Issue 4, Volume XXXIV, July/August 2023

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

INSIDE NEWS

Delivering smarter

Our annual automation, robotics and vision systems feature demonstrates the growing importance of this sector in delivering productivity gains for users

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

The first ever Automation UK exhibition organised by BARA took place this June, co-located with UKIVA’s Machine Vision Conference and was hailed a success by visitors & exhibitors

NEW MACHINERY

Markem-Imaje has launched the 9750+ continuous inkjet printer, which is billed as a hybrid coder, to help customers cut costs and reduce inventory needs for both pigment and also dye inks Find out more on page 16

INSTALLATIONS

SCADA software has helped FEI Foods to increase throughput at its new facility

NEWS PLUS

The PPMA Show returns to the NEC this autumn – 26-28 September, so save the dates to see the technology on show www.ppmashow.co.uk

CONVEYOR COMPONENTS

IN STOCK EXTRUSIONS ARE 1000 GRADE UHMW POLYETHYLENE

+44 (0) 1484 864733 sales@pennine.org www.pennine.org

CUSTOM MACHINED PLASTIC PARTS

PENNINE

YEARS 1968-2023

Contents

7 NEWS

The PPMA presents its manifesto which puts automating UK PLC top of the trade body’s portfolio

12 NEW MACHINERY

Multivac’s latest high-speed slicer delivers reliability, sustainability, ease of use and cost effectiveness

22 INSTALLATIONS

Five pages of installations cover a range of end user sectors, but all deliver operational advantage

31 SPECIAL FEATURE AUTOMATION, ROBOTICS & VISION SYSTEMS

This annual feature covers the latest technologies that are being developed to facilitate smarter manufacturing that helps to increase production flexibility and efficiencies

REGULAR FEATURES

20 REGULATIONS

ISO 13849 is a safety standard that applies to parts of machinery control systems that are assigned to provide safety functions and it is now being replaced with a new version, after a transition period that may take up to three years. This document has been reorganised to better reflect the design/development process for control systems and now also includes a focus on a number of risk assessment recommendations

EDITOR:

Gail Hunt gail.hunt@ppma.co.uk

PUBLISHING MANAGER:

Bill Lake bill.lake@ppma.co.uk

ARTWORK CONTRIBUTOR:

Barry Heath

HEAD OF PUBLISHING:

David Chadd david.chadd@ppma.co.uk

A PPMA PUBLICATION

PPMA Ltd

New Progress House, 34 Stafford Road, Wallington, SM6 9AA

TEL: +44 (0) 20 8773 8111

E-MAIL ADDRESSES: publishing@ppma.co.uk show@ppma.co.uk technical@ppma.co.uk

WEBSITE: www.machineryupdate.co.uk

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from specifiers, managers and purchasers of processing and packaging machinery in the UK.

ANNUAL SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

ISSN 0969-4145

56 COMPONENTS

NORD Drivesystems is equipping its products with QR codes which will offer numerous advantages to the customer such as quick direct access to their respective country team. Clients will be able to reach the right contact person who will be able to speak their own language

57 MACHINERY FINDER

Machinery and also services

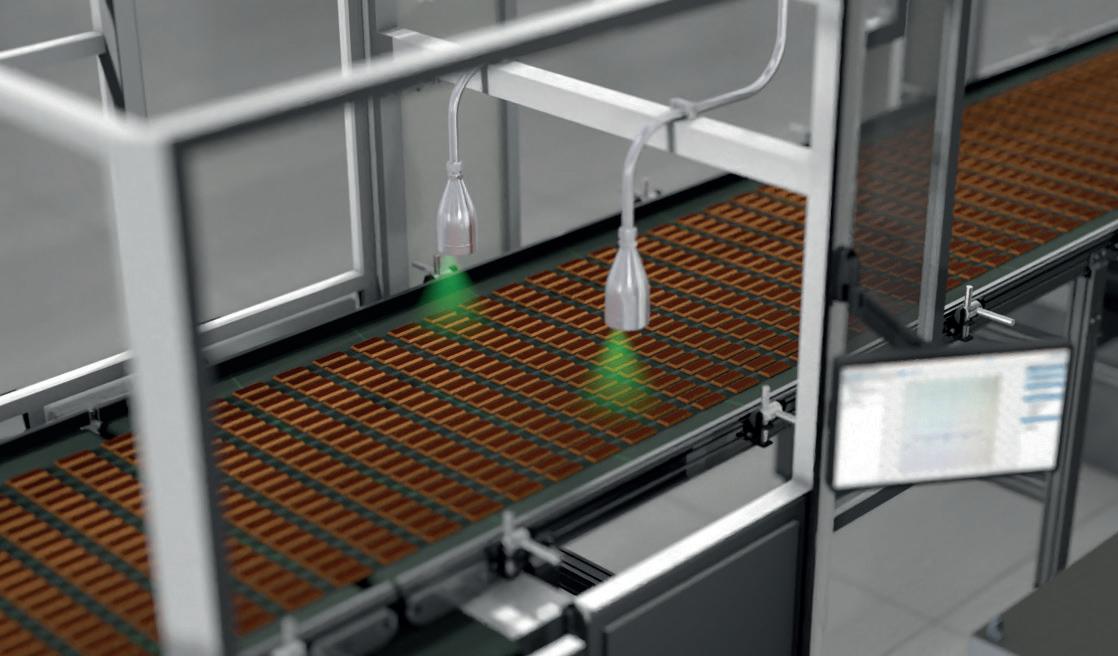

MACHINE VISION COMPONENTS FOR AUTOMATION, CONTROL AND QUALITY INSPECTION

For measurement and inspection including print and barcode verification our cameras, lighting and powerful machine vision software solutions provide the answers.

For food inspection including fruit, vegetables and cereals, ALRAD supplies Multispectral and Hyperspectral vision systems covering all wavelengths from ultraviolet through visible, nearinfrared (NIR) and shortwave infrared (SWIR).

PRINTED BY:

John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

Publishers: PPMA Ltd

Do you need to monitor ‘Hot Spots’ for process control, preemptive maintenance or design inspection?

Our Thermal Vision systems give you the hidden picture.

We offer a wide range of cameras, lenses, lighting, interface cards, cables, housings, software and much more...

Tel: 01635 937000

Email: sales@alrad.co.uk

Web:www.alrad.com

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 3 July/August

2023

22

30

-

-

Safe, error-free operating Intelligent Robot Filler For use with hazardous materials or where there is a risk to the operator Precision Filling Remote Support Removes Operator Error Key Features ABB Robotic Arm Pallet handling conveyor SERVO-controlled diving lance Nozzle dive distance of up to 1m Mettler-Toledo weighing system SERVO actuated camera vision system Capping head with magnetic or grip hold Competitive timelines for on-site installation Email us: info@adelphi.uk.com | Call us: +44 1444 472300 | Website: www.adelphi.uk.com Visit Our Website Shibaura Machine's SCARA and 6-Axis I ndustrial Robots. O ffering control and precision for over 40 years.

Joining pieces to make sense for all of us

Ibelieve that our trade association has a pivotal role to play in advancing industrial automation in this country for the good of all manufacturers. It’s a bold statement, I know, but it is based on the incontrovertible fact that as a group of 550+ expert companies in the field, we can act as the enabler to make this happen.

Industrial automation is an incredible jigsaw, in which I am proud to say that our members hold the corners and edges. We can therefore play the key role of facilitator to piece this jigsaw together for the good of UK PLC. After all, what’s the use of a jigsaw, if you don’t put it together?

Increased automation is the only way forward for UK manufacturing being able to compete on the global stage. And, I would argue, the wealth of technical skills offered by our members can surely make this happen for our end user customers. I do admit, however, that the current political paralysis, which I would say is worse than a political crisis, is not helping any of us to move forward at the moment. Hopefully, whenever we get a government with a workable mandate, this stalemate may be broken.

The road to automating our manufacturing sector is not a straight line – but we can be the pathfinders

Our inaugural Automation UK trade show in June (which was co-located with UKIVA’s Machine Vision Conference), was just one step we, as an association, have made to help make adopting automation, robotics and vision systems easier for everyone. Visitors to the 2-day exhibition in Coventry found the very latest technologies which you can find out more about in this issue (see pages 8-10). You will also find our annual feature on this topic which starts on page 30.

At the event, our CEO Peter Williamson outlined the PPMA’s new manifesto, a document that we think is another important piece of the jigsaw. There are many aims and goals in this document, but investing heavily in education and training is certainly one key part and setting up a new technical department is another. We recognise that one of the problems about the path to industrial automation is that it is not a straight line. It is more like a very complicated maze, which can often be the stumbling block, so we believe this strategy can help people to take the first step more easily.

Everyone knows that increasing automation in our factories is a good idea. We just need to put it at the very top of our to-do list! n

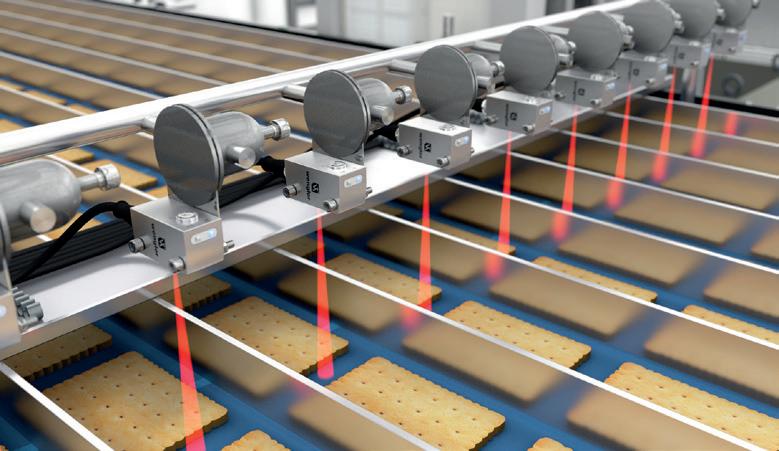

CleaningResistant and Robust Sensors

The sensors for the washdown area are ideal for use in washdown applications in the food, beverage and packaging industries. The high-quality stainless steel 316L housing makes them robust and corrosion-resistant

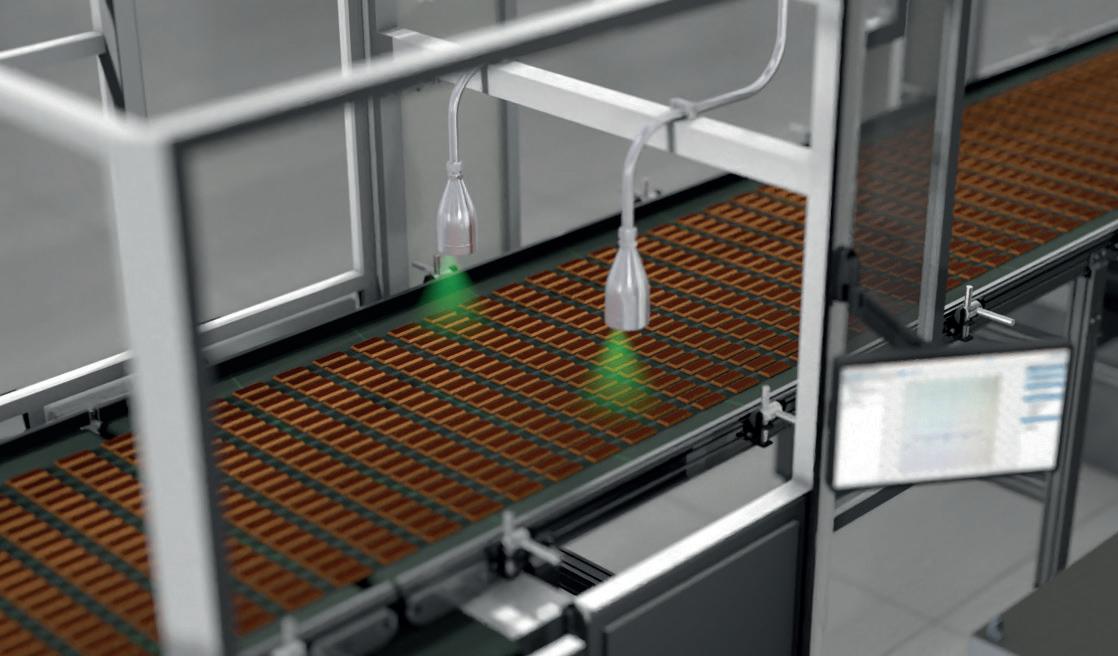

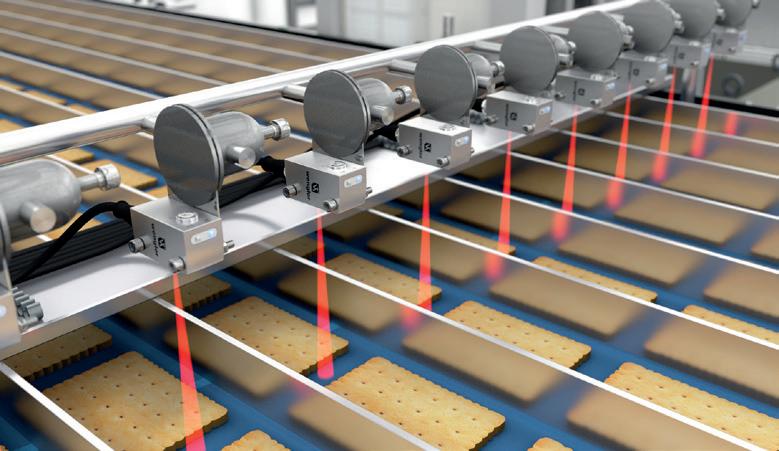

Height and Angle Measurement of Ice Cream Cups via 2D/3D Profile Sensors

Detection of Cookies with Reflex Sensors with Background Suppression

Detection of Food Trays with Reflex Sensors with Background Suppression

Color Control of Baked Goods with Vision Sensor

www.machineryupdate.co.uk MACHINERY UPDATE 5

PPMA matters

James Causebrook

CHAIRMAN, PPMA GROUP OF ASSOCIATIONS (INCORPORATING PPMA, BARA AND UKIVA)

wenglor sensoric ltd. Unit 2, Beechwood | Cherry Hall Road | Kettering Business Park Kettering, Northants NN14 1UE +44 1536 313 580| info.uk@wenglor.com

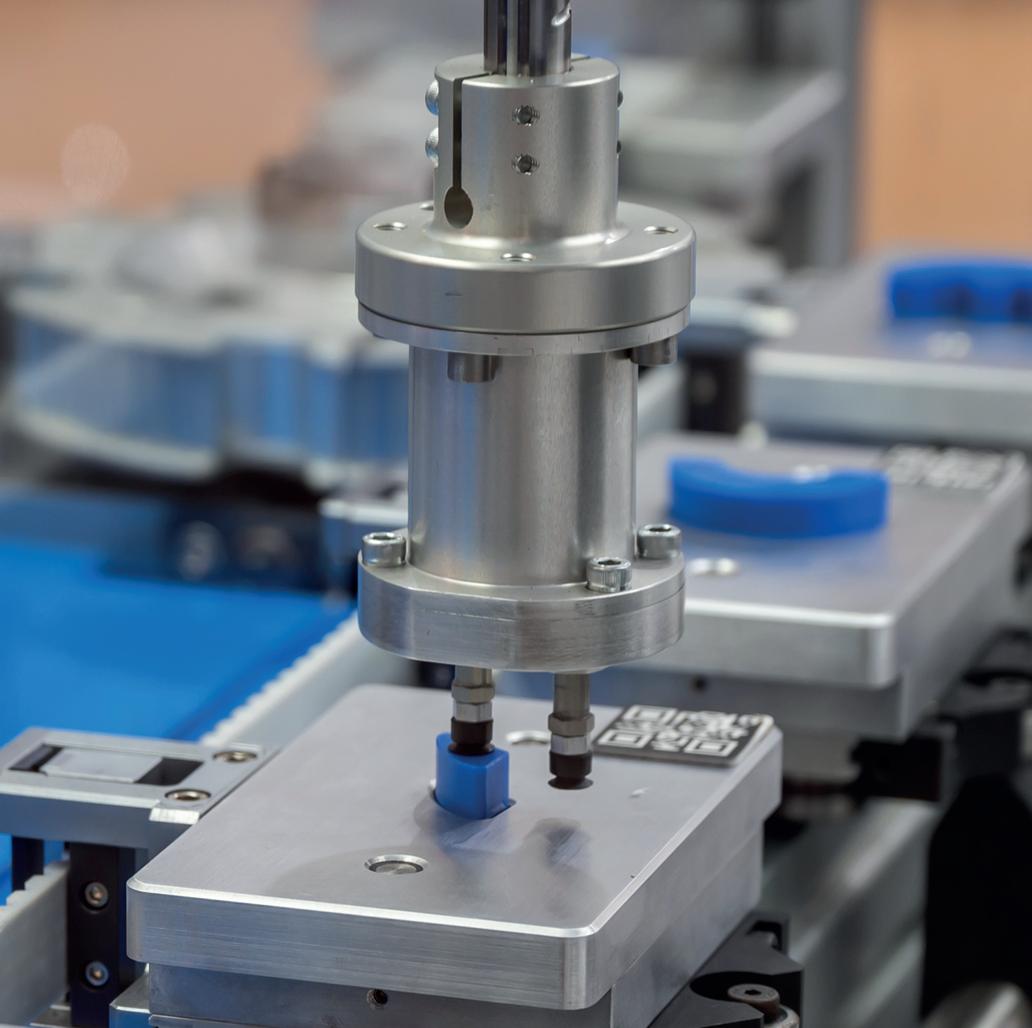

Giving sight to robots

3D vision sensor for plug and play integration into gripper applications from Universal Robots

The perfect combination of powerful hardware and easy - to - use software makes it possible to easily implement vision sensors in gripper applications from Universal Robots.

The core element of the ifm vision sensor is a 3D camera chip. It creates a 3D image using PMD technology and time of flight measurement.

The UR+ plugin ensures smooth and quick integration of the sensor. It detects any object, even moving ones, and transmits its exact position and dimensions to the robot control. Never before was gripper navigation so easy! ifm – close to you!

Go ifmonline Go ifmonline

ifm.com / uk ifm.com / uk

Acquisition will strengthen offer

Combining the two businesses will bring gains in adhesives

Global adhesives company

HB Fuller Company has acquired Beardow Adams, the familyowned UK business that has grown since it was established in 1976 into a multinational industrial adhesive manufacturer.

The acquisition is expected to accelerate profitable growth in many of HB Fuller’s core end markets and generate business synergies through production optimisation and an expanded distribution platform.

“As we combine our businesses, we will be a stronger force in the adhesives industry,” says Jim East, executive vice president hygiene, health and consumable adhesives at HB Fuller Company.

New exhibition combo answered visitor needs for smarter technology

The inaugural Automation UK hosted by BARA (British Automation & Robot Association) at the CBS Arena in Coventry this June was hailed as a great success by visitors and exhibitors alike.

Co-located with the UKIVA’s Machine Vision Conference, the two-day event, proved to be a useful one-stop-shop for automation and robotics, combined with industrial machine vision, that provided end user visitors with a complete range of smarter solutions. As exhibitor B&R Automation’s Stephen

Ratcliffe told Machinery Update, the exhibition was perfectly formed and there was no ‘filler’. This meant visitors could access the latest technology in one place, and from all the key players that were present.

“We are now planning to capitalise on the momentum that has been generated, with double the floor space reserved for 2024,” said Scott McKenna, deputy COO at the PPMA Group of Associations.

The next Automation UK will take place in Coventry from 18-19 June 2024.

PPMA Show returns this September

The PPMA Show returns to the NEC Birmingham this September with over 350 exhibitors showcasing more than 2,650 brands from the full spectrum of packaging and processing technologies.

Acquisition enhances customer offer from Dura-ID and Atwell

Dura-ID Solutions has acquired Atwell Labellers, supplier of self-adhesive labellers.

The PPMA Show is the UK’s largest processing and packaging machinery exhibition, established over 36 years ago and every September, leading companies gather to launch processing and packaging machinery, robotics and industrial vision systems. Organised by the PPMA Group of Associations, the exhibition takes place in Hall 5 of the NEC between September 26 to 28, and will demonstrate equipment designed for food, beverage, pharmaceuticals, household products and toiletries, building materials and supplies, pet care, micro-brewery and distilleries, contract packers and more.

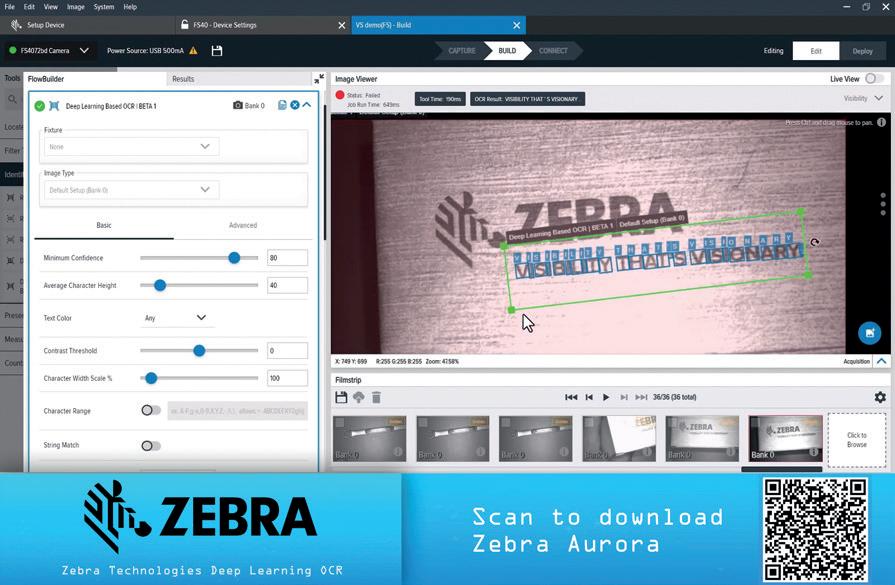

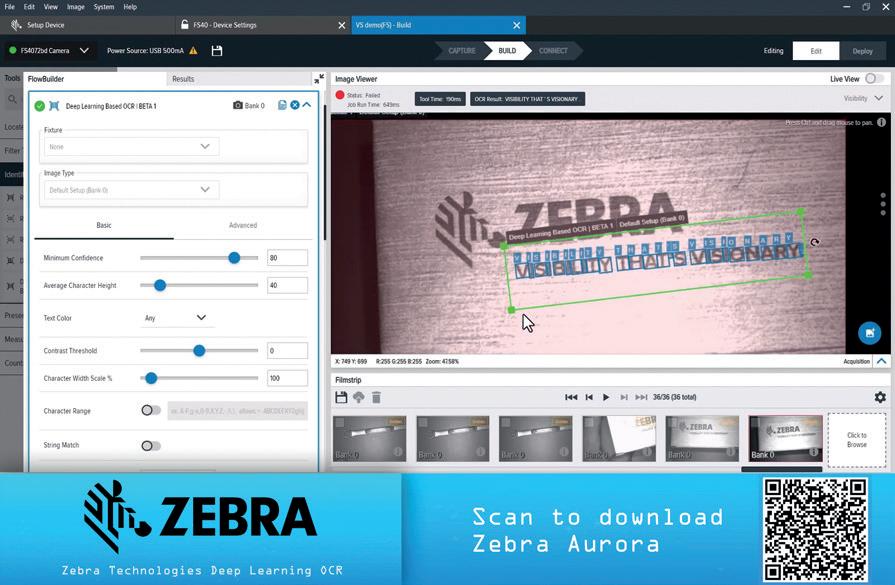

CONFERENCE SAW NEW PRODUCTS AND SEMINARS Vision range brings benefits

Beckhoff Automation took its participation at the Machine Vision Conference as the perfect opportunity to demonstrate, and talk about, its new complete vision system comprising hardware and software which can be synchronised with all control processes. It is billed as offering seamless system integration via cameras, optics, illumination, complete units, software, training and support.

Dura-ID Solutions (part of the investment group Goonvean Holdings) views the move as an excellent way to enhance its customer offering, diversify its customer base and boost existing distribution channels.

Following the transaction, the existing management team and employees will continue to run Atwell Labellers as a wholly owned subsidiary of Dura-ID Solutions, while Shaun Higgins, the managing director of Dura-ID Solutions, will lead the new combined businesses.

“Between the 350+ companies exhibiting there are thousands of years of experience in packaging, processing and automation machinery,” says Richard Little, the PPMA Show director. “Visitors are encouraged to bring their problems and requirements to the show where there will be people who know what to do and there will be plenty of machines to look at actually doing it.”

Register your interest today or for more details visit: https:// www.ppmashow.co.uk/visit

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 7 News

Several exhibitors said that attendees were visiting with real projects in mind

The event is set for more success

First Automation UK event helps visitors to become more efficient

Machinery Update reports on the new technology options demonstrated at the first Automation UK exhibition as well as a range of presentations

Arange of equipment was presented to visitors to the CBS Arena in Coventry for Automation UK, including integrated automation capabilities from ABB and B&R.

ABB demonstrated its GoFa collaborative robot and B&R’s ACOPOS 6D new handling system. Offering a 5 kg payload and a 950 mm reach, GoFa is designed as a collaborative partner for a wide range of applications. The demonstration showed GoFa working in collaboration with B&R’s ACOPOS 6D system, which uses magnetically levitating shuttles to carry products and materials to processing stations, eliminating mechanical wear, and speeding up transit times.

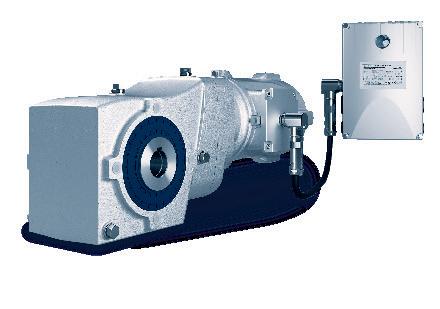

At the show, Apex Dynamics launched the BKM high efficiency hypoid gearbox range, which marks a major expansion of the company’s UK product offering. The BKM line has been designed to complement the company’s existing range of planetary gearboxes. The high efficiency hypoid gear units comprise MV direct motor mount, IEC motor mount, and ST servo motor mount variants. A new generation of hypoid gearboxes,

the BKM range is suited to general purpose machine applications, delivering improved efficiency and performance to help meet reduced energy consumption demands from customers.

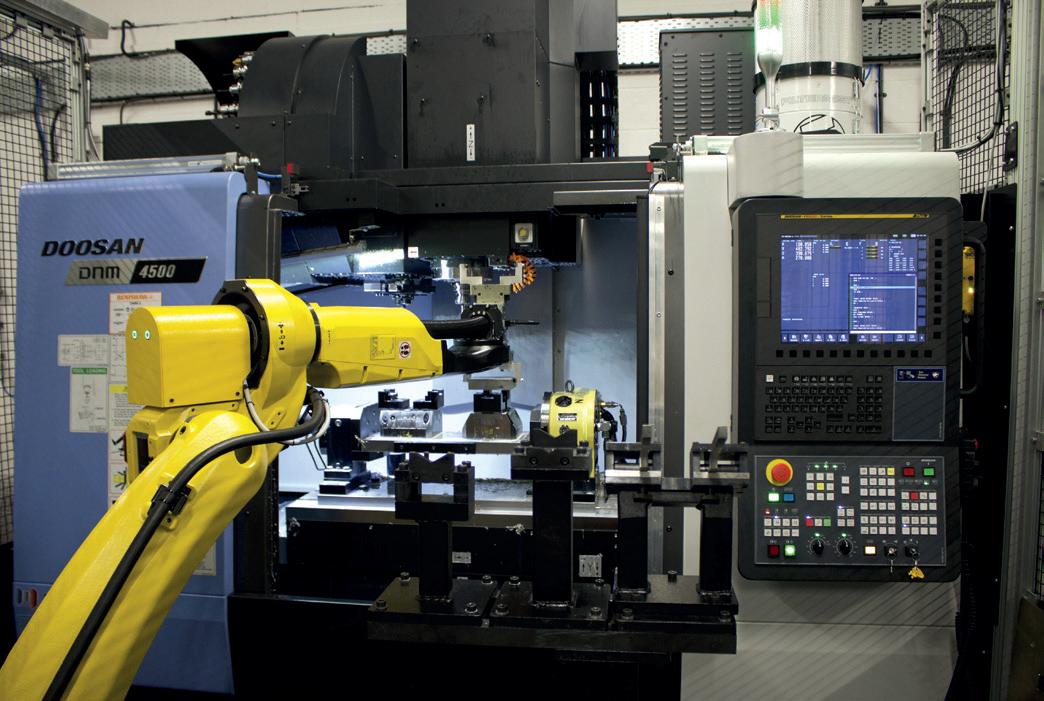

As part of its campaign to inspire the next generation of robotics engineers, Fanuc UK showcased a suite of educationthemed initiatives. Recognising its responsibility to help inspire a future talent pipeline, the company is placing education at the front and centre of its activities throughout 2023. The event served as the perfect springboard to highlight the benefits of a career in robotics, as well as demonstrating to visitors the myriad applications of its robot and cobot solutions.

Heidenhain showcased powerful solutions that are said to set new standards in automation drive systems, including products from its brands AMO, RENCO and RSF. Visitors discovered new inductive rotary encoder variants for robotics applications along with the next generation of inductive scanning.

The KCI 120 Dplus dual encoder with motor position and joint position measurement in a single device is available in three sizes, while the latest

North American trends…

The

He talked about the reduction in orders for both robotics and vision this year and although he predicted a bumpy road ahead in the short term, he was confident that by the 4th quarter, things would be getting back on track.

“While inflation and a slowing US economy may have taken a slight toll on robot orders overall, automotive companies continue to accelerate their purchases as they make the transition to manufacturing electric vehicles,” he said. “Non-automotive companies are

typically newer to automation and may be waiting to invest until they’ve tested recent deployments or see the economy begin to recover.”

In any case, automation makes companies more productive and globally competitive, and the shortages of skilled labour we are seeing right now is proving a barrier to the US reshoring jobs, he said. “Remember, automation is not a job killer; it is the facilitator for creating new and more rewarding careers.

“Remember, that people are the most important part of any automation solution,” he attests. Instead of worrying about losing jobs through automation, we need to talk about how it transforms our world for the better, and in so many ways,” he told MachineryUpdate.

KCI 120 and KBI 136 are compact rotary encoders for large 30 mm or 40 mm hollow shaft diameters.

For Matara, the key product focus on its stand was linear actuators which, along with the motor, are the driving force of a linear motion system. The company offers a substantial range of belt driven and ballscrew linear actuators, including the best-selling MTB and MTS series belt driven actuators, which were on display, including a working version using a Gapp Automation control unit; Gapp Automation has recently joined Matara’s parent company, Rubix.

Mills CNC unveiled the power, flexibility and productivity potential of its range of Doosan cobots at the event. The two cobots, a powerful, heavy-duty H2017 model with a 1700 mm reach radius and a 20 kg maximum payload capacity, and an ultra-versatile M1509 model with a 900 mm reach radius and a 15 kg maximum payload capacity, shared centre stage on Mills’ stand. These cobots took on a series of repetitive and routine pick and place and assembly operations designed to demonstrate their flexibility, dexterity, productivity potential and ease-of-use and deployment.

He felt that one of the key’s was education, where to find a trusted resource and then how to apply the technology successfully.

W www.automate.org

Review 8 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

▸

Jeff Burnstein spoke at Automation UK & MVC

President of the Association for Advancing Automation (A3) in North America Jeff Burnstein was the keynote speaker at Automation UK and the co-located Machine Vision Conference.

Representatives from RMGroup were on-hand to discuss the company’s automation offering, including pick, place and palletising solutions, collaborative industrial robot systems with AMR, and its latest compact palletiser. Being the first integrator in the UK to be accredited

under the A3/BARA Robot Integrators Certification Scheme, RMGroup supplies and manufactures a wide range of automated packaging systems as well as supplying bagging solutions, weighing systems, and high-speed form, fill and seal packaging lines to customers.

Schubert UK included its new cobot, which is now ready for series production, a bar packer with a special infeed, its new Box Motion unit in the flowpacker’s cross-sealing system and its ‘Packaging Perspectives’ customer service for sustainable packaging.

The PPMA Group’s automation goals

On the first day of Automation UK, the chief executive officer of the PPMA Group of Associations Peter Williamson presented his thoughts on how the trade body believes UK PLC must adopt automation to continue to compete in the global market, and also how it could help with this process.

He presented the new PPMA Manifesto for Automation, a document that will be rolled out over the coming months, but essentially it commits the member-led organisation to help overcome the series of challenges facing everyone to ensure that automation is central to the future of UK manufacturing.

It covers the workforce challenge, the UK’s reticence to invest in automation, what the Government can do to support industry and the PPMA goals and commitments.

Mark Stepney, md of Schubert UK, is organiser BARA’s vice chairman and sees this exhibition as an ideal opportunity for companies to get up close and personal with today’s cutting-edge technologies: “With many exciting live demonstrations, compelling information and in-depth consulting, the exhibitors were all committed to giving visitors first-hand insight and impressions of the latest automation and robotics technologies,” he tells Machinery Update

Troax says its Panel Detection revolutionises machine guarding with enhanced safety measures. Visitors could discuss this patent-pending electronic device that detects securely mounted panels, ushering in a new era of active safety. By integrating technology into machine guarding, it enhances the safety and intelligence of existing guards, making them even safer and smarter.

The automatic monitoring system increases safety around production cells while minimising costs associated with accidents. It also transforms traditional mechanical safety into an electronic solution designed for Industry 4.0. This technology takes machine guarding to a whole new level, enabling the detection of unseen dangers and costs, says the company, so that customers can now take greater responsibility for personnel safety.

W www.automation-uk.co.uk

• Proven technology

• Sturdy robust design

• Quick and easy set up between size formats

• Supplied in either tape or hot melt application

• Various options available

• UK engineering support/install

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 9

Automation UK will be back at the CBS Arena, Coventry next year, taking place between 18-19 June

Lantech modular case erector

to

17 Elizabeth Court, St Neots, Cambridgeshire, PE19 8PF T: 01480 382739 M: 07764 772965 E: andrew@maters.co.uk www.maters.co.uk

C1000/2000 case erector from Lantech

capable of up

30 erected cases per minute

CS1000H

Peter Williamson, the PPMA’s CEO, presented

Luke Mealing has been funded

PPMA BEST funds the next generation of young engineers

Premier Labellers has taken on a new apprentice with the help of funding from PPMA Business Education Skills and Training (PPMA BEST), which was established as a charitable incorporated organisation in 2014.

“Apprenticeships are key to fitting in with our ethos of developing our people,” says ceo of Premier Labellers Tracie White.

Luke Mealing, a Harwich local, will receive on-the-job training along with study time and a full-time salary to help him to achieve industry recognised qualifications. He will complete his apprenticeship programme and be debt-free.

Machine vision event shared success with co-located exhibition

MVC 2023 impressed visitors with its unique displays of industrial vision and imaging technology while industry experts imparted unparalleled knowledge in 50 presentations across five seminar theatres on subjects ranging from vision innovation, 3D vision, understanding vision and deep learning/embedded vision.

This 7th Machine Vision Conference (now co-located with the inaugural Automation UK exhibition) provided visitors with the chance to see

the latest in machine vision technology, development and applications as well as its capabilities. During the course of the two-day event, the aisles welcomed a steady stream of visitors to the displays.

“Co-located with the brand-new Automation UK exhibition, and capitalising on the synergies that exists within these sectors, visitor numbers to MVC were at an all-time high,” said Scott McKenna, deputy coo at PPMA Group of Associations. Next year’s event takes place from 18-19 June.

Cobot hub unlocks benefits of robots and automation

Universal Robots has opened its first UK hub in Sheffield. Taking advantage of the region’s rich industrial heritage, this new hub is designed to help UK manufacturers unlock the benefits of collaborative robotics and automation technology.

Leveraging Yorkshire’s strong manufacturing links, the new robotics hub will house offices and a showroom where the latest technology and applications for cobots will be demonstrated. It will also host training sessions and meetings to strengthen relationships between developers, distributors and manufacturers. This new hub builds on the existing facilities and equipment at the University of Sheffield, Sheffield Hallam University, and the Advanced Manufacturing Research Centre (AMRC).

A third-generation British family business is celebrating its 60th anniversary this year

Packaging Automation, a third-generation British family business, is celebrating its 60th anniversary which, it believes, is a true testament to the company’s unwavering commitment to excellence and adaptability in the ever-evolving packaging industry.

Founded by Arthur Penn in 1963, the company initially focused on providing automation solutions to streamline packaging processes. Over the years,

it expanded its horizons, continuously embracing new technologies while recognising

the importance of research and development and investing in cuttingedge machinery.

Through the decades, Packaging Automation’s focus on customer satisfaction has remained at the core of its values, as has its commitment to sustainability and also environmental stewardship. From developing energyefficient machinery to promoting recyclable packaging materials, it has demonstrated its dedication to creating a greener future for the industry.

World’s first remote robot is in Amazon

A pilot project between ABB Robotics and US non-profit organisation Junglekeepers is demonstrating the role Cloud technology can play in making reforestation faster, more efficient and scalable. ABB’s cobot YuMi is automating planting tasks in a jungle laboratory to speed the process.

The new hub shows cobot gains

The new hub shows cobot gains

10 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

YuMi automates seed planting

Review

Keynote speaker Jeff Burnstein from A3 was impressed by the event’s focus

The Penn family has been involved for 60 years

New slicer combines reliability with high speeds across foods

The SLX 2000 is the first of a new generation of Multivac slicers which has been designed to set a new benchmark on many levels that include speeds, reliability, sustainability, ease of use and customer cost-effectiveness.

Introduced at interpack, this high-output SLX 2000 slicer, which can be designed for up to four tracks, achieves a high slicing speed whatever the product. Sausage, ham, cheese and vegan products with a maximum length of up to 1,600 mm can be gently and effectively sliced, even at warmer temperatures. These product slices are then deposited on the portioning system in the predefined arrangement pattern.

Customers of this new machine can also use the sustainable liquid interleaver from Multivac to deliver plastic-free slicing, instead of the conventional interleaving film, which further reduces the consumption of plastics during packing.

Multivac says this slicer achieves a high slicing speed whatever the product company, downtime during recipe or format changes is reduced to the minimum necessary. The IPC control with its HMI 3 terminal also simplifies the operation and reduces potential operating errors, as well as ensuring that reliable and reproducible processes are achieved.

This new SLX 2000 can be used as a stand-alone unit or as a module within a fully automatic slicing and packaging line. The seamless integration of the slicer into the Multivac line control (MLC) ensures that the machine and line are operated efficiently, and this includes start-up, stopping, no-load operation and recipe change throughout the line.

Meanwhile, says the

In operation, the product logs are automatically transported into the slicer, where they are secured by the

product grippers, before being fed into the cutting chamber. A flexible slicing process enables a wide range of portion sizes and shapes to be produced, which are fed over a checkweigher, where any incorrect weights are ejected via the downstream rocker.

Running over a horizontally designed automatic belt loader, the correct portions are buffered and arranged according to the format of the packaging machine, before being loaded into the pack cavities in synchronisation with the advance of the RX 4.0.

The packs are subsequently sealed under modified atmosphere (MAP), before being cut into individual packs and discharged from the packaging machine. The DP 230 direct web printer, which is located at the upper web infeed and equipped with a high-performance TTO 30 thermal transfer printer, is used to print variable data onto the packs.

T 01793 425800

W www.multivac.co.uk

New Machinery 12 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Packline Ltd • Unit 28 • Newtown Business Park • Ringwood Road • Poole • Dorset • BH12 3LL T: 01202 30770 • E: info@packline.co.uk www.packline.co.uk ■ Bespoke Design ■ Stainless Steel Construction ■ Compact and Manoeuvrable ■ Lifting Capacity up to 300kg ■ Interchangeable Attachments ■ Handle Reels of Film or Foil, Drums and Barrels Packline third

Blister track & trace technology was shown to interpack visitors

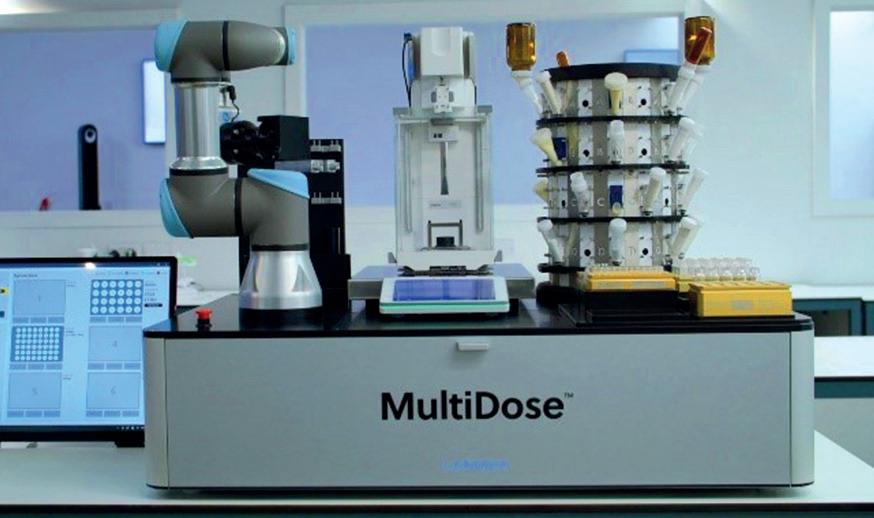

At interpack, SEA Vision introduced its blister track & trace technology for the inline serialisation of primary packaging and aggregation up to pallet level. This solution was installed on the complete blister packaging line at the Marchesini Group’s stand, including the full line from blister to case packer/ palletiser. The clever bit lies in the direct on-line printing via an on-board printer installed on the Integra 720, a solution that complements the existing off-line printing option.

The system manages in-line printing directly on the blister, together with the inspection of codes, and then automatically aggregates with the codes printed on their carton, cases and pallet labels.

Combatting product counterfeiting

SEA Vision and Marchesini Group invested in this challenging project to further enhance product identification, which is a prerequisite in the healthcare industry. The aim of the solution is to combat the risk of counterfeiting when it comes to the primary packaging of drugs and to maximise investments made by pharma companies to ensure that secondary packaging is traceable for 100% safety during product distribution.

T 01525 375190

W www.marchesini.com

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 13

METAL DETECTOR & CHECKWEIGHER RAPTOR COMBI AWARD WInnInG DIGITAL InsPECTIOn sysTEMs fuLLy InTEGRATED X-RAy sysTEM www.fortresstechnology.co.uk RAPTOR X-RAy sEE us AT PPMA 2023, sTAnD B01

Processing and packaging equipment range expands

At interpack, the Rotzinger Group presented its expanded packaging and processing portfolio that included a new compact design blister machine, the Paloma feed placer, the FLK/VRM filling & capping machine and a bar production line.

The new and improved version of its TLT blister machine can process up to 400 blisters per minute. It has undergone a redesign to deliver flexibility, safety and short changeover times, while maintaining high overall equipment effectiveness. For the primary packaging of pharmaceutical products such as tablets, capsules, and dragees, the TLT is a flexible machine that can be connected to several cartoners. Customers benefit from the modular design for simple and easy retrofitting, says the company.

Meanwhile, the Paloma feed placer that picks and places products into cartons, cases, thermoforms, flow wrappers and cartoning machines, was

Free update makes third deep learning method available

A new, free IDS NXT 3.0 software update from IDS Imaging Development Systems makes anomaly detection available to all users of the AI vision system technology with immediate effect.

The improved blister machine offers flexibility and short changeover times users to directly integrate an infeed chain of the packaging machine (horizontal or vertical) into the cell and to load it with oriented products. In bar production, the Group showcased its WRL Flex slitter originally developed by Hansella. Its design allows for repeatable cutting width amendments without changing the cutting knife shaft or the complete slitter which reduces set up times significantly.

also on the stand. “Paloma is our high-performance robot cell that offers outstanding pick and place accuracy,” said Christian Vouillamoz, product manager at the Rotzinger Group.

Using vision-guided highspeed delta robots, the machine identifies incoming products on the conveyor belt and places them correctly into the feeding of the following process. The system can handle both unpacked and packed products and its modular design allows

T 00 49 7151 259 3817

W www.rotzingergroup.com

The intelligent IDS NXT cameras are now able to detect anomalies independently and thereby optimise quality assurance processes. For this purpose, users train a neural network that is then executed on the programmable cameras. To achieve this, IDS offers the AI Vision Studio IDS NXT lighthouse, which is characterised by easy-to-use workflows and seamless integration into the IDS NXT ecosystem.

Another highlight of the release is the code reading function in the block-based editor. 01252 916656

W www.ids-imaging.com T

New Machinery 14 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Anomalies can now be detected

l NEW open leg frame l NEW simplified wash through design l Easy to clean & maintain l High density blue plastic components HYGIENIC CONVEYOR SOLUTIONS OUR TECHNOLOGY IS SHAPED BY YOUR NEEDS Wire Belt Company Ltd, Castle Road, Eurolink Industrial Centre, Sittingbourne, Kent ME10 3RF Tel: +44 (0) 1795 421771 Fax: +44 (0) 1795 428905 Email: sales@wirebelt.co.uk www.wirebelt.co.uk

Flex-Turn® Conveyor / Ladder-Flex™ Conveyor / Straight Conveyor

Let Adpak Provide your Perfect Automatic Packaging Solution

We can offer a vast range of products & technical solutions across many market sectors, we provide our customers with access to new technology and the highest technical standards.

DEPALLETISERS

INTEGRATED LOGISTICS

AUTOMATED GUIDED VEHICLES (AGV)

WRAP-AROUND & DISPLAY BOX

TRADITIONAL & ROBOTIC PALLETISERS

CARTON ERECTORS PICK & PLACE

CARTON CLOSERS

www.adpak.co.uk

3 Pendleside, Lomeshaye Ind Estate, Nelson, Lancs, BB9 6RY Tel: 01282 601444 Fax: 01282 612201 sales@adpak.co.uk

CARTONING

First hybrid printer streamlines ink inventory and costs are cut

Markem-Imaje has launched the 9750+ continuous inkjet (CIJ) printer to help customers cut costs and reduce inventory needs for pigment and dye inks. The market first hybrid coder provides the flexibility to print standard dark codes or colour contrasted codes by using dyes or pigmented inks while delivering premium legibility and permanence.

The new polyvalent ink circuit, billed as the first of its kind for coding, enables manufacturers to use one printer across factories, regardless of ink and/or the packaging used.

“The 9750+ has been designed in direct response to our customers’ needs,” explains Guillaume Montagnat, product marketing manager at Markem. “For the first time, it allows manufacturers to use one model to code in both dye or pigmented ink.”

Traditionally, producing both code types required two types of machines and many different spare parts. By introducing the 9750+ Markem enables manufacturers to achieve both with one printer model.

T 0161 864 8111

W www.markem-imaje.co.uk

16 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

New Machinery

Tel: 0 1865 8 9 1466 Email: info@cap c ode r c o m To discover more about the machines that could transform your company please visit: w w w. ca p c ode r. c o m

Markem’s new 9750+ CIJ unit

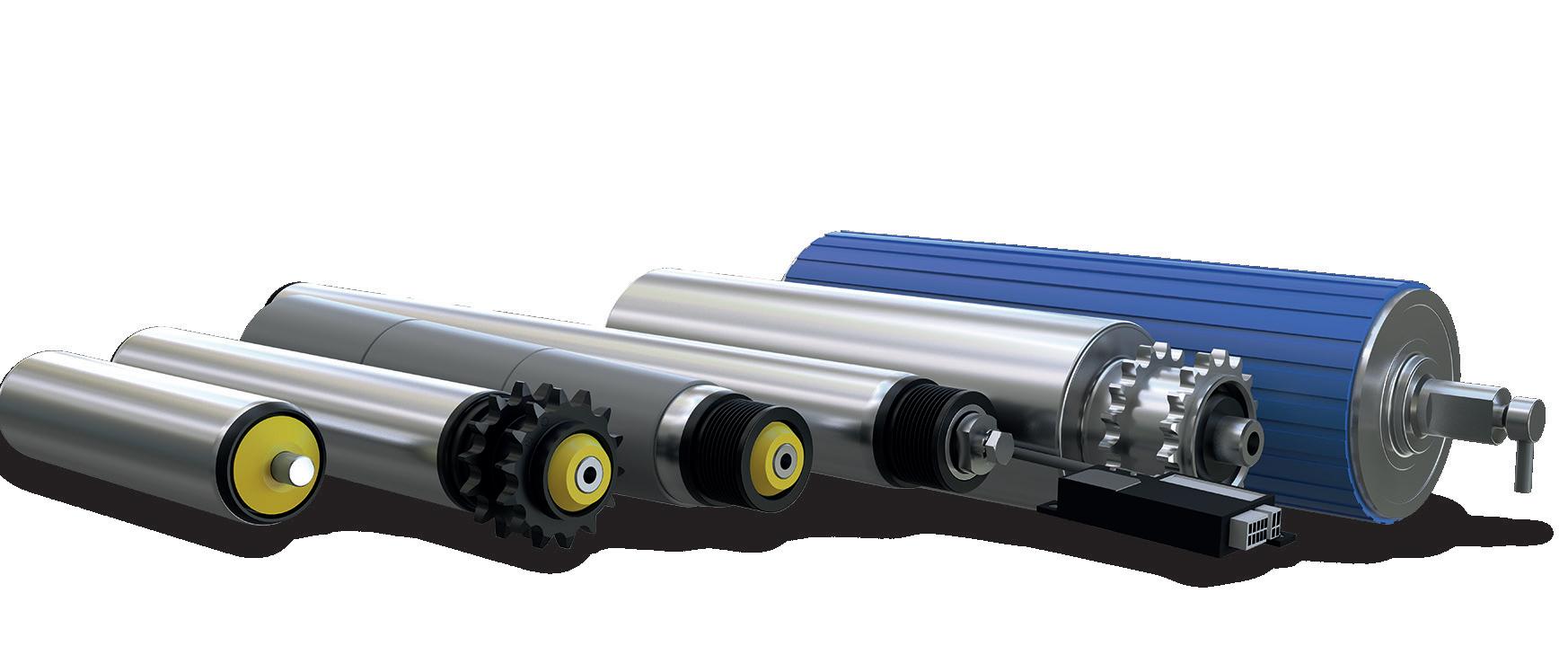

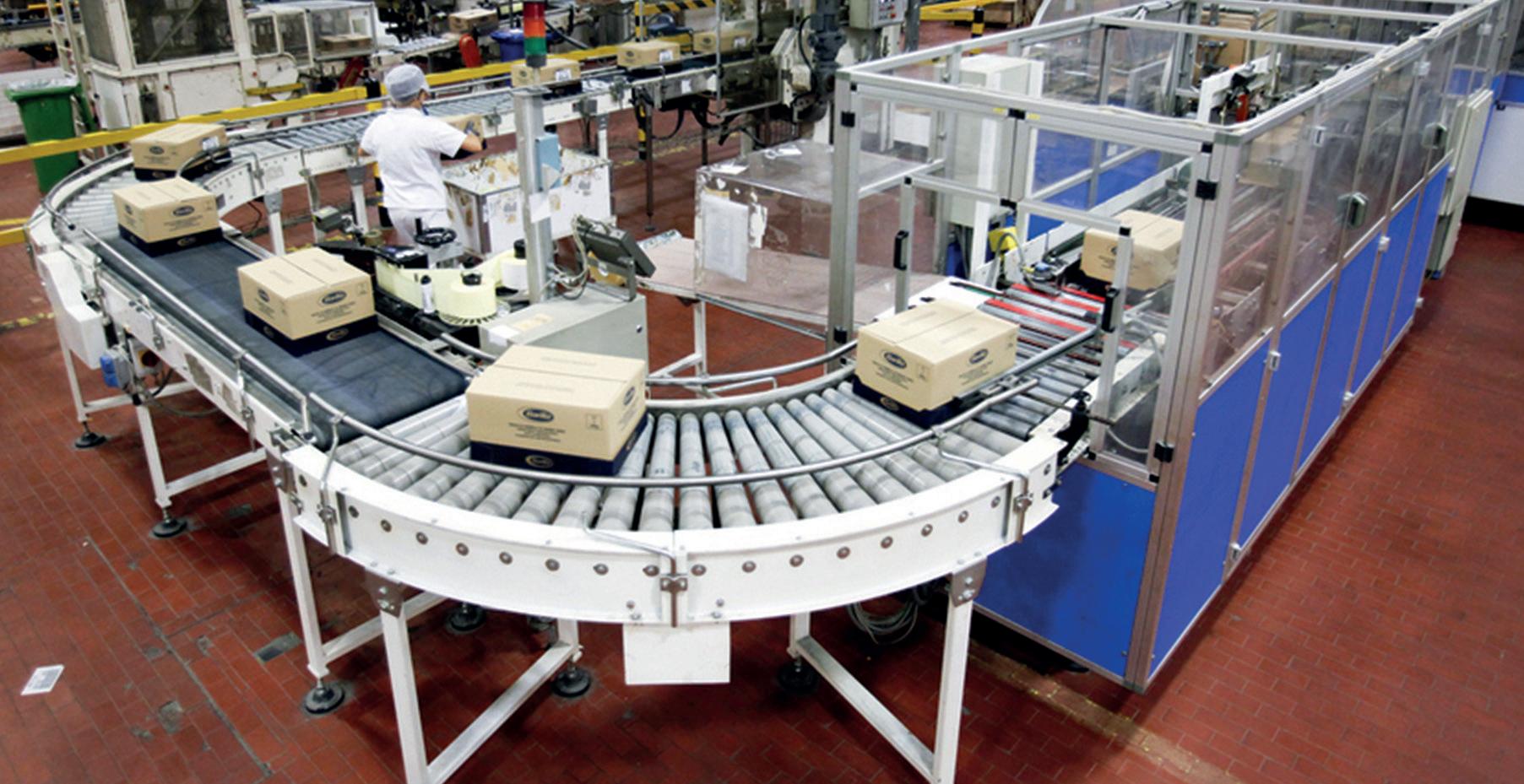

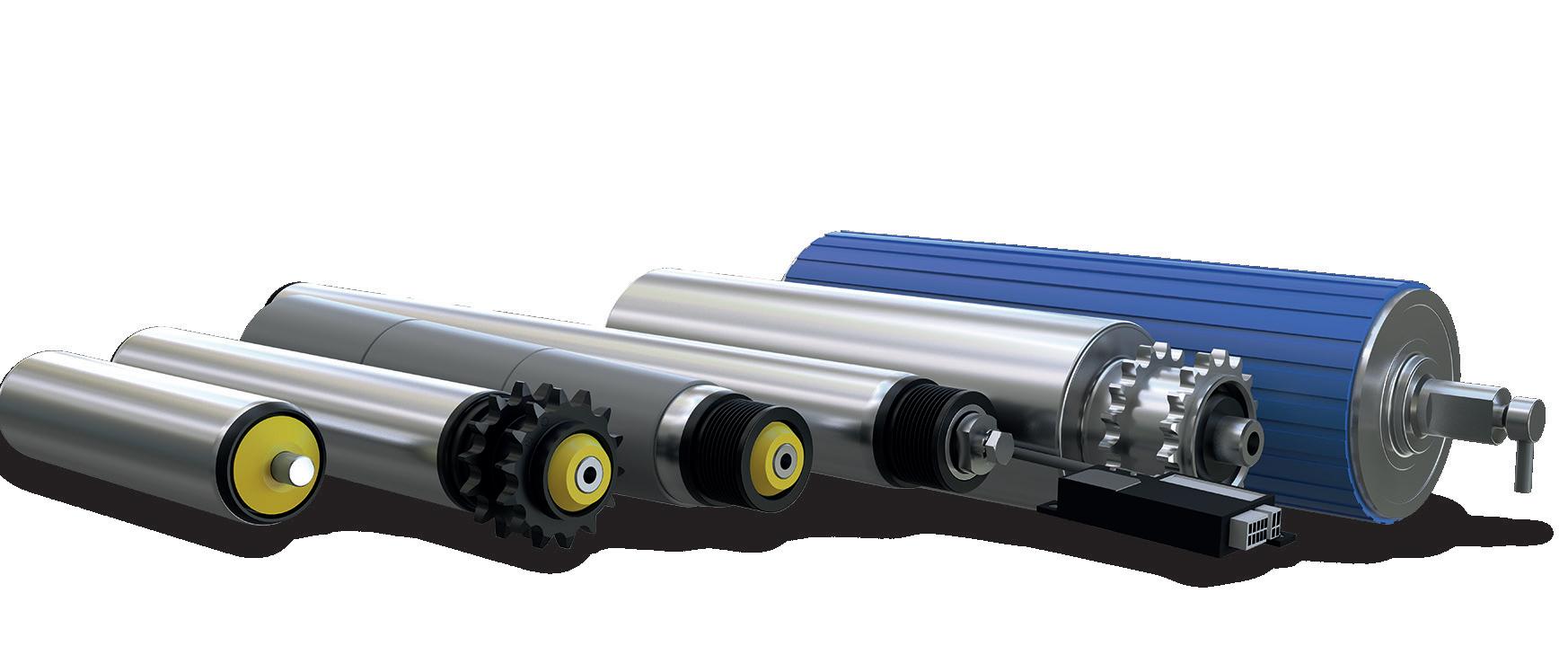

Latest conveyor platform for efficient parcel sorting

Interroll has launched its high-performance conveyor platform (HPP) to cater to the special belt conveyor requirements of the courierexpress-parcel (CEP) market.

The HPP includes an intelligent diverter module which means it can be used for preliminary sorting in conjunction with powerful sorting systems, or as an autonomous mini-sorter. Its clever design allows for the rapid yet gentle sortation of goods including cardboard boxes, small packages, padded envelopes, manila envelopes and polybags.

A robust steel profile with a wall thickness of three millimetres means that the HPP can handle loads of up to 50 kg per metre and operate at speeds of up to 2.5 metres per second. Depending on the dimensions of the goods being transported, it can handle a throughput of up to 10,000 units per hour.

The HPP is designed to be a versatile system that comprises a wide range of

Sensor can fit almost anywhere

New contrast sensor is easy to integrate into pack processes

Leuze’s new KRT 3C contrast sensor can be flexibly integrated into packaging processes thanks to its multicolour capability and small size.

SHRINK FILM

standardised line and curve modules, plus incline and decline modules which can be combined as needed to meet customer-specific requirements.

Using this new option, CEP providers can substantially increase the degree of automation and capacity of their distribution networks – even in smaller package centres.

Interroll’s HPP caters to the belt conveyor requirements of the CEP market needing to be delivered with each coming year, we have engineered a platform that can handle a wide range of package shapes, sizes and weights to offer flexibility and versatility to end-users,” says Hilton Campbell, managing director of Interrroll UK. “The HPP is easy to handle, and its speed of implementation makes it a compelling solution for customer projects.”

“With a wider variety and higher frequency of parcels

SHRINK WRAPPING MACHINERY

T 01536 312770

W www.interroll.co.uk

The smallest contrast sensor it has ever made for the packaging industry, Leuze says operators benefit from a compact device that can be used in many different ways.

The KRT 3C detects reliably and accurately even if there are only small contrast differences and with glossy surfaces or highly reflective materials. This is made possible by the multicolour functionality: red, green, and blue light as well as white and laser red light will not allow any object or printed label to pass through unnoticed.

T

01480 408500

W www.leuze.com

STRETCH WRAPPING MACHINERY

STRETCH FILM

E-COMMERCE PACKAGING

SPARES & SERVICE

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 17

SUPPLY THE FILMS SPARES & SERVICE P CHANGE OLD MACHINE SUPPLY A MACHINE Contact us today T 01484 715111 E info@yps.co.uk W www.yps.co.uk

YPS MU M-J 2021 ARTWORK

THE COMPLETE SOLUTION FOR:

New Machinery

A new feature allows for efficient metal detection

Thanks to its flexible modulation feature MiWave, the Mitus inspection solution from Minebea Intec reliably detects contaminated products of a wide range of sizes, shapes and compositions, to prevent needless incorrect rejections. First introduced at interpack, the metal detector ensures maximum product safety and efficiency on a production line.

The company says this highprecision inspection solution can detect foreign objects in almost all applications in the food and drinks industry. The new modulation feature MiWave, means the system ignores high product effects caused by product shape, size and composition, and minimises incorrect separations in the process. This enables Mitus to reliably detect foreign objects. Another feature of the metal detector is the variety of models available, which ensures it can be easily integrated into existing systems.

In the food industry, reliable

metal detection devices make a difference in how effectively they offset product effects or how the product itself affects the electromagnetic field. Mitus handles this challenge as MiWave artificially modulates transmitter waves and intelligently resolves and analyses the receiver spectrum. This enables the metal detector to automatically minimise the problem of incorrect rejects and therefore provide maximum detection sensitivity for foreign objects made from ferrous and non-ferrous metals, stainless steel and light metals like aluminium.

Mitus is also easy to integrate into existing systems: the inspection unit is available in most standard sizes and

has a rectangular, round or compact detection coil, which means it can be integrated into a system even if there is limited space available. It can also be easily combined with other inspection solutions, such as weighing technology, and integrated into existing production lines.

Cleaning and maintenance are also easier thanks to the device’s design, which complies with Hygienic Design guidelines.

T 0121 779 3131

W www.minebea-intec.com

64mm

Illuminating small scale applications with robust lighting

TPL Vision has extended its modular range with the addition of the modular tiny bar light (M-TBAR) with angle changers which is designed to offer unparalleled flexibility to users and provide a convenient way of expertly illuminating small-scale vision applications that require a robust lighting solution to be effective.

The M-TBAR (6.4 cm) gives the option of customising illumination output and is available in five colours for vision systems requiring robust illumination for inspection, code reading, robotics, labelling and other machine vision applications.

In use, the angle changers securely clip onto the bar light, allowing users to easily adjust the beam angle to suit ambient lighting conditions, test different options, or make modifications.

The addition of a new case sealer to Antalis’ Master’in options bring greater choice to the market at a range of price points to suit packaging operations of all sizes.

Complementing the company’s premium range of new Master’in semiautomatic pallet stretch wrapping machinery, added to its portfolio in February of this year, is the new Master’in Performance P-320 – a semiautomatic case sealing machine with fast plug and

play installation for runs of a single box size.

“The addition of the new Master’in Performance P-320 case sealing machine to our portfolio means we can now offer customers a much broader choice of competitively priced products,” explains head of automation & systems at Antalis Stuart Bates.

Each Master’in product comes with a 12-month warranty with the option to purchase an additional

two-years’ cover. The Italian manufactured machines, plus spare parts, are stocked in the UK and supported by Antalis’ own team of installation, service and maintenance engineers.

T 0370 241 1466

W www.antalis.co.uk

A 12-month warranty comes with the option to purchase a further two-years’ cover for customers

W www.tpl-vision.com T

01738 310392

Latest case sealer and full range of Italian-made machines deliver a greater choice of price points from UK-held stock

18 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Mitus uses MiWave technology to detect foreign objects

The M-TBAR offers user benefits

Latest rules to keep control systems safe

ISO 13849 is a safety standard which applies to parts of machinery control systems that are assigned to providing safety functions. It provides safety requirements and guidance on the principles of design, and the integration of safety-related parts of control systems (hardware or software).

A new version now replaces ISO 13849-1:2015. Once listed in the Official Journal (OJEU) as a harmonised standard, there may be a transition period of up to three years before the superseded version is withdrawn from the OJ, ending its presumption of conformity. However, once it is listed, this new standard will have a presumption of conformity, meaning that following it will ensure your products are in line with corresponding EU rules. Once the new version is listed in the OJEU, it will also become listed as a designated standard in the UK.

ISO 13849-1 provides safety requirements and guidance on the principles for the design and integration of safetyrelated parts of control systems (SRP/CS). This includes the design of software and the standard includes specific requirements for SRP/CS using programmable electronic systems. It also specifies characteristics that include the performance level required for carrying out safety functions. The standard applies to SRP/CS for high demand and continuous mode, regardless of the type of technology and energy used (electrical,

Stewart Robinson PRINCIPAL ENGINEER AND FUNCTIONAL SAFETY EXPERT AT TÜV SÜD

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

hydraulic, pneumatic, mechanical, etc), for every type of machinery.

The whole document has been reorganised to better reflect the design and development process for control systems. It now also includes a focus on risk assessment recommendations. For example, Figure 2 of Clause 4 is an enhanced version of Figure 1 in the current version – breaking out the ‘three-step process’ of risk reduction. However, the overall process

found as application code in programmable logic controllers (PLC) systems, using graphical representation such as ladder diagram or function block diagram. Full Variability Language (FVL) is typically found in computers, for example C++, C#. In ISO 13849 it is mainly used for embedded software, referred to as SRESW. Both LVL and FVL can be used for safety-related application software (SRASW) in accordance with ISO 13849.

interference (EMI) immunity. Example sources of EMI are both natural, such as static & lightning, and man-made intentional transmission and unintentional interference, such as electronics, electric power, communications, machines, and ignition systems. This new part of the standard has been severely criticised by some EMC experts. It provides a scoring methodology (table L.1) that can be used where equipment that integrates electronics can be assessed by considering various measures to achieve immunity.

and the relationship with ISO 12100 is unchanged. The new Figure 3 is also an enhanced version of the current Figure 2, which describes the contribution to risk reduction. Alongside this, Clause 4.6 (subsystems) is new, while significant parts of Clause 4 have been moved to their own clauses for specification, design, and verification.

There is also a new Clause 7 on software safety requirements. At first glance, this is almost a repeat of Clause 4.6 in the previous version. However, changes and additions include explaining the differences between ‘limited variability’ and ‘full variability’ and guidance in deciding between them. Limited Variability Language (LVL) is typically

Greater rigour is required for LVL due to the complexity.

Clause G.5 of Annex G covers the management of functional safety, requiring a functional safety plan to be drawn up and documented for each SRP/CS design project, which should be updated as any changes to the system are made.

Key features of a functional safety plan should include:

• The identification of the relevant activities in the SRP/CS design process and confirmation of the order in which they should take place,

• The identification of the roles and resources required for actioning and reviewing every activity, and

• The creation of a validation plan.

There is also a new Annex L on electromagnetic

Annex M includes additional information for safety requirements specification, while Annex N also introduces the concept of fault-avoiding measures for the design of safety related software. It is intended to help users of the standard apply the requirements of Clause 7 on software safety requirements. Meanwhile, Annex O now covers safety-related values of components or parts of the control systems. This is extracted from a data library format created by the German machinery manufacturers association (VDMA). It has been around for some years and is used in applications like SISTEMA and PAScal to help with the calculations for hardware reliability.

i For more information contact W www.tuvsud.com TÜV SÜD Product Service is the PPMA’s technical and legislative partner

10 MACHINERY UPDATE NOVEMBER/DECEMBER 2021 www.machineryupdate.co.uk

Regulations

ISO 13849 is a safety standard which applies to parts of machinery control systems that are assigned to providing safety functions and it’s being replaced with a new version…find out more here

20 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Once the new version is listed in the EU Official Journal, it will also be listed as a designated UK standard

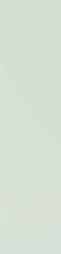

Reliable, low-waste coding delivers traceability wishes

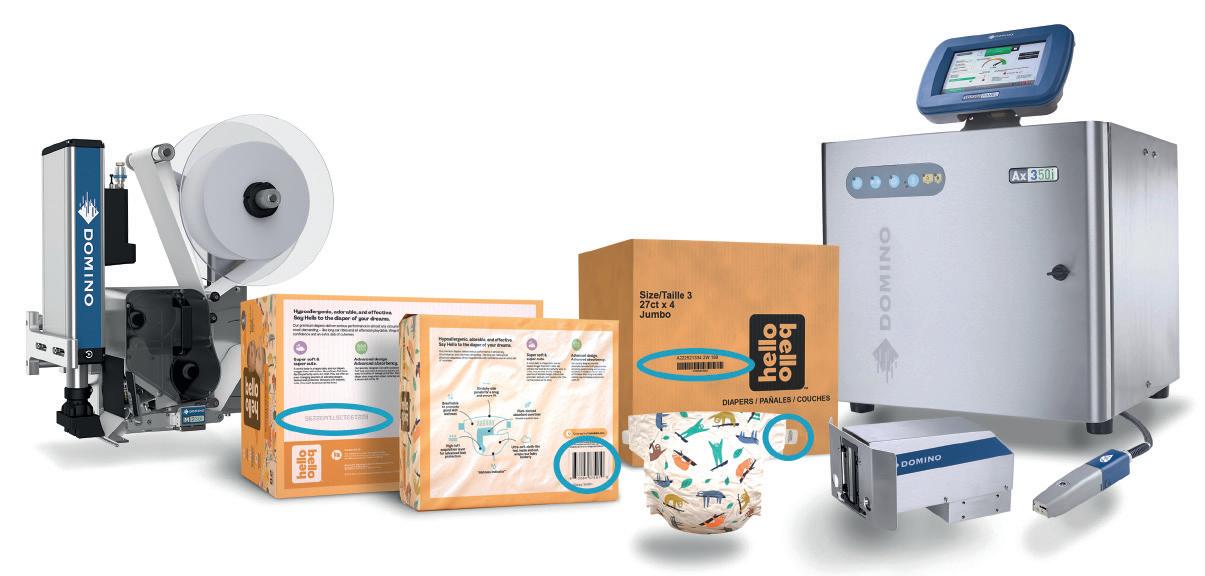

Domino Printing Sciences (Domino) is helping Hello Bello to fulfil its goal of providing ‘premium for all’ baby care products with reliable, low-waste, coding and marking solutions designed for product traceability through production, processing, and also distribution.

“We are on a mission to provide premium products to all people at an accessible price point and we want to do so in a sustainable way,” says Erica Buxton, CEO of Hello Bello. “Finding partners that can help us do that is what we are truly trying to seek out.”

Domino’s coding equipment has a crucial role to play at Hello Bello, ensuring all individual nappies, multipacks, and shipment boxes are printed with the correct codes to allow for worldwide traceability with minimal production

waste or machine downtime.

At the manufacturing plant in Waco, Texas each nappy is individually coded with MEK-free ink using an Ax350i continuous inkjet printer –with a code composed of a lot number, line number, and individual product number to allow for each nappy to be assigned to the correct multipack bags and shipment boxes. Additional Ax350i printers then apply aggregated codes onto each multipack.

The Domino installation also covers secondary and tertiary coding requirements

Eco demand resulted in new working

for retail and distribution. Hello Bello installed M230i-TB print and apply labellers for applying universal product codes to multipacks and boxes – these codes are used for worldwide tracking of items shipped to retail stores. As a final step along the line, Domino’s Cx350i secondary packaging printers, equipped with dual printheads, print A-grade barcodes with vegetable-oil-based ink on both sides of the outer corrugated boxes.

T 01954 782551

W www.domino-uk.com

Digital embellishment press installation is bringing BI format advantage to UK firm

An Ishida x-ray inspection system and checkweigher combination has played a key role in enabling one of the UK’s contract packing companies to implement a new packaging solution for a food client.

Universal Flexible Packaging is a long-term partner of Asian-inspired food brand itsu. itsu wanted to reduce the amount of packaging for its premium noodle cup range with a new cup and foil sealed lid. However, this meant quality checks using traditional metal detectors would not be possible, and for a filling and packing system where the majority of the equipment is built of stainless steel, x-ray provided the best solution for both brand and consumer protection.

While x-ray inspection technology delivered effective quality control, the challenge was to keep the lightweight cups upright. Ishida’s solution was to use its entry-level IX-EN-2463 x-ray inspection system with a lower 50kV voltage and remove its protective curtains.

WEB2PRINT PROVIDER

Printed Easy provides a wide range of printing services and has expanded and developed into a sophisticated Web2Print provider in recent years, achieving considerable

growth in a challenging marketplace. The printer will be using the Scodix Ultra 6000 by adding foil, and both raised and flat UV to a wide range of commercial products, as well as more complex and detailed embellishments for highly eye-catching and tactile print finishes. Clients will also have the latest SHD (Smart High Definition) embellishment options at their disposal, highlighting the economical range available via the

Ultra 6000 with not only the lowest cost-per-sheet, but the high quality available.

LOW COST-PER-SHEET

“The B1 format and new polymers allow low cost-persheet which competes with conventional UV on a flat finish, while SHD brings us breakthrough quality in terms of sharpness and detail,” says Jon Lancaster, managing director of Printed Easy.

T 01442 206100

W friedheimpackaging.co.uk

As the pots enter the chamber an extended guarding provides full protection from the x-ray process without the need for the curtains.

As well as being able to come up with a suitable solution, the company’s IX-EN x-ray inspection system was very competitively priced.

The IX-EN is integrated with Ishida’s DACS-G checkweigher, which provides a final weight check to ensure that all ingredients in the pot are present.

T 0121 607 7700

W www.ishidaeurope.com

Printed Easy has invested in a Scodix Ultra 6000 SHD digital embellishment printer that has been sold and installed by Friedheim International; it is the first Ultra 6000 in the UK.

22 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Installation News

Product and bag codes allow Hello Bello to track each nappy to the individual pack

Metal detector Mitus®

Maximum product safety even with the highest product effects

Mitus® with the flexible MiWave modulation is a metal detection system that prevents contamination of tiniest metal particles in a product flow. Mitus® analyzes multiple electromagnetic frequencies simultaneously to provide the highest sensitivity and prevent false rejects even with unstable product effects. All Mitus® metal detectors thus ensure maximum product safety and output.

Maximum

Minebea lntec UK Ltd. 2670 Kings Court, The Crescent Birmingham Business Park, Solihull Parkway I Birmingham B37 7YE Phone +44.121 779 3131 | Email sales.uk@minebea-intec.com NEW MiWave Technology

detection Minimum rejection

• Stainless steel conveyor systems • Standalone units or fully integrated • Robotic and end of line equipment • Bespoke engineering capabilities • Turnkey and standalone solutions • Integration and project management • Service support and upgrades • Partnered with Lita Palletising Systems for over 30 years www.kensal.com sales@kensal.com | tel: +44 (0) 1 582 425 777 Kensal Handling Systems Ltd, Kensal House, President Way, Luton, LU2 9NR Kensal Handling Systems

Installation News

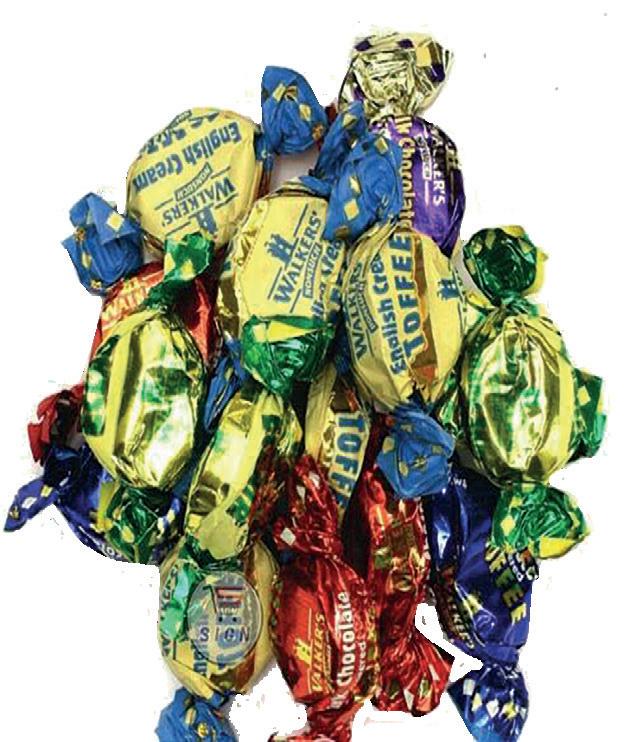

Less giveaway for toffee range

Toffee manufacturer

Walkers Nonsuch has invested in a Multipond weigher and a bagmaker from Purpak to keep up with the growing global demand for its products.

The Stoke-on-Trent firm was founded in 1894 and is run today by the fifth generation of the Walker family. Sales of the English toffee have grown consistently over the years and is now exported to over 45 countries.

Last year, the company decided to invest in a new high-speed line to allow its production output to keep up with the growing global demand.

The company chose to

partner with Multipond and Purpak to look at its packing capabilities and invest in the latest options.

Multipond has an R&D facility in High Wycombe where Walkers was invited to bring its products to carry out packing trials. The results of these trials demonstrated that its confectionery products could be packed at speeds of up to 150 bags per minute. The resulting Multipond weigher installed at its factory is a 16-head machine with auto calibration which, as well as high speed production, has also achieved less product giveaway for the firm.

T 01494 471580

W www.multipond.com

Reducing plastics film use for foods

Yorkshire

Packaging Systems (YPS) has collaborated with Bigham’s to implement a new sustainable shrink wrap film for its range of up-market ready meals.

YPS has supplied a BFFri anti-fog shrink film which has 30% recycled content. “This versatile material is extremely lightweight, fully recyclable, and has been easily integrated into the company’s packaging machinery,” says Josh Gibson, sales director at YPS.

This film has made an immediate impact on Bigham’s plastics usage by delivering a 12.31% overall plastics reduction. In addition, the plastics reduction, plus the use of 30% recycled content, has seen an approximate carbon footprint reduction of 117,000 KG+.

“Collaborating with YPS to implement a new packaging

material has significantly impacted our business operations,” explains James Rhodes, category buyer at Bigham’s. “We’ve drastically enhanced our sustainability credentials by reducing our carbon footprint and reliance on plastics.

“The service and support offered by the team have been invaluable, and their professionalism is unrivalled.”

The YPS team went into Bigham’s to fully implement the new material to ensure it ran smoothly through the business’s system.

T 01484 715111

W www.yps.co.uk

Paddle blade mixers are proving to be an environmentally safe solution for a treatment plant handling APCR waste

FCC Environmental has installed two 7500 litre large scale paddle mixers from JR Boone at is Knostrop Treatment Plant in Leeds to stabilise APCR (air pollution controlled residue) waste from a network of incinerators.

Chosen for their robustness and reliability, the mixers are processing 25,000 tonnes per annum, producing a stable material for safe landfill. “We identified the JR Boone mixers quite early on in the project, and chose

Martin, general manager at FCC Environmental Knostrop.

To cope with the harshness of the process, which sees the mixers handle acidified water to produce a ‘sludge’ that is safe for disposal to landfill, the mixers are fitted with wear-resistant arms and

blades, with the number of moving parts minimised.

Two identical mixers are in place at Knostrop and the short length to diameter ratio of these two units ensures that mixing is completed in the shortest time possible, while the ‘omega’ shape of the mixing vessel makes sure all material in the mix is fully entrained by the blades, so every part of the powder is treated.

T 01260 272894

W www.jrboone.com

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 25

YPS provided Bigham’s with invaluable support

is

Walkers Nonsuch

meeting demand

them because they are tried and tested,” explains Ian

Two paddle blade mixers work well at the facility

Installation News

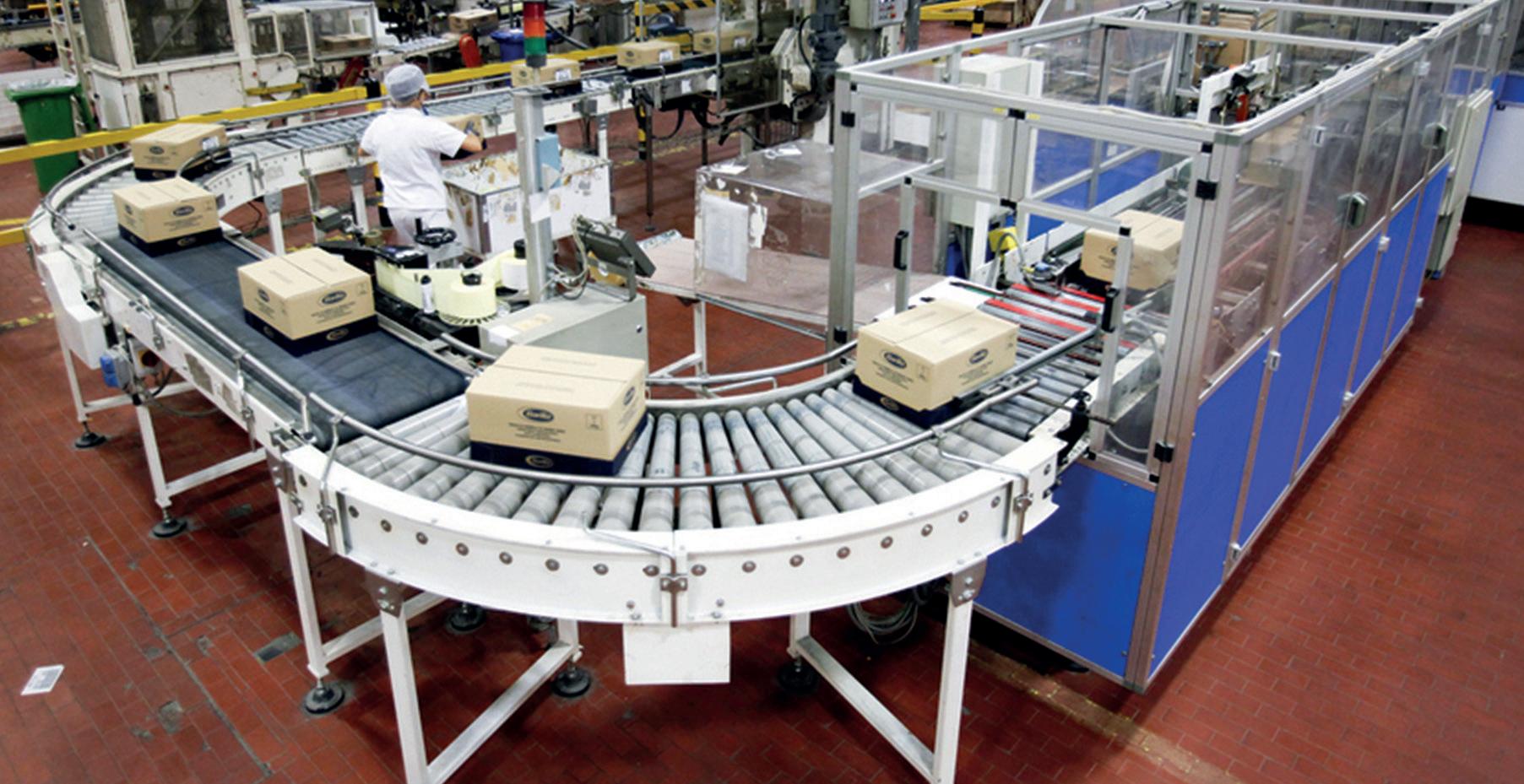

Plant monitoring/control software delivers rice and grain plant gains

Emerson’s supervisory control and data acquisition (SCADA) software is helping FEI Foods to increase throughput and overall equipment effectiveness (OEE) at its brand new processing and packaging facility.

To help meet plant efficiency and rising cost challenges, plant operators are increasingly looking to specify advanced digital technologies during the plant design phase. This includes the implementation of SCADA solutions that can integrate all parts of production, equipment and systems, collect and analyse key performance data and then present this to operators and management. A recent example of this can be found at FEI Foods, which has implemented Emerson’s new generation of SCADA/HMI solutions for plant monitoring and control to support increases in throughput and efficiency at its new processing and packaging facility.

FEI Foods can now collect key performance data to improve its operations

A completely new plant provided FEI Foods with the perfect opportunity to digitally transform its existing operational technology and practices with the implementation of advanced automation software to help maximise plant efficiency and productivity. A key focus was improving access to data and transfer of data to support inventory management and

for packaging production/ printing.

At the existing FEI Foods production facilities, all inventory control declarations and the sending of production information to printers for packaging and labelling was performed manually.

FEI Foods was keen to firstly, fully automate this process, secondly, to provide both operators and executives with

full visibility of the production process and OEE and thirdly, access key operational data on which continuous improvement decisions could then be based.

To provide the necessary information for operations and engineering teams, an integrated SCADA solution was needed that could interconnect all the new automation equipment over the factory data communication network. In addition, the new solution needed to interface with FEI Foods’ enterprise resource planning (ERP) and inventory control systems, as well as its printing, labelling and applicators.

PLATCON, an automation and electrical design company, was chosen as the system integrator for the project, and selected Emerson’s Movicon.NExT SCADA platform to meet the stringent requirements of this new factory.

T 01695 713600

W www.emerson.com

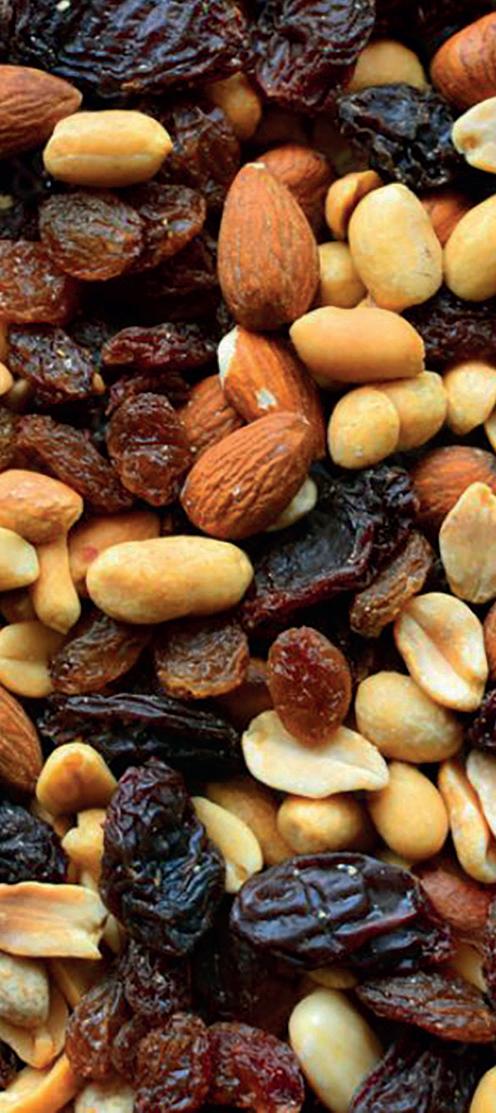

Bespoke conveying system is helping an oats producer to increase throughput and meet strict hygiene requirements

Spiroflow and Cablevey Conveyors have collaborated to provide Scottish oats producer with a bespoke conveyor system. The solution has not only helped increased productivity but has also allowed Oat Co. to minimise hazardous dusting, maintain product integrity and meet strict hygienic requirements for food handling.

Oat Co. Scotland needed to replace its existing bucket elevator for rolled oats with a new conveyor system that

had to be fully enclosed to ensure that the oat-based products were not contaminated with external foreign particles during the conveying process. Furthermore, it had to be designed to fit into their existing setup and integrate with their current oat mill.

The bespoke solution consisted of a Cablevey tubular drag conveyor system and a Spiroflow low-loading bulk bag filler with an integrated holding hopper. The tubular

drag conveyor system gently delivers the rolled oats to the filler in a totally enclosed environment, minimising both degradation and dusting. Incorporating an inspection camera monitoring system and clear inspection ports to ensure proper maintenance, the hygienic conveyor can be quickly cleaned using the dry wiper disc system to wipe away any accumulating fine particles.

The bulk bag filler contains a special low-loading ramp

and low-profile pallet base to enable the unloading of filled bulk bags by pallet truck when a forklift is not available. The filler also minimises dust with a reverse jet filter and accurately fills by weight with its low-level weighing platform to minimise overfilling and product giveaways.

“The commissioning process was the best I have experienced,” said Oat Co.’s Ray Marquardt.

T 01200 422525

W www.spiroflow.com

26 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

KEY FEATURES

• HIGH SENSITIVITY TO ALL METALS

• INTEGRATED CONTROLS for line speed and rejection

• HIGH IMMUNITY to environmental interference

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

CEIA CONVEYOR INSPECTION SYSTEMS PIPELINE INTEGRATED SYSTEMS IXC AND WEB-SERVER FUNCTIONS www.mds.org.uk UK FULL SERVICE AND TECHNICAL SUPPORT ∂ 24-7 Help Line and Assistance ∂ Metal Detector Validation and Retailer Code of practice training CEIA AUTHORISED DEALER ∂ Contact us on: 0161 286 8750 ( TECHNICAL) - 0161 286 8755 (SALES) metal detection services

Installation News

A robotic line replaces a labour-intensive process

RMGroup has installed an automated pouch line at US-based Buckman’s to automate the packing process of various-sized pouches of pool sanitisation chemicals making it the fifth robotic system the company has installed from RMGroup. Aiming to increase production and boost efficiencies without adding to staffing costs, Buckman’s new line needed to pack up to 12 pouches per minute, in weights ranging from 2 to 10 lbs, into three varying case sizes. Following the solution proposal, RMGroup provided Buckman’s with a digital twin of the pouch line to provide assurance that the system would meet these requirements.

Once approved, the final installation included a Lantech automatic case erector to convey cases into the loading position of the pick and place cells, where two ABB IRB 1600 robots pick pouches using vacuum end-of-arm tools, to place them into the cases. Once a case is full, it is sealed

with a tape sealer and labels are applied prior to being transferred to the end-of-line robot palletiser – an ABB IRB 660 palletising robot with a vacuum gripper head. The robot is complemented by RMGroup’s 2-on-the-floor palletising configuration. These two pallet loading positions allow operators to remove completed pallets safely from one cell while

Sandwich sealers are handling more sustainable options

Sandwich King has been using plastic packaging sealers from Soken Engineering for 15 years but to highlight its more sustainable packaging credentials to customers, the sandwich manufacturer installed one of Soken’s highest-performance linear automated heat-sealing machines, the HS60C.

the robot continues to palletise in the other cell.

“RMGroup’s robotic system more than meets our expectations,” said Jeff Buckman, president of Buckman’s Inc. “They are great people to do business with, know what they are doing, communicate well and work hard to get the job done.”

T 01686 621704

W www.rmgroupuk.com

Capable of heat sealing 2,200 card skillet sandwich packs per hour, this investment in the HS60C model has been followed by the ‘Advanced’ model in the series. This gives Sandwich King even more packaging capacity with an additional machine that can seal 2,880 packs/hour.

“Quality and sustainability underpin the Sandwich King brand,” says its operations manager Jason Hirst. “All our packaging is now recyclable, and our card packs are biodegradable.”

01525 376000

W www.sokenengineering.com T

ink jet technology has alleviated code pain-points for a growing wellness company marketing CBD products

Thermal

Wellness company Orange County CBD has sourced an RF Lite thermal ink jet (TIJ) machine from Rotech to automate its batch coding process, after its boost in popularity meant that manual labelling was becoming too time-consuming and costly.

The increasing popularity of Orange County’s CBD products meant that co-founder Aaron Spinks began to look for alternative ways to its manual method of applying batch codes

to its cartons. He also required something that could guarantee clear, permanent codes and eliminate mislabelling errors.

The company wants to normalise use of CBD products

Rotech says the RF Lite is perfect for quick growing companies such is Orange County, as it is capable of

running at high speeds of up to 60m/min – a key consideration for Spinks, as he needed it to keep up with increasing

production volumes.

And with the RF Lite making a positive impact to its production process, Orange County then looked to Rotech for a way to automatically overprint variable data directly onto the labels being applied to the vials of oil. The compact nature of Rotech’s Integra TIJ printer means it can work seamlessly with other equipment, including label applicators.

T 01707 393700

W www.rotechmachines.com

28 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

Customers value product quality

The 2-on-the-floor palletising configuration allows for continuous operation

Robot range is helping to produce mass-customised kitchen cabinets

Leading European kitchen specialist Nobia has selected ABB Robotics to supply robotic automation solutions for its new factory in Jönköping, Sweden, to help make production more efficient, less arduous for employees and also more sustainable.

“Working with Nobia, our robotics solutions will enable fast mass-production of customised kitchens, meeting consumers’ increased demand for tailored and personalised product choices,” explains Andrea Cassoni, managing director, general industry, ABB Robotics.

Robot installation delivers efficiencies

The supply of ABB robots will enable Nobia to achieve its vision for more flexible and more automated manufacturing that’s capable of producing customised products at scale. The robots included are IRB 7600, ideal for heavy applications, IRB 4600, a general-purpose robot that increases production capacity and improves productivity, and IRB 6700, the highest-performance robot in the 150–300 kg class which, on average, takes about 2.5 tons per day off the shoulders of an employee.

The robots will enable the factory to produce customised cabinets with 75-80% higher efficiency (time) in comparison to non-automated processes.

T 01908 350300

W www.abb.com

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 29

Machinery Update, 149 x 225 mm, Digitalisation M, CC-en91-AZ281 06/23

ACOPOS 6D

Creating new dimensions of adaptive manufacturing.

ACOPOS 6D allows you to move products freely through an open manufacturing space –unbound by the limits of one-dimensional production flow. Magnetic levitation provides six degrees of freedom for unprecedented processing density on a fraction of the floorspace. br-automation.com

B&R | A member of the ABB Group

Learn more

Feature: Automation, robotics & vision: intro

Smart technology is the new normal in manufacturing

Welcome to our automation, robotics and vision systems feature in which we are covering a range of brand-new smart technologies that are all designed to make manufacturers’ lives easier.

Whether it is developing new equipment faster through digital twins, or new software that delivers operational gains, robotics that ease labour issues or vision systems used as an enabling or inspection technology, the market continues to move on apace; with new sectors joining the party all the time, too.

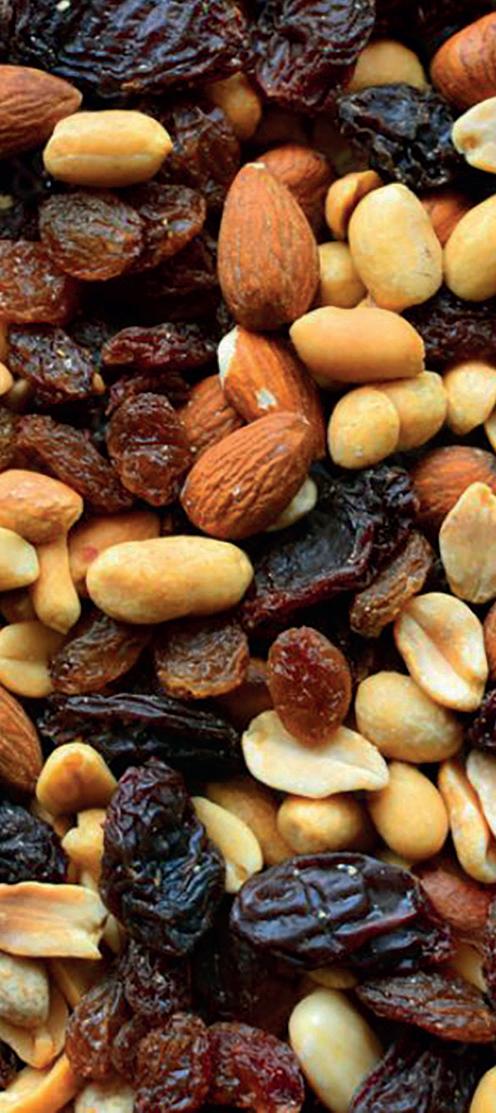

For instance, Nick Cesare, md of Pace Mechanical Handling believes that UK agriculture will soon join the list of industries that are adopting smarter automation. He believes that within a decade, robots will be just as common in agriculture as they are in the automotive industry. This is because agriculture is a repetitive process that has, for many years, relied on people to plant, harvest, sort and pack produce.

“The impact of Brexit, increased employment costs and increasing pressure to adopt precision farming methods have spurred UK agriculture into finding a way to do more with less,” he says. “Drones are being used to assess the quality of crops and it won’t be long until there is a robot on every farm and in every packhouse.”

Away from packaging and processing, robots are of course, also being developed for manufacturing products themselves. For instance, recently Verder company Packo Pumps has transformed its manufacturing process by integrating robots into its production lines for various tasks including electropolishing. This move has elevated the hygienic standards significantly.

Data-based smart operations are defining a new paradigm in just about every industry and,

Making a difference

Packo Pumps has transformed its electropolishing process for its range, making it a more hygienic process all round. Enjoy the next 26 pages of this annual feature

says Cama Group’s Filippo Aspesi, digitalisation at device, machine, plant and enterprise level is completely rewriting the rule book in terms of how companies can function and operate. “Today, the most powerful resource in an engineer’s toolbox is operational data,” he says.

CONSIDER NEW WORKFLOWS

Meanwhile Garry Lewis of Omron UK believes machine builders need to consider how to optimise workflows to take advantage of mobile robots. “This could involve reorganising production lines or redesigning machinery or incorporating artificial intelligence and machine learning technologies,” he says.

Adhan Khan from Beckhoff Automation UK believes that with more companies needing to

cope with high-mix, low-volume manufacturing, non-traditional automation has a key role to play. Flexibility, modularity, a small physical footprint and mobility solutions are required which are made possible by onboard software intelligence, more lightweight and responsive hardware and low-code/no-code applications. The company offers the XTS linear transport system to meet these goals.

Augmented reality (AR) technology proved invaluable during the pandemic, when technicians couldn’t travel to sites easily to fix machines. Today, AR is also being used by Rockwell to capture and share tribal knowledge of experienced workers for new workers and service technicians.

As my 90-year-old Mum would say: “Whatever will they think of next?”

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 31

Right ingredients for sweet success

Global confectionery manufacturer is using technology from CKF Systems to deliver its ingredients accurately

CKF Systems has installed and commissioned its latest ingredients handling system for a brand leading global confectioner that utilises the latest technology in measured ingredients handling.

The system is built on the CKF engineering team’s experience for accurately delivering and mixing ingredients for inclusion within the confectionery sector and wider food industry, aiding its clients’ drive for new product lines and automation of operations within its UK manufacturing facility.

In operation, the accurate inclusion of additional

ingredients into parent product bars of confectionery creates specific and bespoke system challenges to overcome. From the very start of the inclusion process, the inclusion materials can be a mixture of natural and/or manufactured, refined ingredients. CKF has therefore developed the materials handling equipment and systems for the variety of transportation packaging formats that typically contain the ingredients. These include bin tipping, bulk bag hoist systems, hopper storage and also vacuum handling.

The quality of the ingredients, once input into the system, has to be guaranteed to meet the final product specification.

And while production refined ingredients are more likely to be of a regular specification and quality, more natural products that are often used for inclusion, will be sourced globally and seasonally. This can result in the irregular quality of the ingredient which is why CKF screening systems are used to remove unwanted inclusions in the form of oversize, undersize, skin, shell, broken and stalks. With the use of refiners, clump forming ingredients (formed within packaging and transportation) will be separated, providing a regular quality and precise particle size of the ingredients into the system.

CKF has developed a range

Coping with an irregular quality of transfer and conveying mediums to suit a range of ingredient specifications which all focus on spillage prevention, transfer speeds, dust extraction, air conditioning and product damage.

Feature: Automation, robotics & vision systems 32 MACHINERY UPDATE JULY/AUGUST 2023 www.machineryupdate.co.uk

▸ Lamonde Automation Limited Quality Products: Expert Advice sales@lamonde.com | www.lamonde.com | +44 (0)20 3026 2670 4, 5 & 8 Port Industrial Ethernet Switches Din Rail & Surface Mounting Options Rugged Aluminium Housing PoE Devices Available Plug & Play thirdpageland_ppma_mayjune23_teltonika_switches.pdf 1 24/05/2023 11:52

To ensure accuracy of the ingredient mix, CKF has delivered systems with dynamic belt weigh feeders, screw feeders and weigh mixers. Each element is integrated and controlled to optimise ingredient volumes, matching production recipes and delivering on customer specification.

Continual measurement and feedback of the flow of each ingredient is a key feature of the systems, providing clear information, data and an alarm if the correct flow of ingredients for a specific recipe is not within tolerance.

Customer specification and the recipes required determines the layout of the inclusion system and is therefore specific to each application. Flexibility provides the opportunity for any number of ingredients to be introduced to a specific recipe, in operation. These inclusion systems are also designed to manage

the stoppage, buffering and start-up of ingredients during interruptions within the main production line.

Delivery of the ingredients

mix/molten chocolate ratio to the main production line is via a bespoke servo-driven oscillating system which provides an even supply of

mix across the full width of the mix supply hopper to the main moulding plant.

T 01452 728753

W www.ckf.co.uk

www.machineryupdate.co.uk JULY/AUGUST 2023 MACHINERY UPDATE 33