9th to 11th December 2025

FEBRUARY 2025

info@polymersandrubbermatters.com www.polymersandrubbermatters.com

info@polymersandrubbermatters.com

9th to 11th December 2025

info@polymersandrubbermatters.com www.polymersandrubbermatters.com

info@polymersandrubbermatters.com

Global Polymers Market size is forecast to reach around $ 997.77 billion by 2030, after growing at a CAGR of 5.4% during 2024-2030. Polymer is one of the widely used chemical products in almost all the sectors such a medical, aerospace, packaging, automotive, construction, electrical appliances, and medical sector, and consequently, the global polymers market is thriving. Polymers are used widely as a substitute of metal and mineral based products due to its high performance, cost-effectiveness, and low weight. Increase in the retail sector and prospering e-commerce industry is demanding for more packaging material that is influencing the significance of the polymers market. The major factors driving the growth of this market are the increasing demand for polymers in various end-use industries, the rising adoption of lightweight and sustainable materials, the technological innovations, and the supportive government policies and initiatives. However, some of the challenges faced by this market are the fluctuations in the raw material prices, the environmental concerns, the competition from alternative materials, and the trade barriers. Furthermore, growing demand for polymer in the electronic industry for the manufacturing of different electrical parts such as switches and sockets are driving the Polymers Market.

The Polyethylene segment is projected to witness the highest CAGR of 7.1% during the forecast period owing to the rising demand from various end-use industry. Whereas, growing uses of high-density polyethylene (HDPE) and Low-density polyethylene (LDPE) in food and beverage packaging like milk and fruit juices, crates, caps for food packaging, drums, and other liquid food packaging and industrial packaging applications drive the market growth. Construction industry is a major consumer of polyethylene which is used in the form of sheets, plates, films, foils, and strips that offer plastic protection to floors. Furthermore, polyethylene is also used in pipes and fittings which form an integral part of various industrial activities. Besides, consumer goods such as bowls, buckets, water bottles, drums, dustbins and plumbing pipes, are a few polyethylene products utilized on a daily basis. Increased sales of consumer goods offer opportunities to vendors in the polyethylene market, which in turn drive the growth of this market.

The injection molding segment is projected to witness the highest CAGR of 6.8% during the forecast period owing to its optical clarity and biocompatibility characteristics. In the injection molding process, large polymer mouldings can be inexpensively manufactured in large quantities for direct usage. Furthermore, the growing complexity of technical biodegradable polymer/bioplastic mouldings drives the demand for a multi-component injection molding process, which in turn propels the growth of this segment. Whereas, the growing demand for plastic components across numerous end-use industries like automotive, packaging, home appliances, electrical and electronics, and healthcare devices is expected to drive the market growth. Besides, various industries are shifting their focus towards injection-molded products in order to enhance their operations and produce products with better quality as per the customer’s requirements. For instance, the automotive industry is replacing steel with plastics to reduce a vehicle’s weight and improve fuel efficiency. Among the regions, the APAC region hold the largest share of more than 36% in 2024 and is projected to witness the highest CAGR of around 7.9% in the global Polymers Market followed by North America and Europe during the forecast period. The growing economies of South East Asian countries, growing disposable income, easy availability of raw materials used to manufacture plastics, and rise in population propels the growth of this market in the APAC region.

info@polymersandrubbermatters.com

InterviewwithMauritiusSchmitz, ScientificDirector,Institutefor Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

Plastic packaging made from recycled material? Yes, but please as high quality as possible – and recyclable! This poses great challenges for manufacturers, because the use of recycled materials still often leads to downcycling. One key to more sustainable plastic packaging lies in digitalisation. This is also where the KIOptiPack project comes in.

In an interview, Mauritius Schmitz talks about the requirements for plastic packaging, the role that design plays in the sustainability of packaging and the extent to which artificial intelligence can support this.

To make plastic packaging more sustainable, the entire value chain must be considered. The KIOptiPack innovation lab deals with the beginning of the value chain - design and production. What role does design already play in sustainability?

Mauritius Schmitz: Product design plays a central role in the sustainability of products. It defines the choice and consumption of materials and thus the types and quantities of plastic introduced into the cycle. It also influences functionality and suitability for (packaging) use, manufacturability and production efficiency. Furthermore, product design can facilitate or complicate the sorting, separation and reprocessing processes – which in turn determine the quality of the resulting recyclates.

Schmitz: Even with sustainable

packaging design, the same, or at least comparable, expectations and criteria must be fulfilled for the product as for products made of virgin material.

This is about product functionalities, such as barrier properties, purity and mechanical stability, and about subjective requirements from the consumer's point of view, such as appearance, smell and safety. But also the processability of the chosen material in the production process plays a decisive role for a functioning product design, by this I mean, for example, the thermal or flow properties of the plastic.

AI can be used to take these complex and diverse influences into account and make them optimisable. By using AI, these influences can be made quantifiable and packaging designers can get a better idea of how their designs affect the different requirements and how they can optimise them to create more sustainable packaging.

Graphic: Illustration of the support provided by AI throughout the entire plastic packaging cycle; Copyright: Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

Copyright: Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

How can AI make production more sustainable?

Schmitz: To improve the quality of plastic packaging, AI is used in different production phases. AI is already used at the material receiving stage to detect material fluctuations and adjust the processing accordingly. During the processing stages, neural networks are used to

generate and optimise process models. In this way, correlations between material characteristics, process settings and quality can be recognised and used for correct process adjustment. In the KIOptiPack project, the processing methods compounding, flat film and blown film extrusion, injection moulding and thermoforming are specifically considered.

Graphic: Goals of KIOptiPack; Copyright: Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

Copyright: Institute for Plastics Processing (IKV) in Industry and Craft at RWTH Aachen University

Why is cooperation with industry – i.e. companies like Brückner, Reifenhäuser or Pöppelmann – important?

Schmitz: Cooperation with industry is of great importance and depends in its way on the respective industry. However, an important aspect that has not been sufficiently considered so far is the consideration of the entire value chain. In order to achieve optimal sustainability, changes have to be made at various points in the value chain, which may not be initiated and implemented out of their own motivation. For example, the responsibility for more sustainable plastic packaging could be shifted to the collection and reprocessing process alone, but this would certainly not be the most effective and sustainable approach. Instead, it makes more sense to develop incentives and business models that enable global change and load-sharing along the entire value chain.

To achieve this goal, it is essential to understand the hurdles and

potentials for each participant. Through the AI Application Hub, which networks project partners from established machine manufacturers to technology start-ups, as well as from research institutes to food manufacturers and distributors, the possibility of a direct exchange along the entire value chain is created. Only in this way can we achieve a common understanding of the potentials of more sustainable packaging production.

What will the plastic packaging of the future look like?

Schmitz: It is difficult to predict what packaging will look like, because we will also be able to develop and produce sustainable plastic packaging in great variety in the future.

These will be individually tailored to the specific application, so that they fulfil minimal material consumption and at the same time reliable suitability for the application. At the same time, however, this packaging will have to be returned to the cycle with the minimum possible losses.

What can already be predicted with great certainty, however, is that the packaging of the future will contain a maximum proportion of recyclate. It will preferably contain only one type of polymer and be easier to handle when sorting and separating.

In order to improve and simplify the sorting processes, digital – and at best global – product or material passports, which are currently being developed through various initiatives, will play a decisive role.

And in this area, we will not make progress without digitalisation and artificial intelligence methods.

How much energy could you save with a Yizumi D1 machine? What other efficiencies could you get? Call our engineers today for a chat on 01933 27 27 47 or visit us at:

Interview

Sometimes you have to see a problem with your own eyes – or feel it with your own feet – to want to do something about it. At least that's how it was for Christian Schiller, who launched cirplus, a digital marketplace for recyclates.

In an interview, he talks about the moment when he realized that he wanted to actively combat plastic pollution and how he is doing his part with cirplus.

Mr. Schiller, how did you come to found cirplus?

How did you come up with the idea of a digital marketplace for recyclates?

Christian Schiller: It all started with a trip around the world in 2017. After setting up the German offshoot of the ride-sharing community BlaBlaCar, I treated myself to some time out on the water. On the way from Colombia to Panama, I was dangling my legs in the water when suddenly something touched me and I realized we were driving through a carpet of plastic. It was a nightmare. How can it be that this material, worth trillions when we extract it from the earth's crust as petroleum, later ends up as trash in

the ocean? Something can't be right. Back in Germany, I did some indepth research with my partner Volkan Bilici, a software developer with experience in the plastics industry. It turned out how much plastic waste ends up in thermal recycling - in other words, in the waste incineration plant – even in collection-conscious Germany.

Schiller: Germany celebrates itself as the recycling world champion, but lags behind when it comes to plastics. Less than 6 percent of the waste from the yellow bag ends up back in production, even though the Packaging Act stipulates a recycling rate of 63 percent by 2022. The problem with plastic recycling is also the varying composition of the waste, because all kinds of things end up in the garbage can. This makes it difficult for recycling companies to produce consistent quality of secondary raw materials.

Therefore, there is a lack of recycled material, and the little is also relatively expensive. Recycled goods, however, must be economically competitive with virgin petroleum products. Until then, it is ecologically disreputable because it is not reused at the end of its life cycle. Here, there is certainly a need to raise awareness among both industry and consumers to make a significant contribution to environmental protection. But despite all the hurdles, as with glass and paper, I saw an opportunity to reconcile ecology with economy. That's how

cirplus came to be founded. To what extent do you contribute to climate protection with cirplus?

Schiller: cirplus is a kind of digital wholesale market for recycled plastics. The first step is to network waste disposers and recycling companies that produce recycled plastic from the waste. Processors can obtain this via the platform as raw material for new products, such as shampoo bottles. These packaging manufacturers supply brand-name manufacturers with bottles made from recycled plastic. That way, plastic ends up on the shelf and not in the ocean or incinerated. It also saves millions of tons of the valuable resource petroleum and doesn't contribute to the world's CO2 pollution.

What role does digitalization play in this?

Schiller: Of course, digitalization and AI also play a crucial role at cirplus. We are digitizing the procurement process. Costs can be saved at every stage of the value chain: cirplus helps to find new suppliers or customers, offers integrated material testing, and optimizes logistics right through to payment processing and complaints management.

On the other hand, cirplus increases transparency and security of supply. Thanks to worldwide networking, comparability and the ability to conclude contracts, every plastics processor can see from which

material stream a supplier has produced a recyclate. The platform thus anticipates regulatory dynamics and already integrates the idea of digital product passports, as recently demanded by the European Parliament.

You have initiated a standard for recycled plastics at the German Institute for Standardization (DIN). What is that all about?

Schiller: With the so-called DIN SPEC 91446, both buyers and sellers can be provided with standards for high-quality plastic applications in the future. This has not existed before. The next step now is to establish these standards in the market and ensure that recycled material is tested regularly. By bringing standards and transparency to demand and to offers, we are virtually a digital catalyst in the entire recycling process.

How do you think the plastics industry needs to develop in the future?

Schiller: In the future, a path must be found in which bioplastics lead away from plastic production from fossil sources. By then, plastic that has been used as packaging, for example, can be recycled up to ten times before it ends up in an incineration plant. That's the only way plastic will have a sustainable future. I mean, we fly to Mars and can't manage to run plastic in circles. That's absurd, and for me it's also a failure on the part of policymakers.

Copyright: Viinilinna, Aino Maaranta

InterviewwithAmeliaDales, CommercialDirector,Packamama

If wine bottles were designed for the first time today, they would look different – the British start-up Packamama is sure of that. Especially in view of the climate crisis, packaging needs to be rethought. This is how Packamama's flat plastic bottle came into being, which is not only highly sustainable but also makes quite a visual impact. In an interview, Amelia Dales talks about the advantages of plastic, the extent to which the flat wine bottle saves CO2 and why this is particularly exciting for the wine industry.

You say: "We took the wine bottle and made it better." What does that mean?

Amelia Dales: We believe that wine needs better bottles – ones that are up to the challenges of the 21st century, first and foremost the climate crisis. Round glass wine bottles are heavy, spatially inefficient, high in emissions easily breakable and dangerous if they have shattered. If designing bottles from scratch, you would do it differently. In fact, you would create a bottle

with the opposite features, which is what we have done at Packamama.

Why did you choose plastic for this?

Dales: We did not choose plastic, we chose the most scalable sustainable material available which is 100% recycled PET. No other available solution competes for a scaled solution at this time. We are clear in our communications when explaining our material choice and that starts with highlighting that plastic is an oversimplified term for a group of polymers that behave and perform very differently. This makes it hard for consumers and those that do not work in materials or packaging to have a clear understanding of what is good and what is not from an environmental and commercial perspective. We choose to use food grade rPET as it's a best-in-class material for our application; lightweight, robust, visible glass like properties, low energy required to produce, move, and recycle, and importantly the most widely recycled plastic in the world, contributing further to circular material use.

In what way is your bottle more sustainable than conventional wine bottles?

Dales: Our bottles are more environmentally sustainable because

they are made from a lightweight material which takes more than 6 times less temperature to blow. By changing the shape and material, we offer wine companies a bottle that is on average 87% lighter and can fit up to double the amount of wine in most given spaces, such as on a pallet, on shelf and in the fridge at home.

This significantly reduces costs and emissions through the often long and complex wine supply chain. Round glass bottles and their associated secondary packaging and transport are the largest contributors to wine's carbon footprint and so this is the area where a significant improvement, or better bottle, can have the greatest positive impact. The wine industry is at greater risk than most from the extreme weather events brought about by global warming, which will become more frequent as the climate crisis worsens. Studies show that if we reach two degrees Celsius rise in global temperatures, over half of the current vineyard land would no longer be suitable for producing grapes for wine. The use of 100% recycled PET and the flat shape of our bottles allows wine companies on average to halve their carbon footprint.

Dales: One of the key elements in creating the Packamama bottle was to ensure recyclability by design. PET is easily and widely recyclable, in the UK 99% of local authorities provide kerbside collection. In addition, we recommend a specific cap, made from polypropylene, and labels, including appropriate wash off adhesives. Not needing to separate components and the use of mono, not mixed, materials is fundamental in making it simple and easy for consumers to recycle our bottles once they have enjoyed their wine. Therefore, we do not recommend disposal, but we recommend recycling.

Dales: With our current wine bottle format, we have offices and production in both the UK and Australia. Spring this year saw us launch a collaboration with closures giant Vinventions in France, and next we will launch in the US. In addition to growth across multiple geographies, we will also broaden our product portfolio this year to include a 750ml flat Burgundy bottle and a flat 187ml Bordeaux bottle. We are also active in studying bio-based materials or other potential novel materials of the future.

Recycled plastics are often less efficient than new plastics. But they can be upgraded - namely by using fibre composites. In turn, they make the plastics difficult to recycle. The All-Polymer project shows how both are possible: highperformance materials and a closed cycle.

In an interview, Prof. Dr. Silke Rathgeber talks about the AllPolymer project, Röchling Automotive's participation in it, and the extent to which fibre-reinforced plastics can save material and energy.

To what extent is there still a need to catch up when it comes to recycling fibre-reinforced plastics?

Prof. Dr. Silke Rathgeber: Secondary plastics often have poorer mechanical properties than primary materials. This means that the recycling of plastics is in most cases inevitably associated with downcycling. Plastic composites are generally not recyclable. This does not correspond to the goal of a resourceefficient Circular Economy, in which

raw materials should remain in the cycle for as long as possible without loss of value. Nevertheless, due to their properties (low density, design flexibility, media stability, energyefficient processing, durability), plastics offer many advantages in terms of resource efficiency compared to other material classes, such as metal or even wood, especially in lightweight construction, logistics, the construction industry, etcetera. The goal must therefore be to upgrade recycled secondary plastics through new design concepts and to process them into new products that are 100 percent recyclable.

In the All-Polymer project, you researched exactly that. What were the goals?

Rathgeber: The goal of All-Polymer is to add value to secondary plastics by means of cost- and energyefficient unidirectional (UD) fibrereinforced tapes (UD tapes), which are either applied to a component using an additive tape-laying process for local reinforcement or integrated into a component as inserts in injection moulding or compression moulding processes. Instead of using energy- and costintensive glass and carbon fibres, the innovative approach is to use plastic fibres. These can be produced in an extraordinarily energy-efficient way, are sorted according to type and are completely recyclable.

How did you go about your research?

Rathgeber: The potential to use recyclates from one application in another high-value application was investigated using use cases from different industries. Here we focused on important key industries such as automotive (Röchling

Automotive), logistics (Infinex Holding) and agriculture, forestry and construction (Hahn Kunststoffe). The start-up A+ Composites produces UD tapes with the plastic fibre Dyneema®, which are unique worldwide according to the fibre manufacturer DSM.

By investigating the tape-component adhesion as well as by means of mechanical characterisation, the requirements for the various applications could be identified and the UD tapes and component properties adapted. The connection between the component and the UD-Tape was made using a welding or pressing process, depending on the application. Both processes could be significantly improved through the cooperation and adapted to the requirements of the components. Stable processes leading to well adhering tapes were realised.

An examination of the ecological and economic framework conditions by the Technical University of Kaiserlautern (Chair of Sustainability Management) supported the technical development. The status quo of the participating companies in the Circular Economy could be recorded through an accompanying circularity assessment. In addition, potentials were identified through which the project participants can position themselves even more sustainably in the future. For one of the use cases, a life cycle analysis including a CO2 balance was also prepared.

You were also provided with a prototype by Röchling Automotive. What was the basic idea here? What were the results of the investigations?

Rathgeber: Röchling Automotive was involved in the project as an associated partner. The company has set itself the strategic goal of acting in a sustainable and value-conscious manner. This includes supporting new developments in the plastics processing industry that aim at increased resource efficiency, recycling of plastics and more recycling. Several series of tests were carried out with different car parts. The aim was to use the fibrereinforced tapes to compensate for a drop in performance of the components with recycled material and to reduce or make obsolete the proportion of long fibres or the insertion of glass or carbon layers by using completely polymer-based unidirectional fibre reinforcements. The feasibility could be demonstrated in a prototype.

To what extent can the results of the All-Polymer project contribute to more sustainability in the plastics industry?

Rathgeber: The technical, ecological and economic results have shown that several types of upgrading can be realised. By using fibre-reinforced tapes, the recycled content can be increased and a loss of performance due to the use of recycled material can be compensated for. This can open up new, demanding areas of application for components that are 100 percent recyclable. Another possibility is to reinforce components, which can thus be made lighter in construction. This not only saves material, but also energy in the life cycle of the product during every transport process.

InterviewwithDr.-Ing.AnneLamp,

CEO & Co-Founder, traceless materials GmbH

As early as 1908, textile engineer Jacques Brandenberger invented cellophane, a film made of natural polymers. However, the material was displaced by synthetic polymers with the development of numerous plastics. In the wake of the climate crisis, natural polymers are now coming back into focus as an alternative to fossil raw materials. traceless offers such an alternative.

In an interview with K-MAG, Anne Lamp talks about traceless, the production of the material and its possible applications.

Dr Lamp, with traceless you have developed a new type of material. What is it about?

Dr Anne Lamp: traceless® is a natural, plant-based plastic

alternative. We use plant-based residues from the agricultural industry to produce a thermoplastic granulate that can be further processed using standard plastics processing methods. My motivation for developing the traceless® material was to develop a biocompatible material according to the cradle-to-cradle principle –100% bio-based, naturally compostable, free of potentially harmful substances, climate-friendly and resource-efficient in production and processing.

Lamp: The basis for the production is plant-based raw materials – more precisely: a side stream from industrial grain processing, for example brewery or starch production. We have developed an efficient and simple process to harness the natural polymers in it. This is the secret behind our materials. The challenge: to bring this technology to scale! At an industrial production level, the production is price-competitive with plastics, but we are not there yet. In the two years since our founding, we have built and commissioned a pilot plant and are currently producing our

materials there. A larger demonstration plant is being planned. We want to start building it this year. In view of the great demand, time is pressing!

For which products is the material particularly suitable? What is it not suitable for?

Lamp: traceless® has thermoplastic properties, and can be processed in a similar way to many plastics – for example into moulded parts, films or paper coatings. Injection moulded parts are a great potential. In general, a biocircular material is suitable wherever products easily end up in the environment or where conventional recycling is difficult. Of course, new materials like ours cannot yet replace all plastics, especially in the highperformance sector. The material is stable in storage, but when exposed to weather and moisture it begins to decompose – one of the advantages of the material, but one that makes it rather unsuitable for a garden chair, for example. Therefore, disposable products or packaging are of particular interest, where the enormous resistance of plastic is not necessarily needed.

Where exactly is the material used? Do you already have experience?

Lamp: Our first product on the shelves is a small hook that we developed together with the fashion retailer C&A. The injection-moulded part is used for this purpose. The injection-moulded part is used to hang up socks. C&A is planning to significantly reduce the amount of conventional plastics in packaging and came to us looking for solutions. Especially with a small part like the hook, recycling is difficult in practice, so a plastic-free solution was interesting here. After some development time, the launch of this innovative project then attracted a lot of attention, there was a lot of press and positive feedback. Many C&A customers, on the other hand, hardly noticed that the hooks were different, because apart from the amber appearance, they look quite similar. We consider that a success – our material should work just as easily as plastic!’

Last year you won the Next Economy Award as part of the German Sustainability Award. What does this award mean to you?

Lamp: It was an important award for us because it recognises the core objective of our company: to drive the green transformation of our economy. Especially in the consumer goods sector, sustainability claims are omnipresent but usually difficult to verify. We see the fact that the high-calibre jury has recognised our business model as sustainable after a thorough examination as a great external confirmation that we are on the right track. Of course, such a prestigious award is also important for our customers – processors, brands and retailers. But it is also very clear that we have not yet reached the end. We want to produce one million tonnes of traceless® material by 2030, and replace less sustainable materials in many applications –we still have a long way to go!

You also participated as an exhibitor at K. How did the trade fair go for you?

Lamp: As a young company founded in 2020, it was our first K as an exhibitor. We don't offer plastic, but a natural material, but it can be processed like plastic – so it was clear to us that we would not only participate as a visitor, but also as an exhibitor. We were one of the only

suppliers of natural polymers, so the interest was correspondingly great! We had an unbelievably large number of exciting discussions with processors and brand owners, from which some promising new development projects have already emerged. It was also a great opportunity to expand our network:

Ontheveryfirstday,IwasabletomeetGermanStateSecretaryDr.Christiane Rohleder for a personal discussion together with some industry representatives. It was really exciting to enter into dialogue and to understand even better how our solution can contribute to mastering the challenges of the entireindustry.traceless:materialmadefromplant-basedpolymersprotects climate and environment

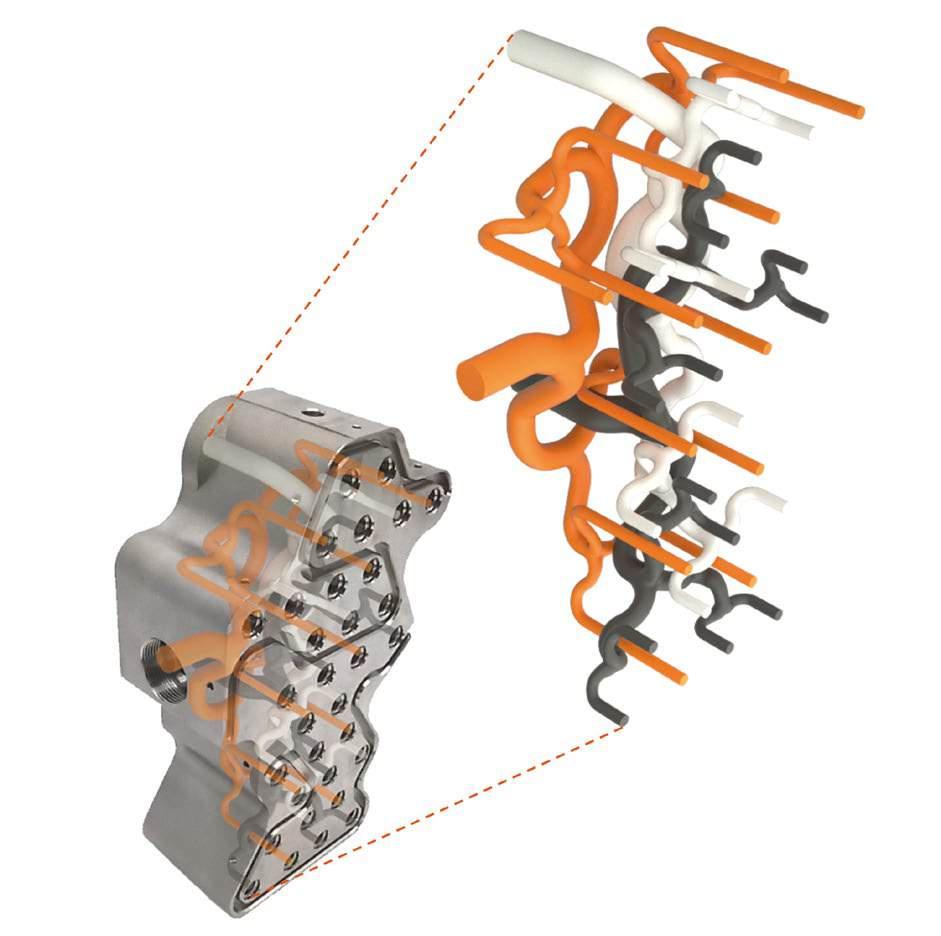

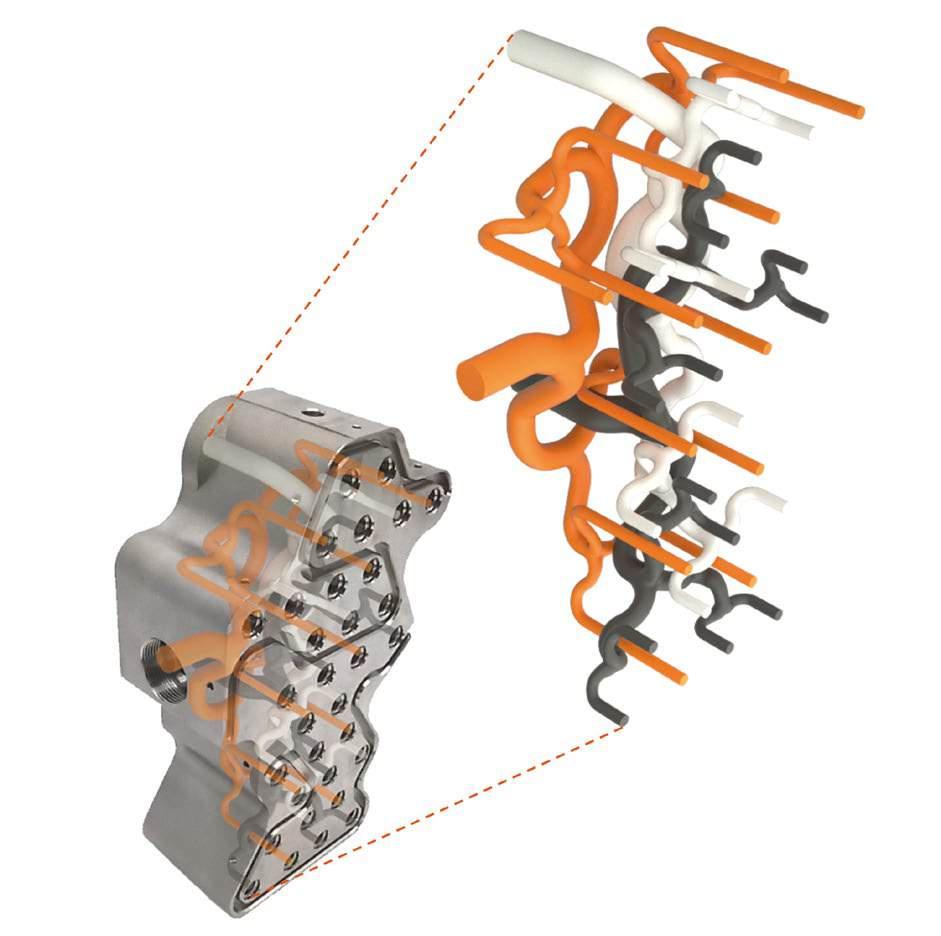

The Streamrunner ® is an additively manufactured hot runner with maximum design freedom. Through the free three-dimensional design of the runners, completely new possibilities are created in multi-component injection moulding.

• New possibilities for product designers

• Distribution of different plastic components or colours over a very small area

• Channels can be intertwined with each other

www.hasco.com

Interplas,Birmingham 26-28September2023 Booth 4/A12

The versatility of plastic is one of its strongest characteristics, and it makes it particularly popular amongst designers. Once you have found the right plastic for a project, you have endless design possibilities. Plastic is also a favored material for BASF's design team: in collaboration with Citroën, the chemical company rethought the classic carwith plastic as the central building block that made the implementation of the innovative concept possible in the first place.

Alex Horisberger: In many aspects, the concept car answers questions that are directed at the mobility of tomorrow: How can I simplify my commute? Can a vehicle save resources and be fun at the same time? How can it look good at the same time? The result is a particularly lightweight yet robust and durable automobile - without frills, unnecessary luxuries and well thought out down to the smallest detail.

What challenges arise in such a development? What requirements have to be met?

Horisberger: Durability, recyclability

and simplicity play a crucial role in the novel concept. At the same time, the aim was to make sustainability look good. And in terms of production technology, the simplification principle was also consistently implemented; for example, the driver and passenger doors are identical. During development and design, we worked closely with Citroën to select the right materials from BASF's broad portfolio.

To what extent can plastics help meet these challenges?

Horisberger: Plastics are incredibly versatile and can therefore contribute to the functionality and functional integration of many vehicle components. Our polyamides have also proven their longterm durability many times over under typical automotive conditions without aging or corrosion. Of course, the sustainability aspect is also crucial: BASF is developing plastics that enable both mechanical and chemical recycling to support the industry in its transition from a linear to a circular economy. In addition, these engineering plastics

can be made from renewable or recycled raw materials.

Horisberger: We are dealing here with the reversal of the normal approach to a product, because often the prevailing principle is 'form follows function'. But when we look at a car from a sustainability perspective, materials and manufacturing technologies have to come first. In this project, the boundaries were pushed further and further, whether by using materials in unusual ways or by fundamentally rethinking the design of a component.

Which plastics are used in the concept car and why exactly these?

Horisberger: To make Citroën's vision of reusability and simplicity a reality, BASF relied on the material of a single TPU product family for the interior, for example, thereby facilitating mechanical recycling at the end of the product life cycle. Thanks to their versatility, our TPU grades enable different functions in the process. One visionary highlight of the concept, for example, was the production of a 3D-printed seat

made of TPU material that is both highly flexible and functional. The iconic storage compartment (Elastollan®) and the vehicle floor (Infinergy®) are made from the same product family. The exterior features lightweight yet robust plastic components that on the one hand reduce energy consumption while driving, but on the other hand leave design managers with all the design options they need. The hood, roof and pickup-like trunk made of Elastoflex® are strong enough to be used as ladders, roof tent bases or for transporting Christmas trees.

How do you assess future developments as far as the use of plastics in design objects is concerned?

Horisberger: In the numerous customer projects we carry out as BASF Creation Center, we see that the versatility of plastics, combined with the right sustainability concepts, offer designers endless possibilities to design clever products that really make consumers want to act sustainably. Just as oli impressively demonstrates: Modesty and sustainability can look good!

The all new eQ-SERIES raises the benchmark in energy savings in its category. Its advanced regenerative servo drive reduces energy consumption. The eQ-Series also allows to handle a wider range of applications. The eQ-Series maximizes acceleration and provides ultimate precision and repeatability throughout the cycle, thanks to its best-in-class servo drives. The eQ-Series delivers better shot weight and cycle time consistency throughout its cycle. It’s a new industry standard for an All-Electric Injection Molding Machine.

Responding to the growing global awareness of modern plastics' environmental impact and the depletion of fossil-based raw materials, Palsgaard A/S, a Danish company that pioneered plantbased polymer additives, has developed a full range of plantbased alternative ingredients for sustainable materials production. As plastics are utilized in an evergrowing range of sophisticated industrial applications, polymer manufacturers are continuously developing new polymer materials. These new polymer formulations have to be carefully designed to meet individual applications' demanding requirements in key industrial sectors, such as automotive and aerospace industries, healthcare, food production, and consumer goods manufacturing.

The established industrial polymers' properties are often not wellenough suited for such a wide range of specialty applications. The properties of industrial plastics can be tailored by the incorporation of additives in their formulation.

Additives are chemical compounds added to base polymer materials to improve their processability, achieve desired physical or chemical properties, and extend the finished product’s life span. Although the additive's content is typically only a few weight percent, the impact on the polymer material's performance is significant. Owing to their low weight and cost, corrosion resistance, and outstanding physical properties, modern polymers have replaced traditional materials, such as paper, glass, and metals, in many packaging applications. At present, packaging accounts for nearly 40% of total plastic consumption globally. However, the wide adoption of plastics in the modern

economy poses significant environmental problems related to sustainable plastic production and recycling. Whereas 35% of metal, 30% of paper, and 18% of glass are recycled, only 3-4% of packaging plastics are currently recycled or reused worldwide. The usual options for plastics disposal are energy recovery and landfill disposal, with very little value extracted from the waste products.

Plant-Based Polymers and Additives Can Boost Plastics Sustainability

The increased demand for more sustainable material production with a low environmental impact and carbon-neutral lifecycle shifts manufacturers' attention towards bio-based polymer formulations that contain low-cost sustainable polymers additives derived from plant extracts or biomass. Plastics used in food-contact packaging are being increasingly scrutinized for potential harmful effects on food safety and human health.

Palsgaard S/A, a pioneering Danish supplier of sustainably produced food and polymer additives, has developed an extensive range of plant-based dual-use additives to fulfill these challenging health and sustainability demands. Based on its comprehensive expertise in natural emulsifiers for food manufacturing, Palsgaard's additives can be used both in food products and food packaging. Palsgaard's original focus has been on developing and manufacturing plant-based food emulsifiers that play an instrumental role in enhancing texture, stability, and shelf-life for ice cream, confectionery, and bakery products.

The emulsifiers are chemical compounds that combine different molecular properties in one molecule. They act as surface-active agents at the interface between two immiscible substances (such as oil and water), blending the substances

into stable emulsions. To achieve this, the emulsifiers contain hydrophilic and hydrophobic functional groups at the opposite molecular ends. The hydrophobic end has an affinity to fats, while the hydrophilic end exhibits affinity to water. This dual affinity makes the emulsifiers ideal for mixing oily and aqueous substances into a smooth texture.

Over the years, molecules with similar properties have found applications in non-food products, such as cosmetics, personal care products, and packaging. When added to polymers, in particular packaging plastics, they serve as plasticizers, anti-fog, anti-static surfactants, dye dispersing aids, lubricants, protective coatings, and mold release agents.

Palsgaard’s plant-based polymer additives, branded Einar® after the company founder Einar Viggo Schou, are derived exclusively from edible plant sources. These include sustainably sourced rapeseed, sunflower, coconut oils, and RSPO (Roundtable on Sustainable Palm Oil) certified segregated palm oil (meaning that the certified palm oil is kept separate throughout the supply chain).

Ulrik Aunskjær, the company's global director for non-food business, explains that Einar® plant-based polymer additives are glycerol and polyglycerol esters in chemical terms made exclusively from vegetable fatty acids.

The two most important product lines within the Einar® range are surfactants used to reduce fogging and static charge accumulation in

polymer packaging materials. Both products rely on the migration of the plant-based additives to the surface of the packaging material. The surfactants interact with the condensed droplets or attract ambient moisture to the surface to prevent large droplet formation electrostatic charge build-up, respectively.

The anti-static properties ensure that no dust and contaminants are attracted to the packed food. Simultaneously, the anti-fog packaging enhances the food visibility and shelf-life by preventing droplet formation and bacterial growth. Related: The World’s First Naturally Biodegradable Plastic Alternative Palsgaard’s additives are mostly used in processing polypropylene (PP) and polyethylene (PE), which are the most commonly used packaging materials. However, the company continually expands the Einar® range with new additives suitable for crystalline polymers, such as polyethylene terephthalate (PET), and different processes, including injection molding, foaming, and coating. Due to the inherent food safety of Einar® additives, unlike their fossil-based counterparts, they are not subject to the strict concentration and additive migration limits aimed to eliminate taste and odor alteration of the packaged food and other health hazards.

The entire Einar® range is produced in CO2-neutral factories and from 100% renewable feedstock. The plant-based polymer additives are a perfect fit in

sustainable materials production and a direct replacement for fossil-based additives in existing polymer formulations.

In response to the fast-growing demand from packaging and plastics manufacturers for sustainable materials production and reduced fossil feedstock depletion, the Danish company has invested 750 million Danish Kroner (US$ 121 million) in a new pellet production line with a capacity of 10,000 tonnes per year.

The expansion of the pellet line addresses the needs of extrusion and injection molding manufacturing, where the availability of pelletized raw materials enables a clean and straightforward manufacturing process.

Palsgaard is commissioning an advanced spray cooling tower with new reaction, distillation, and esterification plants in addition to the new pellet line. The investment is expected to further increase its manufacturing capacity by 30,000 tons per year, doubling the manufacturer’s production capacity for plant-based polymer additives in the next three years

The GRAFE GROUP, Blankenhain, has developed a masterbatch for the identification of materials in industrial 3D printing. „This means that the authenticity of licensed materials can be reliably and unmistakably determined already in the filament processed in this additive manufacturing process“, explains Lars Schulze, Head of Colour Development and Material Sciences. At present, he sees the main areas of application as prostheses in medical technology, but also system-relevant machine or automotive parts that have to withstand warranty or recourse claims. Nevertheless, other sectors such as furniture, electronics, or consumer goods could also be interesting for the originality check.

„In the future, more and more products and spare parts will come from 3D printers. Already today, their number is increasing rapidly in private and industrial use. If one now imagines that spare parts for licensed products are printed from inferior and untested material, recourse claims or warranty claims

would be forfeited and, in the worst case, property damage or personal injury would occur“, Schulze reports. This is where GRAFE's idea comes in: „We work a marker into the filament, which can be used to check whether the correct material has been used. It is permanently in the component and cannot be removed. Due to its nature, the marker offers perfect protection against counterfeiting and proof of originality.“

As an exclusive development partner, GRAFE relies on the security pigments from Tailorlux. The company also supplies the matching Tailor-Scan 4 hand-held measuring device, onto which a reference file set to the safety marking is loaded. It then indicates whether the respective marking is present or not.

„The operation is very straightforward. The originality of the plastic used can be checked directly from the filament to the componenteven through glass or foil packaging“, explains the expert. Furthermore, certification laboratories could also check the material. The

inspection electronics to be used can also be integrated directly into an existing 3D printing system, apart from the hand-held scanner!

GARFE: Filament identification directly in the plastic for originality check

Schulze points to the significant basic idea with which the safety principle can be consistently applied when testing the filament takes place directly in the printing unit. However, this must be integrated by the manufacturers of the 3D printers. „When the spool is inserted, a sensor in the printer can check the safety markings in the filament. Printing starts only when it is ensured that the material is the right one. Unlike the principle of colour printers, which use electronics to determine whether the original colour cartridge has been inserted, the 3D printer can directly check the material”. Our solution is already developed and works“, says Schulze. So far, the marker has mainly been used for PLA and PETG (glycol). However, it can also be used in PA and PC. There is no

influence on the colour. Due to a wide selection of markers, almost any plastic can be equipped, he assures.

The batch dosages are comparatively low and can be realised from one percent. The colour has the greatest influence. Components coloured with CarbonBlack require a slightly higher dosage than others. Carbon fibres also influence the result. Ultimately, it can be said that each filament can be marked with a maximum dosage of three percent.“

GRAFE is currently looking for industrial partners to develop appropriate products or printers. According to the Head of Colour Development and Material Sciences, the costs for marking depend on the desired protection. „A basic marker that is not developed specifically for a company, an industry, or a particular product is comparatively cheap. A solution that can be used worldwide exclusively for only one specific product is therefore more cost-intensive“, says Schulze.

German materials manufacturer Covestro inaugurated a new production line for highperformance Thermoplastic Polyurethanes (TPUs) that will be used for production of paint protection films (PPF). The new line is located at the company's existing site in Changhua, Taiwan. The investment and the expansion of its production capacities for highperformance Thermoplastic Polyurethanes at the site had been announced in 2022.

At the inauguration of the new line, the company also launched its new Desmopan®UP TPU series. UP stands for "Ultimate Protection". The series offers high durability, adaptability and aesthetics, protecting automotive surface coatings from harsh environmental conditions. The material can also be used to protect wind blades or screens of smart devices.

"We are convinced that our customers and the TPU market enquire not just materials suppliers, but partners to jointly develop solutions. We at Covestro have the capabilities to be such a partner," says Dr. Andrea Maier-Richter, Head of TPU at Covestro. "We strive to collaborate with our customers and along the value chain to unlock the

potential of Desmopan®UP and meet the growth ambitions of core industries such as automotive and wind."

A value-add solution offering increased sustainability with no compromise on quality

Photo: Gloved hands applying a paint protection film on the hood of a car; Copyright: Covestro TPU for paint protection films, as used for protecting cars like shown in this picture, will be produced in the new manufacturing line in Taiwan.

The global PPF market is projected to grow steadily until 2030, with the Asia-Pacific region accounting for the largest share of the overall market. The expected growth in that region in turn is driven in large part by the growth of the Chinese market. At the same time, North America and Europe are showing solid growth projections as well.

The high interest in the material stems mostly from increasing attention of vehicle owners to the aesthetic condition of vehicles and particularly their surfaces. TPU is a performance benchmark in PPF for quality, long-term aesthetics and surface integrity. Covestro is one of the biggest international suppliers of

TPU resins for PPF production.

"We are really excited to start our new production line and launch the new Desmopan®UP series to meet the increasing demand for high-performance PPF in the Asia-Pacific region and around the world," says Lisa Ketelsen, Head of TPU in the Asia-Pacific region. "This is a perfect example of how Covestro is committed to providing our customers with innovative, high-performance solutions to meet emerging challenges. In addition to this, we can also further develop our product range together with our customers thanks to our local R&D capabilities."

In PPF, the choice of materials and its formulation play a decisive role. Covestro has put years of research into formulation and advanced manufacturing technologies to build the basis for the Desmopan®UP-based TPUs for PPF. It provides superior UV durability, excellent hydrolysis and chemical resistance, as well as outstanding optical clarity. This ensures long-lasting performance, weather resistance, and impact resistance. In addition, Desmopan®UP allows PPF to adapt to the complex designs and surfaces of different vehicles quickly and easily.

The new standardised E 2600 chill vents save you time and money during design, production and procuring spare parts.

Sophisticated geometry for optimal venting and fast cooling

Three sizes available with 3D data

Cost-effective delivery from stock thanks to standardisation

AVAILABLE IMMEDIATELY

When flying, every gram determines the fuel consumption of the aircraft. To make air travel more climate-friendly, aircraft must become lighter. This can be achieved with components made of plastic, especially fibre composites. The start-up herone produces such. The special thing about them: They are thermoplastic fibre composite profiles with customised properties.

In an interview, Dr Christian Garthaus talks about the extent to which the composite profiles can be customised, what advantages this has and how the environment in particular benefits from it.

Dr Garthaus, in 2018, you founded herone as a spin-off from the Technische Universität Dresden. How did that come about?

Dr Christian Garthaus: After several years of research at the TU Dresden, my colleagues Daniel Barfuß, Alexander Rohkamm and I decided to bring our developments into commercial use independently for customers who were already interested. At that time, we had already been working for many years with well-known industrial customers who showed strong interest in industrialisation. This was the first time the idea came up. With the help of the EXIST research transfer programme of the German Federal Ministry for Economic Affairs and Climate Protection, high-tech start-up projects that involve complex and risky development work are funded. This programme enabled us to make the transition from research to self-employment. After six months, we then founded herone GmbH.

You offer composite profiles that are tailor-made. What does that mean exactly? How do you achieve that?

Garthaus: By customised composite profiles we mean the individual integration of additional functions directly into the component – during the manufacturing process. For example, our herone technology combined with the unique properties of thermoplastics allows us to integrate forcetransmitting elements such as gears or threads made of the same matrix material directly into the composite component. This makes the component lighter and more robust and at the same time saves the number of process steps required and thus costs. By integrating standardised interfaces, such as the thread, we offer an easy way to use the components and thus to exploit the potential of the lead component.

Garthaus: Our cost-efficient fibre composite profiles are used where loads, movements or liquids are transmitted and particularly high demands are placed on the material, such as pressure, temperature or force transmission. In addition to resistance, the components often have to be particularly light. This is particularly in demand in the aerospace, medical technology, sports or automotive sectors.

Currently, our team of 13 mainly aerospace engineers and lightweight constructors is working, for example, on prestressed engine compartment struts and innovative hydrogen fuel lines for emission-free flying in the future. Basically, many areas of application are conceivable for our products.

To what extent do your products contribute to more sustainability in these areas?

Garthaus: Based on the automated processing of thermoplastic tapes in a braiding process and subsequent consolidation in an internal pressurebased pressing process, our herone technology can be used to produce thermoplastic composite hollow profiles in a resource-saving and costefficient way. These completely dispense with metals, but not with their advantages. Formerly metal connecting elements are made from the same thermoplastic base material, so that the composite components are completely recyclable. By using recyclable and recycled thermoplastic material, we are exploring new ways to close the material loop for high performance products.

In direct application, for example as a tension-compression strut in an aircraft, our products contribute to fuel and CO2 savings with weight savings. Every kilogram saved can save several tonnes of fuel over the life of the aircraft, depending on the aircraft.

What are the biggest challenges in your work? How do you meet them?

Garthaus: Anyone who wants to bring a product into series application in the aviation sector needs a lot of stamina and a stable, viable business model including well thought-out financing. As soon as the prototype developments are to be transferred to production, you need your own certified manufacturing facilities that meet aviation standards. In our case, this meant having a completely new production hall built while we worked with plant engineers to develop our special machines as a pilot line. During these processes, our entire team is confronted with new tasks and challenges every day. I think that with a good portion of courage, willingness to learn and a motivated, broad-based team, we grew into new areas together, piece by piece.

Garthaus: In the next few years, we want to get our developments "in the air to fly". In concrete terms, this means that we would like to transfer our projects into ongoing series production and produce aerospace components in large quantities. Parallel to this, we want to create the first series components outside of aviation, for example for sports and leisure, which should combine performance and sustainability.

There is much discussion these days about the circular economy, and the means for incorporating plastics into this model. Recycling a used plastic bottle back into a clean, new bottle has some obvious environmental advantages. But a much more impactful model, in many cases, would involve turning tons of discarded plastics into products with a very long lifespan.

Using recycled plastics in construction or in roadways, for example, helps to take those materials out of circulation for many years. And there can be additional benefits – such as leveraging plastics' light weight, durability and elasticity to enhance the final products. Two groups in very different parts of the world –Finland's Block Solutions Oy and Costa Rica's Center for Regenerative Design and Collaboration – are doing just this.

Block Solutions is combining mixed recycled polypropylene (PP) and other plastics with wood-fiber byproducts from Finland’s forest industry to produce a

biocomposite. It then is injection molding this material to produce large, patent-pending, Lego-like blocks that snap together and can be used to construct low-cost buildings. The firm says it can also use plain recycled plastics to make the blocks. Rebuilding schools in Indonesia. For its first major project, the company used its beige EcoBlocks to rebuild a five-classroom school in a small, earthquakedevastated village in Lombok, Indonesia.

In a recent interview with social enterprise news outlet Pro Bono Australia, Duncan Ward, the Indonesia-based founder of Classroom of Hope Ltd., said of Eco-Blocks: "It took six days to build the school with these things. It would usually take around three to six months [to build a school], but these blocks are fully interlocking and come in groups of two, four, and eight, which makes things quicker." The lightweight blocks have a degree of elasticity, thanks to the plastic in them, which makes them less likely to cause significant harm in earthquake-prone areas. The weight of the Eco-Block wall is only onetenth that of a conventional cinderblock wall. The injection molded Eco-Blocks are lightweight, durable and easy to install. Copyright: Alfred

Minnaar. An Eco-Block building also costs much less to construct compared with typical methods. "A standard government classroom in Southeast Asia costs on average US$14,000," Ward said. "An EcoBlock classroom costs about $7,000. Plus, it only takes around five hours to build."

The Classroom of Hope team has now ordered enough Eco-Blocks to rebuild eight schools previously destroyed in the earthquake –making the startup of a factory to make the blocks in Indonesia vitally important. Block Solutions hopes to have the plant up and running by mid-2022.

"Once the factory is built, Classroom of Hope will become a major customer and we'll launch a program to build the additional 200 Lombok schools that were lost in the 2018 earthquake," Ward said. Additionally, the South African-born Ward told Pro Bono Australia, "For every classroom we can build with Eco-Blocks, we’re also removing two to three tonnes of plastic waste from the environment."

It took just six days to build the Lombok school, instead of the usual three to six months, and cost about half as much. Copyright: Alfred Minnaar. Block Solutions CEO Sanna Silfverberg explained in an email interview that her firm collects its plastic feedstock from "normal household waste or other sources with safe and traceable origins." The firm's recycling partners "provide us with proof of origin for the material," she said. "This is really to make sure that the blocks are safe to build with." The resulting biocomposites contain 50 to 70 percent plastic, and the firm currently does not incorporate any additives into the compounds. She said the company can use waste PP, polyethylene (PE)

and PET, and continues to investigate other resins. Outside of Finland, Block Solutions says it expects to use alternate fibers for its product, such as bamboo, sugarcane, acacia and rice husk. "The carbon footprint of our product is close to zero," the company claims.

The Eco-Blocks are joined together using a rubber hammer, and can be modified with normal woodworking machines, for example, to cut out holes for electrical sockets. "A 30square-meter building can be built in 2.5 hours by two persons without any professional experience in construction," the company says on its website.

"PP is the most suitable resin for processing and gives good quality finishing and strength," Silfverberg noted. "PE is also very close in performance to PP, but a little softer. PET has a slight disadvantage with the weight and processing, but it is working nicely in the production."

Compared to typical, 5-inch cinder blocks, Eco-Blocks offer roughly double the load capacity. Block Solutions notes that an extensive set of tests have been performed by an external accredited institute to verify the product's characteristics. This includes thermal conductivity (Uvalue determination), fire testing, load-bearing and tensile-strength testing. The blocks do need to be covered with gypsum board or concrete, the company noted, in order to reach the needed fireresistance requirements.

While Block Solutions currently operates only three injection presses in Finland, the company is preparing to set up numerous factories in the next six to nine months, in Indonesia, Ghana, Rwanda, Uganda, Egypt and Kenya, with additional plants also in the works. The firm says it is making progress in Australia, Brazil, New Zealand, Vietnam and Malaysia.

“ACROSTAR”

An established, reliable, dynamic and flexible partner to the UK Plastics Industry, Wonderpol o ers a full range of products and services.

A comprehensive range of thermoplastics in pellet or powder form

An industry leading Toll-Pulverising service

A brand new, custom Toll-Repacking service

An extensive additives and pigments sourcing service

All quantities serviced or supplied, from Container Loads, Truck Loads or Pallet Multiples, right down to single sacks.

Whatever your requirements, contact us today and you will find our reliable, e cient, and knowledgeable team ready to assist you.

The Streamrunner ® is an additively manufactured hot runner with maximum design freedom. Through the free three-dimensional design of the runners, completely new possibilities are created in multi-component injection moulding.

• New possibilities for product designers

• Distribution of different plastic components or colours over a very small area

• Channels can be intertwined with each other

www.hasco.com

Interplas,Birmingham 26-28September2023 Booth 4/A12

Single, Twin Parallel or Conical, Multi -start and mixing, we offer a wide choice in Nitride and hardened alloy screws.

Single or Twin Barrels for extrusion and barrels for injection and blow moulding Nitride and Bimetallic that meet and exceed OEM standard

Fast Track Services for refurbishment, on site wear check surveys and technical support, full in -house design facilities...and much more.

To discover more about our products and service, please contact us: Tel 01920 465201

E.mail enquiries@magog.co.uk www.magog.co.uk

Need to invest in Injection Moulding equipment, but concerned about the impact of the Pandemic?

BOLE Injection Moulding Machines incorporate the latest Servo Motor technology and patented designs to help reduce your exposure to an ever-changing market.

Worried about delivery times? Don’t be.

We have stock of machines between 100t – 650t from our EKS, FE and DK ranges which are backed up by our team of in house engineers and a 3 YEAR WARRANTY on non-consumable mechanical parts that can be delivered within 5 days from order.

Contact us to find out about our Part Exchange scheme.

Heinrich Axmann GmbH & Co. KG in Cologne, Germany, has made a significant shift towards sustainability by adopting an all-electric injection molding machine, the EcoPower Xpress, provided by WITTMANN. This move has led to a reduction in energy consumption by over 30% for producing thin-walled packaging, marking a significant step towards eco-friendly production methods.

The switch to an all-electric injection molding machine signifies Heinrich Axmann's commitment to reducing energy consumption and enhancing efficiency in the production of sophisticated thin-walled packaging. Compared to hybrid models, the EcoPower Xpress offers substantial energy savings, highlighting the potential for sustainable practices within the industry.

Axmann developed a plastic tray that can be opened using a tearopen mechanism at the bottom of the packaging. The edge of the packaging folds back up, the food glides gently onto the plate and looks just as appetising as when freshly prepared and filled into the packaging tray. Copyright: WITTMANN

Heiner Axmann, CEO of Heinrich Axmann GmbH & Co. KG, has developed a plastic bowl with a unique tear-open mechanism that

addresses the common challenge of transferring ready-made meals to a plate without spoiling their appearance. This innovative solution not only improves consumer convenience but also adheres to the highest standards of hygiene, especially beneficial for institutions without their kitchens.

Established in 1932, Heinrich Axmann specializes in plastic packaging solutions. The company's vast experience has led to continuous innovation, including the development of the new ready-toeat food bowl, a product that promises to secure a significant order from the USA. This development underscores the importance of creative solutions in addressing modern packaging challenges.

The EcoPower Xpress represents a significant advancement in injection molding technology for Heinrich Axmann. This all-electric machine is capable of handling the stringent requirements of manufacturing thinwalled packaging with varying wall thicknesses. The inclusion of a Sonic high-speed robot further optimizes the production process, ensuring high-speed, reliable movements critical for achieving short cycle times.

The trend towards thinner, more material-efficient products is driving the demand for advanced manufacturing technologies. The all-electric

drive of the EcoPower Xpress aligns with Heinrich Axmann's sustainability goals, offering a compelling example of how technological innovation can contribute to more energy-efficient and cost-effective production methods.

In its pursuit of sustainability, Heinrich Axmann has also invested in renewable energy solutions, including extending its photovoltaic system. CEO Heiner Axmann reflects on the company's direction: "Energy efficiency is now the most important criterion whenever we invest in new machines and technologies." Discussions with WITTMANN about adopting DC technology with a battery storage system further demonstrate the company's dedication to minimizing energy consumption across all operations.

SABIC, a leader in the plastics and rubber industry, is set to launch its latest innovation, EXTEM™ RH resins. These highperformance resins are designed for use in the production and assembly of micro-lens arrays (MLAs), offering advanced scalability and manufacturability in commercial onboard and co-packaged optics.

"As data traffic increases exponentially, driven by AI, IoT and 5G technologies, rapid adoption of opto-electronics has become critical for improving data center bandwidth capacity and energy efficiency," said Scott Fisher, General Manager of Technology at SABIC Specialties.

EXTEM™ RH resins offer key performance benefits and processing capabilities for MLAs, addressing the challenges of traditional materials like glass and thermosets. These resins can be injection-molded into

a wide variety of free-form optical lens designs, thanks to their high glass transition temperature of 280°C. This flexibility allows for the production of complex-shaped lens arrays without secondary operations like grinding and polishing, providing a more cost-effective solution.

To demonstrate their utility, SABIC's EXTEM™ RH resins have been used to create beam-expanding optical elements. These elements are installed on each side of the optical connector interface, coupling the fiber array to larger free-space beams. This approach relaxes lateral alignment tolerances and reduces occlusion from contamination, like dust particles.

High-volume production of microoptics with a relatively low per-part cost is a significant challenge with traditional materials like fused silica or glass. In contrast, EXTEM™ RH resins support micro-molding, allowing for

the efficient production of millimeter-sized components at scale while maintaining high signal integrity and low optical loss.

SABIC's unique approach also involves using optically transparent adhesives to align micro-optics with fiber and photonic integrated circuits (PICs) before the reflow step. This simplifies the packaging process, offering a streamlined solution for the manufacturing of optical components.

SABIC's approach to co-packaged optics goes beyond just introducing new materials. The company also demonstrates an alternative interconnect material, nano-silver sintering paste, developed collaboratively with the Chip Integration Technology Center (CITC). This paste can replace standard epoxy adhesives, providing better stability and reducing thermal expansion coefficient (CTE) mismatches.

Another feature of SABIC's technology is the ability to create lens arrays with total internal reflection. This innovation allows for a 90-degree bend of the optical coupling between VCSEL/PD and PIC in a standard MT ferrule connector, showcasing the flexibility of EXTEM™ RH resins.

The high-heat-resistant EXTEM™ RH resins recently won a 2023 Edison Award Gold Medal in the Next Generation Manufacturing category, underlining their impact on the industry. With SABIC's support from its Optical Center of Excellence in the Netherlands, customers can access advanced assistance in thermoplastic processing, component design, and optical performance measurement.

YOUR LOCAL EREMA CONTACT LEEVAMS INCORPORATED Makarpura Vadodara | INDIA www.leevams.in

Whether it is inhouse, postconsumer or bottle recycling: you can only close loops in a precise and profitable way if machines are perfectly tuned for the respective application. Count on the number 1 technology from EREMA when doing so: over 6000 of our machines and systems produce around 14.5 million tonnes of high-quality pellets like this every year –in a highly efficient and energy-saving way.

InterviewwithFridolinPflüger,Co-Founder,HolyPoly

Recycling begins even before disposal. The entire life cycle of a product should be considered as early as the development stage. The start-up HolyPoly supports brand manufacturers throughout the entire recycling process. Their mission: to make plastics recycling a matter of course. To meet the growing demands, they recently opened the ClosedLoop Factory.

In an interview, Fridolin Pflüger talks about the opportunities offered by the new Closed-Loop Factory, why the recycling process starts before the waste and how HolyPoly is helping to raise awareness of plastic recycling.

You inaugurated your Closed-Loop Factory at the end of last year. How has its development affected HolyPoly's capacities and opportunities in plastics recycling?

Fridolin Pflüger: This step was the right decision at the perfect time. First and foremost, we wanted to use the new technical centre to concentrate our machinery in one place in order to implement the increasing number of projects as smoothly as possible. We have purchased new machines for sorting plastics and expanded the conveyor systems so that we can meet the growing requirements of our customers. Thanks to the modular structure of our factory, various test setups can be flexibly connected in series to test the optimum constellation of recycling steps for series processes. This simplifies the temporary use of rental machines in particular, allowing us to dynamically

adapt our technical capacities to project requirements. As a final step, we are currently planning to set up our own laboratory in the ClosedLoop Factory in order to expand our analytical capabilities.

Can you describe the process that HolyPoly goes through from receiving the plastic waste to manufacturing new products?

Pflüger: Our work actually begins before the "waste", because the cycle can only be closed sustainably if recycling is considered for the entire life cycle of a product. That's why our projects often start with a discovery phase, an in-depth analysis to explore new recycling prospects in strategically important markets and regions.

It would be ideal if the return and recycling of products were already planned during the development phase. However, as this is generally not the case, we use modern UX design approaches to develop ways of returning the product to the market, for example through innovative take-back systems and recycling programmes. We always optimise these for specific product

groups so that we can design a customised recycling process with particularly high-quality source material. After collection, the disposed plastic products – in this case bottles and soothers from NUK – must first be sorted. They are then processed into recyclate, from which new products can be made.

Copyright: HolyPoly

HolyPoly invests a great deal of energy and expertise in the development of these recycling processes – from dismantling and sorting to formulations and compounding, in order to adapt the recycling material for the desired application and compensate for possible fluctuations in quality. Our new Closed-Loop Factory has become a crucial piece of infrastructure: Here, we are able to map all processes in-house on a pilot plant scale. What is created here can then be quickly transferred to industrial production processes together with long-standing and experienced partners.

The final phase then begins with circular product development. The focus is now on the design, layout and manufacture of plastic products with the main objective of

maximising the recyclability of the new product.

What challenges do you see in the scaling of recycling processes and how does HolyPoly meet them?

Pflüger: Scaling recycling processes is ultimately the key to success: the use of recycled plastics only makes economic sense once a "critical mass" has been reached. Our previous projects, for example for Bosch, have proven that with the right processes, recyclates are ultimately produced that are in no way inferior to virgin material. This applies to quality, appearance and all regulatory requirements such as pollutant guidelines and the applicable legal standards. Now we are faced with the challenge of bringing the price of the recyclate into an appropriate economic relationship with the virgin material and you guessed it: the solution is called scaling.

However, we see the biggest structural obstacle in the massive investment backlog in large parts of the German economy. The energy transition is not feasible without solar and wind power plants. The same applies to the Circular Economy: without investment in the necessary infrastructure, it will remain nothing more than a beautiful dream.

HolyPoly counters the low willingness to invest with facts: With the data from our feasibility studies and the test runs in the Closed-Loop Factory, we can generate very well-founded business models with a view to profitability and investment requirements. These business cases show that a competitive material price can be achieved with a high volume throughput using the latest technologies and that the investments will pay off. If one also assumes medium-term price increases for new materials – for example due to rising CO2 taxes or crude oil prices – this will sooner or later even result in a competitive advantage.

How is HolyPoly helping to raise awareness and acceptance of plastics recycling in the industry and beyond?

Pflüger: The declared aim of HolyPoly is to make plastic recycling a matter of course. However, a conscious approach to plastics is only possible if there are suitable offers. For the industry, this means that preserving the value of plastics must become a key aspect of their economic considerations.

In short: recycling must pay off – at least in the long term. Only with this prospect will companies be prepared to incorporate recycling and technical cycles into their business models. After all, such a transformation process requires a great deal of commitment and high levels of investment because suitable processes and infrastructure often do not exist. The major brand manufacturers in particular have a special role to play on this path: they can provide effective impetus that can transform the entire system and make the plastics industry more sustainable. This is precisely why HolyPoly is focussing on these companies.

We can help you select the machine that will meet your desired throughput rates based on the specific type of scrap. One size fits all? We don’t think so.

Picking the right rotor type is so important. Whether it’s purge, film, fiber, pipes, profiles, or any other kind of plastic, we have the ideal rotor in mind for your specific application.

The screen defines the output size of the material being shredded. Available from 10-100mm.

With 20 years of experience, a fully-stocked parts/service department, and a growing headquarters, the WEIMA team comes standard with every machine.

perfectly tailored to your needs FOR ALL

Stäubli Fluid Connectors o ers a new End-of-Arm-Tooling range, along with consultation for customized robotic material handling solutions. Through our partner FIPA, we can now provide a broad portfolio. Stäubli Fluid Connectors therefore makes gripping, suction and cutting available for all robots worldwide from a single source - including manual or automatic robotic tool changing systems.

Always a customized solutions for your requirements Broad technology portfolio for Material handling from a single source

Flexible and durable systems for lasting productivity Worldwide on site with highest consulting and service quality