Issue 3, Volume XXXIV, May/June 2023

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

INSIDE NEWS

Fulfilling eCommerce

Our feature this issue covers technologies that meet the need for not just sourcing sustainable materials but also combining them with productivity at eCommerce facilities

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

The first ever Automation UK exhibition organised by BARA takes place this June at the CBS Arena in Coventry from 20 – 21 which will be co-located with the Machine Vision Conference

NEW MACHINERY

Although Multivac’s new series of tray sealers are compact, they still offer the same high output as the existing TX 7 and TX 8 series, along with reliability, hygiene and ease of operation Find out more on page 12

INSTALLATIONS

A 36 head twin weigher will be installed to meet demand for popular sweets brands

NEWS PLUS

If you missed our first sector eBulletin covering the latest developments in robotics, you can find it on our website www.machineryupdate.co.uk

+44 (0) 1484 864733 sales@pennine.org www.pennine.org PENNINE CUSTOM MACHINED PLASTIC PARTS UHMWPE Nylon Acetal PTFE Poly Carbonate ALL EXTRUSIONS ARE 1000 GRADE UHMW POLYETHYLENE Outstanding resistance to impact and wear FDA & USDA approved for direct contact with food Antistatic and Lubricated grades also available YEARS 1968-2023

7 NEWS

12 NEW MACHINERY

22 INSTALLATIONS

30 SPECIAL FEATURE iNTERPACK REVIEW

In our 18-page review of the returning interpack exhibition, you will find details of the new machinery and services shown

48 SPECIAL FEATURE e-COMMERCE

Several PPMA members across a range of technologies have developed equipment for the ever-expanding eCommerce sector that allows fulfilment operations to increase their efficiencies and productivity

48

REGULAR FEATURES

10 REGULATIONS

Lithium-ion batteries are found in virtually all types of electrical and electronic devices, including advanced industrial equipment. For industrial environments, the proper storage and risk management of these batteries is critical in helping to keep a site and workers safe and so in this issue, we have included a guide to the wide range of safety standards to adhere to

EDITOR:

Gail Hunt

gail.hunt@ppma.co.uk

PUBLISHING MANAGER:

Bill Lake bill.lake@ppma.co.uk

ARTWORK CONTRIBUTOR:

Barry Heath

HEAD OF PUBLISHING:

David Chadd david.chadd@ppma.co.uk

A PPMA PUBLICATION

PPMA Ltd

New Progress House, 34 Stafford Road, Wallington, SM6 9AA

TEL: +44 (0) 20 8773 8111

E-MAIL ADDRESSES: publishing@ppma.co.uk show@ppma.co.uk technical@ppma.co.uk

WEBSITE: www.machineryupdate.co.uk

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from specifiers, managers and purchasers of processing and packaging machinery in the UK.

ANNUAL SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

ISSN 0969-4145

52 COMPONENTS

Impending obsolescence of a key control component on a guillotine machine saw BCH adopting the KF180 planetary gearbox series from Apex Dynamics which has delivered significant improvement

56 WHO WHAT WHERE People, events and diary dates

58 MACHINERY FINDER Machinery and also services

Sollas MU S-O 2021 artwork

IMPROVE

your products

THE BENEFITS OF OVERWRAPPING:

Excellent appearance

On-pack promotion with printed film

Cost reduction

Closed packaging

No heat radiation

Efficiency

Ease of operation

Flexibility

Low maintenance

Easy opening with tear tape

PRINTED BY: John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

Publishers: PPMA Ltd

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 3 May/June

2023

24

Contents

Biodegradable film & paper OVERWRAP

Over 10,000 machines sold world-wide!

01256 896930 sollas.com your sales,

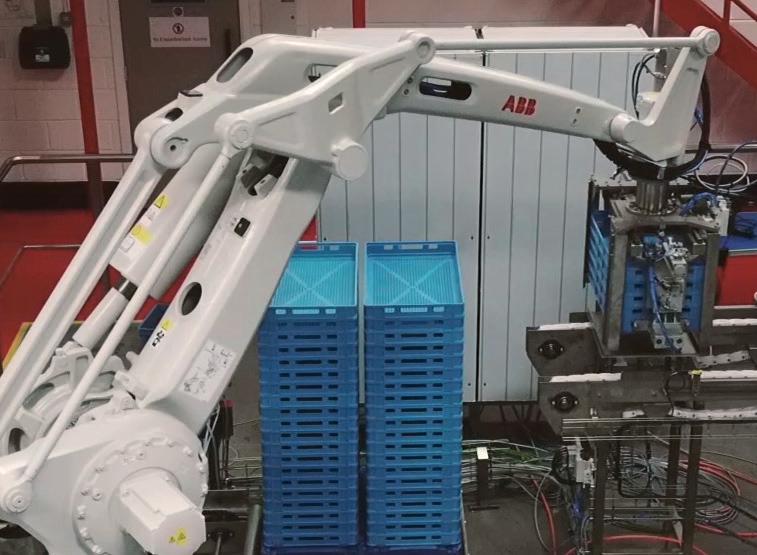

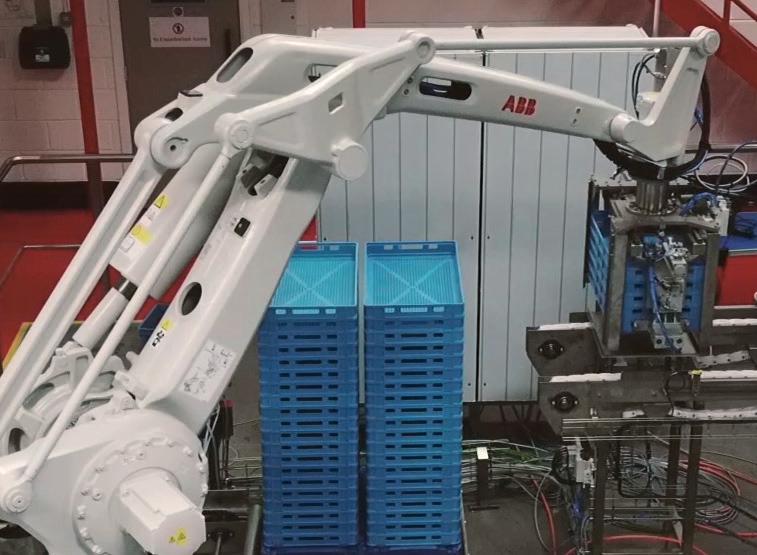

A leading UK robotic and automation systems integrator

CKF are an established Robotics and Automation Integrator that have been operating for over 35 years. CKF are a complete turnkey solution provider developing cutting edge systems to propel their customers into a more productive, efficient and resilient future.

CKF can offer:

1.Robotic Palletising

2.Product, Case and Pallet Conveyors

3.Industrial Automation

4.Robotic Pick, Place and Pack

5.Process & Packaging Systems

See us on stand D01

www.ckf.co.uk

PPMA matters

Face-to-face is still the business go-to

James Causebrook

As the first interpack exhibition to take place for six years proved in May, there is nothing quite like face-to-face contact with existing customers and potential new partners.

And although I have returned from the seven-day Düsseldorf trade fair exhausted, I am once again enthused about how exhibitions are often the best way to have meaningful contact with end users. Not only to explain our own product offer, but also to better understand their changing needs and to build lasting partnerships, in whatever part of the world we operate. These relationships can obviously thrive through modern comms, but I would argue that an initial face-to-face chat –however brief – can be a very effective enabler.

As chairman of the PPMA Group of Associations, my visit to Germany has also filled me with hope and excitement for this June; a month which will see our brand-new Automation UK exhibition take place at the CBS Arena, Coventry (20 – 21).

CleaningResistant and Robust Sensors

The sensors for the washdown area are ideal for use in washdown applications in the food, beverage and packaging industries. The high-quality stainless steel 316L housing makes them robust and corrosion-resistant

Height and Angle Measurement of Ice Cream Cups via 2D/3D Profile Sensors

Detection of Cookies with Reflex Sensors with Background Suppression

Meeting

at

trade events is still the most valued (and fun) form of contact between a buyer and seller

Owned and organised in conjunction with BARA, the British Automation & Robot Association, the event is designed to promote the use of, and assist in the development of, industrial robots and automation across British industry. Visitors will be able to see live working demonstrations of the latest automation and robotics technology, helping them make informed investment decisions.

Co-located with the successful Machine Vision Conference event, visitors to Automation UK will also be able to cross-over and see the latest developments in industrial vision and imaging systems. Organised by UKIVA, the UK Industrial Vision Association, the event promotes the use of image processing technology that offers benefits right across UK manufacturing.

I am excited about these co-located events as I believe we are offering an accessible, face-to-face platform that will help visitors to learn about easy, off the shelf improvements that will make their daily lives better.

You will find more information on these co-located events in this issue (pages 18 – 21), as well as an interpack review (pages 30 – 47).

One thing that was a pleasure to see during interpack was the quantity of PPMA member developed equipment that has already embraced the circular economy, sustainability and/or digital technologies. Features to facilitate a greener and more efficient world are already designed-in for the benefit of customers across all manufacturing sectors.

Detection of Food Trays with Reflex Sensors with Background Suppression

Color Control of Baked Goods with Vision Sensor

www.machineryupdate.co.uk MACHINERY UPDATE 5

n

CHAIRMAN, PPMA GROUP OF ASSOCIATIONS (INCORPORATING PPMA, BARA AND UKIVA)

wenglor sensoric ltd. Unit 2, Beechwood | Cherry Hall Road | Kettering Business Park Kettering, Northants NN14 1UE +44 1536 313 580| info.uk@wenglor.com

The KCI 120 Dplus dual encoder High-accuracy robot motion

Imagine the bene ts of motor feedback and position measurement from a single compact rotary encoder installable on all robot axes. Look no further than the new KCI 120 Dplus dual encoder from HEIDENHAIN. It lets you master the inaccuracies that plague dynamic,

Advanced robotics solutions

highly articulated robots, such as gearbox backlash and forces induced by the application at the end effector

The KCI 120 Dplus turns a conventional articulated robot into a high-accuracy production system and a dependable cobot.

HEIDENHAIN (G.B.) Limited +44 (0) 1444 247711 sales@heidenhain.co.uk robotics.heidenhain.com

New robot and vision options co-locate for a unique 2-day event

Industrial products firm is celebrating its 100th anniversary

Over the past 100 years, the family-run company Phoenix Contact has evolved from a commercial agency for industrial products founded in Essen, Germany, into a global manufacturing company.

With products and solutions for the electrification, networking, and automation of all sectors of the economy and infrastructure, the company has a passion for innovation and technology. Today, the company continues to drive all of this forward –together with a commitment to the sustainable development of habitats and economic spaces.

“This anniversary is a special moment for us,” says Phoenix Contact CEO Frank Stührenberg.

The brand new Automation UK exhibition and the well-established Machine Vision Conference will be co-locating on Tuesday 20 and Wednesday 21 June, at the CBS Arena in Coventry to bring visitors a unique opportunity to see the best in robotics and vision systems at one dedicated event.

Owned and organised in conjunction with BARA, the British Automation & Robot Association, the event is designed to assist in the development of industrial robots and automation in British industry. It will highlight the latest products, developments and solutions in robotics and automation,

Learning session on the changing robot landscape is success

TODAY, CONDAIR OPERATES ACROSS 23 COUNTRIES Enjoying a 75-year milestone

Humidity control specialist Condair is celebrating its 75-anniversary this year. Having been founded in Switzerland in 1948 by chemist Dr Bernard Joos, the company is marking the occasion across its many offices around the world, including in the UK.

“We are very proud of our company’s values and heritage,” says Condair Ltd managing director Tony Fleming.

with solutions on display for visitors to improve efficiency and productivity in their operations (you can find out more on page 18 in this issue).

Co-located with the very successful Machine Vision Conference event, visitors to Automation UK will also be able to cross-over and see the latest developments in industrial vision and imaging systems at this UKIVA, the UK Industrial Vision Association, organised event. Over 40 technical seminars are also available to visitors (find out more on page 20).

Register for free today to learn about the advances in these enabling technologies. W www.automation-uk.co.uk machinevisionconference.co.uk

UK firm has achieved the UL 508A rating to meet US demands

Shawpak has achieved certification by UL Solutions, as an authorised UL approved panel manufacturer, to UL standards 508A which means panels can now be designed, manufactured and built in-house and shipped to the United States.

Due to increasing US orders, Shawpak’s engineering director Chris Stopes says it was critical that the company developed its processes to ensure compliance to UL standards. “Gaining UL certification gives us the ability to maintain full control of the electrical design phase of a machine,” he says.

In March, the RMGroup along with ABB Robotics UK held an interactive workshop that offered guidance through the robotics and automation landscape.

Attendees at ABB’s Milton Keynes HQ saw several live demonstrations of applications utilising industrial and mobile robots including palletising, pick and place, materials handling and storage operations.

Presentations from ABB personnel and sensor solutions from Sick UK were also part of the day, as was a lively panel discussion covering a range of topics including barriers to adoption and also the next generation of options.

“Having this knowledge transfer opportunity is invaluable,” said RMGroup’s group director Rosie Davies.

Celebrating 130 years during interpack 2023

Ishida Europe celebrated the 130th anniversary of the company’s founding in 1893 in Kyoto, Japan. To mark the occasion, Ishida’s president Mr Takahide Ishida – who represents the fifth generation of the Ishida family to lead the company – cut the first slice of a commemorative cake.

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 7 News

A popular interactive workshop

Phoenix Contact continues to grow

Marking the significant milestone

Industry guide to compressed air installation is now available

The British Compressed Air Society (BCAS) has launched a new compressed air installation best practice guide (BPG 101-6). It covers ‘installation’ in terms of the collection of equipment and processes within the compressed air system. The guide provides information that can help users reduce their energy consumption and ensure maximum uptime, while meeting legislative requirements to ensure health and safety is prioritised.

Guide is written by industry experts

Providing step-by-step information for the correct specification, installation and maintenance of compressed air equipment as well as its end-of-life removal, the 272-page guide is designed for compressed air industry employees, plant engineers, maintenance technicians and end users.

The best practice guide is divided into a series of easy-to-read chapters to make specification as straightforward as possible. These cover compressed air system assessment, equipment selection and system design, including pipework and more.

Companies can purchase the guide either as a PDF download or a hard-wearing, bound copy for £14.95 (plus VAT and postage) directly from the BCAS website.

W www.bcas.org.uk/knowledge -base/best-practice.aspx

News 8 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Tel: 0 1865 8 9 1466 Email: info@cap c ode r c o m To discover more about the machines that could transform your company please visit: w w w. ca p c ode r. c o m

Chairman of family firm passes away

The owner and chairman of Packaging Automation

Anthony Penn sadly passed away after a short illness, in March. He died peacefully with his family at his side.

Packaging Automation was established in 1963 by his father Arthur Penn and in 1968 Anthony, the eldest of four siblings, joined him in the business, going on to become managing director in 1990 and then stepping into the role of chairman in 1998.

He continued to play an active role in the business, that has over 60 years of tray sealing experience and equipment installed in fresh produce packing facilities worldwide, right up until March this year, paying regular visits to the factory and taking the time to chat to colleagues.

Anthony’s legacy will live on. He was a great engineer (becoming a chartered engineer at the age of 25), an innovator and was passionate about passing on his knowledge and experience to future generations. Through the company’s apprenticeship scheme which Anthony established in the 1980s, the business has trained more than 100 engineers. He was a great man who will be sadly missed.

Queen’s Award rewarded international trade gains

Employees at Bradman Lake and their guests celebrated The Queen’s Award for Enterprise 2022 at an official ceremony at its headquarters in Beccles, Suffolk at the end of March.

To honour Her late Majesty, the Lord Lieutenant of Suffolk – Clare, Countess of Euston –visited the Bradman Lake headquarters to present the manufacturer with an engraved crystal bowl together with the formal Award Citation, personally signed by Her late Majesty and the then Prime Minister Boris Johnson.

Also present at the ceremony was Mark Pendlington, DL, Chair of the Lieutenancy Business & Enterprise Group, David Harrison, chief operating officer of the PPMA Group (Processing & Packaging Machinery Association) and Leszek Wysocki, International Trade Adviser for International Trade –Southern Region.

The Award for International

Trade is in recognition of the company’s outstanding performance for its range of equipment in global markets over the past three years. Managing director of Bradman Lake John Marlee thanked those present at the ceremony telling them that the award “is a tribute to the expertise and hard work of the entire Bradman Lake team.

“We are extremely proud to receive the Queen’s Award for Enterprise, which recognises international growth and our innovative solutions in packaging technology,” he continued. “Since winning the award last summer, we have continued to invest in R&D to continue to drive our growth strategy.”

The event concluded with a tour of the Beccles factory.

New UK distributor has been named for the heat transfer fluids produced by Paratherm

TrAchem Lubricants and Oil-Store have been appointed to stock and distribute the complete range of heat transfer fluids and system cleaners from US company Paratherm in the UK, and across mainland Europe. The product range covers low and high temperature fluids, NSF HT-1 food grade fluids and thermal system cleaners formulated for a wide variety of industries including biofuel, chemical processing, food & beverage,

oil & gas and plastics.

“With the backing of Paratherm’s technical expertise, and the training that has been provided, our sales team are in a great position to support end user customers from initial enquiry through to after sales support,” says Oil-Store’s sales director Daniel Tait.

L-R: Andrew Newton-Swallow of Paratherm/CPI, Daniel Tait and Lubrizol’s Scott Wainwright

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 9

The Lord Lieutenant of Suffolk (centre) presented the engraved crystal bowl and award scroll to Bernard Langley, director, Bradman Lake and Langley Holdings plc (left) and John Marlee, the md of Bradman Lake (on the right)

In March, Anthony Penn sadly died

Lithium-ion batteries must be stored safely

Lithium-ion batteries are found in virtually all types of electrical and electronic devices, including advanced industrial equipment. While technology development has advanced over the last few decades, it has also presented new fire and explosion risks. For industrial environments, the proper storage and risk management of lithium-ion batteries is critical; and there are a wide range of safety standards, including IEC 62133, UN/DOT 38.3 and IEC 62619.

While battery manufacturers and developers are continually improving lithium-ion battery design and performance, this can make them more vulnerable to small manufacturing defects or internal damage from the physical impact with another object. Variations in battery design, and the quality of materials and manufacture can also cause potential safety risks.

Of course, this problem will be magnified if large quantities of batteries are stored on-site or transported between industrial facilities. Fortunately, there are important steps that operators of industrial facilities can take to reduce the risks. For example, idle batteries in storage are not typically subject to internal ignition. However, large-scale testing has shown that lithium-ion batteries behave similarly to unexpanded plastic commodities in a fire.

Therefore, sprinkler protection should be provided.

Fully charged lithium-ion

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

Marcus Sampson BUSINESS LINE MANAGER FOR TRANSPORT AT TÜV SÜD

batteries have a higher energy density and are therefore at greater risk of generating significant heat from short circuiting caused by internal defects. It is therefore important to ensure that lithium-ion batteries stored in the longer-term are charged at levels below 50% charge capacity and kept at temperatures between 4-27deg C. This will help to minimise the risk of thermal runaway from manufacturing defects or internal failures.

bins for example, their battery terminals should be covered with insulating material. This will help to ensure that the terminals do not accidentally come in contact with metal or other battery contacts that could close the battery circuit and result in an unintended energy discharge.

Likewise, bins holding damaged or discarded batteries should be separated by at least three metres from all other storage areas, as well as bins holding other potentially

batteries, ensure that battery chargers and batteries being charged are separated from other combustible contents by at least three metres.

While usually safe, as lithium-ion battery charging can cause safety problems, stations designated for charging large format batteries should be separated from other combustible materials by at least one metre. For larger format batteries, such as those used in mobile equipment, battery chargers and batteries being charged should be separated from other combustible contents by at least one metre. Stations used for charging small format batteries should be set on a firm, non-combustible surface and be separated from other combustible materials by at least 30 centimetres.

Before disposing of damaged or unwanted lithium-ion batteries, in waste

combustible materials. This separation will help to reduce the risk of spreading a fire that might originate amongst discarded or waste batteries. In addition, these bins should be metal and have metal lids if practicable.

Internal components and mechanisms in lithium-ion batteries are also highly susceptible to physical or mechanical damage when the battery is subject to a severe external force or when it is dropped on a hard surface. Any external evidence of damage should therefore trigger concerns about a battery’s internal integrity, and it should be safely disposed of in bins intended solely for damaged batteries. For larger format batteries, such as mobile equipment

As lithium-ion batteries bring so many positive benefits to industrial innovation, they will continue to evolve as manufacturers seek new ways to increase battery density and reduce size. Therefore, the safety of lithium-ion battery technology will continue to be investigated to address unexpected hazards that emerge. As we learn more about the risks associated with the use, bulk storage and recycling of lithium-ion batteries, changes in standards and best practices can be expected as well. It is therefore vital that the safety of lithium-ion battery technology and its storage remains under scrutiny so that these evolving hazards can be addressed.

While there are hazards specific to lithium-ion battery storage in industrial environments, there are fundamental strategies that machinery users can implement to reduce the potential risks associated with battery-related fires and explosions.

10 MACHINERY UPDATE NOVEMBER/DECEMBER 2021 www.machineryupdate.co.uk

Regulations

i For more information contact W www.tuvsud.com/en-us/ services/testing/battery TÜV SÜD Product Service is the PPMA’s technical and legislative partner

For industrial environments, the proper storage and risk management of lithium-ion batteries is critical, and so here’s a guide to meeting the wide range of applicable safety standards

10 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

The proper storage along with risk management are critical in avoiding any battery malfunctions

26-28 SEPTEMBER 2023 NEC, BIRMINGHAM

PPMA Show is the UK’s largest event for processing equipment, packaging machinery, industrial robots and vision systems

FREE TO ATTEND REGISTER YOUR INTEREST NOW

www.ppmashow.co.uk

A compact tray sealer series mixes space efficiency with a high output

Although Multivac’s new series of tray sealers are a compact option, they have been designed to offer the same high output as the existing TX 7 and TX 8 series, along with reliability, hygiene and ease of operation.

When compared with the existing TX range, the TX 6 series has been completely redeveloped with the aim of producing a compact and cost-effective solution. “The design language, functionality and areas of application are however based on their bigger brothers, the TX 7 and TX 8 series,” emphasises Franziska Schreiber, product manager at Multivac. What distinguishes the TX 610 from the TX 620 is essentially the machine length and the usable size of the die.

The new TX 620 was shown for the first time at interpack in May and was the core element of a complete line solution on the Multivac main stand. It was packing ready meals under modified atmosphere in a sustainable cardboard

Changing to different pack formats is a simple task that doesn’t

tray, which was sealed reliably with a thin recyclable film.

“Thanks to their small footprint, the TX 6 series makes a major contribution to increasing output in the smallest of spaces – and all this on a very sustainable, flexible and cost-attractive basis,” says Schreiber. The company has now completed its product range in the TX class.

require tools

These new models, which were developed with rapid product change and high cycle output to suit a wide range of applications, include intelligent machine and line control, a high standard of hygiene, and also reliability. They can be easily integrated into many production environments thanks to their compact construction –and even designed as a

two-track solution for even greater efficiency.

Both models are equipped with robust servo drives, which guarantee maximum speed and gentle product handling over the long term. The intelligent machine control and die concept, the so-called X-tools, ensure that the investment in these models is always futureproof, says the company. Particularly since both the TX 610 and TX 620 are designed for use with Multivac Smart Services and Multivac Line Control – both of which are tools for providing maximum transparency and efficient line operation.

The machines can run trays from a wide range of materials including paperand fibre-based materials as well as plastics. The range of applications extends from sealing only through to modified atmosphere packaging and right up to MultiFresh vacuum skin packs.

T 01793 425800

W www.multivac.co.uk

New Machinery 12 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Packline Ltd • Unit 28 • Newtown Business Park • Ringwood Road • Poole • Dorset • BH12 3LL T: 01202 30770 • E: info@packline.co.uk www.packline.co.uk ■ Bespoke Design ■ Stainless Steel Construction ■ Compact and Manoeuvrable ■ Lifting Capacity up to 300kg ■ Interchangeable Attachments ■ Handle Reels of Film or Foil, Drums and Barrels

third

Packline

Latest peristaltic pump offers increased flow rates for users

Verder Liquids is introducing the new Verderflex Dura 80 peristaltic pump which is designed for a wide range of applications in the process industry. And with its improved flow rate and durable construction, the company says it is a reliable and efficient asset for any business that relies on pumping technology.

Improvements to Verder’s legacy pump, the VF80, include its increased flow rate, which now tops out at 42 m sq/h and a maximum differential pressure of 16 bar. This makes it an ideal solution for high-flow applications and means that it’s capable of handling even larger and more demanding industrial applications than its predecessor.

The new Verderflex Dura 80 pump

“This pump sets new standards in performance and ease of use, providing an ideal solution for applications where high flow and discharge pressure are required,” says Michael Homer, managing director at Verder.

Additionally, the Dura 80 features a lifting point for supporting the front cover if it needs removing, a lubricant filling point and a new access cover for cleaning which are all designed to provide easier operation and maintenance.

T 01924 221001

W www.verderliquids.com

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 13

The #1 item picker MX Suction Cup Family www.piab.com info-uk@piab.com 01509 857010

Collaborative robot can handle heavy payloads

Omron has launched its new TM20 cobot with a payload of 20 kg that is ideal for tasks such as palletising, machine tending and materials handling. Even though it handles heavy payloads, it has a small footprint and a reach of 1.3 metres.

This latest addition to the Omron family of TM cobots is designed to work seamlessly with other products from the company including sensors, controllers, and software, to provide a comprehensive automation solution for industrial customers.

One of its key features is its lightweight design, weighing in at just 33 kg. This makes it easy to integrate with mobile robots to provide greater flexibility and efficiency in industrial environments. The cobot also comes equipped with special joint covers to protect it from cutting oil and other hazardous materials, making it suitable for use in machine tending applications.

“We are excited to launch

With a reach of 1.3 metres, Omron’s new

the TM20, which expands the capabilities of our cobot family and gives customers the ability to automate heavy payload applications,” says Fernando Vaquerizo, fixed and cobots product marketing manager at Omron Europe.

“The cobot is designed to be easy to use, reliable and safe and relieves operators from tasks that involve heavy lifting, while working safely side by side with people.”

Static control along with web cleaning options were shown

At ICE Europe in March, Meech International presented its latest developments to support smooth production in the converting industry. Its well-established static control and web cleaning products were shown as well as two of its newer web cleaners – the CyClean-RTM and RoClean-CTM.

TM20 cobot is ideal for palletising

For companies in the process of evaluating an investment in collaborative robots, Omron’s ROI calculator can help, including easy and affordable leasing opportunities. In addition, a wide range of support services, including installation, training, and maintenance are offered, to ensure customers get the most out of their investment.

T 01908 258258

W www.industrial.omron.co.uk

An enhanced version of Meech’s original CyClean, CyClean-R comes as a single or double-sided non-contact web cleaner that utilises positive and negative airflows to clean low-tension webs. It has a compact design, making it suitable for use in tight spaces and can be used on narrow webs of up to 700 mm.

Meanwhile, RoClean-C is the latest contact web cleaner. Utilising brush rollers, RoClean-C is positioned above or below a guide roller on the web production line, so it avoids all issues of tension to provide a high level of surface cleaning.

T

01993 706700

W www.meech.com

New Machinery 14 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

SUPPLY THE FILMS SPARES & SERVICE P CHANGE OLD MACHINE SUPPLY A MACHINE Contact us today T 01484 715111 E info@yps.co.uk W www.yps.co.uk

WRAPPING MACHINERY

FILM

WRAPPING MACHINERY

FILM E-COMMERCE PACKAGING SPARES & SERVICE THE COMPLETE SOLUTION FOR: YPS MU M-A 2021 ARTWORK

SHRINK

SHRINK

STRETCH

STRETCH

ACOPOS 6D

Creating new dimensions of adaptive manufacturing.

ACOPOS 6D allows you to move products freely through an open manufacturing space –unbound by the limits of one-dimensional production flow. Magnetic levitation provides six degrees of freedom for unprecedented processing density on a fraction of the floorspace. br-automation.com

B&R | A member of the ABB Group

more

Learn

System reads and verifies QR codes on product packs

WMH has developed a system for reading and verifying QR codes on round packaging at up to 200 packs a minute.

The new system uses four scanners grouped together to view a round can or pot from different angles to create a single 360 degree image. This allows the QR code to be identified, whichever orientation the product is presented. A fifth scanner mounted above, scans the lid and the two images are compared by the software to ensure a match.

If a mismatch is detected, the line can either be stopped for manual removal or the line can be linked to a reject system to automatically remove any defective products.

Suction cups are eCommerce win

Suction cups from Piab’s MX range are currently providing reliable picking solutions to UK eCommerce customers.

Available in several sizes from 25-65 mm, the MX cup combines a strong set of bellows with a thin and flexible lip made out of its Duraflex material that is designed to increase suction cup longevity. The range can be used to handle difficult to grasp thin bags and pouches, as well as cardboard boxes, so offers speed benefits as there is no need to change suction cups between products.

Laser welding unit uses thin films to meet plastics targets

Newtec demonstrated its Laser Flowpack700 fully automatic laser welding machine at the MacFruit exhibition in Italy in May which has sustainability built into its design. Ideal for ultra-thin films, and suitable for a wide range of packaging applications, including fruits and vegetables, the machine has a capacity of up to 80 punnets a minute. Newtec says a key advantage is the Flowpack700’s ability to combine laser sealing and cutting in one machine, simplifying and automating the production process. This feature, it says, eliminates the need for complex processes and ensures smooth operation for customers.

costs for lifting applications, even on difficult objects. Low vacuum levels can also be used, reducing the chances of wrinkling or denting the packaging surfaces.

Because it can handle PE-film down to 10 µm, it is EU-2025 plastic initiative compliant.

T

01406 426526

W www.newtec.com

The MX range has been designed with logistics and eCommerce in mind.

T 01509 857010

W www.piab.com

01579 383788

W www.wmh-uk-ltd.com T

In addition to this versatility, the MX range has also been designed to work as efficiently as possible. Up to 50% less vacuum flow is required with MX suction cups, reducing the energy

• Our special eCommerce feature begins on page 48 of this May/June issue

• High-resolution piezo printers for product marking and case coding

• Prints up to 72mm high with one printhead; can stack up to four

• UV-curing ink available

• Suitable for printing on plastic, metal, glass, cardboard or wood

www.t-mark.co.uk

sales@t-mark.co.uk

New Machinery 16 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Unit is adaptable for other formats

Difficult to grasp thin bags can be handled reliably

The new machine is cost efficient

ǀ 0870 803 1877

Product/allergen checks made by a cost-effective new system

Faedah Solutions has developed Check Sure Perception which is a mobile system that can not only read the date code on a pack (all standard formats configured), and check it is correct for the product being produced, but can also read ingredients lists and check the allergens listed against that in the product’s database. This helps capture misprints or missing allergens.

It is billed as a cost-effective step up from standard paperwork checks by Faedah managing director Wayne Johnson for manufacturers that can’t afford an inline system.

The system can check for allergens

Running on a central database, the operator selects the product being run. This calculates the date code based on the P+ and format set for the product. The operator then takes a photo of the date code on the pack, utilising the tablets’ onboard camera before selecting the date code area to be checked. The system then reads the date code and checks it against the calculated date and format. If it is correct, a green border is displayed. If incorrect, a red alarm is raised to the operator. The same happens for the allergen check.

The system can also scan and check pack and case barcodes, using a Bluetooth wireless hand scanner, to speed up scanning and also improve ease of use.

T 07487 217665

W www.faedah-solutions.co.uk

Identification & Access Management ...

... Safety and Security in one system

How to guarantee employee protection against machine hazards, maintain productivity and also shield control systems from unauthorised internal or external manipulation? All hot topics in industry, especially in the face of increasing digitisation.

Pilz modular ‘Identification & Access Management’ solutions have this covered, offering functionality such as user authentication, safe operating mode selection, data and network security and access management.

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 17

Pilz Automation Technology ◆ Corby NN18 8TJ ♦ Telephone: +44 (0) 1536 460766 ♦ Email: sales@pilz.co.uk ♦ Website: www.pilz.co.uk

for

personalised solution! Scan the QR Code to find out more about our ‘Identification & Access Management’ Solutions

Contact us

your

First Automation UK event helps visitors to become more efficient

Automation UK sees leading players gather

Taking place at the CBS Arena in Coventry on 20 - 21 June, the very first Automation UK highlights the latest robotics & automation solutions to benefit visitors’ operational efficiency. Owned and organised by the British Automation & Robot Association (BARA), over 50 exhibitors, along with a full seminar programme, will greet visitors to the event. For free registration, visit www.automation-uk.co.uk

Epson Europe

This year, Epson celebrates 40 years of producing industrial robots, with 80,000+ units installed in factories globally. Its product range includes SCARA robots, 6-axis robots, and all-in-one series robots, supporting customers with manufacturing and smart production in industries such as automotive, life sciences, and consumer products. The company seeks to continue helping customers innovate and improve their product quality while cutting production costs.

W www.epson.co.uk/robots

Festo

Festo will be showing how easy it is to swap from one PLC manufacturer to another when using the Festo CMMT multiprotocol servo and stepper drives, and the versatile new

CPX-API/APA distributed I/O and bus driven valve terminal ranges. The company’s applications engineers will be on-hand at the show and in its Customer Applications centre to support implementations and to help users to get up and running quickly.

W www.festo.co.uk

via TIA or Step 7, for example, IP address assignment or redundancy settings.

W www.indu-sol.com/en

Piab

Valve terminal ranges are versatile

Indu-Sol

Indu-Sol says with its new PROmesh B8 industrial switch, a high performance and reliable switch has arrived on the market to address the price and performance-savvy machine and plant builders’ sectors. The PROmesh B8 is simultaneously PROFINET and Ethernet IP certified, which makes product procurement, integration and maintenance significantly simpler for companies that operate globally.

The managed switch saves valuable time and personnel resources for the installation and commissioning, as the devices can be configured/ parameterised automatically

Products demonstrated on the Piab stand will span a wide variety of formats to meet needs across many sectors. In the spotlight is the company’s suction cup range which includes a large standard offering, along with the latest suction cups that have been developed for specialist applications, including the BGX for flimsy film bags, as well as the egg and fruit specific suction cups. Visitors are invited to discuss specific applications to find out what vacuum solutions can be provided.

W www.piab.com

Robotiq’s off-the-shelf screwdriving solution which can transform a cobot into an efficient screwdriving cell will be shown, along with a robotic polishing demonstration. The MiR250 mobile robot will also be on the stand. W www.rarukautomation.com

wenglor

Among products that visitors to the wenglor stand can discuss is the new triangulation laser distance sensors from the P3 series that can provide precise measurement results at distances of up to 1,000 mm. It’s not just the high accuracy that’s world-class, but also the intuitive operation concept, the high-quality aluminium housing and the built-in TripleA technology that gives the P3 series the status of gamechanger for triangulation sensors in industrial automation, says the company.

W www.wenglor.com

RARUK Automation

RARUK Automation will be highlighting a wide range of its latest robotic solutions including two Universal Robots collaborative robot (cobot) application solutions, a Mobile Industrial Robots’ autonomous mobile robot and the ER-FLEX mobile cobot which will be loading and unloading a mock CNC machine.

wenglor’s sensors are very accurate

Preview 18 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Epson offers a full range of options

Suction cups meet specific needs

The PROmesh B8

RARUK can meet many robotic needs

Machine Vision Conference Preview

Content-packed event delivers new options and also seminars

Visitors to this year’s Machine Vision Conference will discover the latest industrial vision products as well as an interesting seminar programme

Over 40 companies will be on show at this year’s two-day Machine Vision Conference (MVC) taking place at the CBS Arena , Coventry from 20 – 21 June, along with more than 40 technical seminars dedicated to machine vision users and also engineers. Combined, says organiser UKIVA (the UK Industrial Vision Association), this confex is a must attend event for anyone looking for a vision solution for their business. It is also co-located with the new Automation UK exhibition for the first time.

This year, Acrovision will be demonstrating at least two examples of what it describes as AI/machine learning vision that solve identification or inspection problems that traditional vision tools have been unable to resolve.

concentrating on explaining the benefits of using AI OCR (optical character recognition) for various identification tasks. Whether it is a laser-etched serial number on an automotive part or a use-by-date on a wrinkled consumer product pack, Acrovision will demonstrate how new ‘Edge Learning’ tools are making these previously problematic applications, easy to solve.

Scorpion Vision will show how Mech Mind’s new generation AI+3D robot vision tech can support rapid development of 3D vision for robot picking challenges. The company will use a random bin picking application to illustrate how, by automating much of the application building process, Mech Mind’s intelligent robot solutions can accelerate

manager for machine vision Nathaniel Hofman will use his debut MVC presentation to launch new Nova SensorApps for onboard processing of measurement, presence and inspection tasks on the company’s 3D snapshot cameras. It’s the first time that the Sick Nova toolset is available for 3D, running on both the Visionary S stereo vision sensor and the Visionary T mini 3D time-of-flight camera.

Acrovision bills itself as masters of customer friendly Deep Learning vision

However, the demonstrations will be using technology that challenges the assumption that AI/Deep Learning vision has to be expensive and/or difficult and time consuming to implement, as they use easy to setup smart cameras that don’t require external PCs or any special software.

For the company’s conference presentation, Acrovision is

the design of challenging 3D robot vision applications.

“Mech-Mind’s AI+3D robot solutions essentially provide the key building blocks that systems integrators and machine builders need to design 3D vision driven robots,” explains Scorpion’s md Paul Wilson.

Meanwhile Sick UK’s newly appointed market product

With the Nova app, 3D applications can be set up quickly and easily without programming using an easy-to-use graphical user interface in a web browser.

Visitors can also discuss with Zebra Technologies its new Deep Learning Optical Character Recognition (DL-OCR) that supports manufacturers and warehousing operators who increasingly need fast, accurate, and reliable readyto-use deep learning solutions for compliance, quality, and presence checks. This new industrial-quality DL-OCR tool is an add-on to

Zebra Aurora software that makes reading text quick and easy. DL-OCR comes with a ready-to-use neural network that is pre-trained using thousands of different image samples. It can deliver high accuracy straight out of the box, even when dealing with very difficult cases. Users can create robust OCR applications in just a few simple steps –all without the need for any machine vision expertise.

Register for free here: machinevisionconference.co.uk

W www.acrovision.co.uk

W www.scorpionvision.co.uk

W www.sick.co.uk

W www.zebra.com

20 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

The Sick Visionary S robotics application

Mech Mind’s AI+3D solution is ideal for a range of manufacturing tasks

Installation News

Latest multihead weigher will handle sweet brands

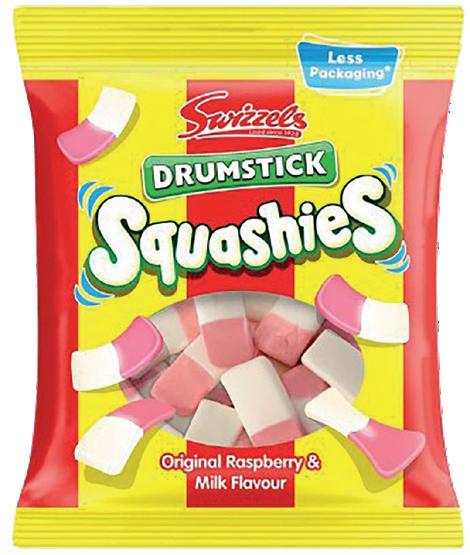

Increased demand for its popular confectionery brands has led Swizzels Matlow to build a new factory in Middlewich which will be supported by further weighers from Multipond UK.

A new 36 head twin weigher will be installed and commissioned by the middle of this year.

Multipond UK supplied its first weigher to Swizzels in 1993. This was a 14 head weigher sold to weigh Rainbow Drops into bags over a vertical form, fill and seal bagmaker supplied by tna Solutions. This Multipond equipment was chosen as its software had filters to mitigate the vibrations from the product trolleys which rumbled on the old wooden floor of the factory.

In 2012, Swizzels started to produce Squashies, and this brand’s success demanded higher packing speeds for the small bags. The Multipond 28 head twin outlet weigher was therefore supplied which allowed

small bags to be weighed at 400 packs per minute.

At the same time, the 28 head’s low profile meant it fitted into the existing factory which had restricted headroom. A feature that Multipond says competitor equipment couldn’t cope with.

Squashies has proved to be a great success for Swizzels, fast becoming the most sold sugar sweet brand in the UK. Multipond has therefore continued to support the company with weighers to keep up with the now global demand.

For instance, the addition of a new 36 head twin weigher meant these Squashies could be packed at speeds of up to 440 per minute in small bags.

Swizzels’ expansion,

Bagging equipment has simplified flow for expedition meals

Swedish Outmeals is now benefiting from Schur Star bagging equipment which has streamlined production flow while reducing staffing needs for its extensive range of expedition meals.

These meals are wet or dry, and also include vegetarian solutions, lactose and gluten free products, as well as halal meals and with growing demand, a more systematic approach to production was required to stop packing errors.

and demand for its products, has led to this new factory in Middlewich being built. The new factory will allow Swizzels to produce its bestselling product in higher volumes. The new weigher from Multipond will support this continuing market growth.

T 01494 471580

W www.multipond.com

Now, its packing machine has an adaptable filling line that can hold up to ten filling stations so that each item is packed from a different one. In the machine, the bags open to their full width to give operators both hands free to place the items accurately in the bag to prevent any errors.

W www.schur.com T

00 49 461 99750

quality

When Origin Kitchen needed to upscale its production to meet demand for its spreads and desserts range of products, it turned to Roboqbo’s universal processing system.

A single product trial was all that the start-up company needed to know that Roboqbo was the perfect solution for Origin Kitchen. Not only was it able to complete all parts of the manufacturing process in one single vessel in less than a quarter of the time, but the product quality and

shelf-life for the vegan range was much greater. With all ingredients being cooked together, the flavours were more intense, having bonded together throughout the whole process. The greater sheer offered also enabled better sized particulates, enhancing the creamy mouthfeel even further. And, as a small business with big aspirations, the zero-oxidation

achieved through vacuum cooking opens the brand up to larger distribution through major retailers, says UK agent Holmach.

As well as being able to manage the increased production demands for its own product range, the Roboqbo has also opened Origin Kitchen up to offering co-manufacturing solutions for a number of artisanal producers.

T 01780 749097

W www.holmach.co.uk

New processing equipment for a range of vegan products has speeded up production while improving food

22 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Manufacturing time is now just 25 minutes

The brand continues to be successful

New Machinery WASTE REDUCTION 11,197kg* less waste REEL REDUCTION 15,840* fewer reels MORE LABELS PER REEL 56%* 583 vs 375 *Based on 102mm sq label, 70m reel length & usage rate of 792 reels/month. Source; UPM Ra atac THE SAVINGS... Be GREEN and EFFICIENT with a Linerless Label Printer from ZEBRA LONGER BETWEEN ROLL CHANGES! WITH NO MORE BACKING PAPER! Unit 27 Eagle Road, Manorside Ind Estate, Redditch. B98 9HE T; +44 (0)1527 523242 | E; sales@thermalprintersupport.com www.thermalprintersupport.com • Stainless steel conveyor systems • Standalone units or fully integrated • Robotic and end of line equipment • Bespoke engineering capabilities • Turnkey and standalone solutions • Integration and project management • Service support and upgrades • Partnered with Lita Palletising Systems for over 30 years Kensal Handling Systems www.kensal.com | sales@kensal.com | tel: +44 (0) 1 582 425 777 Kensal Handling Systems Ltd, Kensal House, President Way, Luton, LU2 9NR

Mixer is handling brutal process to make hazardous material safe

Changing rules for managing hazardous wastes presented a challenge for waste management company

Augean PLC which was resolved by installing a mixing unit from J R Boone as part of a £1.2 million project.

Augean took the decision to make a substantial investment in the most advanced treatment unit for chemical waste in the UK when the legislation was pending, and the company has been pleased with the results. Its J R Boone mixing unit combines the shredded waste with cement and PFA (pulverised fly ash) to form a cake which can then be safely consigned to designated hazardous landfill sites.

The plant can accept a wide variety of waste containers ranging from 1M3 IBCs through to 200 litre steel drums and 50 litre plastics drums. In operation, the operator loads combinations of these containers onto a large infeed conveyor which delivers them

to the heavy-duty shredder reducing everything to 25 mm or less. After loading the containers, the process is remotely controlled from the computerised operator panel to keep human intervention to a minimum.

The waste is then fed into

the mixer with a measured amount of cement and PFA. The mixer then combines and encapsulates the waste particles with a cementitious coating and the finished product is then discharged into a skip for transport to landfill.

As the mixing is a pretty

brutal process, and the mixing machine needs to be up to the job, a series of tests carried out in a pilot plant on a full range of wastes showed that the proposed design could meet the brief. This was therefore scaled up into the full-size unit, which includes a 6-tonne horizontal paddle blade mixer driven by a 132Kw motor.

The mixer consists of a semi-omega shaped mixing chamber with outboard bearings carrying a contra flow paddle blade agitator. Adjustable packed glands seal the agitator as it passes through the ends. The mixing chamber, ends and agitator are made from carbon steel with agitator blades in wear resistant ‘Abro’ steel. The discharge is via a specially designed heavy duty flush fitting valve.

Making the unit dust-tight was also a key requirement and so an extraction and treatment system for volatile components was included.

T 01260 272894

W www.jrboone.com

VMECA product specialist and UK agent for over 20 years. Vacuum challenges? Simmatic has the solutions.

AUTOMATION UK 2023

COVENTRY BUILDING SOCIETY ARENA

BRINGING PNEUMATICS AND VACUUM TOGETHER

Simmatic’s experienced engineers will be at Automation UK on the 20 th and 21st June. We’re on stand A18 so, come and see us and say hello to our friendly team. With extensive expertise in vacuum & pneumatic industrial handling solutions, we invite you to challenge us with your difficult-to-handle products.

Watch VMECA’s NEW vertical MV-Magic Grippers in action:

- Innovative compact design

- Closer mounting centres

- Maximises surface area for handling

Installation News 24 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

J R Boone’s mixing unit combines shredded waste with cement and PFA

01299 877770 sales@simmatic.co.uk www.simmatic.co.uk Unit 11, Sandy Lane, Stourport-on-Severn, DY13 9QB

Amulti-million-pound investment increases capacity in efficient way

Prepared fresh vegetable supplier Fenmarc has enjoyed the benefits of additional throughput and efficiency at its Wisbech factory since installing new weighing and packaging lines, allowing it to expand its range with both new and existing customers. The new lines feature multihead weighing technology along with four GIC3100 high speed vertical form, fill and seal (VFFS) packaging machines, which now give Fenmarc higher speeds, greater accuracy and a lower cost of ownership.

Head of engineering Terry Holland

“The previous three lines had been running 18 hours a day, seven days a week since 2015,” explains Terry Holland, head of engineering at Fenmarc. “The lines were showing their age and needed more frequent expensive maintenance; some parts had become obsolete and were no longer supported; and new machinery offered better accuracy and performance.”

Phase one of the project was completed in 2020 and proved to be so much more flexible, faster and more accurate than the previous set-up. “That’s why we decided to commission an additional two lines, which were installed in August last year,” says Holland.

T 01427 611885

W www.gic.uk.net

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 25

BLH Series Oriental Motor (UK) LTD www.oriental-motor.co.uk – info@oriental-motor.co.uk – 01256 347 090 EZS Series AZ Series CVK Series BLE2 Series KIIS Series DGII-Serie KIIS Series Angle Gearboxes STEPPERMOTORS BLDC MOTORS AC MOTORS ACTUATORS We have the solution. Position. Transport . Rotate

New machinery for food manufacturers

Foodex Manufacturing Solutions took place at the NEC in April and saw a number of PPMA member companies demonstrate the latest processing options and packaging machinery that are all designed to make food manufacturers’ sites more efficient and profitable. Here, we highlight just some of the equipment on show…

Process control options give recipe and energy savings

Promtek demonstrated how its process control solutions for smart recipe handling and monitoring real-time power consumption can potentially transform a business at this year’s Foodex Manufacturing Solutions. Its StoraWeigh control system and Condor technology was demonstrated to visitors which can provide a strategic overview into all aspects of production, including ingredient reformulations, climate impact and energy costs.

Condor’s all in one platform uses predefined algorithms to accurately calculate energy efficiency. A web-based modular integration with rigorous user specific security properties, Condor provides customised batch reports with key information by connecting to multiple systems such as process control, ERP or PLC/SCADA.

As well as energy usage, Condor also allows security management and monitoring of raw material parameters.

Promtek’s system provides traceability and tracking of materials for recipes, with real-time monitoring of lot information. An integrated platform with StoraWeigh enables all the information to be collected and managed in one place This can be customised to suit changing needs.

T 01782 375600

W www.promtek.com

Ending non-compliant food label withdrawals

At Foodex Manufacturing Solutions, JentonDimaco showcased its latest Veri-VIEW software that checks food labels against robust source data before any food packs leave the factory floor.

The company says this ‘belts & braces’ automated approach to label verification can accelerate the verification process, catch mis-labelled products early, enable product to be reworked and re-labelled, resulting in fewer costly and brand-damaging food Emergency Product Withdrawals (EPWs).

“Checking the image quality and presence of a printed label is essentially only half the story and could be futile and non-compliant,” emphasises JentonDimaco managing director Dr Russell Sion. “Particularly if the production and retailer source data that food labels are being checked against isn’t correct or the most up-to-date version.”

Mitigating the risk of human errors, the addition of Veri-VIEW software helps to

ensure that all of the variable and non-variable label data matches up. Providing an instant overview of label integrity, Veri-VIEW captures in real-time, all the data generated by every system on the factory floor giving a complete overview from one convenient central display. Production and technical personnel get to see what’s happening as new data is issued, with the assurance that all actions are

automatically recorded. Putting this into context, this means that when a supermarket makes a label adjustment during the production run, for example to a price, the Veri-CENTRAL server will pick this up instantly. This information is then automatically relayed to every Veri-PACK labelling system within seconds and the action taken documented.

T 01234 851515

W www.dimaco.co.uk

Packaging and also processing equipment was demonstrated and discussed on stand

Visitors to the Multivac UK stand at this year’s Foodex Manufacturing Solutions could see and learn about its range of packaging and processing equipment from entry level up to high-output solutions while enjoying fresh baked pretzels and a barista-made coffee.

Equipment demonstrated ranged from a compact thermoformer to a free standing tray sealer; from a conveyor belt labeller to a high-speed bowl cutter;

from a vacuum filler to new portioning equipment, and also bakery technologies that meet the needs of the artisan as well as fully automated

manufacturing. A range of sustainable materials concepts could also be discussed.

T 01793 425800

W www.multivac.co.uk

Review 26 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Multivac UK showed a range of units to deliver flexibility and productivity

JentonDimaco says its label verification system mitigates against any EPWs

For more efficient cleaning and higher system availability

The new compact conductivity sensors LDL100 and LDL200 from ifm impress with their fast and precise media differentiation.

This helps you to control CIP processes efficiently and to increase the availability of your system. The new LDLs are also simple to commission: They are ready for use out-of-the-box and transmit the conductivity and temperature of the medium via a single M12 connection - digitally and loss-free thanks to IO-Link. As there is no additional evaluation unit required, you also save system costs. So easy, so good.

ifm – close to you!

Discover the new easy way to control CIP processes. ifm.com / uk ifm.com / uk Go ifmonline Go ifmonline years WARRANTY on ifm products

Entry-level range for drinks start-ups deliver expansion

In a bid to help start-up dairy, water, beer, beverage, spirit and wine producers take their operation to the next stage, without compromising product integrity, AVE UK unveiled a range of entry-level processing, packaging and bottling equipment at Foodex Manufacturing Solutions.

As well as large-scale full turnkey systems, the company also offers UK customers a range of semi-automated solutions ideal for small to mid-range producers that combine Italian heritage with today’s latest digital and sustainable improvements. From mini turnkey lines for processing beverages; semi-automatic wine filtration systems; 1,000 bottles-perhour rinser/filler/cappers; and even mini dairies, start-ups found a suite of automated and semi-automated solutions to help them ramp up production without busting their budget or affecting the quality of their finished product. And this is all backed up by on-the-ground, 24/7 local

support from AVE’s UK-based team of experienced engineers.

“Making the leap from start-up, artisan or kitchen production can seem daunting,” says Steve Bradley, AVE UK’s sales and marketing director. “Business owners often worry that the integrity or authenticity of their product will be impacted if they automate any of their processes; that the level of investment required will be too high and negate any

High speed pouch coding system was introduced at show

profit margin; or that modern automated systems will be too complicated or cumbersome for them to operate.

“In fact, the opposite is true as our portfolio of bottling, packaging and processing solutions bring together authentic Italian production methods with easy-to-use semi-automated innovation, at a competitive price point,” he tells Machinery Update.

T 01252 733200

W www.aveuk.net

At this year’s NEC-based Foodex Manufacturing Solutions, Rotech Machines introduced a pouch version of its original RF Lite equipment that already handles carton and sleeve coding. Since it was first introduced, the feeder has assisted hundreds of food & drink manufacturers in stepping up their date coding and this same compact design, costsaving technology, can now batch code pouches reliably.

The RF Lite Pouch sits alongside the Shuttle and Friction variants. Visitors could see an off-line batch coding system through the RF Lite as well as an on-line maintenance-free thermal inkjet printer, both of which allows users to trim their waste at every stage of production.

T 01707 393700

W www.rotechmachines.com

Ensuring food safety and also efficiency with a range of weigh, label and inspect equipment

Weighing, labelling and inspection technologies from Minebea Intec along with powerful software tools that ensure safety and efficiency in the processing and production of foodstuffs were seen on its stand at Foodex Manufacturing Solutions.

The VisioPointer is one of three vision inspection products from Minebea Intec which the company believes enhances the already popular inspection portfolio. It is also one of the key products

that helps drive automation within food production and manufacturing.

Combined with the WPL-A automatic weigh price labeller, customers can automate the entire end of their production lines where labelling plays a significant part of the manufacturing process. This WPL-A at the show was seen alongside the company’s static weigh price labeller (WPL-S).

“Increasing pressures on factory managers are forcing

more parts of the production to become automated which is where Minebea Intec can offer expert weighing, labelling and inspection solutions,” explained Peter Walker, country manager for UK and Ireland.

The company also offers a range of metal detectors, x-ray systems, recipe management software and in-line checkweighers such as the Flexus, which was available to view at the exhibition.

T 0121 779 3131

W www.minebea-intec.com

28 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

The Minebea checkweigher Flexus

Review

The RF Lite Pouch was launched

Wine making solutions are offered, from pressure tanks to bottling systems

Converting data in cost-efficient way

At this year’s Foodex Manufacturing Solutions ifm electronic focussed on its moneo IIoT platform which has been developed to provide a convenient solution to the challenge of converting the huge amount of data produced by modern plant and machines into useful information that can be used to reduce downtime, optimise efficiency and also cut costs.

IIoT solutions can be delivered at a modest cost

Inspecting on a small footprint

IIoT is currently seen as a technology that has enormous potential, but IIoT solutions have the reputation of being costly and difficult to implement. The moneo system eliminates these problems by making it easy to implement powerful and scaleable IIoT solutions at a modest cost, says ifm.

At the heart of the system is moneo OS, which provides flow modelling and automatic alarm functions as well as

facilities for managing all of the other moneo software modules. These include moneo RTM which can be used to implement fully customisable user interfaces presenting plant and machine information in numeric, graphical or dashboard formats; moneo configure, which offers powerful configuration and management facilities for connected IO-Link sensors and devices; moneo infopoint which collects data from connected devices; and moneo edgeconnect which allows easy and secure interchange of data with IT systems.

T 020 8213 0000

W www.ifm.com/uk

Many food SMEs are increasingly seeking compact, high performance, and energy efficient contaminant detection equipment which is why Fortress Technology showcased several of its small footprint solutions which are intentionally designed to save processors valuable production space without compromising on sensitivity. Offering detection of magnetic and non-magnetic metals in flour, rice, cereal, corn, grains, sugar, seeds and spices, the Fortress mini gravity metal detector, featuring a 75mm anti-static

in-feed pipe with a high-speed reject valve, is one example on show. It was created specifically for busy ingredient lines where space is limited.

On conveyor inspection lines, a retail-spec combination metal detection and checkweighing system provides an alternative spacesaver. Mounting these systems on the same conveyor results in a far smaller footprint than stand-alone units would occupy. At the exhibition, Fortress presented its most compact option, the 100 mm belt width Raptor Combi.

T 01295 256266

W www.fortresstechnology.com

• Increases shelf life (for up to 3 days)

• Medical, Pharma, Parts

• Greener packaging options

• Food-to-Go and Convenience packs

• Less food waste

The mini gravity metal detector was on offer to SMEs visiting Foodex

www.machineryupdate.co.uk MAY/JUNE 2023 MACHINERY UPDATE 29

FROM SINGLE PACK MANUAL TO HIGH SPEED LINEAR AUTOMATIC MACHINES SOKEN ENGINEERING IS PART OF THEJENTON GROUP

QUALITY

HEAT SEALING MACHINES FOR SANDWICH, WRAP, SALAD AND READY MEAL PACKS

P A C K S E A L S E L L www.sokenengineering.com 01525 376 000

Calculating waste makes perfect sense

Domino Printing Sciences (Domino) invited interpack visitors to complete its Waste Calculator to identify hidden causes of waste on their production lines and prioritise areas for investment as part of their ‘Journey to Zero’.

Part of Domino’s sustainable manufacturing showcase at the exhibition, Domino’s Waste Calculator is designed to highlight key areas where production line inefficiencies and errors can lead to excess physical and financial waste. It also demonstrates the role that smart manufacturing solutions and integrated coding and marking technologies can play in helping manufacturers to target ‘zero’ waste on their production lines.

“Our Waste Calculator helps identify where inefficient processes and errors could be contributing to wasted products and, by extension, wasted energy,” explained Jeremy Jones, global marketing director at Domino.

“We outline the steps manufacturers can take to ensure that the energy, time, and funds they invest are spent creating the maximum possible number of high-quality, sellable products.”

Domino’s Waste Calculator provides users with a bespoke in-depth report, or a simplified, industry-average-based overview centred on five hidden causes of production waste: manual data entry; manual code inspection; unreliable technology; service delays; and lack of integrated data.

T 01954 782551

W www.domino-uk.com

interpack connected

again

Under the heading ‘Welcome Home’, for seven days in May, interpack welcomed visitors from all over the world, connecting the industry on a global level and acting as both a marketplace for new developments as well as a content hub.

Organisers say the exhibition delivered what it promised and exceeded exhibitors’ expectations: by bringing together approximately 143,000 visitors from 155 countries, many of which came with firm intentions to buy.

Two thirds of them came from outside Germany, and alongside many European countries, the largest visitor nations were India, Japan and the USA. They were greeted by 2,807 exhibitors that showcased the considerable range of new machinery that has been developed since interpack 2017.

The next interpack will be held in Düsseldorf from 7 – 13 May 2026, but in the meantime, the next 17 pages of this issue covers just some of the new technologies on show this time.

VDMA calls for less bureaucracy to help engineering to thrive

At interpack, chairman of the VDMA Food Processing and Packaging Machinery Association Christian Traumann, and group president of Multivac, appealed to politicians to do more to reduce bureaucracy for mechanical engineering and to open up markets.

“If a transformation of the manufacturing industry is to succeed, we must not be overwhelmed with regulations, but must be supported by policies that promote industry and small and medium-sized enterprises,” he told the VDMA press conference. “Innovation needs entrepreneurial freedom and competition,” he said, referring to slow approval procedures in Germany and also the current and upcoming EU regulations.

In an increasingly protectionist environment, he said, the EU must focus on free trade agreements. Only then can new barriers be prevented from being erected for European industry.

Expanding operations in the UK, Ireland, USA and Canada for customer advantage

At interpack, the UK arm of Grunwald announced an enhanced partnership with Grunwald GmbH, the specialist supplier of format flexible cup and bucket filling and sealing equipment.

This new partnership will see Grunwald Ltd offering all marketing, sales and aftersales support in the UK, Ireland, USA as well as Canada, which is a new territory for the business.

Samantha Smith (operations and projects director at Grunwald Ltd) and James Causebrook (md of Grunwald Ltd), the renewed partnership will also see the two teams working collaboratively in new areas for customer gain.

A four-line rotary filling and sealing machine on its stand was finding favour with visitors as this compact unit offers a long shelf life, labour savings and short payback.

Spearheaded by Ralf Müller (md of Grunwald GmbH), Causebrook, Smith and Müller unite

T 01529 414999

W www.grunwald-uk.com

30 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Review – Introduction

Waste Calculator offers benefits

Christian Traumann at interpack

all the latest developments on a global scale

A successful return for interpack after a 6-year hiatus thanks to COVID-19

Innovative. Efficient. Individual. Intelligent lines for maximum productivity

» Processing

» Product loading

» Packaging

» Labelling & printing

» Quality inspection

» Box loading & palettizing

MULTIVAC is an experienced manufacturer of automation solutions. With our comprehensive understanding of your products and requirements, we develop solutions for even the most complex of packaging and automation tasks - from a single automation process to a complete factory solution. Developed, delivered and serviced by MULTIVAC as your engineering partner, your complete contractor and one-stop supplier.

www.multivac.uk

Units optimise manufacturing

Mpac showed visitors to interpack its end-to-end manufacturing capabilities that are designed to help food and beverage, healthcare and pharmaceutical businesses to optimise their manufacturing processes as well as new digital tools including the Mpac Cube.

The company demonstrated a range of cartoning, case packing and palletising equipment including a new high-speed tray former that has been designed to replace plastic trays by running lightweight corrugated cartons.

It is designed to handle the transition from plastics to more eco-friendly carton materials as customers all over the world demand more sustainable options.

Its small footprint means that the machine can fit in almost every factory layout, replacing or working together with existing tray

Mpac launched the

Unstable bottles are easy to collate

denesters, if required.

Also on show was an hygienic continuous carton machine that handles small and large carton sizes and allows for gentle product handling and carton closing at up to 500 cartons a minute as well as an hygienic, open design concept horizontal case packing machine that handles a wide range of case formats at up to 25 cases per minute.

Machinery from Mpac is available in the UK from Springvale Equipment.

T 01420 542505

W www.springvaleltd.co.uk

Sidel unveiled the new Cermex ProSelex flexible collating system for complex unstable bottles. This gentle, streamlined, grouping device is designed to work with any type of case packer and is designed to deliver efficiency, high availability, and greater operability.

Acting as an integrated module of a case packer that is receiving products upstream from one lane, the latest Cermex ProSelex continuously pitches, collates and prepares the container batches before they are transferred, and case packed. Based on a simplified and streamlined

kinematic process, this new generation improves on the performance of the previous module with an increased speed capability of up to 300 products per minute, and on a more compact footprint. Productivity is also delivered by additional timesaving, achieved through a reduction in changeover time, courtesy of a simplified and repeatable process for operators, which anticipates an average changeover to last between 1 minute for a new collation to 2 minutes 30 seconds for a complete bottle change.

T 01707 292820

W www.sidel.com

Overwrapping range of equipment can handle paper-based materials as well as recyclable and/or biodegradable film

At interpack, Marden Edwards showed a range of its overwrapping equipment that, as well as traditional films, can also handle BOPP and biodegradable BOPLA films along with paper-based materials to wrap individual cartons and carton collations.

For instance, reduced packaging can be achieved by offering banding of packs or groups of packs in widely recyclable PE, using the company’s cost-effective stretch bander that holds

The range of overwrappers was demonstrated

packs tightly together for distribution or point of sale presentation. And as no shrink tunnel is required, the unit also offers low energy consumption.

This stretch bander was joined on the stand in Germany by a manual individual carton wrapper; a multipack bundle in paper; an individual carton overwrapping in paper; and an individual carton overwrapper with fully adjustable tooling.

The overwrappers are designed to provide a versatile solution to add not only shelf appeal but also tamper

evidence and also eliminate any odour contamination.

Other features offered by the range of overwrappers include seal area flexibility which allows the longitudinal seal to be positioned either on a trailing edge or on the base of the carton, depending on carton design and any marketing needs along with geometrically exact end folds to give a sleek finished look for confectionery packaging.

T 01202 861200

W www.mardenedwards.com

Review 32 MACHINERY UPDATE MAY/JUNE 2023 www.machineryupdate.co.uk

Fewer change parts offer cost efficiencies and an optimised time to market

Thermoformer and wrapper demonstrate sustainable gain