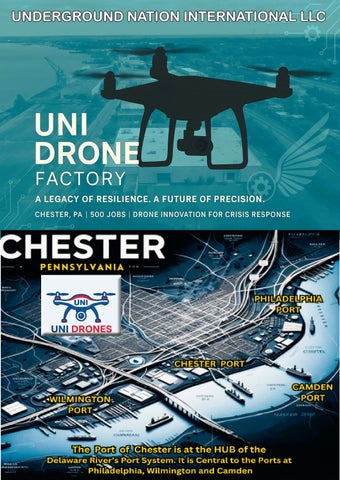

From Recovery to Readiness: Chester’s Comeback Starts Here: 500 jobs. One factory. A future reengineered.

In Chester, we don’t wait for help—we build it. The UNI DRONE Factory is turning centuries of industrial grit into 21st-century readiness. Our drones aren’t just machines—they’re lifelines. Fighting wildfires. Mapping flood zones. Delivering aid in pandemics. Inspecting bridges before they collapse. Filling public service gaps before they grow.

This isn’t just job creation—it’s mission activation. Every hire is a first responder, an innovator, a steward of public safety. Chester’s workforce won’t just revive the City’s legacy—they’ll redefine America’s emergency response.

The Future Is Flying Out Of Chester. And It’s Powered By DRONES.

“Rising from Resilience: Why Chester Needs UNI DRONE”

The City of Chester has long carried the weight of industrial decline, environmental injustice, and systemic underinvestment. But what the outside world often overlooks is Chester’s unmatched reservoir of resilience, creativity, and determination. The UNI DRONE Factory is more than a business proposal—it’s a blueprint for renewal.

Imagine a future where Chester isn’t defined by crisis but by leadership in crisis response. Where our young people don’t leave to seek opportunity—they build it here. Where drones crafted on the banks of the Delaware River help rebuild floodprone neighborhoods, map aging infrastructure, monitor air quality, and even deliver support in mental health emergencies. That future starts now.

UNI DRONE bridges past and future: honoring Chester’s legacy in manufacturing while infusing it with 21st-century tech—AI, 5G, and real-time data analytics. It brings over 500 jobs, not just in assembly but in design, software, logistics, education. It turns Chester into a drone innovation hub, with apprenticeships that uplift veterans, returning citizens, and ambitious youth. Every rotor that spins at UNI DRONE spins toward Chester’s empowerment.

At its heart, UNI DRONE is local—but it’s also scalable. As drone demand surges globally toward $63.6 billion by 2025, Chester becomes a player in that market, showing how community-rooted innovation can be both profitable and healing.

This isn’t just economic development. It’s narrative reclamation. It’s Chester saying: We are the architects of our own future. WHAT CHESTER MAKES MAKES CHESTER

A RESOURCE FOR POLICE & FIREFIGHTERS

UNI DRONES ARE NOT FOR WAR

WE FIGHT NATURAL DISASTERS

WILDFIRES, FLOODS, EARTHQUAKES INFRASTUCTURE FAILURES

WE ARE INDISPENSIBLE TOOLS FOR OUR FRONT LINE DEFENDERS

Community Impact of UNI DRONE Factory on the City of Chester: 500+ jobs created across tech, logistics, repair, and crisis response

• Drone deployments for wellness checks, infrastructure safety, and surveillance

• STEM partnerships with local schools; building Chester’s future workforce

• Living-wage opportunities for returning citizens and caregivers

• Environmental monitoring: air quality, flooding, and disaster prevention

• Startup incubator for Chester-based drone businesses

• Rebuilding pride in Chester’s legacy of innovation and resilience

“Why This Matters to Chester”

“When I talk about 500 new jobs, I’m not just talking economics—I’m talking dignity. These roles will train our youth, welcome our veterans, and give second chances to people who deserve them.

This factory isn’t just producing drones. It’s producing health, safety, and opportunity. It’s scanning the skies so we can breathe easier and respond faster. It’s restoring Chester’s legacy—not with nostalgia, but with innovation.

We’re turning a city known for hardship into a hub for hope. And for me, as a City Resident, that means everything.”

Frank Porter,

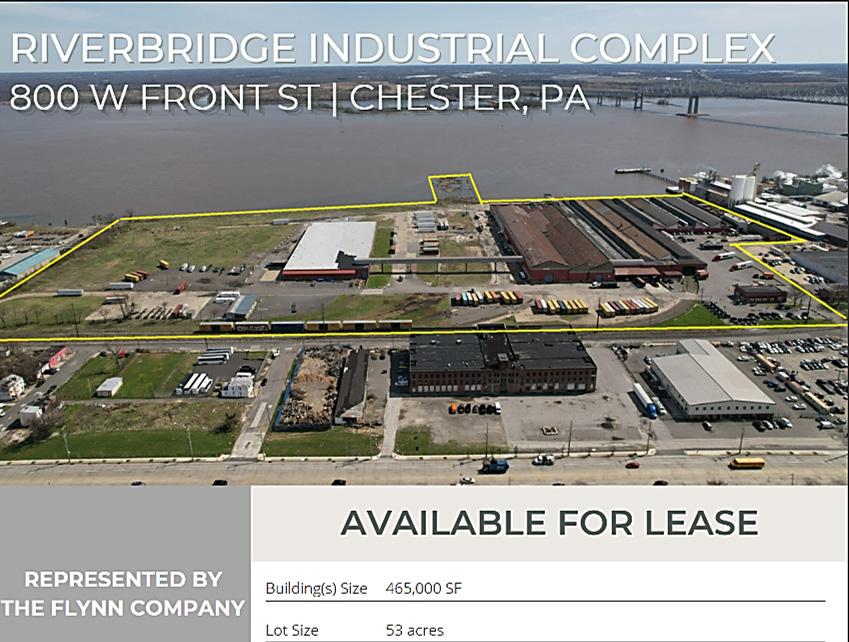

PROPOSED PROJECT LOCATION

Pitch Deck Integration: Building “B” – A Launchpad for UNI DRONE

Site Overview

Location: Positioned in Chester’s existing industrial zone—ideal for manufacturing, shipping, and workforce accessibility.

Size: ~20,000+ SF, offering flexible layouts for assembly lines, storage, and training facilities.

Cost: Estimated listing at $1.5–2 million depending on negotiation, retrofitting, and tenant improvements.

Why It Fits UNI DRONE

Adaptive Use Potential: Building “B” allows rapid deployment of Phase 1 operations without major construction delays.

Zoning Alignment: Existing industrial/commercial zoning means fewer permitting hurdles.

Infrastructure Ready: Access to power grid, loading bays, parking, and proximity to major roadways support drone transport logistics.

Strategic Framing for City Officials & Investors

“UNI DRONE is not hypothetical—it’s ready to land. Building ‘B’ offers a concrete site for job creation, community impact, and rapid activation.”

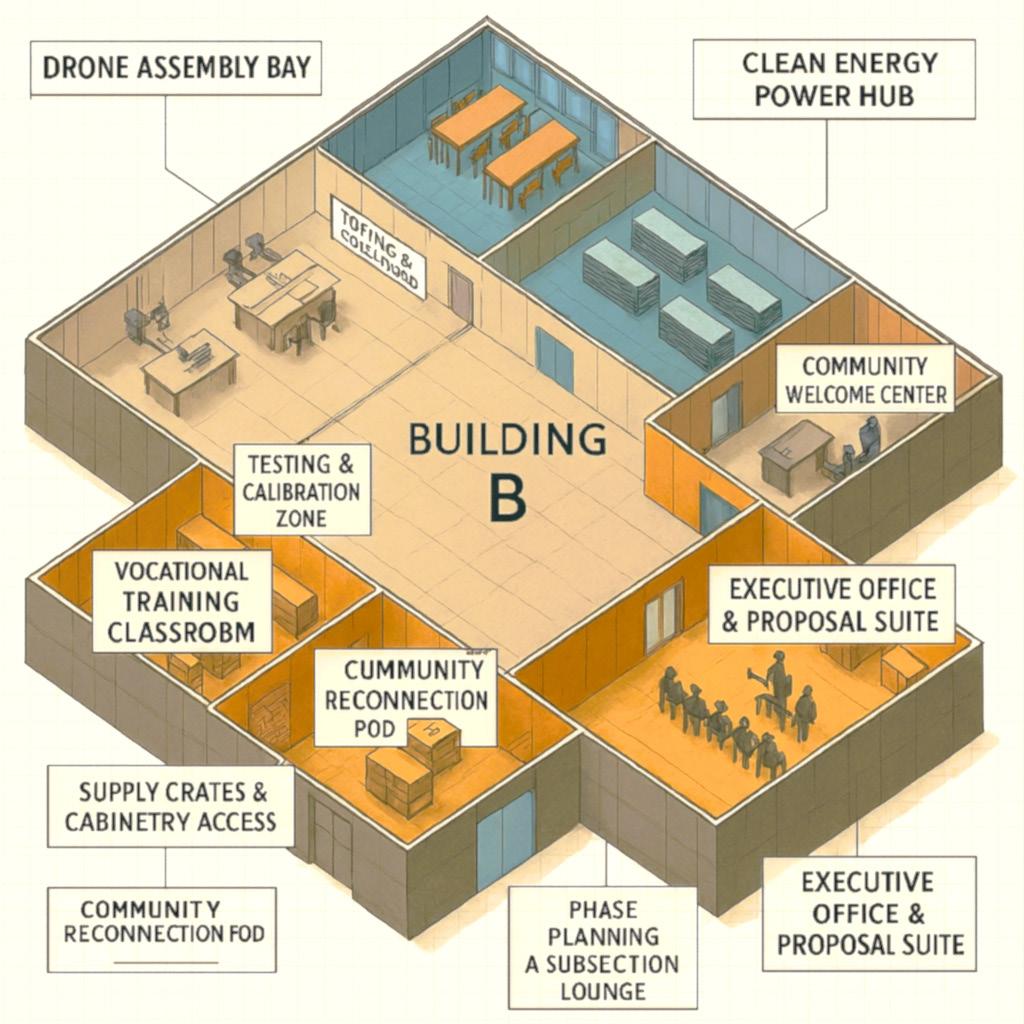

Schematic layout of Building B

A community-based drone manufacturing facility. Space divided into the into six key zones:

1. Drone Assembly and Testing Bay

2. Vocational Training Classroom

3. Clean Energy Power Source Hub

4. Crisis Response & Storage

5. Community Welcome Center; and

6. Executive Office and Proposal Suite.

Style flat 3D, blueprintinspired, and readable for stakeholders

Funding Breakdown

For under $4M, UNI DRONE can activate real jobs, real training, and real output—within Chester’s existing industrial ecosystem.”

Line Item

Building Acquisition

Renovation & Retrofitting

Equipment & Inventory

Estimate

$1.5–2M

$500K–750K

$1M

Hiring & Training (Initial 50 Staff) $350K

Legal, Permitting & Zoning $100K

Phase 1 Total $4M