humans in a con ned area, the measures are necessary to protect industrial assets from expensive damage.

The condition of the operating environment has a signi cant e ect on the safe operation of a truck, so Annex A must be used to eliminate hazards when preparing the operating zone.

Annex B lists all signi cant hazards, hazardous situations or hazardous events that must be considered during the life of the truck. Not only should this include hazards relevant to the machine when it is being used as intended, this should also cover conditions of misuse that are considered

Current standards have not been designed around the concept of interconnectivity and interoperability

mitigated by using three safety measures incorporated in AGV design:

1. Personnel detection system

2. Speed control system

3. Braking system control

Likewise, in a con ned area, with no human presence allowed, an AGV making its nal approach to a machine for docking may pose a collision risk between two industrial assets. This unsafe docking event risk may be mitigated by using two safety measures incorporated in AGV design:

1. Speed control system

2. Parking braking system control

Although there is no risk for

reasonably foreseeable

by the manufacturer.

The Performance Level (PL), found in ISO 13849, for the di erent safety functions are based on the hazards listed in this annex.

When designing the safety functions, it is vital that the complete system is taken into account so that the interrelationships between the multiple functions of the AGV are considered to optimise safety, for the protection of operators and other assets around them. For example, the AGV’s control system must manage both safety and nonsafety functions, so it must be

taken into account that some safety functions may not only impact safety, but also non-safety functions.

INDUSTRY 4.0 NEEDS

Machinery safety standards de ne a set of general physical hazards that are used during type certi cation. However, current standards, such as ISO 3691-4 have not been designed around the concept of machine connectivity and interoperability. While Industry 4.0 sees reduced risk in several areas, the range and exibility of connected interfaces introduce a new set of risk issues. As production facilities become more complex, operators must manage a rapidly evolving system that incorporates multiple interdependencies, while minimising downtime.

For now, ISO-3691 takes us a step further as it is well aligned with ISO 13849-4. This is a safety standard which applies to parts of machinery control systems that are assigned to providing safety functions. It provides safety requirements and guidance on the principles of design, and the integration of safety-related parts of control systems (hardware or so ware). So, it provides invaluable guidance for carrying out safety assessments for the complete AGV.

i For more information contact W www.tuvsud.com

TÜV SÜD Product Service is Automate UK’s technical and legislative partner

10 MACHINERY UPDATE NOVEMBER/DECEMBER 2021 www.machineryupdate.co.uk

EXPERT AT TÜV SÜD

10 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

New Machinery

X-ray solves riddle of higher-speed bar lines

Highlighting a trend towards systems tailored to meet the needs of speci c market segments, Ishida has launched a space-e cient x-ray unit designed to suit high-speed lines running individual owwrapped products, such as countline bars.

The IX-EN-2493-Compact will t easily on to existing lines, says Ishida, and will keep pace with line speeds of up to 120m per minute, which is double the speed of a typical x-ray inspection system.

A key feature here is the machine’s split conveyor design. Traditional x-ray has a single conveyor with protective curtains to contain the x-ray beam within the machine. But these curtains can interfere with the movement of light, ow-wrapped packs, potentially creating product jams.

In the case of the

Small, high-speed bars are a problem

IX-EN-2493-Compact, the curtains are raised above the conveyor so as not to impede the progress of packs. The x-ray beam hits each pack

as it passes over an aperture in the conveyor, and is captured and contained within two large metal plates.

The options when using x-ray on primary packs of this size used to be very limited, says quality inspection control sales specialist Glen Oxborough.

“The only e ective solution was to carry out the inspection in the secondary packaging, either when the packs were part of a multipack or in their outer cases ready for onward delivery,” he explains. Of course, the implication was that, if a contaminant was detected, the entire multipack or case had to be rejected.

The new system features Ishida’s proven Genetic Algorithm technology, allowing the inspection process to be optimised for greater sensitivity to speci c types of foreign body.

T 0121 607 7700

W www.ishidaeurope.com

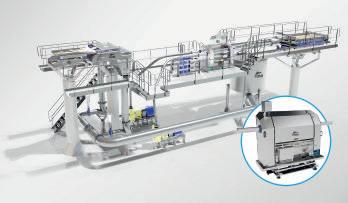

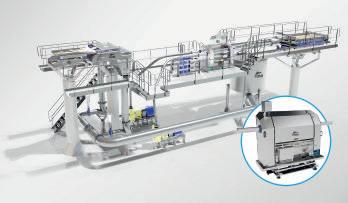

Two-in-one pouch-filling and outer case packing suits flour and powdered foods

Rovema has launched a new line for packing powdered and granulated dry food products into pouches and then into outer cases, in a transporte cient, compact traded unit.

The new extension of the company’s SBS series of machines is said to o er maximum exibility in the smallest of spaces, with versatility in bag design. Filling corn our, Rovema says the system will produce and pack into cases 100 x 1kg ‘block’ pouches per minute,

forming 10 outer packs.

Chief technology o cer Ingo Hamel explains some of the challenges with the SBS Twin.

“The precise co-ordination of primary and secondary

packaging, a well-thoughtout overall layout, and an optimised material ow with the best possible accessibility are crucial,” he says. Rovema planned to launch the machine at Hispack, Barcelona, in the second week of May.

T 01296 310490

W www.rovema.com

Flow-wrapper suits needs of first-time use

BW Flexible Systems has added the Hayssen R300 to its flow-wrap portfolio, bringing together manual product infeed and easy changeovers along with automated adjustments to maximise uptime.

According to BW, the R300 is ideal for wrapping baked goods such as single cookies or pastries.

“The Hayssen R300 was designed with first-time machine owners and operators in mind,” says product line leader Brantley Turner. “It provides a more userfriendly experience compared to other hand-fed flow-wrappers, with features that make this machine easy to learn, set up and use by any operator.”

Key priorities have included minimising the chances of setup error and improving operator ergonomics. With staff turnover rates on the rise, says BW, the more intuitive humanmachine interface (HMI) allows faster learning and onboarding for operators.

The ultra-low roll height facilitates operator access, it adds, and there are simple features to eliminate jaw jams. It has clear guards and an open design to provide better visibility into the long-seam unit, allowing safe and timely troubleshooting.

While the machine is beginnerfriendly, says BW, it offers options for upgrades and further automation, should that be required. The adjustable folding box can suit a wide array of products, in case ranges change.

Additional hygienic design features make the R300 easy to clean. The infeed incorporates an open-channel stainless steel design and sloped pans underneath.

T 0115 967 8787

W www.bwflexiblesystems.com

12 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

The SBS Twin unites pouch filling with case packing

Booster Regulator/Air Tank

Very

SMC - more than just pneumatics www.smc.uk Call 01908 563888 or email sales@smc.uk. Scan the QR code for further info and get in touch with our experts via the details below. Stay in touch on Increase factory air pressure by up to 4 times! Air-only operation requires no power supply, reduces heat generation, and allows easy installation.

Series VBA/VBAT NEW

model with pressure increase ratio 2 to 4 times (VBA11A) No power supply or wiring needed Easy installation

heat generation Air-only operation

Renewed

Low

no electricity is used,

is no impact on cylinders, solenoid valves, etc. Operation is safe because no electricity is used. Simply insert the unit in the air line. Requires far less space than installing the compressor.

is no need to install dedicated electrical wiring.

little heat is generated because

and there

There

Robot cell can integrate a range of small systems

Zimmer Group says its ZiMo exible robot cell o ers cost-e ective and straightforward process automation for small, medium-sized and variable batch sizes, thanks to its compact design and mobile concept.

According to the company, no prior programming knowledge is required when commissioning the system, and the cell can be used with a range of smaller industrial robots or cobots, set up via the Zimmer human machine interface (HMI).

A comprehensive range of accessories and end e ectors is available, including gripper and vacuum tooling or, for example, sensor technology.

MATCH robot modules mean that recon guration is possible without major e ort or expense. Floor scanners can be integrated at each of the unit’s four corners to provide a safe operating environment.

ZiMo combines compact and mobile design

UK managing director

Richard Mason emphasises the bene ts of supporting operators in monotonous, time-consuming tasks without the limitations of shi -length.

“The variable set-up options for the workbench and its compact size make ZiMo a

reliable, exible cell for almost any small robot or cobot application, including loading and unloading of machines, pick-and-place tasks or assembly. Users of the system will bene t from reduced cycle times, enhanced productivity and improvements in consistency and quality.”

Visual and leak checking in one

Vial inspection and leak detection will run in combination

consistency and quality.”

Zimmer points out that the proliferation of cobots over recent years and an increase in the adoption of smaller industrial robots has sparked greater interest in these options for automation. But at the same time, barriers still persist, including perceptions of complexity, investment costs, training and skills requirements. The aim with ZiMo is to address many of those perceived barriers, as well as the real challenges, with many other robot systems, to do with installation and line integration.

T 01283 542103

W www.zimmer-group.com/en/

Syntegon says that, for the first time, the Achema show will see its latest AIM vial inspection system efficiently combine this critical function with leak detection. The AIM5 machine on the stand will twin a pre-rotation tower and camera technology for the visual inspection of liquid and lyophilised products with a finely-calibrated oxygen sensor on the starwheel.

“With the AIM series, Syntegon has been setting standards in the flexible inspection of vials, syringes, cartridges and ampoules for decades,” says director of product management for pharma liquid Tobias Göttler.

Much more will be shown at Achema, which runs from 10-14 June in Frankfurt.

T

01332 626262

W www.syntegon.com

New Machinery 14 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Multiple inspection options can combine in single compact unit

Sealpac is now supplying an All-in-One end-ofline inspection system from Antares Vision Group, bringing together in less than two metres of line space any three inspection modules from a menu of seven, including micro-leak gas detection, x-ray and dynamic checkweighing.

The LDS module from Antares exerts a slight pressure on each pack, allowing the gas inside to escape if there are micro-perforations.

Target molecules of the escaping gas are detected by infra-red or laser spectroscopy, Sealpac explains. Alongside x-ray and checkweighing, metal detection and camera recognition can be speci ed as one of the three technologies built into the same space on the line.

The system is uniquely compact

Managing director of Sealpac UK Kevin Witheford calls the development a “major step-change”.

“There’s nobody who can put three of those technologies in one machine that is less than two metres,” he claims, adding that most checkweigher and metal detector combos on the market measure more than this together.

He points out that, when line equipment has to move to accommodate larger combined inspection systems, services also have to be reconnected.

T 0845 302 3056

W www.sealpac-uk.com

It’s important to look beyond the short term, which is why Krones is working on “Solutions beyond tomorrow”. Beverage filling lines, digital services and plastics recycling: Krones’ innovative solutions combine superior performance with sustainability. Machinery

Shaping the future together

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 15

krones.com

Update, Sustainability, 149 x 225 mm, CC-en53-AZ067 03/24

New Machinery

French fries can be cut at maximised capacity

TNA solutions has presented its new hydro cutting system for french fries, the conti cut, which it says can easily deliver against the industry’s highest output capacity requirements of around 30 tonnes per hour.

Global sales manager for processing Twan van den Berg quotes GlobalData gures for this dynamic category.

“With the global French fries market set to grow to over $40bn in terms of value by 2027, our customers require solutions that deliver maximum capacity and the highest levels of e ciency and uptime,” he says.

The conti cut features an integral ‘switcher’ which, says TNA, favours e ciency by working with the designated alignment tubes and integrated, interchangeable knife blocks. It will, for example, achieve the longest cut size possible while allowing di erent shapes, such as sticks, wedges and slices, to be created. The smooth cut surface is said to reduce oil

pick-up and fat content. With the use of a owmeter or pressure transmitter on the switcher, blockages caused by broken knives, for example, or stuck product can be readily detected, says TNA.

The switcher automatically rotates from one knife block to another, allowing the operator to remove any clogging.

“Compared with a mechanical cutter, where centrifugal force is used to drop potatoes randomly on to a high-speed rotating cutting head, the TNA conti

cut hydro cutting system uses the alignment tube within the switcher to ensure the potato is consistently positioned lengthways to produce a longer cut,” says van den Berg. The conti cut system, which was presented at the Anuga FoodTec show in Germany, demonstrates the company’s in-depth understanding of the balance required to satisfy consumers and retailers while keeping brands pro table, he says.

T 0121 628 8900

W www.tnasolutions.com

Medical test automation meets system needs of high accuracy, variable volumes and speed

Festo has teamed up with integrator QM Systems to develop new automated equipment for the lling, capping and labelling of test vials at speeds of up to 3,000 vials per hour.

Festo was approached by a customer working with a respiratory testing product, demanding not only high speeds but also reliable traceability back to individual patients.

“The challenge with this project was the ne

tolerances, tight accuracies, variable dispense volumes and high throughputs,” says commercial director at QM Kristian Richardson.

QM designed the line based on Siemens control. The Festo handling system li s each vial and lines it up vertically, before presenting it to the dosing head for lling. A cap is applied using torque monitoring to ensure the lid is tted correctly. The vial then shi s to the horizontal and is presented for labelling.

T 0800 626422

W www.festo.co.uk

Robot runs box erecting and loading

TM Robotics has worked with Finnish machine builder Orfer to develop a compact robotic system which opens flattened cases, folds the flaps, seals the base and fills them, all within a single cell.

The Orfer BoxCellPlus goes one step further than the existing BoxCell system, adding case erecting and taping to its functions. The Finnish company has worked since 2004 with TM Robotics, a key distributor of systems from Japan’s Shibaura Machine, formerly Toshiba Machine.

CEO of TM Robotics Nigel Smith worked with Orfer on the robot specification, considering features including reach, payload and cycle time. In the end, he recommended standardising on the Shibaura Machine TH650A high-speed SCARA robot for both BoxCell variants.

Smith ruled out a six-axis or spider-style robot. “Packing is a classic pick-and-place application,” he explains. “It doesn’t require the dexterity of a six-axis robot, and needs a greater working envelope than a spider-style robot offers.

“Shibaura’s SCARA robots can reach as far as 1.2m, but the TH650A is one of our bestselling robots due in large part to its reach of 650mm, which is closely equivalent to the reach of the human arm.”

Again, in terms of payload, the manufacturer’s SCARA robots can lift up to 20kg, but the TH650A’s 10kg is considered ideal for most food packaging applications.

T 01707 290370

W www.tmrobotics.co.uk

16 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

The switcher system will ensure the potato is always positioned lengthways

Festo’s EHMD applies preset torque to caps

Weigh, Label, Inspect

The new product VisioPointer® is one of ree new Vision Inspection products from Minebea Intec and fur er enhances e already popular inspection portfolio. It is also one of e key products at helps drive automation wi in food production and manufacturing. Combined wi e Automatic Weigh Price Labeller WPL-A customers can automate eir entire end of production line where labelling plays a significant part of e manufacturing.

The new product VisioPointer® is one of ree new Vision Inspection products from Minebea Intec and fur er enhances e already popular inspection portfolio. It is also one of e key products at helps drive automation wi in food production and manufacturing. Combined wi e Automatic Weigh Price Labeller WPL-A customers can automate eir entire end of production line where labelling plays a significant part of e manufacturing.

2670

Crescent Birmingham Business Park, Solihull Parkway

Birmingham B37 7YE Phone

Minebea lntec UK Ltd.

Kings Court, The

I

+44.121 779 3131 | Email sales.uk@minebea-intec.com

food safety and e ciency

Ensuring

2670

Birmingham Business Park, Solihull

Phone

and e ciency

Minebea lntec UK Ltd.

Kings Court, The Crescent

Parkway I Birmingham B37 7YE

+44.121 779 3131 | Email sales.uk@minebea-intec.com Ensuring food safety

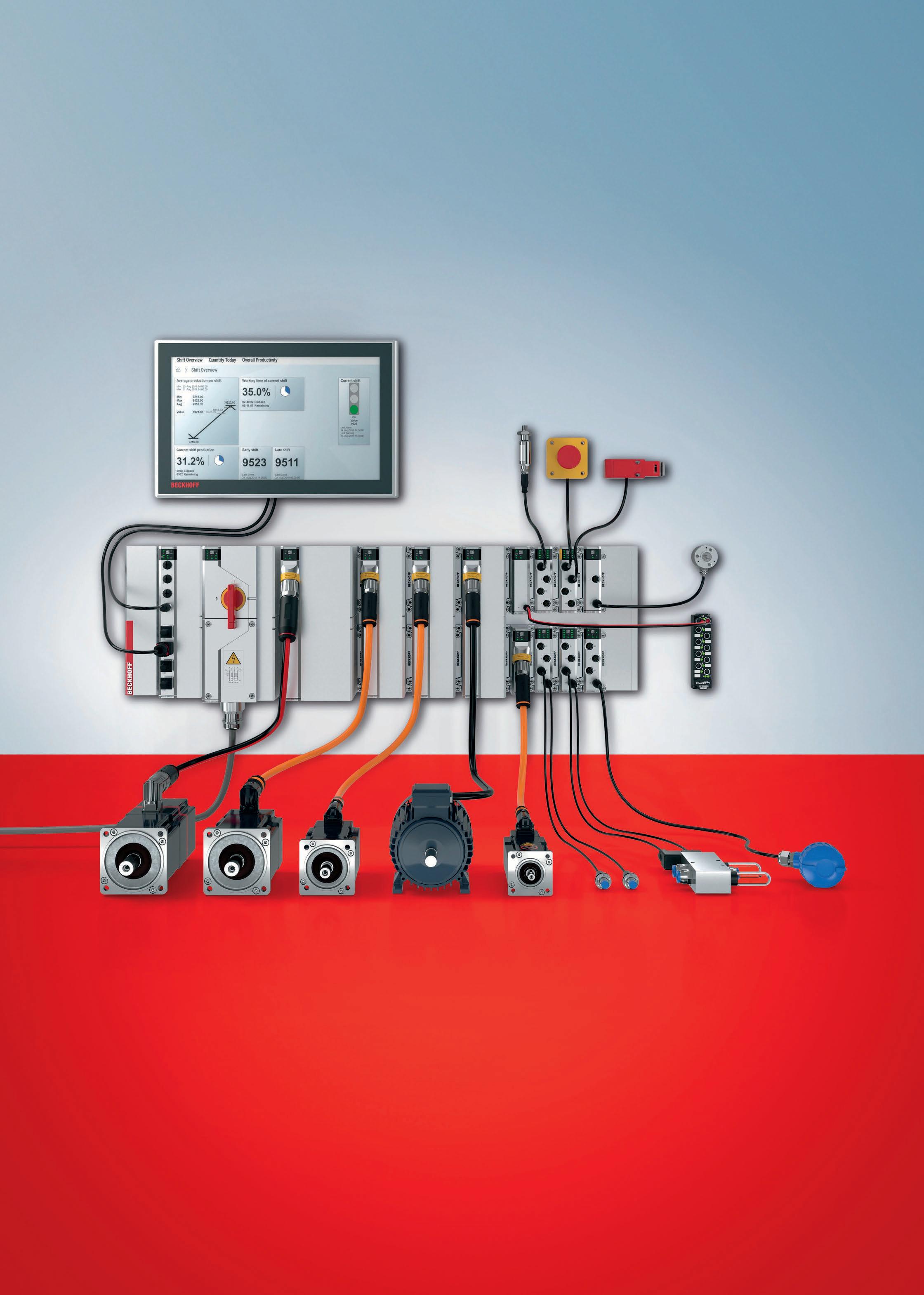

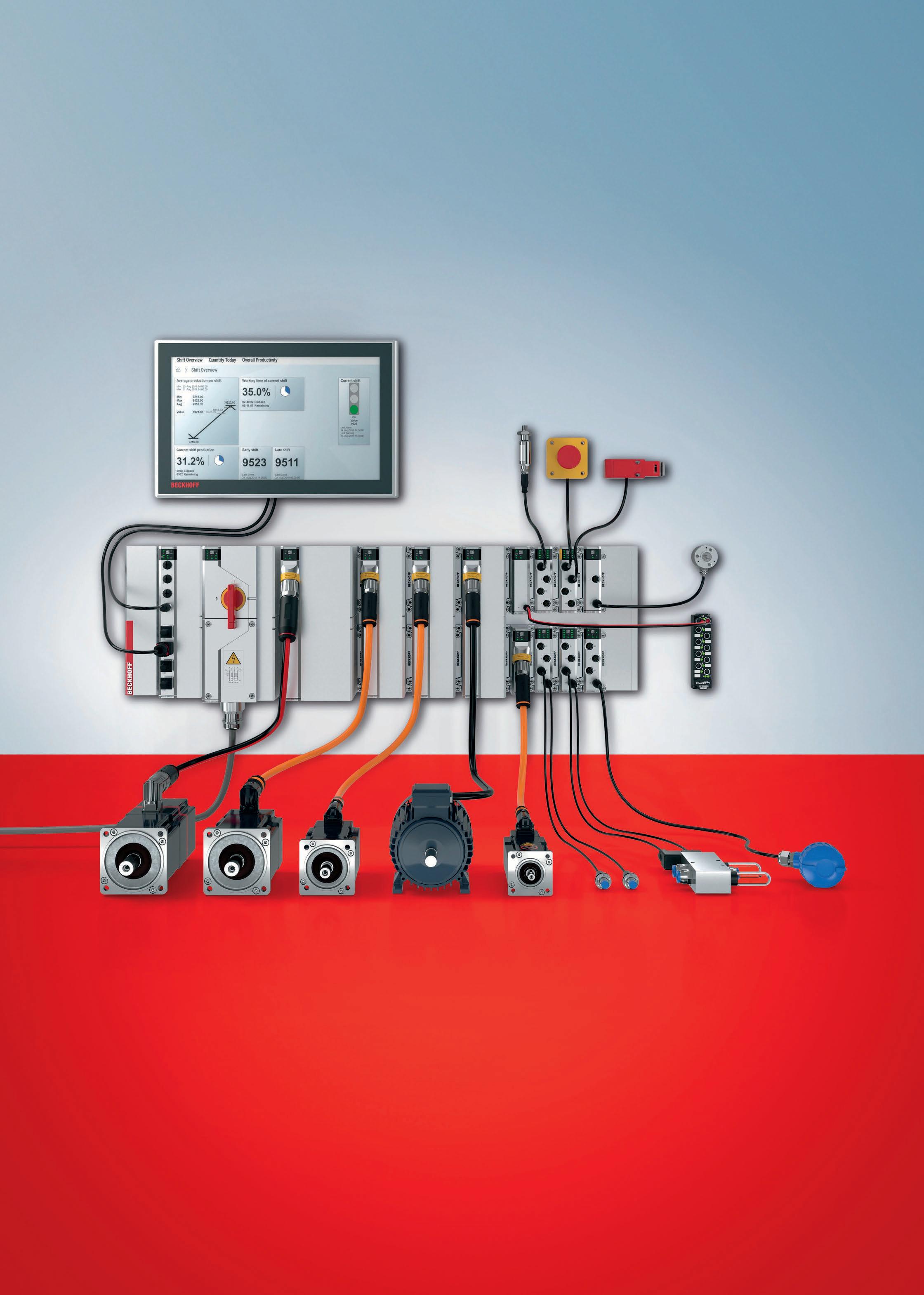

Automation UK sets out to close technology gaps in just two days

This June, Automation UK 2024 promises to reach well beyond the robot to embrace systems integration, controls, sensors, safety and much more

Anyone visiting Coventry’s CBS Arena for the Automation UK 2024 show (June 18-19) a er a year away is likely to be struck by at least two features of the event: rstly, by the size of the overall area; and secondly, by the number of seminars and other presentations scheduled.

CEO of Automate UK Peter Williamson con rms the rst of these points. “There’s more space, but individual stands are also bigger, meaning there will be more room for those types of live demo which really re people’s imagination,” he says.

Organiser BARA (the British Automation and Robot Association) believes the shared location with the Machine Vision Conference (MVC – see p20) is a winning formula. This preview aims to give a avour of what visitors can expect from the event, rather than being a comprehensive overview, and to o er a sense of the range of technologies on show.

Those showing industrial and collaborative robot arms on their stand will include Kuka. Others such as Safety Systems Technology will, as the name suggests, demonstrate options for complying with PUWER, BS, EN and ISO safety standards.

Simmatic Automation will be demonstrating a range of grippers, including its all-in-one Magic Gripper vacuum generator and cup. Other applications of vacuum are also on show. “The VTC Vacuum Conveyor range provides a dustless, hygienic and ATEX-rated way to transfer powders and granular material at up to 8.5 tonnes an hour from point A to B,” says sales support engineer Ben Priest.

ifm will be parking up its truck

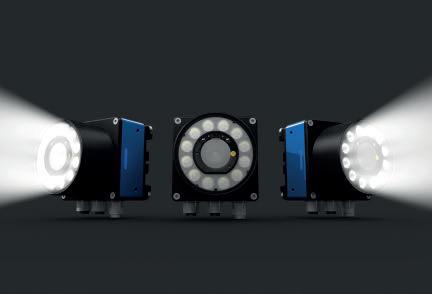

ifm electronic will be manoeuvring its two-storey exhibition lorry into the venue in order to demonstrate how its camera systems have been condensed into powerful sensors. Combined with high-resolution imaging and advanced so ware, they o er capabilities from contour detection to code reading, says the company, with simplicity and ease of integration as priorities. Its wider range encompasses

position and motion-control sensors, safety technology, industrial imaging and communication products, says ifm.

Schmalz UK will be putting its electric-only, compact vacuum pumps through their paces. This will include the ECBPMi with its 3kg payload, the ECBPi with a 10kg payload and the GCPi regulated pump with integrated interface for the best possible control and monitoring.

Grippers displayed by the company will include the PXT, designed to provide optimal grip for lightweight robots. Since this is about empowering the end user, too, demonstrations will show just how easy it is to design a gripper of this sort via the company’s website and how it is possible to modify a gripper using only a few basic tools.

SMC Corporation can supply magnetic and pneumatic grippers, as well as vacuum options, and will demonstrate a selection of end-of-arm tooling. Wireless solutions and air management systems are among other technologies that will be on the stand.

Piab will have its own range of suction cups on show and, in terms of practical applications, a cobot palletising tool being used on a UR20 robot. The company’s

18 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Preview

Simmatic technology

The organisers believe that co-locating with MVC benefits both the events

Schmalz has a range of grippers

session themes include how to select machine control architecture

wider range of vacuum automation components will also be on the stand.

The crossover between equipment on the stands and presentations in the seminar programme will be an important one, as exhibitor AP Technologies explains.

The UK company, which sources systems from di erent suppliers, will be showing a range of time-of- ight (ToF) sensors. Director Martin Sharratt tells Machinery

Update how pleased he is that Broadcom, one of the suppliers represented by AP, will be discussing the role of its

fully-integrated ToF sensors in factory automation.

As Williamson at Automate UK points out, visitors are likely to be pleasantly surprised not just by the number of speakers but also by the quality of presentations on o er.

“I’ll be there taking part in the latest UK Automation Forum roundtable, talking about the skills gap live at the show,” he says. “And there will be many more industry experts delivering high-calibre presentations on the various stages around the event.”

As well as the UK Automation Forum and the ToF presentation, expertled seminar themes will include: the steps involved in deploying a robot; selecting your machine control architecture; protection against surges; apprenticeship programmes; gantry-based linear robots; impacts of AI in the food industry; strategic programming for improved robot cell performance; exploring alternatives to cobots; breaking down barriers to the adoption of robots; rethinking agile manufacturing; and the energy-e cient replacement of electro-mechanical pumps.

Free registration at: www.automation-uk.co.uk

www.machineryupdate.co.uk MACHINERY UPDATE 19

Seminar

AP Technologies spells out ToF

Piab has a cobot palletising tool

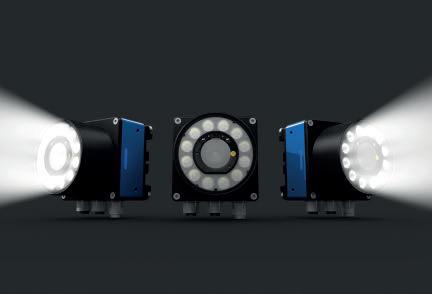

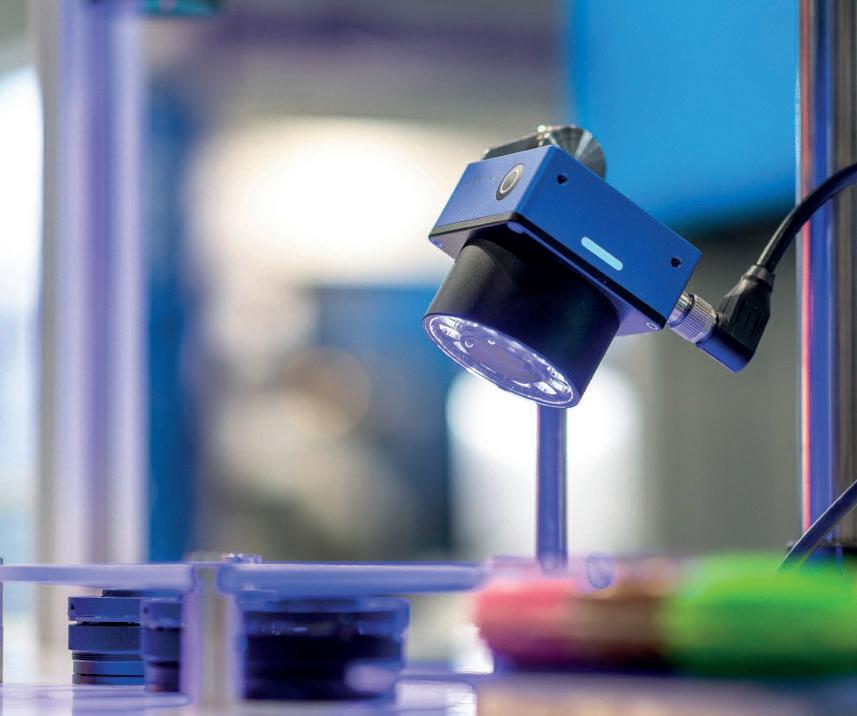

Machine Vision Conference Preview

Machine vision finds broader perspectives

The Machine Vision Conference 2024 will combine its working exhibits with focused technical presentations

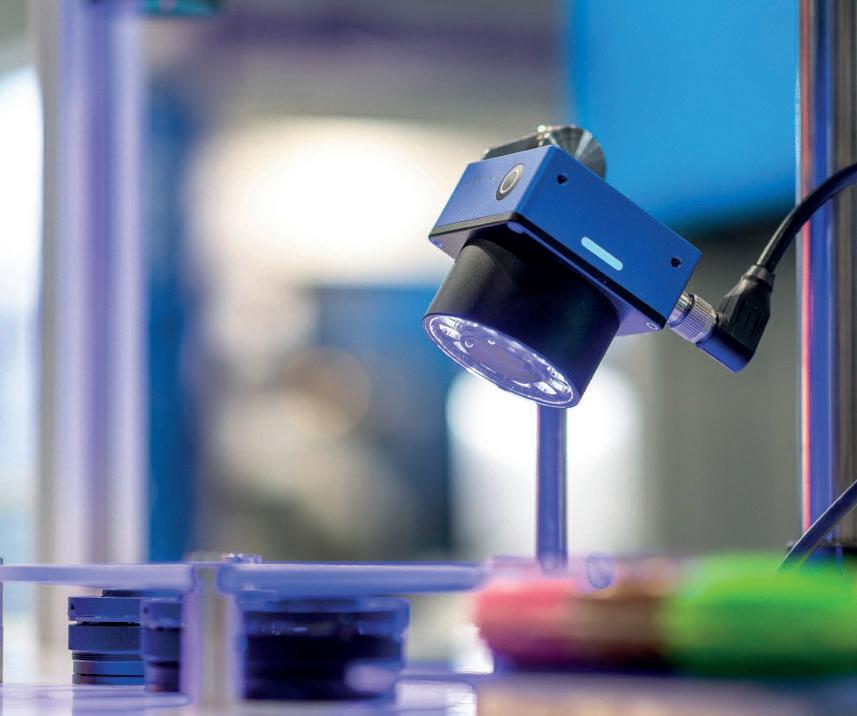

Organised by the UK Industrial Vision Association (UKIVA), part of Automate UK, the Machine Vision Conference (MVC) has consolidated its reputation for high-level debate, while maintaining a sharp edge of practical demonstration alongside the theory.

The two-day conference and exhibition will run in tandem with the Automation UK show (18-19 June 2024) in the Coventry Building Society Arena, Coventry.

By the end of May this year, says CEO of Automate UK Peter Williamson, visitor registrations for MVC 2024 were up 40% or 50% on the same time last year. This growth in awareness and popularity could re ect the way vision technologies increasingly cut across sectors.

“MVC will clearly show that machine vision is a huge market in its own right, and do that by demonstrating that applications in industrial automation are only one market segment out of many that rely on the technology that will be on show,” Williamson explains.

To provide an example, German-based Parkvi says it o ers vision systems for a cross-section of industries, from food processing to automotive, e-mobility, pharmaceuticals – and tyres. It supplies systems from a number of manufacturers, and at the show will be talking about applications from AI-based seam inspection in welding to Deep Learning OCR (Optical Character Recognition) and bin-picking.

Alrad Instruments is another company supplying a range of equipment from di erent sources and for a variety of applications, including long-range thermal imaging, LiDAR time-of- ight camera technology, as well as lenses, LED machine vision lighting and other accessories.

Others, such as Smart Vision Lights, concentrate on those critical peripherals – including, in its case, an allin-one light kit with no fewer than six di erent machine vision lights in a single “easy-to-use, multifunctional product”.

Many of those with products on display or o ering live demonstrations will also be talking to MVC audiences about their technologies.

Nathaniel Hofmann, market product manager for machine vision at SICK UK, will be trying to convince listeners that: ‘Vision guidance for robots does not have to be di cult’. “This is a subject that I’m passionate about,” he tells Machinery Update. “The UK is not adopting robots into the industrial marketplace as quickly as many of our European neighbours.”

He believes that the advent of cobots has changed the automation landscape. “The user knowledge level to set up and deploy a robot these days is more straightforward than ever with collaborative robots and it really is the same with robot-guided vision from SICK.”

Meanwhile, his colleague, global strategic product manager Viktor Smedby, will be explaining how the company’s

products ‘make quality control stress-free’. He will discuss how the SICK Nova in-camera environment o ers a scalable development platform for 2D, 3D and AI applications.

At Scorpion Vision, technical director Tim Tanner is also due to tackle the issue of AI. “We aim to address the widespread misuse of the term in the industry, where it is o en used as a marketing ploy rather than representing genuine AI implementation,” he says.

It does have a role to play, he concedes, in some areas where classic machine vision pattern matching or segmentation falls short and where the integration of Deep Neural Networks (DNNs) can improve system performance.

“Our core message is to showcase the transformative impact of AI, particularly DNNs, when implemented e ectively in real-world scenarios,” says Tanner. As an exhibit, Scorpion Vision will show a robot cell equipped with a 3D AI camera.

Another focus for MVC presentations is GigE vision. Get Cameras’ Aitor de la Fuente will discuss this interface and contrast it with network cameras, highlighting the factors that should be considered when deciding which interface is best suited to a given industry or application. “We will discuss the speci cations of the industrial network camera that we have in our portfolio and the new development

20 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Live demonstrations are a key attraction

AI-powered

Scorpion Vision has a 3D AI camera

Aitor de la Fuente of Get Cameras

Speaker Tim Tanner, Scorpion

of a Get Cameras USB3 to IP streaming device,” he says.

At Allied Vision, European sales manager Richard Oakley will be picking up the same theme, in his case looking at ‘Unlocking the potential –leveraging GigE cameras for advanced vision solutions’. Advantages, as he will point out, include the coste ectiveness of components and its ability to handle di erent levels of data throughput over long cable distances.

On the other hand, GigE system design can appear complex. “The co-ordination of cameras, vision components and host systems continues to pose challenges for many users, particularly in high-throughput systems

and demanding multi-camera applications,” he says, adding that he will take the audience through the decision making process when it comes to designing a needs-based GigE vision system.

Free registration here: www.machinevision conference.co.uk

www.machineryupdate.co.uk MACHINERY UPDATE 21

Richard Oakley from Allied Vision

The event has won a reputation for punchy, well-informed presentations

The new SOMIC 434

SOMIC has created a one-stop solution for all future-oriented packaging concepts with the new 434 series. It has been cleverly engineered to cater for tray packaging, tray-cover or wraparound solutions. Based on proven, tested and

standardised

For more

please

visit

function groups, it offers maximum performance on a compact footprint.

information

call 01256 467177 or

somic-packaging.co.uk

ALPMA GB Limited SOMIC are represented and supported in the UK by ALPMA GB Limited 1 Devonshire Business Park Knights Park Road, Basingstoke Hampshire RG21 6XN Telephone: 01256 467177 Email: sales@alpma.co.uk www.alpma.co.uk ALPMA is a globally-renowned mechanical engineering company who produce machines

for the dairy

food industry throughout the world. A one-stop solution for all futureoriented packaging concepts

and installations

and

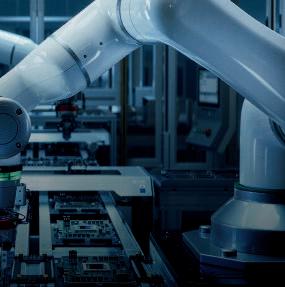

Greek injectables plant automates sterilisation

Athens-based pharmaceuticals manufacturer DEMO is using eight di erent FANUC robots to manage the varying requirements and provide 24-hour production in a traybased operation sterilising plastics containers and bags.

DEMO’s long-standing equipment supplier SABO has an equally well-established relationship with FANUC. “We prefer FANUC equipment,” says technical director at the injectables company Argyris Lellos.

“To date, we’ve automated four production lines using a total of 12 FANUC robots.”

The sterilisation stage is clearly of paramount importance in a pharmaceuticals plant.

Following this, plastics ampoules are lled with injectables, while bags are used for sterile solutions.

The robots perform a variety of tasks, loading, unloading, pick-and-place and transporting trays, containers and bags.

Two sizes of 6-axis robot handle multiple containers (rear) and bags (front)

For the loading and unloading of plastics containers into and out of trays, SABO selected the M-710iC lightweight 6-axis robot. A SABO-designed end e ector works at speed to transport multiple containers in a single li .

Two larger FANUC R-2000iC/165F 6-axis robots handle the trays. These are able to li loads of up to 165kg and can operate in restricted spaces. The other installed systems are two M-10iD/12

robot arms and three DR-3iB/8L delta robots. The delta robots use suction cups to handle bags.

For Lellos, the bene ts were clear from the start.

“We now have 24/7 uninterrupted production, with faster throughput, reduced production costs and less downtime,” he says.

“We’ve also saved space due to the small footprint of the robots.”

T 024 7605 3000

W www.fanuc.eu

Supplier steam test bench provides more customer reassurance

R&D installations at a supplier’s site play an important role, as highlighted by a new steam test bench at the Schubert & Salzer Control Systems headquarters in Ingolstadt, Germany.

All relevant properties of control and on-off valves, such as speed, precision and leaktightness, can now be tested under real conditions and, if necessary, improved. The test bench steam boiler can produce up to 400kg of saturated steam per hour. The system complements the water test bench, modernised only a few years ago.

The installations form part of the customer training centre, where test options go well beyond industry standards, says the company.

T

01952 462021

W www.schubert-salzer.com

VMECA product specialist and UK agent for over 20 years. Vacuum challenges? Simmatic has the solutions.

BRINGING PNEUMATICS AND VACUUM TOGETHER

VMECA’S PREMIUM SPEEDER

Do you have a constant battle keeping on top of vacuum filters due to excessive particles or water?

The VMECA PS230 Premium Speeder could be the solution to your problems. Ideal for picking fresh produce with loose, porous or wet surfaces.

KEY FEATURES:

- Straight through design

- Integrated vacuum - air driven

- Aluminium or stainless steel

- Choice of vacuum lips FDA, metal detectable

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 23 Installation News

01299 877770 sales@simmatic.co.uk www.simmatic.co.uk Unit 11, Sandy Lane, Stourport-on-Severn, DY13 9QB

Key properties can now be tested

Complete hot cross bun line offers many pluses

Amajor UK baked goods manufacturer has installed an ‘end-to-end’ installation for Easter-market hot cross buns and for bread rolls, sourcing the equipment from European Process Plant (EPP).

EPP, which can o er speci cations from small batch level up to an output of 48,000 buns per hour, supplies systems for ingredient handling, mixing, dough dividing, proving, depositors for the ‘cross’ paste, baking and packaging.

It has developed its own fruit hydration system to tackle the challenge of fruited dough drying out, as sales director Stewart Morris explains. “The system gives bakers precise control of dough moisture content, and now they can save costs by using dried fruit instead of the more costly rehydrated fruit,” he says.

More broadly, automated ingredient handling comes courtesy of Shick Esteve. Options from VMI for gentle

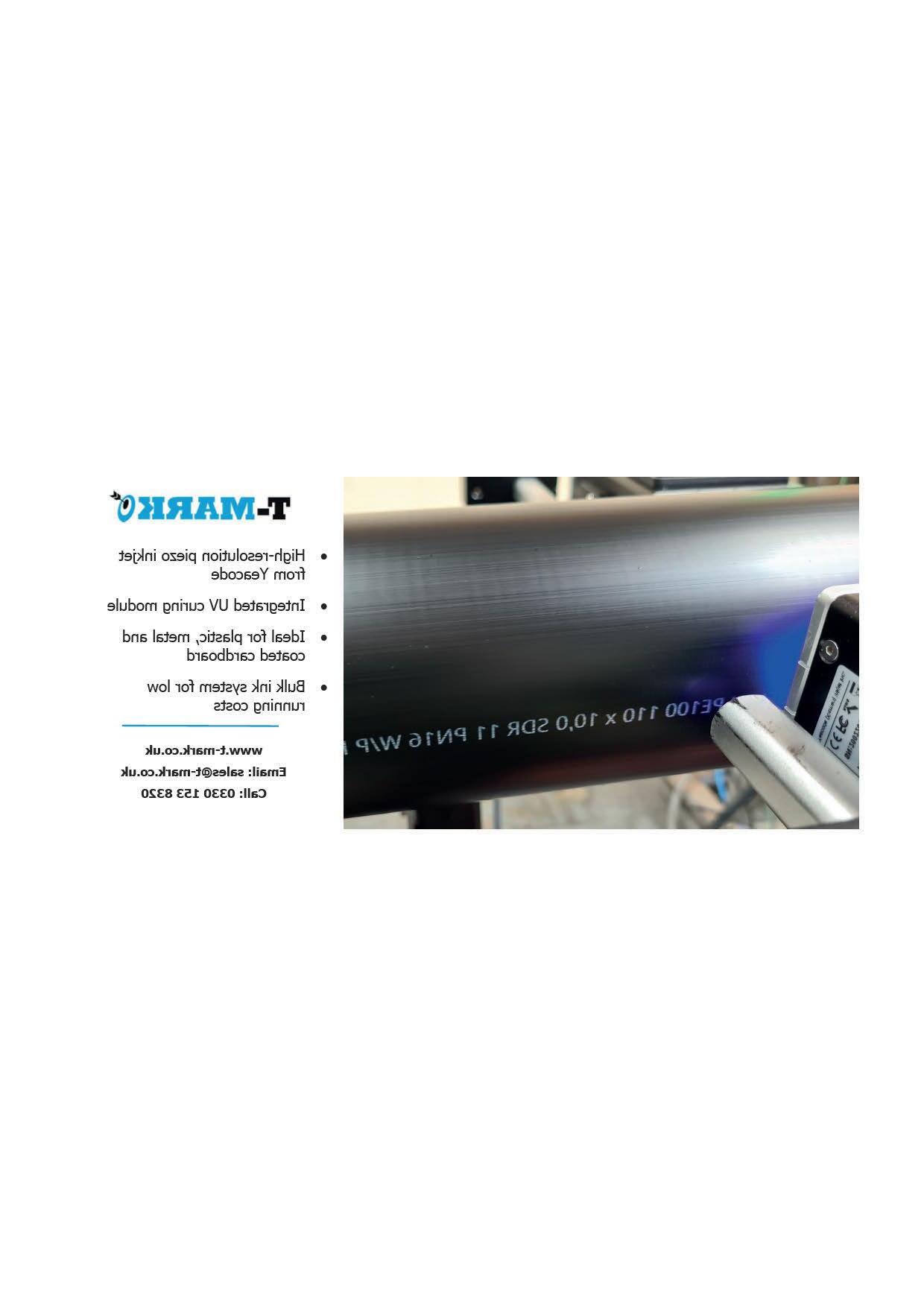

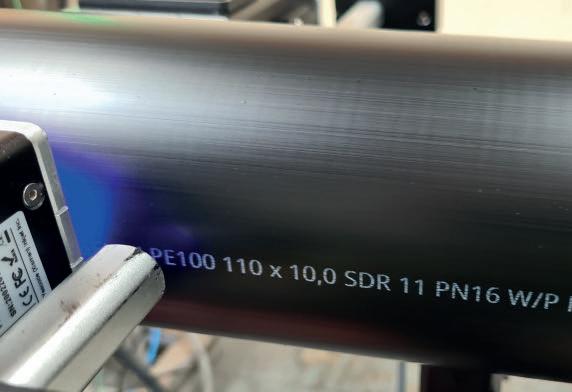

High-resolution piezo inkjet from Yeacode

Integrated UV curing module

Ideal for plastic, metal and coated cardboard

Bulk ink system for low running costs

www.t-mark.co.uk/uv-curing

24 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

while the rack provers

Installation News

Call:

153 8320

Email: sales@t-mark.co.uk

0330

Print-and-apply joins software to meet edible oil regulatory demands

Aceites Urzante, a producer of olive and seed oils in northern Spain, is now using Integra modular so ware from Macsa id, along with its Lineal idBlocks 4020/6020 printand-apply systems, to ensure it complies with international labelling regulations.

The family oil business today exports to more than 80 countries, and claims to be the third largest producer of olive oil in Spain. The printand-apply systems along with the so ware help to control, manage and optimise Urzante’s ve production lines, according to Macsa id.

Labelling regulations are a priority

The labellers are said to be ideal for working in harsh environments and feature a linear pneumatic cylinder which allows di erent label lengths to be applied with the tamp applicator, with stroke lengths of between 100mm to 800mm, says the equipment supplier. Cases and pallets are labelled with the applicators.

The Integra so ware automates collection of production data and, at Aceites Urzante, is linked to Microso Dynamics Nav enterprise resource planning (ERP) so ware.

T 01462 816091

W www.macsa.com

www.camagroup.com cama-UK@camagroup.com

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 25

Cama Group is a leading supplier of advanced technology secondary packaging systems continuously investing in innovative solutions.

Technology inspired by human talent NUREMBERG - GERMANY 07 - 10 MAY 2024 HALL 7A - BOOTH 7A - 515

Installation News

New and existing systems bring operation in-house

When cider-led beverage business Aston Manor wanted to bring a rework operation for canned drinks in-house, it turned to longstanding equipment supplier Yorkshire Packaging Systems (YPS) for advice.

Aston Manor manufacturing and engineering director Paul Cli ord was keen to build existing, under-utilised machines – some of it from YPS – into the new line.

“The modular nature of the equipment we owned from YPS could be easily combined with new machinery to create a full packaging line for the new product,” he says. “Throughout the discussions, YPS sought to nd the best solution for our new requirements.”

The new rework operation allows Aston Manor to take a range of di erent products and combine them in a single collation. In this case, a 24-count tray of canned drinks is shrink-wrapped for stability.

The new line includes an Ulma heat shrink tunnel,

previously used on another line. This was incorporated into the new operation with minimal recon guration, says YPS. The beverage company also acquired a new sleeve-wrapper/sealer with integrated in-line infeed.

“This investment delivers additional packing capacity with exibility that could prove invaluable as our business moves forward,” says Cli ord, underlining how

pleased the company is with the YPS equipment, service and support.

Managing director of YPS Glyn Johnson says this e cient use of resources resulted in the most coste cient outcome.

YPS carried out trials on the new line, demonstrating that it could easily cope with the required throughput.

T 01484 715111

W www.yps.co.uk

The line includes laser coding

Thermal transfer and laser together offer coding serialisation

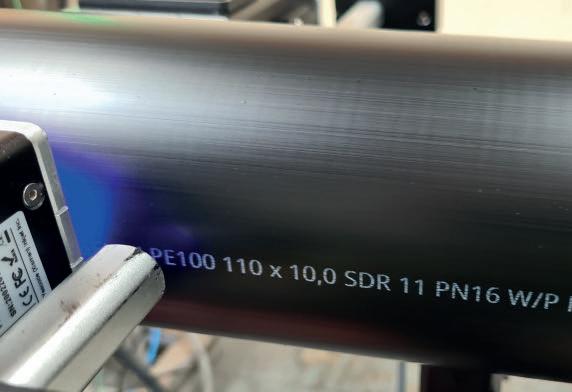

Domino Printing Sciences has contributed to a fullyintegrated, high-speed serialised coding operation for German pharmaceutical manufacturer Aspen.

The supplier’s V320i thermal transfer overprinter (TTO) and U510 UV laser combine to provide traceability coding, together with automated machine vision for quality control of both codes and a reject system.

Aspen approached Domino’s Polish distributor Intrex looking for a coding system for a bottling line running at 150bpm. The customer was looking for a complete installation from a single supplier, managed from one human-machine interface.

The TTO produces serialised labels for the HDPE bottles, while the UV laser applies a code for internal stock control to the base.

T

01954 782551

W www.domino-printing.com

Compact robotic monoblock forms trays and fills them with cartons

for leading European confectionery manufacturer

Cama Group has supplied a series of monoblock carton-in-tray collating machines, integrating digital, servo and robotic technologies, to a leading European confectionery manufacturer.

The IF296 monoblock forms trays and then loads them with cartons of bars via two infeeds from Cama cartoners. Two robots, designed and developed in-house by the machine builder for this speci c

application, phase and prepare the cartons. These are then picked and placed into trays in any one of a variety of pre-determined

arrays at speeds of up to 360 cartons per minute.

The IF296 was designed to have a compact footprint.

The machine also ticks all the boxes in terms of best possible uptime, overall equipment e ectiveness (OEE) and total cost of ownership (TCO), Cama claims. As the customer’s needs change,

the modular design means that the system can adapt, so investment value is always maximised.

Integrated augmented reality (AR) functions are said to give operators more intimate, intuitive and unrestricted insights into the workings of the machine, making training, changeovers, maintenance and the identi cation and ordering of spares more streamlined.

T 01793 831111

W www.camagroup.com

26 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Augmented reality (AR) gives operators improved machine insights

Existing equipment and new systems could be combined to create a new line

KEY FEATURES

• HIGH SENSITIVITY TO ALL METALS

• INTEGRATED CONTROLS for line speed and rejection

• HIGH IMMUNITY to environmental interference

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

CEIA CONVEYOR INSPECTION SYSTEMS PIPELINE INTEGRATED SYSTEMS IXC AND WEB-SERVER FUNCTIONS www.mds.org.uk UK FULL SERVICE AND TECHNICAL SUPPORT ∂ 24-7 Help Line and Assistance ∂ Metal Detector Validation and Retailer Code of practice training CEIA AUTHORISED DEALER ∂ Contact us on: 0161 286 8750 ( TECHNICAL) - 0161 286 8755 (SALES) metal detection services

Feature: Fresh produce – Intro

Fruit and veg pose some very speci c process challenges

Overall, data on the size and growth of UK fresh produce markets looks positive, but how this translates in terms of productivity and pro tability among UK farmers and their immediate customers remains to be seen.

The value of UK fruit and vegetable markets stands at £25.28 billion this year, according to Mordor Intelligence, and it estimates the gure will rise by just under 3% year-on-year to reach £29.28bn by 2029.

At the same time, HM Government has pledged to more than double the value of productivity scheme grants to British farmers to more than £220 million. Given the current emphasis on ‘food security’, it would be good to think that at least some of this funding could nd its way into investment in various levels of processing and packaging for those farmers and co-operatives with the volumes to justify it.

But even for those larger processors able to bene t from economies of scale, strategies for automation can be hard to visualise, let alone implement. Workforce recruitment and retention is harder than ever, with little sign of new options for the admission of overseas labour. And yet, with retail margins remaining stubbornly low, the leap to full or even selective automation can seem daunting.

ALL NEEDS CATERED FOR

Nonetheless, Automate UK’s membership can cover every process and packaging operation and every degree of automation within any given machine category, from vision-assisted robotics to semi-automatic traysealers and – to take two very random examples – from vision sensor-driven Deep Learning to label applicators available to rent rather than purchase outright.

Automate – but to what degree?

ALTech says it has a wide range of labelling systems available to rent, helping to navigate peaks and troughs in demand

The Deep Learning capability is proposed by SICK as a way of classifying natural products based on visual appearance. It is described as being ‘example-based’ rather than ‘rule-based’, and so ideal for in nitely-variable produce.

Labelling machine rental is an option from ALTech, which points out that this can be a way of navigating the complexities of seasonal peaks and labour shortages.

There are further layers of complexity with fresh produce. Greg Harper of SMC contrasts the relative ease with which many foodstu s can be handled and the particular limitations of this sector. “It can still be challenging to handle fresh produce with robotic manipulators,” he says, “especially when these products are so easily cosmetically damaged, leading to spoilage and making them di cult to sell.”

As the following feature shows,

SMC has its own answer to the question: ‘How best to handle delicate, oddly-shaped fresh produce?’, and there are others with their own options for robotic handling.

Further areas generating multiple solutions for fruit and veg packaging include lidding systems, as these pages demonstrate, quality control and weighing for di erent types of product.

A glance at the various weighing systems alone underlines the point that the range of machinery options is wider than ever, in terms of speed, accuracy, volume, customisation (in the case of larger systems, to t in the space available), productspeci c design – and cost.

If fresh produce faces more potential headaches than some other sectors, it is also an area where sometimes relatively simple solutions can make a signi cant di erence to quality, the bottom line or both. n

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 29

Feature: Fresh produce

Diverse characteristics of produce make handling far more complex

Robotics solutions which support the distribution center of the future

Optimizing the operation of your modern distribution center

Making distribution smarter has never been easier. Through innovative robotic automation applications, distribution centers can achieve greater flexibility, productivity and scalability. To find out more about how we can help you optimize your operation, download our new logistics ebook https://bit.ly/LogisticsSolutionseBook or call 01908 350300.

The fact that many types of fresh produce are easily damaged has given rise to some ingenious ways of handling them, as has the often wide variation in terms of shape, size and even softness, as SMC Corporation explains. Business development manager for food and packing solutions Greg Harper gives the example of the range visible in a typical bag of potatoes. “The contours of the surface will differ and in some products you may even have a difference in density,” he points out. “This natural variability limits the options for physical handling without complex gripping systems or onerous grading of the products down to tighter

SMC’s MH-X7654 or ‘elastic finger’

Many applications can be handled using one or two vacuum cups, he says, citing SMC’s ZP3P cup with sealing skirt. This is the type of system designed to cope with minor ridges or texture variations on the surface. SMC also has bellowed cups, such as its ZP3P-JT. But, Harper asks, how do you handle a delicate ‘porous’ product such as a head of broccoli?

The answer could be SMC’s new MH-X7654 ‘elastic finger’. Constructed from stainless steel and silicone rubber, it is compliant with FDA regulations, says the company, and can pick and place easily damaged product even in tightly-packed arrays. T 01908 563888

W www.smc.eu

30 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

—

From labelling to lidding

Multivac has a labeller that doubles as a fast and adaptable

lidding system

For fruit and vegetable lidding where no airtight seal or modi ed atmosphere is required, Multivac has its TopCLOSE peel/reseal system based on a conveyor belt labeller, saving on the space and investment of a larger packaging machine. The labels have adhesive only on the contact area of their surface, and are permitted for direct contact with food. They can incorporate a tear ap and reseal option and be cut to suit right-angled and round trays.

Because there is no heat involved, there are fewer variables to contend with in terms of adhesion to the tray, says labelling product manager David Hadley. “It’s a fantastic concept that can

The L 330 conveyor belt labeller will apply lids at up to 250ppm reduce line length signi cantly and gives the ability to run at a massive speed,” he reports. “One of our customers has achieved up to 200 packs per minute.”

Multivac puts the top lid application speed for the line at 250ppm. A ‘zero-downtime’ version is available for uninterrupted operation. Running TopCLOSE on the L 330 conveyor belt labeller allows for the addition of variable data as well as inspection of print quality. The line adapts quickly and easily from one tray size or shape to another with the intuitive setup display, and without the use of tools, says Multivac. The same is said to be true for the insertion of new label rolls.

T 01793 425800 W www.multivac.com

The Complete Package

Our Range

www.machineryupdate.co.uk MAY/JUNE 2024 MACHINERY UPDATE 31

PFM Packaging Machinery Ltd, PFM House, 2 Pilgrim Way, Stanningley, LEEDS LS28 6LU T: +44 (0)113 239 3401 E: sales@pfmuk.com W: www.pfmuk.com Our Service ■ Dedicated After Sales Team: industry leading service and spare parts support ■ In House Training Facility: bespoke training for your team on our premises or yours ■ Privately Owned Family Business: flexible solutions to meet your needs ■ Complete customer satisfaction guaranteed

■ Horizontal flowrappers ■ Vertical form fill seal bag makers ■ Horizontal form fill seal pouch machinery ■ Multihead weighers ■ Complete packaging lines

Latest trends in packaging fresh produce

Packaging remains the pre-eminent way of preserving, protecting and presenting products of all kinds.

But what are the leading trends when it comes to fresh produce?

Packaging Automation (PA) provides its own analysis of this, quite literally, ‘evergreen’ sector.

•Sustainable packaging.

Options here include recyclable or compostable materials, aimed at reducing waste while maintaining product freshness;

•Eye-catching packaging.

Produce might have once had a reputation for functional packaging, but today, new formats are increasingly being used to di erentiate products and enhance brand visibility;

•Provenance and product information. Consumers want to know more about a product’s origin and nutrition. Giving more rather than less information enhances trust and satisfaction;

•Portion control.

Convenience remains king with fruit and other products for on-the-go snacking, and individual portion pots can be a great way of providing pre-portioned packs;

•Shelf-life extension.

Technologies such as modi ed atmosphere packaging (MAP) are increasingly being used with produce, in an e ort to preserve quality and avour for longer;

• Automation.

Here, the company points to its own equipment options such as the Rev5 traysealer and PA miweigh weigh scales, which help to minimise giveaway and optimise resources. According to the supplier, automation in general ensures precise sealing and measurement, minimising waste and aligning with sustainability goals.

PA points out that the company has its own trial facility, available for fresh produce growers to run tests on new packaging materials and identify the best option for their product.

T 01565 755000

W www.pal.co.uk

A revolution in hard-to-handle

Piab claims it has more than one answer to the challenges of handling easily-damaged produce

Fresh produce packing will inevitably involve some sort of compromise between the need for e ciency and the need to protect items from damage, and Piab believes it has added to the innovations catering for gentle handling with its range of suction cups and grippers.

The multi-lip design on the FCX suction cup and its ability to function e ectively even at low vacuum levels make it an ideal option for forming a seal with inconsistent surfaces and for handling delicate items. It is designed for energy e ciency and versatility, says Piab, and complies with food safety standards. Should parts of the gripper nd their way into food, they will show up on downstream detection equipment.

When it comes to bagged product, the BGX suction cup is able to grip loose bags, Piab explains. This can be especially helpful in packing items such as salad leaves or herbs, which are prone to damage. The same system will form a strong bond with the full range of today’s

packaging lms, it adds, including biodegradable and recyclable materials.

Leap AI’s PikPak end-of-line intelligent packaging system utilises a combination of advanced robot handling, vision and so ware to ensure seamless and coste ective picking and placing of product into trays and boxes. It does this using the FCX and BGX suction cups, says Piab, and tooling on the PikPak robots is interchangeable.

A LEAP TOWARDS LOW COSTS

According to Leap AI, the PikPak system can handle up to 150 products a minute, can reduce labour costs by up to 60% while increasing throughput by 50%, and o ers return on investment in less than two years.

In other unbagged applications, Piab explains, its piSOFTGRIP vacuum gripper might be the best tool for the job, o ering gentle but secure handling, without the risk of crushing product.

T 01509 857010

W www.piab.com

32 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Feature: Fresh produce

The FCX suction cup is able to grip fresh products directly even when they have an irregular surface

CAPTURE THE WINDS OF CHANGE. QUICKLY, AND WITH GENTLE HANDLING. BROUGHT TO LIFE WITH SCHUBERT.

Fresh, crispy baked goods are delicious, But they tend to crumble during packaging. Our solution: gentle robotic hands and a 3D scanner to monitor quality. In a machine that adapts to a wide variety of products in no time at all, Packaging them fully automatically in sustainable materials. In line with our Mission Blue: Only if it’s good for the planet, it’s good enough for our customers. www.schubert.group/en/bakery-packaging/

Feature: Fresh produce

Inside sealing yields results

G Mondini says its new ange-free technology for use with board punnets o ers signi cant bene ts

When it launched its INSeal lidding system earlier this year, G Mondini UK claimed the new technology set out to revolutionise the entire concept of sustainable packaging in relation to plastics usage, and made the important point that this would be “without the expected on-costs”.

The system, based on cartonboard packaging, is a ange-free concept designed to minimise plastics waste, the company says, while remaining robust all the way from the packaging line to point-of-sale.

It was developed speci cally with the fresh produce sector in mind, says Mondini, transforming assumptions about sealing by eliminating the distortion that comes from the ange during the loading and sealing processes. This means the pack remains sturdier through the entire supply chain, it claims.

options. Importantly, says Mondini, it does this without any dramatic increase in costs. This is a welcome change from the many ‘sustainable’ packaging innovations which come with a major price tag attached.

As the company explains, angefree board trays and punnets are readily available on the UK market, allowing for the easy adaptation of existing operations. As well as the signi cant bene t of reducing plastics consumption, it points out, the use of INSeal is also associated with reduced carbon footprint, thanks to the elimination of the tray ange and to the transport and storage space saving that results from this.

company emphasises the pleasing aesthetics, which are achieved while minimising the use of plastics in comparison with other traditional systems, such as ow-wrap and rigid lid

From May this year, companies are able to trial the technology at the G Mondini UK Customer Experience Centre in Stone, Sta ordshire, where it is being demonstrated in conjunction with the machinery manufacturer’s Cigno system.

Mondini describes the Cigno as a “plugand-play, compact tray-sealer” with a “pocket-sized footprint”. It o ers an open and hygienic, fully wash-down design, and can be used with many di erent sealing styles and pack formats.

T 01785 812512

W www.gmondini.co.uk

The

34 MACHINERY UPDATE MAY/JUNE 2024 www.machineryupdate.co.uk

Flange-free packaging saves on plastics usage but is robust, says Mondini

No fold breakage. PerfectFold liquid creaser. PRECISELY FOLDED Discover now: robatech.com/perfect-fold 28 MAY - 7 JUNE BOOTH C10 HALL 12

Make the most of your product filled into flexible packaging

Fill your product in a wide variety of shapes and sizes.

IMA is a reference brand for filling products like baby food, soft drinks, cooking sauces, purees, pet food, etc. with a wide range of pouch machines into flexible packaging - with or without spout. The complete and highly customised service also includes end-of-line solutions. Make the most, with us.

IMA Dairy & Food UK Ltd.

Retford Enterprise Center

Randall Way, Retford, DN227GR phone +44 1777 712 632

ima.it/foodanddairy

Feature: Fresh produce

A

company in Italy has automated its produce handling

Having installed two Ishida weighing systems, an Italian company handling di cult products including olives, artichokes, baby onions, dried tomatoes and mushrooms is seeing signi cant bene ts in terms of line speeds, e ciency and labour requirements.

The Menù company based in Medolla, northern Italy, which supplies the catering industry, took delivery of two Ishida Fresh Food Weighers (FFWs). The rst of these, the 12-head CCW-R2-112WB, was originally selected to overcome a problem when weighing a mix of ingredients into cans. But once the bene ts were clear, in comparison with manual weighing, a second six-head CCW-R2-106WB was installed for the weighing of vegetables into stand-up pouches.

Filling speeds have increased dramatically. On the 12-head operation, output rose from around 30 cans per minute (cpm) to 50cpm, while the six-head weighing line is lling up to 20 pouches a minute.

Pack sizes are 1kg and 2.5kg stand-up pouches on the six-head machine, while the cans lled on the 12-head weigher are 1,050g and 600g. Accuracy is within 5-10% of target weight, says Ishida.

Whereas before up to eight operators were required on the weighing lines, now only two people monitor the operation.

TRANSFORMATIONAL TECH

Technical director at Menù Massimo Baccarini never had any doubt that Ishida would deliver the e ciency, accuracy and reliability the business was looking for.

“We have been delighted with the performance of the Ishida Fresh Food Weighers and how they have helped us transform a manually-intensive operation into a much more streamlined and e cient solution.”

As well as being a strong option